Mixed heating LNG gasifier

A vaporizer and hot water technology, which is applied in the field of LNG vaporizers, can solve the problems of vaporizer fin vibration, reduced vaporization amount, incomplete vaporization, etc., so as to reduce the impact force of hot water and ensure the buffer effect. , the effect of increasing the amount of gasification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

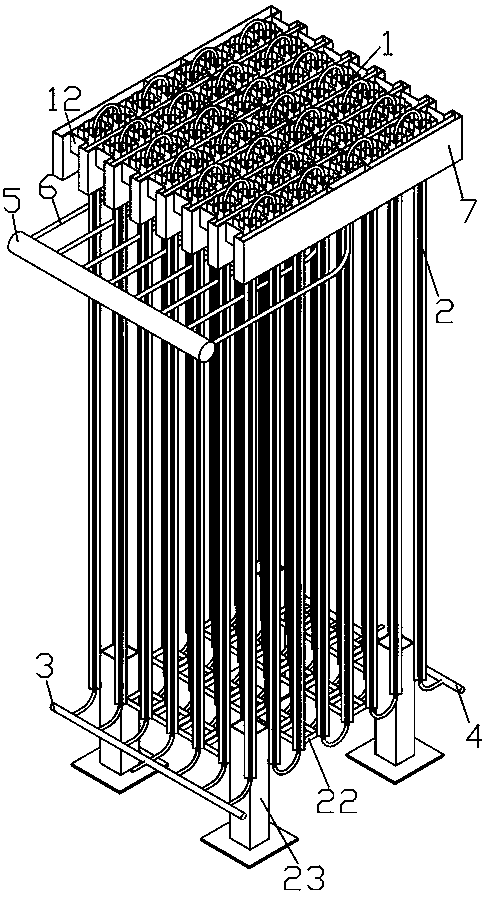

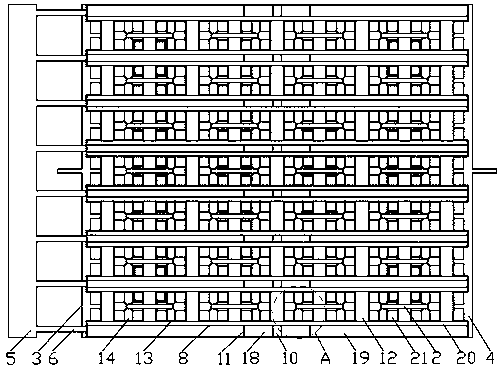

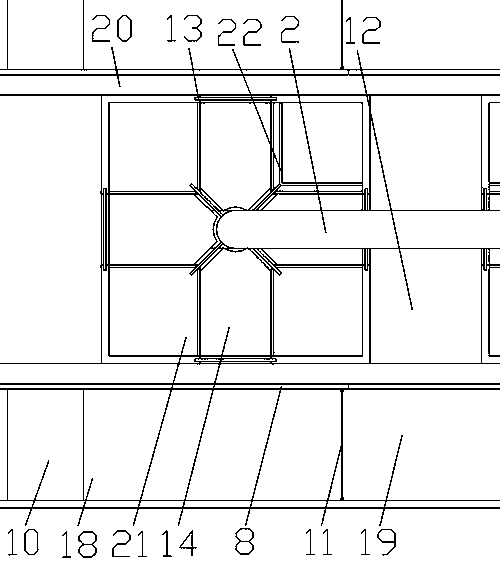

Embodiment 1

[0020] A mixed-heating LNG vaporizer is composed of a hot water distributor (1), finned tubes (2), an LNG distribution box (3), an NG gas collection box (4) and the like. Hot water distributor (1) includes hot water distribution tank (5), water inlet pipe (6), hot water tank (7), convex overflow plate (8), cylindrical buffer (9), buffer cover (10 ), distribution board (11), grooved channel (12), overflow board (13), drainage board (14), characterized in that: one end of the water inlet pipe (6) is connected to the hot water distribution tank (5), and the other One end is connected and fixed to the outer center of the bottom of the hot water tank (7), and the inner center of the bottom of the hot water tank is connected and fixed with a cylindrical buffer (9), and the cylindrical buffer is provided with a first-level buffer plate (15) at intervals from bottom to top , secondary buffer plate (16), tertiary buffer plate (17), each level of buffer plate is provided with a pluralit...

Embodiment 2

[0022] The height of the low sides on both sides of the convex overflow plate (8) is 9 / 10 of the height of the middle high side, and the middle high side of the convex overflow plate is equal to the side of the hot water tank. The water hole diameter is 15%~30% of the inner diameter of the water inlet pipe (6), the circular water hole diameter of the secondary buffer plate (16) is 50%~85% of the circular water hole diameter of the primary buffer plate (15), and the third buffer The diameter of the circular water hole of the plate (17) is 50%~85% of the diameter of the circular water hole of the secondary buffer plate (16). 12) The depth is 1 / 2 of the depth of the hot water tank (7), the distance between adjacent groove channels (12) is consistent with the distance between adjacent hot water tanks (7), and the bottom of the slot of the overflow plate (13) is located at the convex Under the low sides of the shaped overflow plate (8), the diversion plate (14) is at an angle of 30...

Embodiment 3

[0024]When the ambient temperature is high and the NG outlet temperature and gas output meet the requirements, the hot water distributor on the top of the gasifier does not work, and the gasifier uses air as the heat source to heat the LNG. When the ambient temperature is low, the gasification of the LNG When it is not complete, the vaporizer uses the hot water from the factory as the heat source to heat the LNG. The hot water from the factory first enters the buffer device located in the hot water tank along the water inlet pipe from the hot water distribution tank. The primary buffer plate in the buffer device , the secondary buffer plate, the tertiary buffer plate and the buffer cover plate located above the tertiary buffer plate perform four-stage buffering for the hot water, and the hot water flows into the buffer zone from the buffer device. The hot water enters the distribution area. After the hot water in the distribution area reaches a certain height, it overflows into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com