A method of gasification and reburning denitrification of electrolytic aluminum waste cathode carbon blocks

A waste cathode carbon block, electrolytic aluminum technology, applied in gasification process, granular/powder fuel gasification, fuel and other directions, can solve the problem of difficult high-value utilization, etc., achieve easy gasification and complete, easy low-nitrogen combustion , the effect of large ash content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

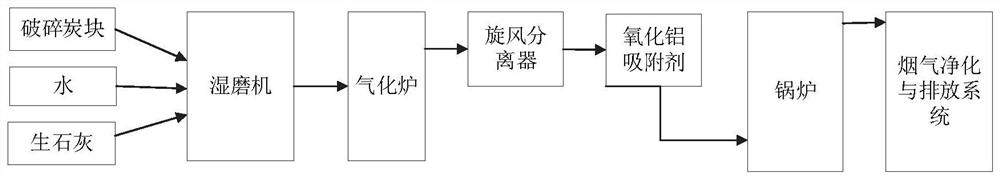

[0037] A gasification and reburning denitrification method and application of electrolytic aluminum waste cathode carbon blocks, comprising the following steps:

[0038] (1) Break electrolytic aluminum waste and old cathode carbon blocks into fragments with a particle size of ≤30mm through a hammer crusher, and add quicklime powder (particle size≤30mm) at a calcium-to-fluorine molar ratio of 1:2, and the ratio of water to solid materials is 60 : 100, carry out ball milling, make carbon slurry fuel;

[0039] (2) The cumulative mass of particles with a solid particle size less than 45 μm in the prepared carbon slurry fuel accounts for 90% of the total mass of solid particles;

[0040] (3) Texaco pressurized gasifier is used, the gasification pressure is 6.5MPa, the gasification temperature is 1350°C; the carbon conversion rate can reach up to 99%, and the effective gas (CO+H) in the gasification gas 2 ) volume content of 83%.

[0041] (4) passing the gasification gas through t...

Embodiment 2

[0044]A gasification and reburning denitrification method and application of electrolytic aluminum waste cathode carbon blocks, comprising the following steps:

[0045] (1) Use a hammer crusher to crush the waste cathode carbon blocks of electrolytic aluminum into fragments with a particle size of ≤30mm, and add quicklime powder (particle size≤30mm) at a calcium-to-fluorine molar ratio of 1:1.5, and the ratio of water to solid materials is 65 : 100, carry out ball milling, make carbon slurry fuel;

[0046] (2) The cumulative mass of solid particles with a diameter less than 45 μm in the prepared carbon slurry fuel accounts for 95% of the total mass of solid particles;

[0047] (3) Texaco pressurized gasifier is used, the gasification pressure is 6.5MPa, the gasification temperature is 1400℃; the carbon conversion rate can reach 99.3%, and the effective gas (CO+H 2 ) volume content of 83.5%.

[0048] (4) Combined with the low-nitrogen combustion transformation of coal-fired b...

Embodiment 3

[0050] A gasification and reburning denitrification method and application of electrolytic aluminum waste cathode carbon blocks, comprising the following steps:

[0051] (1) Break electrolytic aluminum waste and old cathode carbon blocks into fragments with a particle size of ≤30mm through a hammer crusher, and add quicklime (particle size≤30mm) according to the calcium fluorine mole ratio of 1:2, and the ratio of water to solid materials is 65:100 .

[0052] (2) The particle size of solid particles in the prepared carbon slurry fuel is less than 45 μm, and the cumulative mass of particles with a particle size of less than 45 μm accounts for 95% of the total mass of solid particles;

[0053] (3) Texaco pressurized gasifier is used, the gasification pressure is 6.5MPa, the gasification temperature is 1400℃; the carbon conversion rate can reach 99.3%, and the effective gas (CO+H 2 ) volume content up to 83.5%.

[0054] (4) Combined with the low-nitrogen combustion transformati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com