System and apparatus for producing synthesis gas from garbage and biomass raw material

A technology for biomass raw materials and synthesis gas, which can be used in biomass treatment and garbage fields to solve problems such as decay, lack, and inability to popularize applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

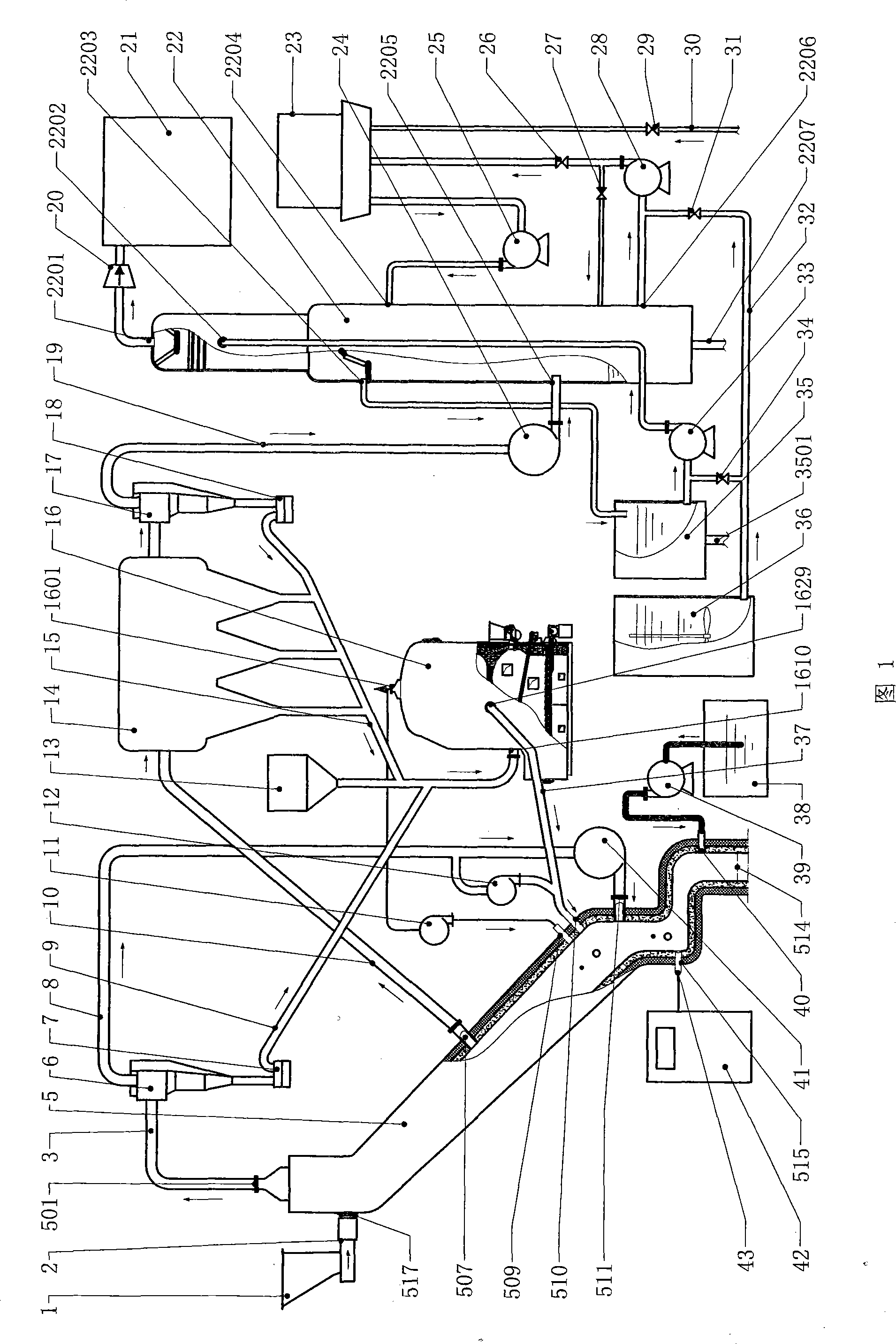

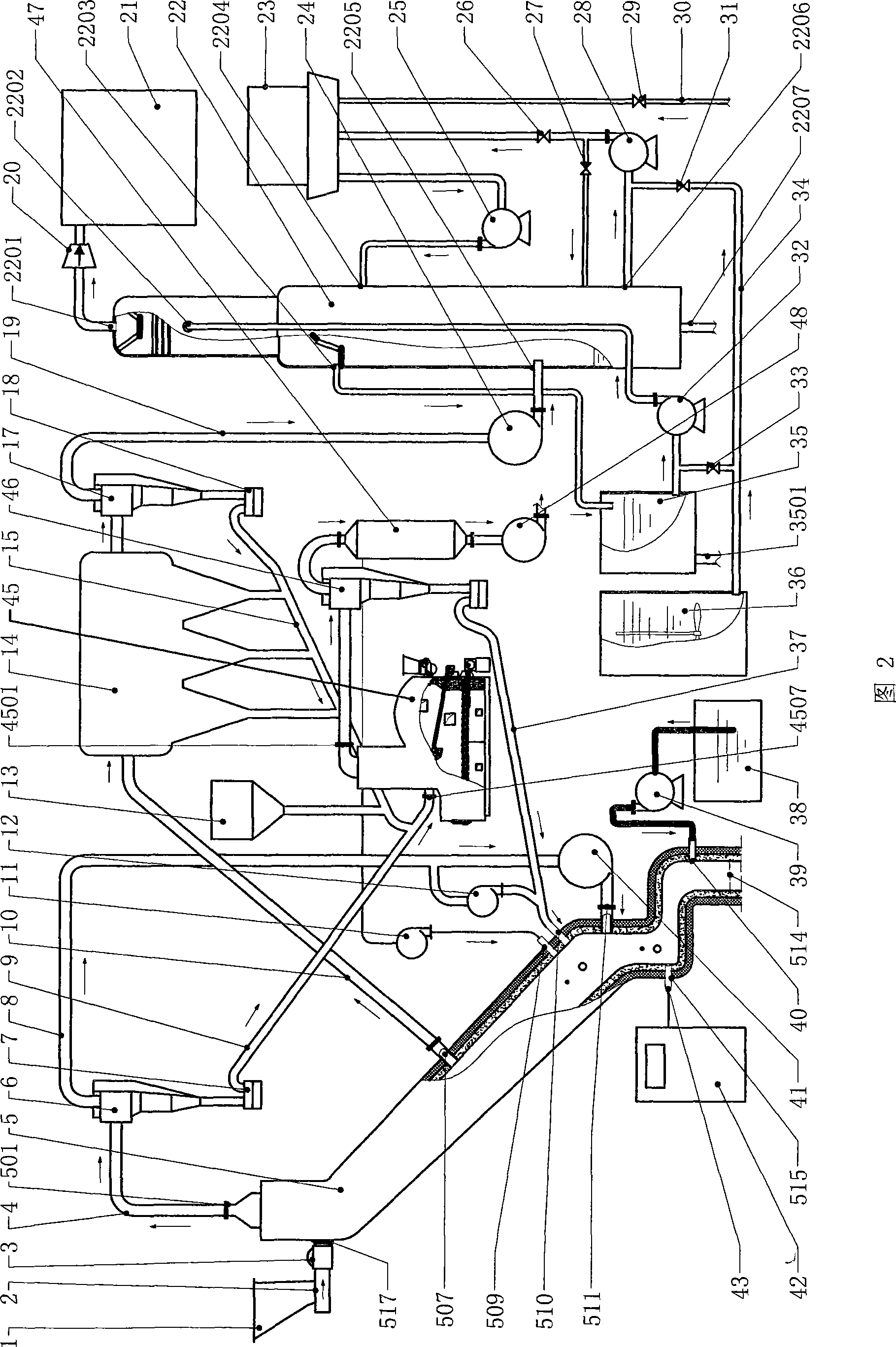

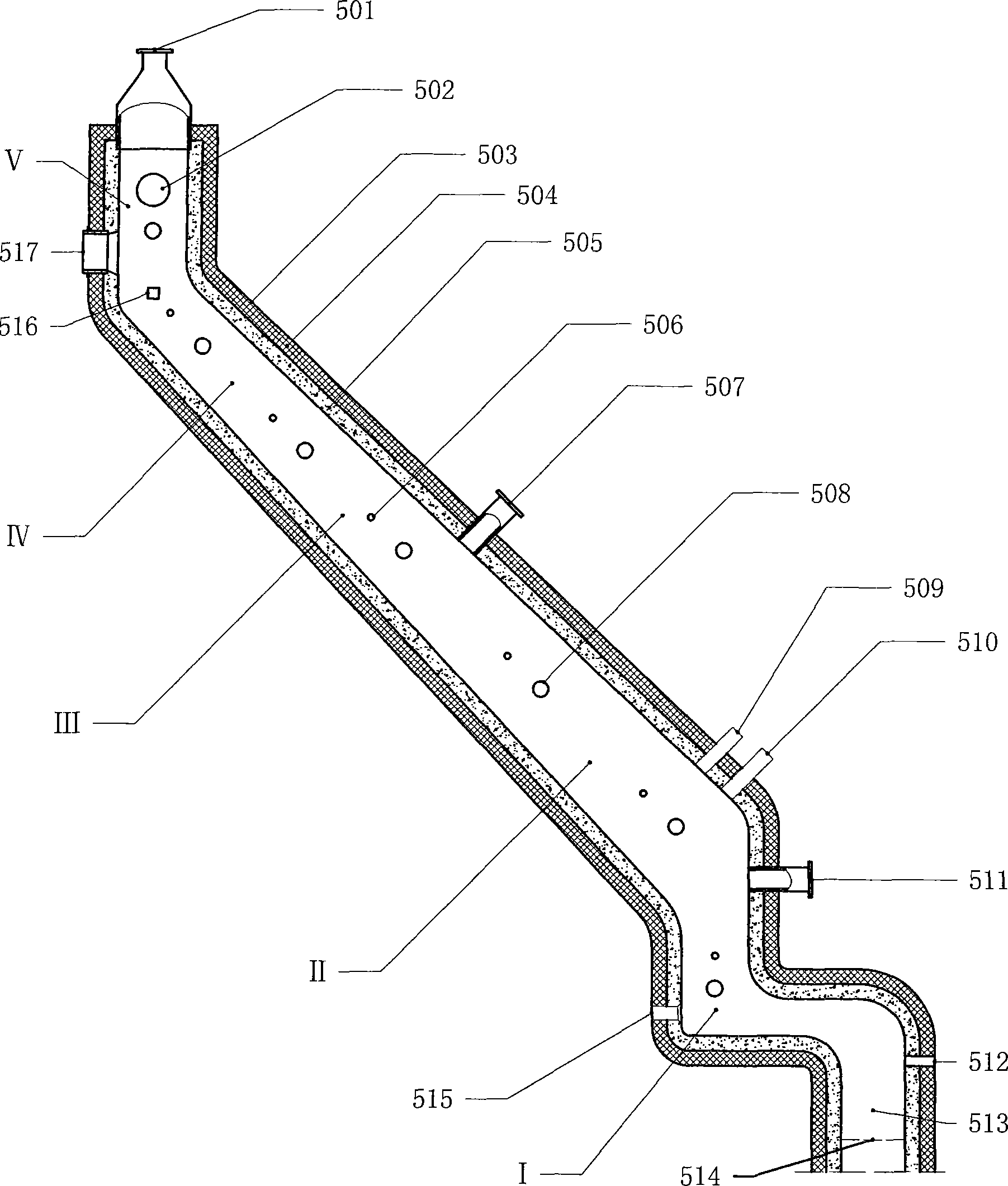

[0028] figure 1In the shown embodiment, the system for producing synthesis gas from waste biomass raw materials mainly consists of a screw compression molding machine (2), a multiphase circulation gasifier (5), a plasma control power supply (42), and a plasma spray gun (43). , multiphase circulation pipe (3), the first gas-solid separator (6), gas phase circulation pipe (8), gas phase circulation fan (41), solid phase delivery pipe a (9), calcium oxide calciner (16), Calcium oxide return pipe (37), high-pressure fan (12), synthesis gas delivery pipe (10) (19), waste heat boiler (14), second gas-solid separator (17), induced air fan (24), wet Purification tower (22), cooling tower (23), cooling water booster pump (25), cooling water circulation pump (28), absorbent booster pump (33), absorbent buffer tank (35), absorbent replenishment warehouse (36), sewage tank (38), sewage pump (39), sewage spray gun (40), compressor (20) and gas cabinet (21), wherein: the main function sect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com