Needle valve mating part of diesel

A diesel engine and needle valve technology, applied in engine components, mechanical equipment, machines/engines, etc., can solve the problems of reducing service life, black smoke from diesel, waste of energy and environment, etc., to prevent carbon deposition problems, increase service life, The effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

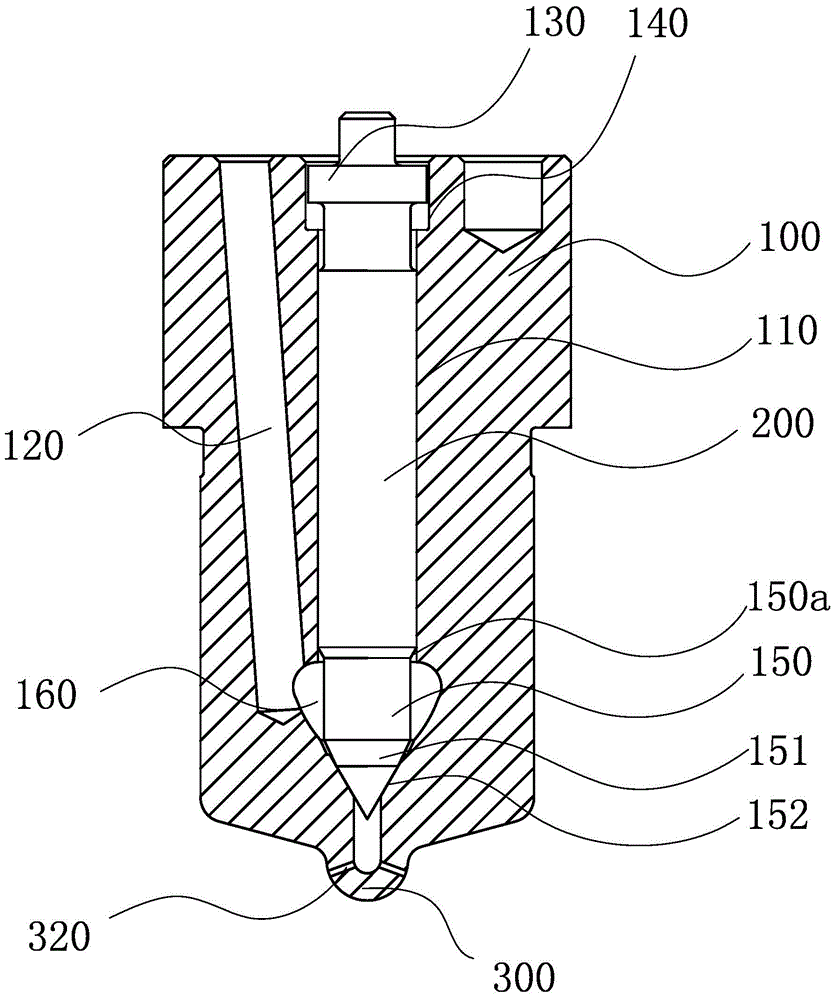

Image

Examples

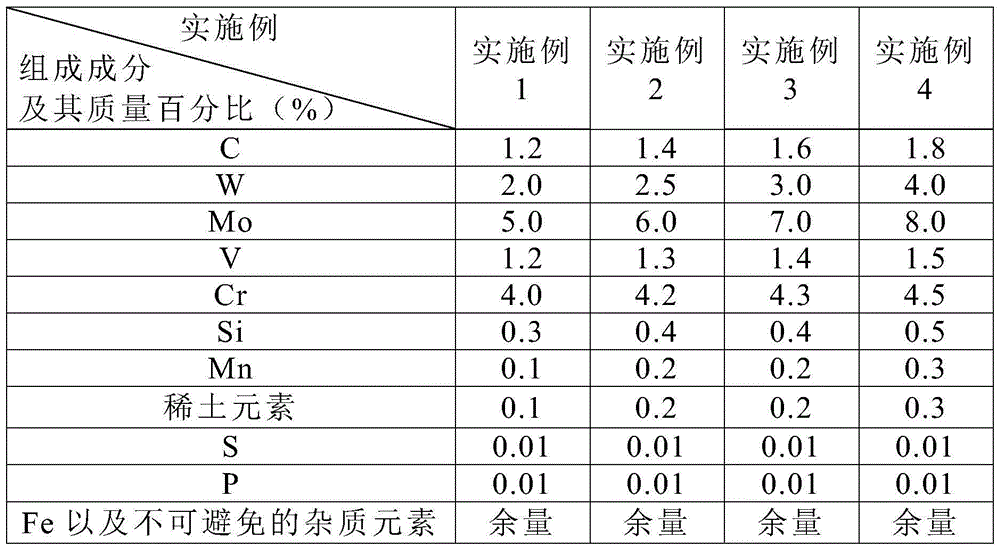

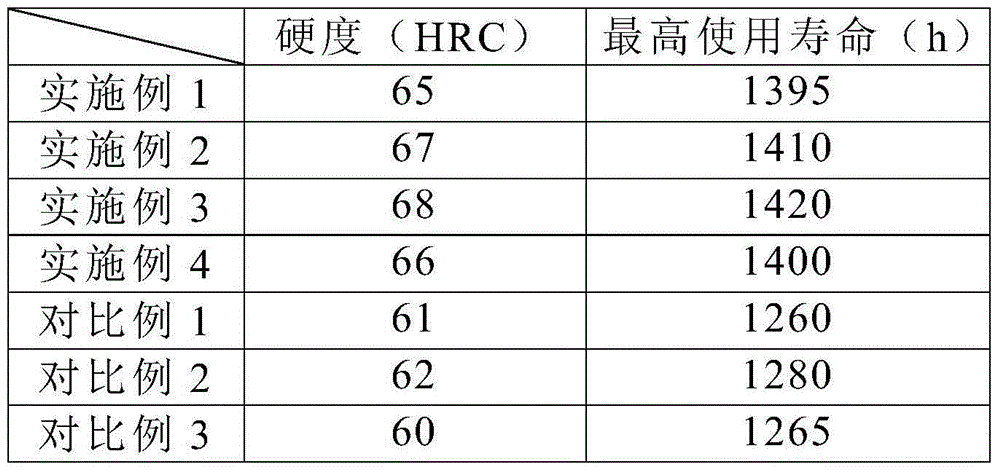

Embodiment 1

[0044] Take the high-speed steel according to the composition and mass percentage in Example 1 in Table 1 to make needle valve blanks and valve body blanks. Then perform annealing treatment, the annealing heating rate is 20°C / h, heat it to 800°C for 6 hours, and then cool it to below 500°C at a rate of 20°C / h and leave the furnace. Conventional machining after annealing followed by quenching. When quenching, preheating is carried out first, and preheating is divided into three stages: low temperature preheating, medium temperature preheating and high temperature preheating. The low temperature preheating temperature is 500°C and the time is 60s / mm; the medium temperature preheating temperature is 800°C and the time is 50s / mm; the high temperature preheating temperature is 1000°C and the time is 40s / mm. Finally, the quenching temperature was kept at 1200°C for 50 minutes. After quenching, tempering is carried out twice, the tempering temperature is 550°C, and the holding time...

Embodiment 2

[0047] Take the high-speed steel according to the composition and mass percentage in Example 2 in Table 1 to make needle valve blanks and valve body blanks. Then perform annealing treatment, the annealing heating rate is 25°C / h, when heated to 820°C, keep it for 5h, and then cool to below 500°C at a rate of 22°C / h and leave the furnace. Conventional machining after annealing followed by quenching. When quenching, preheating is carried out first, and preheating is divided into three stages: low temperature preheating, medium temperature preheating and high temperature preheating. The low temperature preheating temperature is 550°C and the time is 58s / mm; the medium temperature preheating temperature is 820°C and the time is 46s / mm; the high temperature preheating temperature is 1050°C and the time is 36s / mm. Finally, the quenching temperature was kept at 1220°C for 45 minutes. After quenching, perform tempering three times, the tempering temperature is 560°C, and the holding ...

Embodiment 3

[0050] Take the high-speed steel according to the composition and mass percentage of Example 3 in Table 1 to make needle valve blanks and valve body blanks. Then perform annealing treatment, the annealing heating rate is 25°C / h, heat it to 830°C for 5h, and then cool it to below 500°C at a rate of 23°C / h. Conventional machining after annealing followed by quenching. When quenching, preheating is carried out first, and preheating is divided into three stages: low temperature preheating, medium temperature preheating and high temperature preheating. The low temperature preheating temperature is 560°C and the time is 55s / mm; the medium temperature preheating temperature is 830°C and the time is 45s / mm; the high temperature preheating temperature is 1080°C and the time is 35s / mm. Finally, the quenching temperature was kept at 1230°C for 40 minutes. After quenching, tempering is carried out 4 times, the tempering temperature is 580°C, and the holding time is 65min.

[0051] Afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com