A sound-absorbing and heat-insulating pad for an automobile engine compartment

An engine compartment and sound-absorbing pad technology, applied in the field of auto parts, can solve the problems of reducing sound-absorbing performance, carbonization of sound-absorbing materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

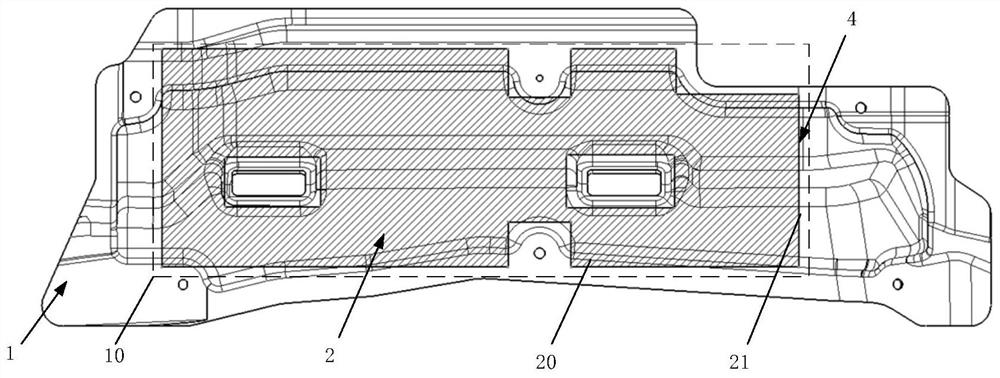

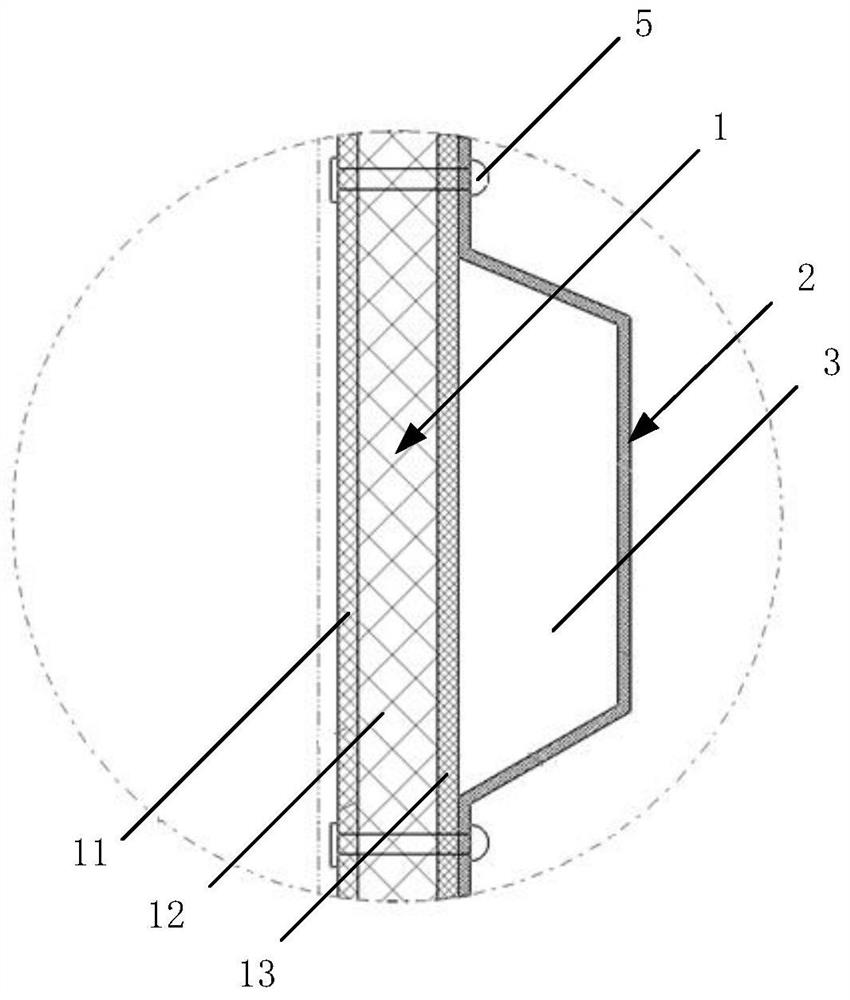

[0030] see figure 1 and figure 2 As shown, the embodiment of the present invention provides a sound-absorbing and heat-insulating pad for an automobile engine compartment, which includes a sound-absorbing pad body 1 and an aluminum heat-insulating layer 2. The position on the body 1 corresponds to the position of the heat source in the engine compartment. One side of the sound-absorbing pad body 1 is connected to the sheet metal of the cover of the engine compartment, and the near heat source area 10 on the other side faces the heat source in the engine compartment. The aluminum heat insulation layer 2 is located in the heat source area 10, which plays a role of heat insulation for the heat source in the engine compartment, preventing the heat generated by the heat source from damaging the sound-absorbing pad body 1 and affecting the sound-absorbing effect of the sound-absorbing pad body 1. Embodiment 1 of the present invention adopts the material composition of the existing...

Embodiment 2

[0044] The basic content of embodiment 2 of the present invention is the same as embodiment 1, and difference is:

[0045] The two side edges of the aluminum material heat insulation layer 2 of the embodiment 2 of the present invention are divided into the first part 20, and the two end edges of the aluminum material heat insulation layer 2 are divided into the second part 21, because the sound source in the engine compartment mainly concentrates on the aluminum Therefore, the two ends of the aluminum heat insulation layer 2 are used as the sound wave inlet 4, and the sound waves generated by the sound source are concentrated for sound absorption.

Embodiment 3

[0047] The basic content of embodiment 3 of the present invention is the same as embodiment 2, and difference is:

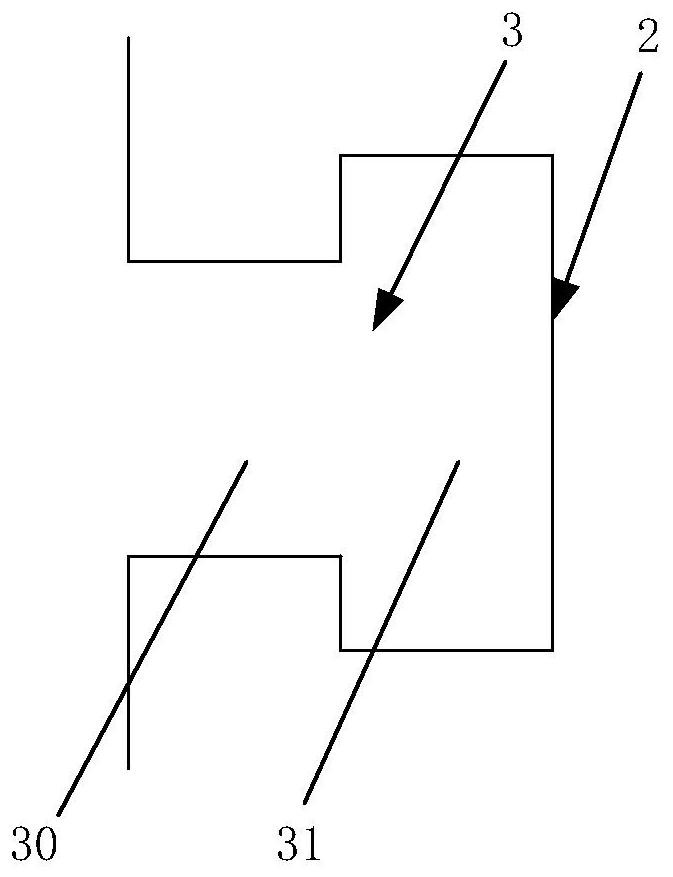

[0048] The cross-section of the aluminum heat insulation layer 2 in Example 3 of the present invention is trapezoidal, and the lower bottom of the trapezoid is close to the sound-absorbing pad body 1, that is, the diameter of the echo cavity 3 is from close to the sound-absorbing pad body 1 to away from the sound-absorbing pad body 1 The direction gradually decreases, so that the sound wave enters the echo cavity 3 from both ends of the aluminum heat insulation layer 2, and the sound wave with a small frequency has low energy, and it is reflected at the edge of the trapezoidal echo cavity 3 and the energy of the sound wave is further Reduced, the sound wave with reduced energy is reflected to the sound-absorbing pad body 1 to be absorbed; the sound wave with high frequency has high energy, propagates to the middle position of the trapezoidal echo chamber 3 and is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Sound absorption coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com