Liquid fuel gasifier

A technology of liquid fuel and vaporizer, which is applied in industrial and civil liquid fuel vaporizer, commercial, and catering fields. It can solve the problems of high energy consumption, low firepower, and slow heating speed, and achieve low energy consumption, environmental protection and use Energy saving and complete gasification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

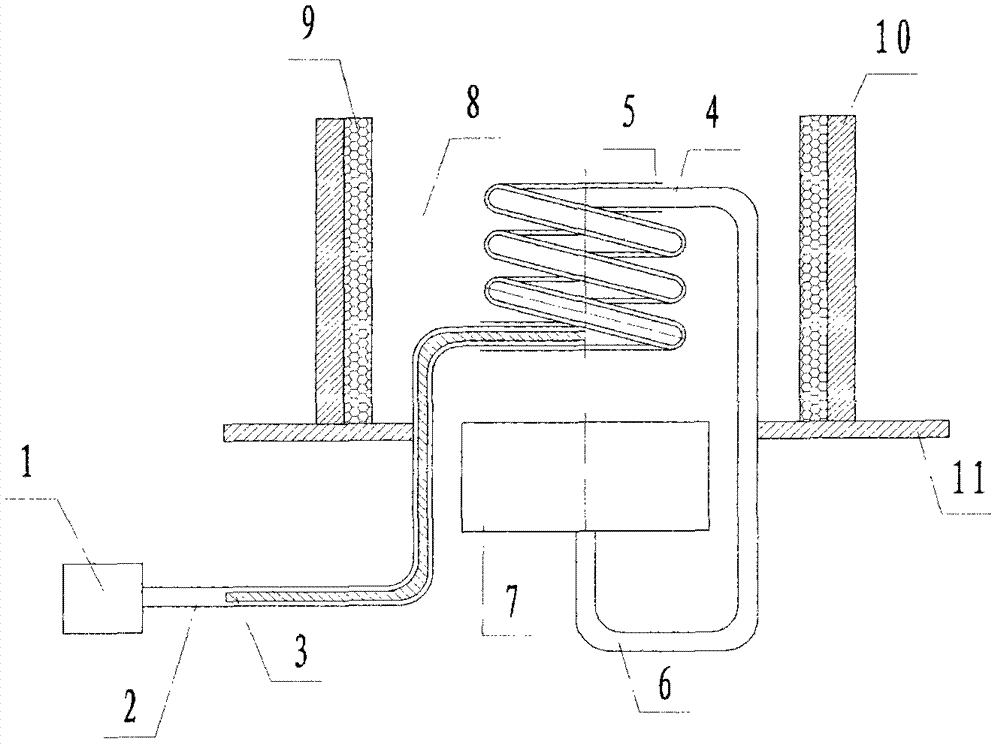

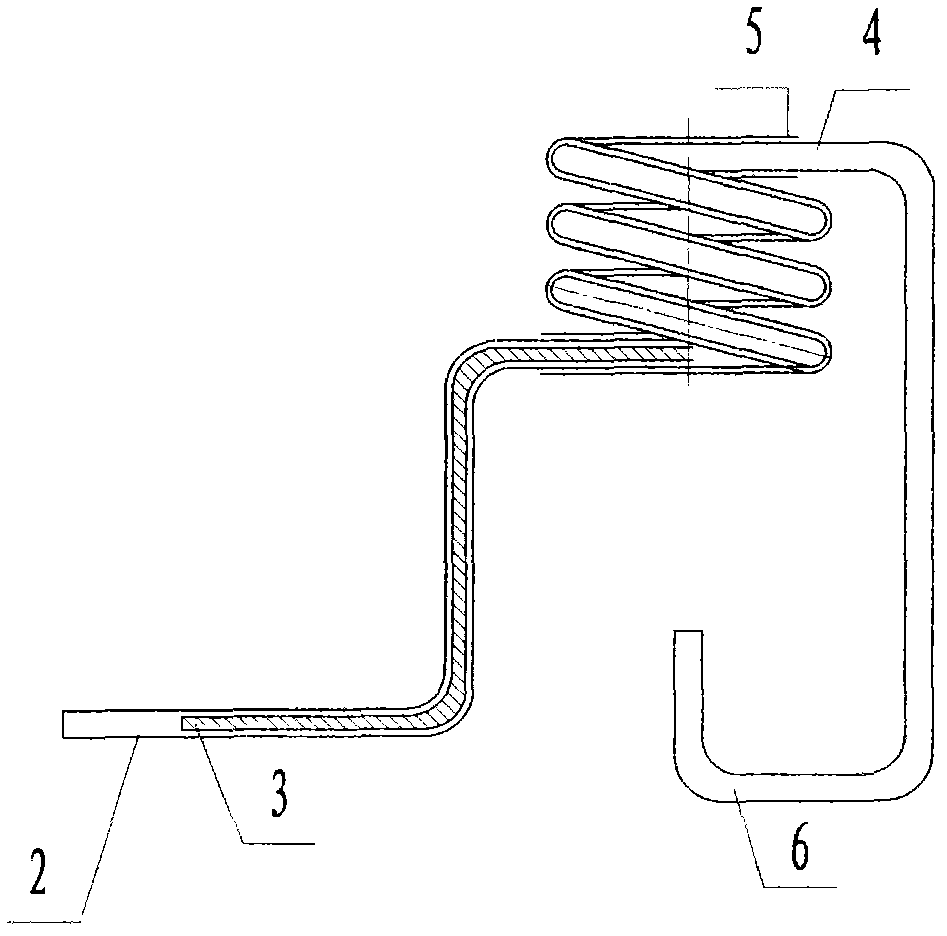

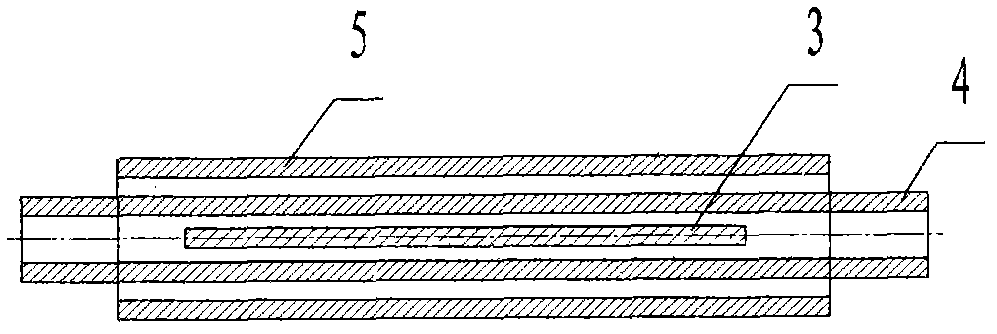

[0040] attached figure 1It is a structural schematic diagram of a specific embodiment of the present invention, the gasification device is installed on the combustion device 7, the combustion device 7 is connected with the gasification pipe outlet end 6 of the gasification device, the gasification device is installed on the fixed frame 11, and the fire ring 10 Installed outside the sound reducing device 9 , the gasification device and the combustion device 7 are installed inside the sound reducing device 9 , and a combustion zone 8 is formed between the gasification device and the sound reducing device 9 . The liquid fuel enters the gasification pipe oil inlet 2 from the valve body assembly 1, and then enters the gasification pipe 4 through the gap space formed by the gas resistance 3 and the vaporization pipe 4. When it is not ignited, the liquid fuel directly flows from the gasification pipe The gas outlet end 6 of the tube enters the combustion device 7. At this time, it is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com