Patents

Literature

56results about "Combustion types" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

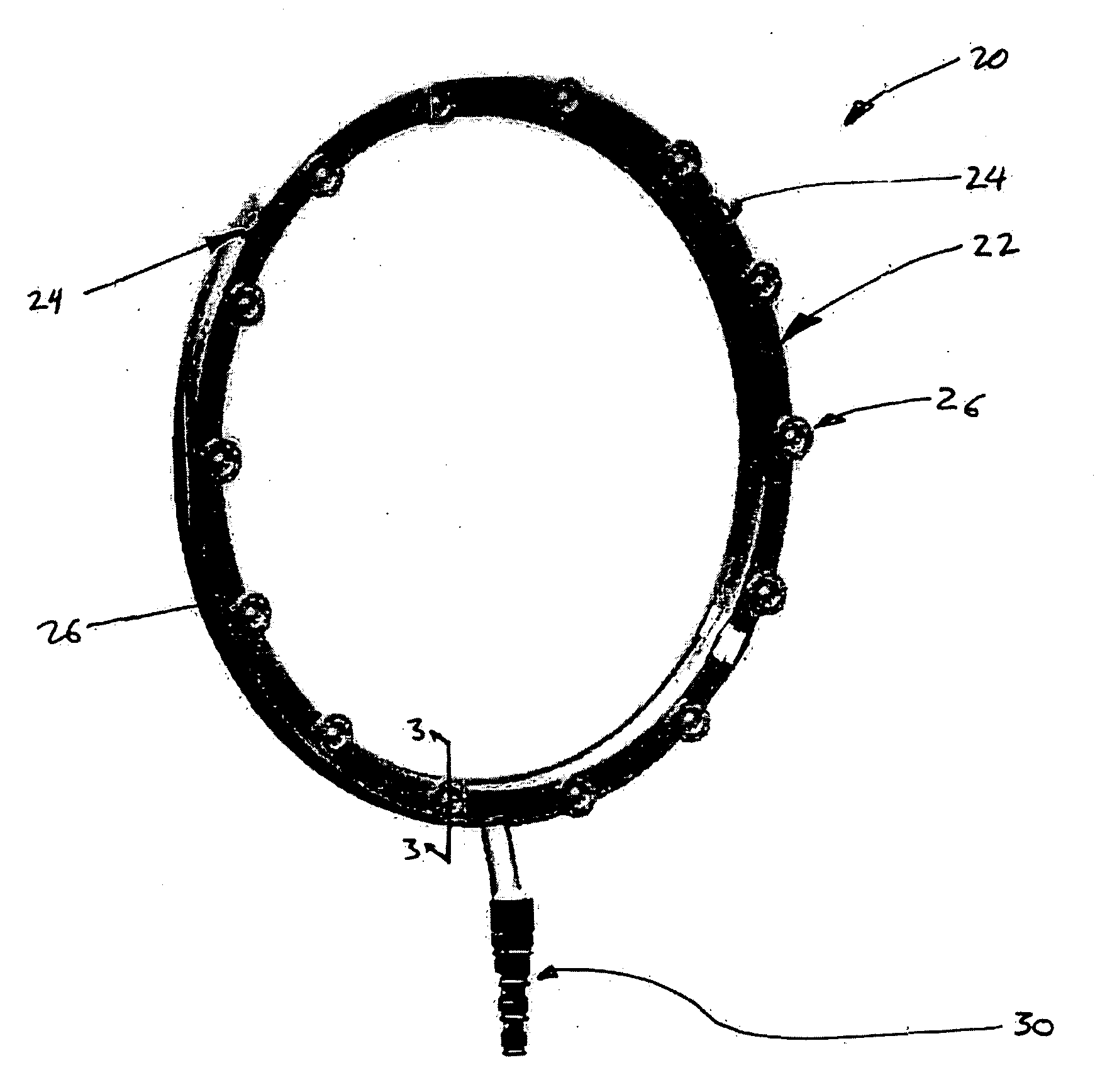

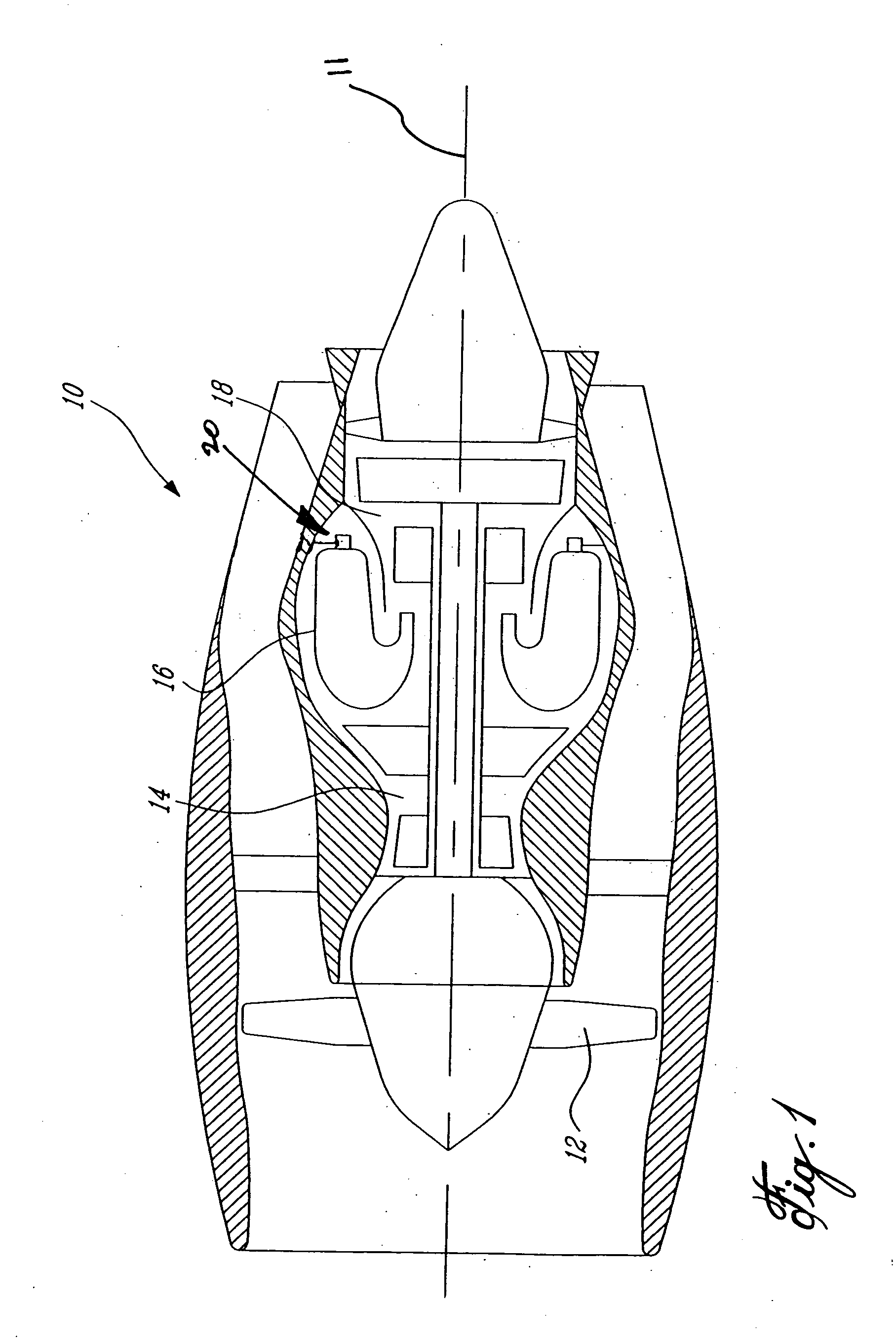

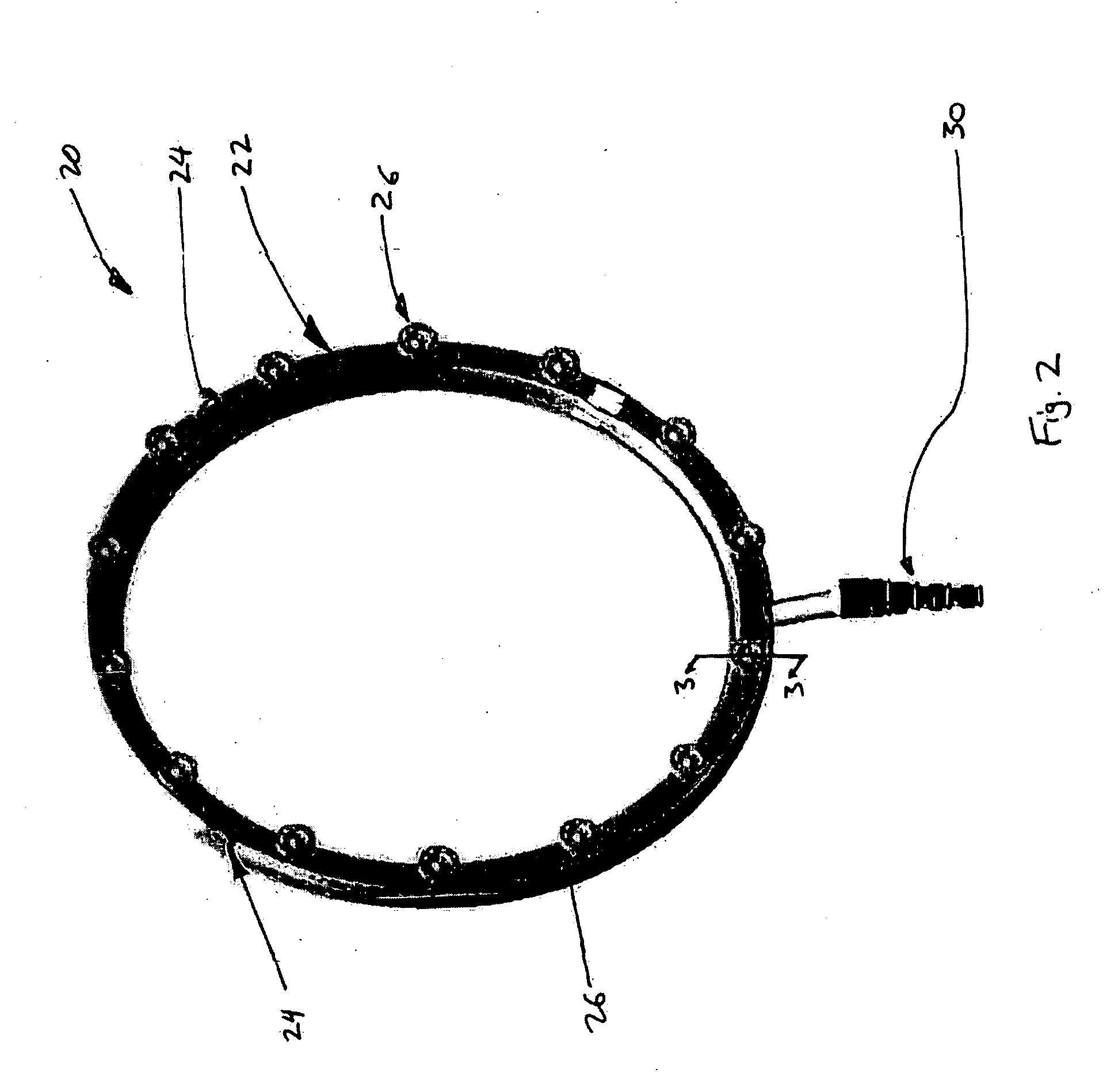

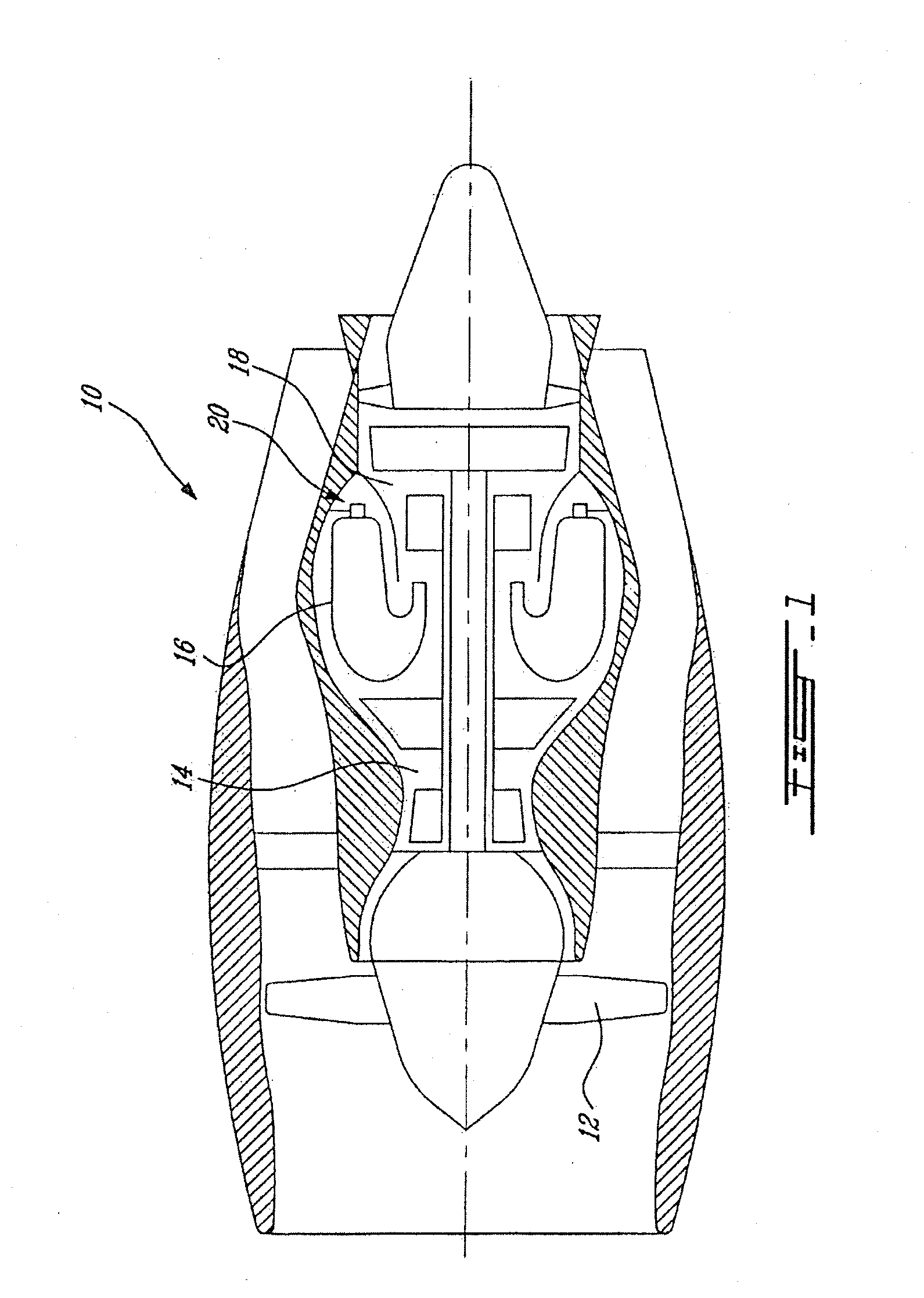

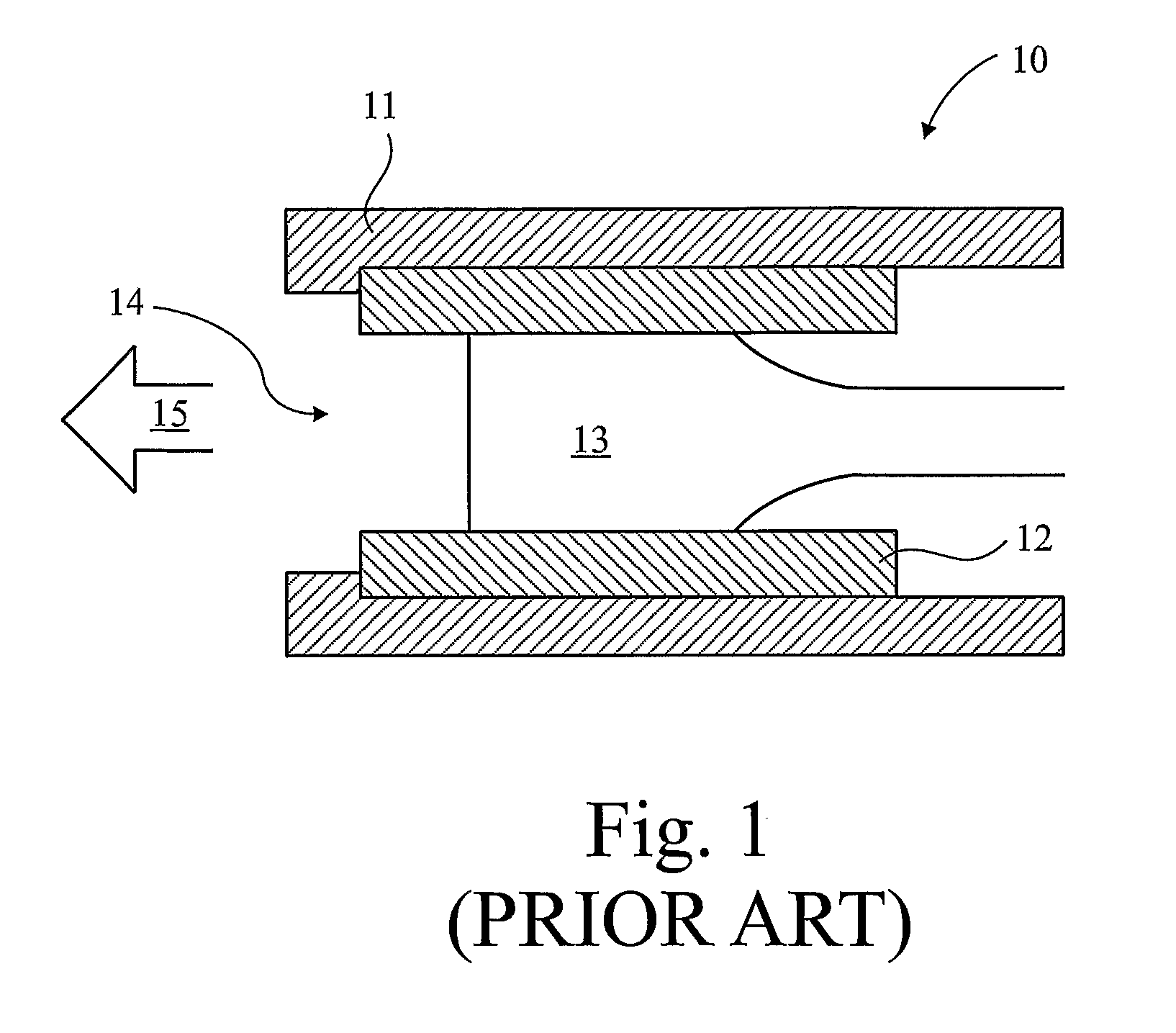

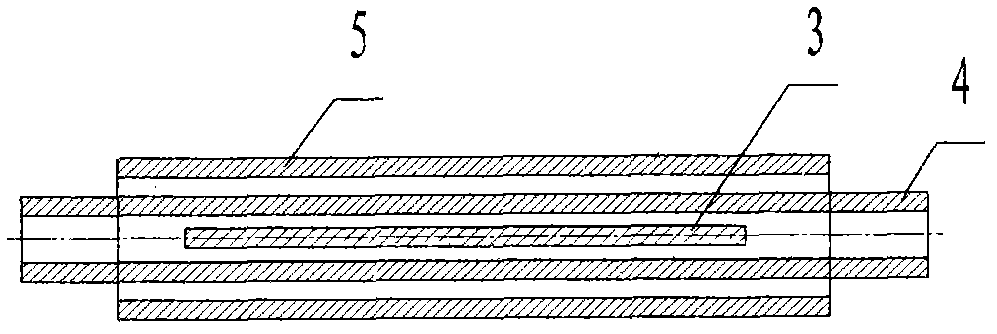

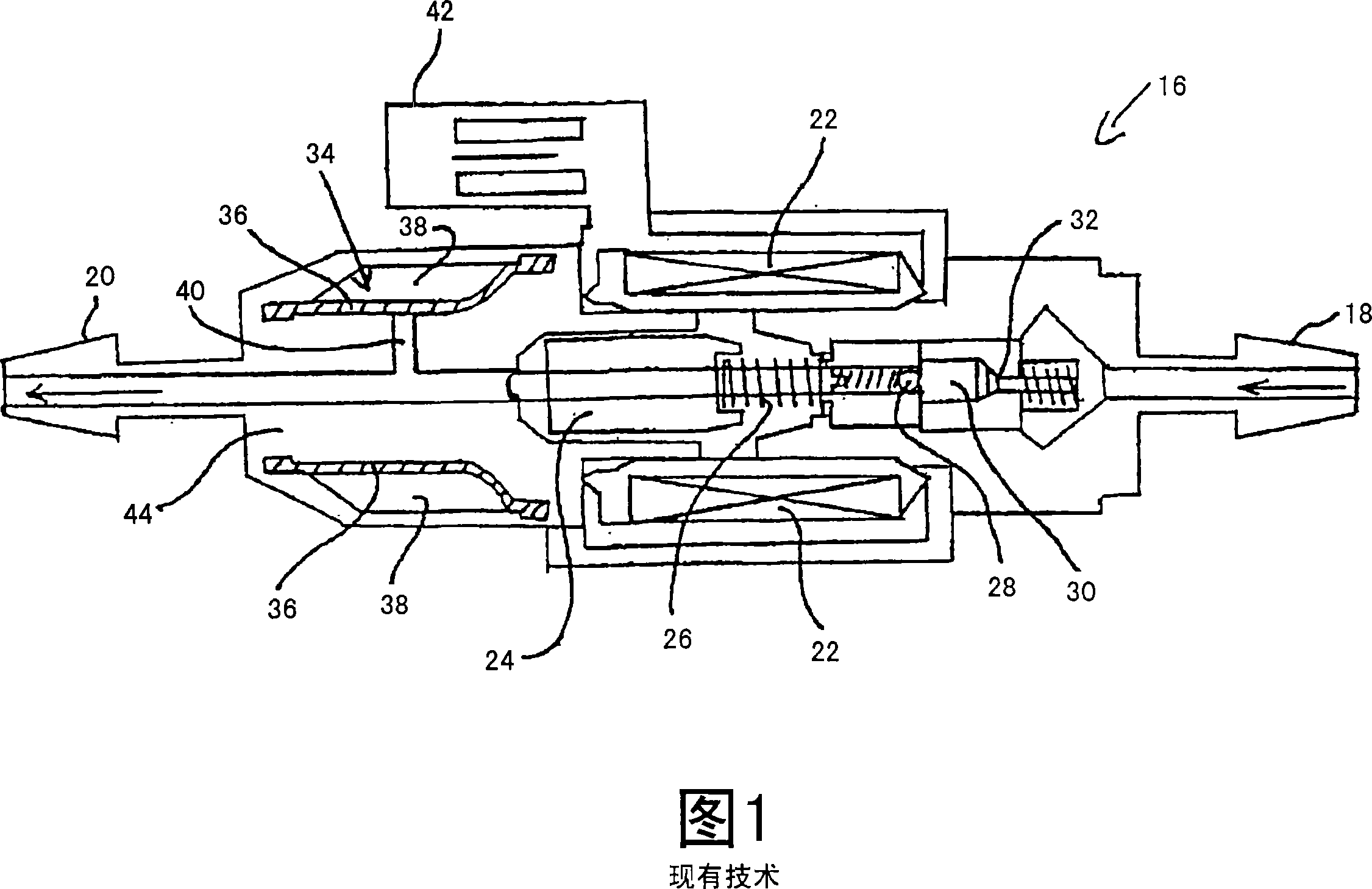

Integral heater for fuel conveying member

InactiveUS20060156733A1Combustion typesTurbine/propulsion fuel flow conduitsEngineeringMechanical engineering

A fuel conveying member for an engine, the fuel conveying member having heating means integrated therein to permit pyrolysis of carbonaceous deposits.

Owner:PRATT & WHITNEY CANADA CORP

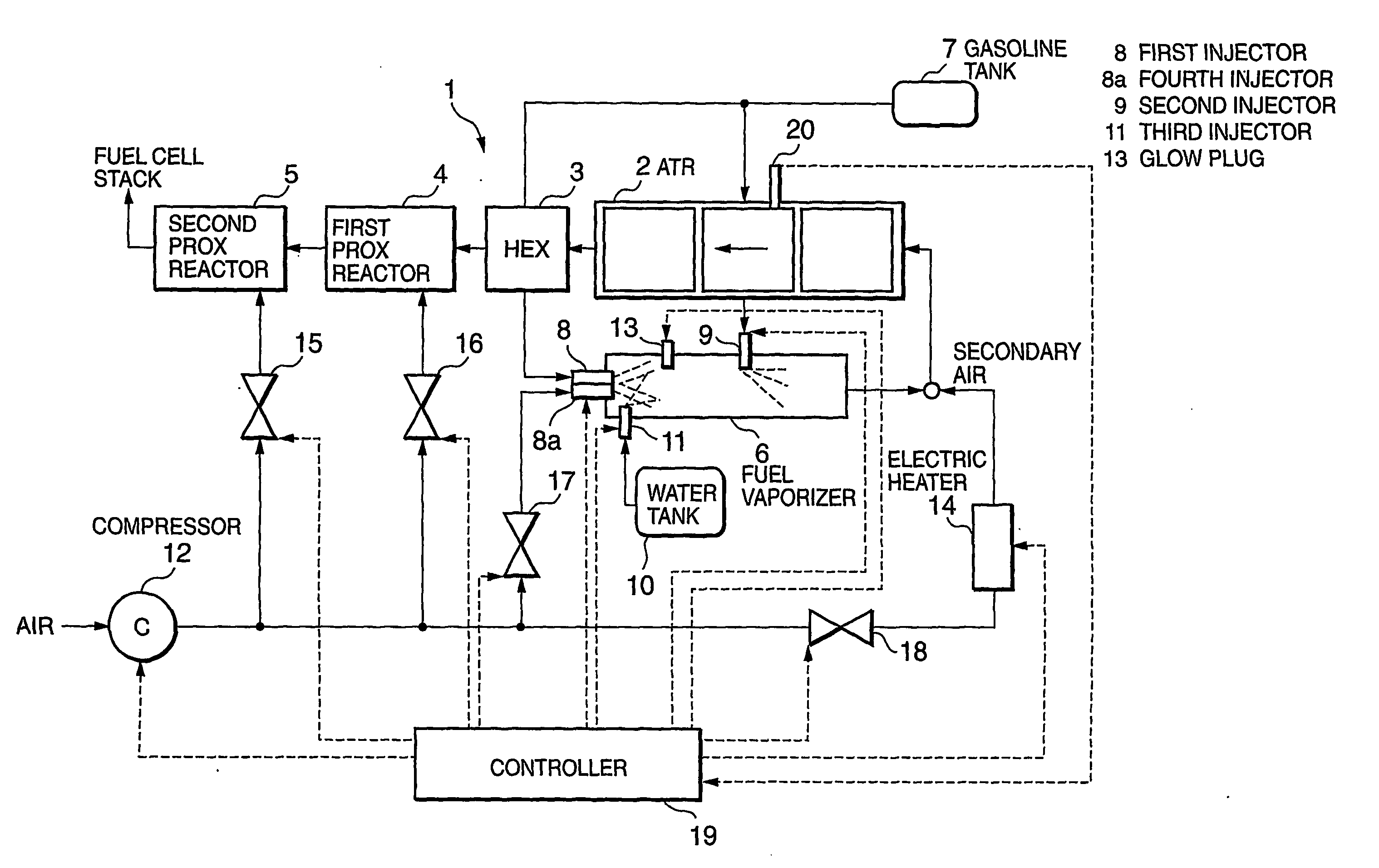

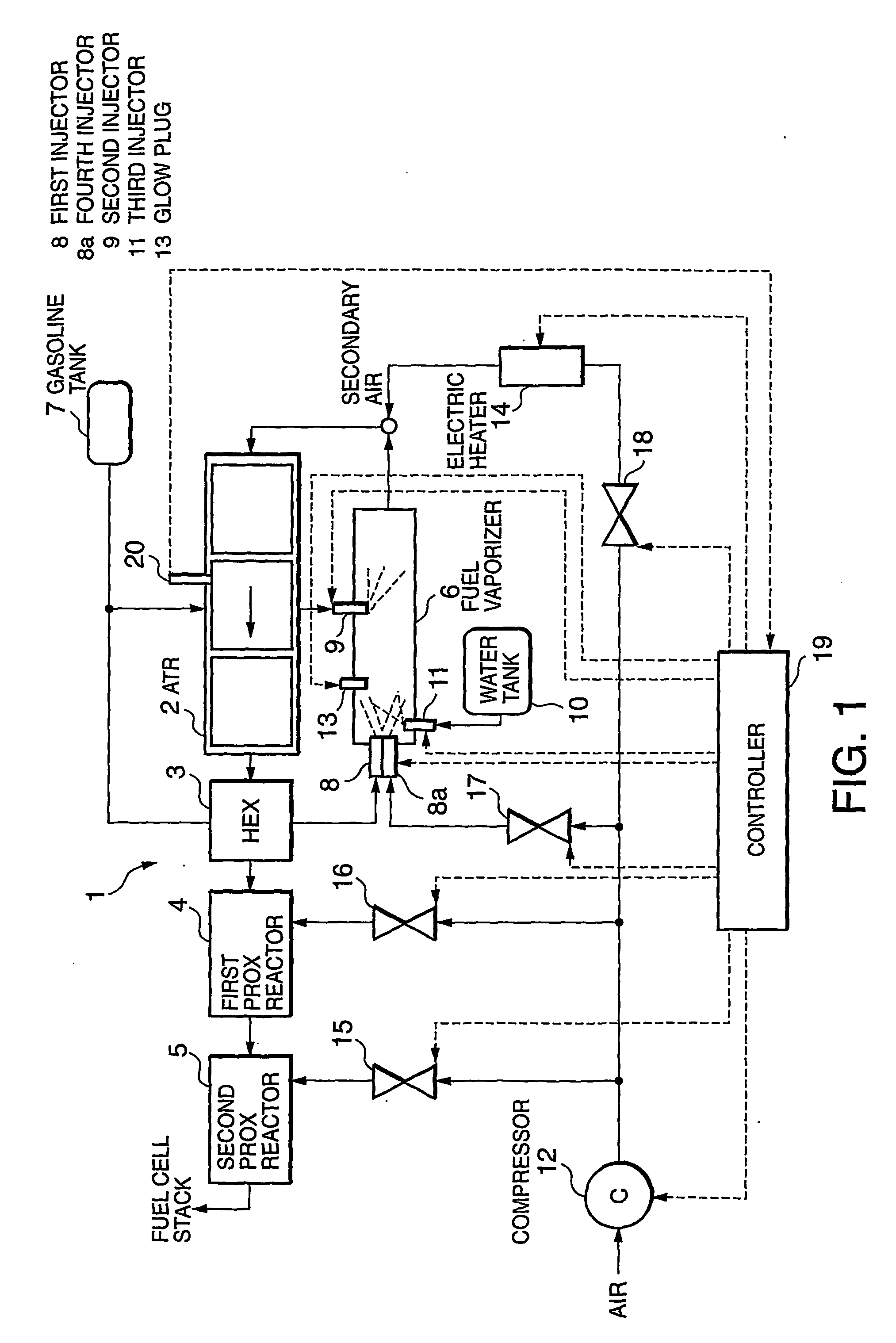

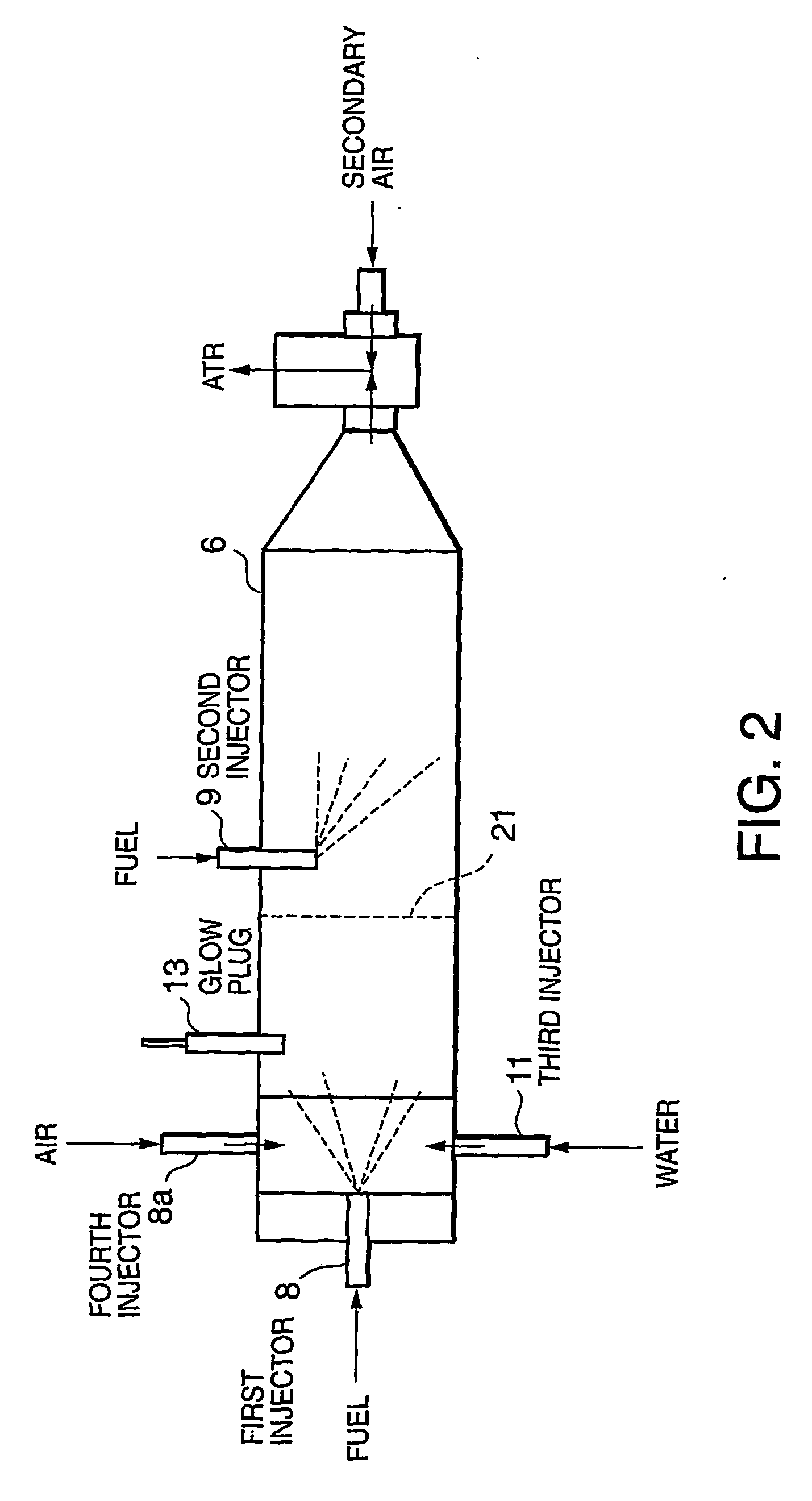

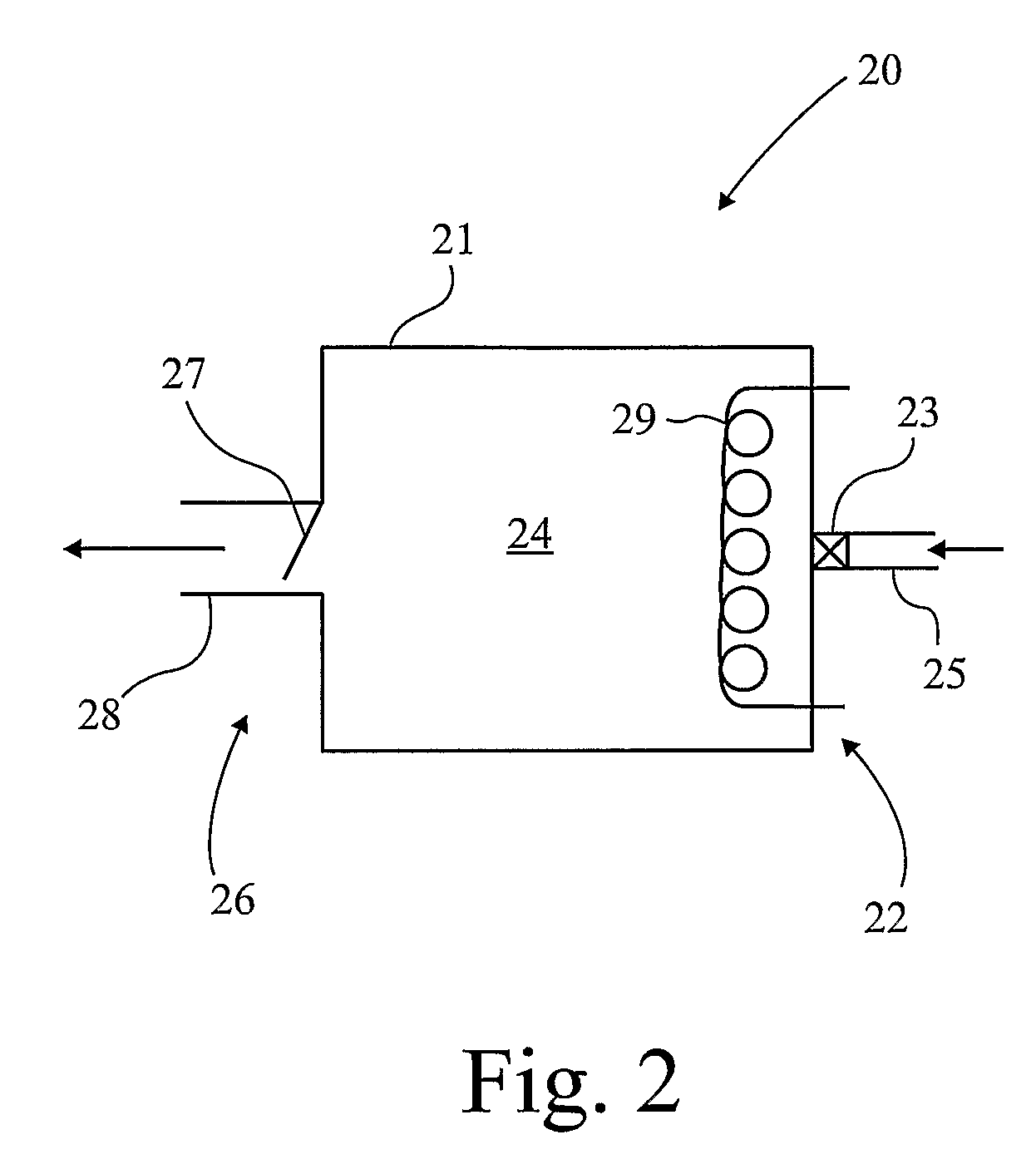

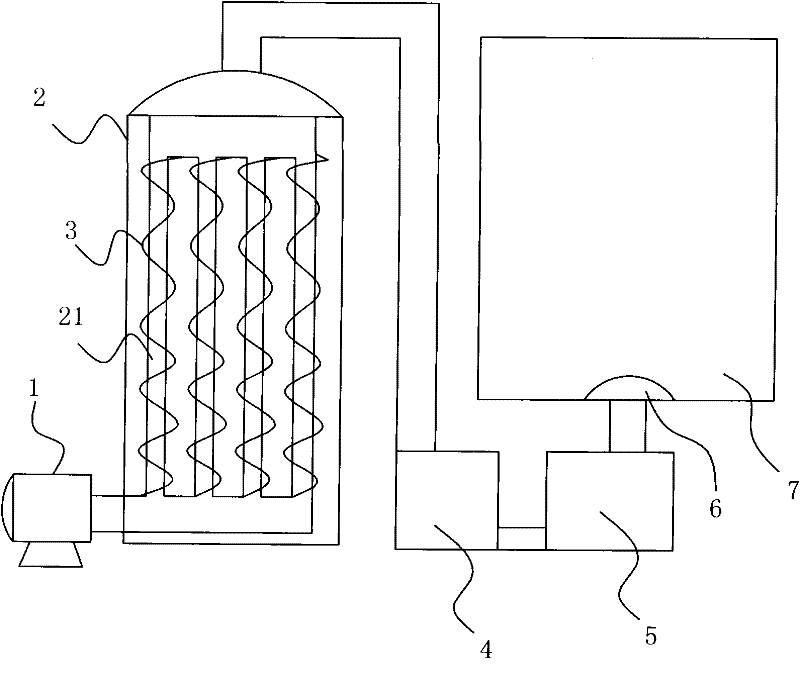

Fuel vaporizing device

ActiveUS20060037308A1High efficiency performanceHigh reforming efficiencyLiquid fuel feeder/distributionHydrogenSteam reformingPartial oxidation

Hydrogen-rich reformate gas is produced by a fuel reformer (2) from fuel vapor containing hydrocarbon, which is produced by a fuel vaporizer (6), by means of a partial oxidation reaction and a steam reforming reaction. A fuel injector (8, 9) supplies fuel to the fuel vaporizer (6), and an air injector (8a) supplies air to the fuel vaporizer (6). A glow plug (13) partially oxidizes the air-fuel mixture inside the fuel vaporizer (6). By controlling the air supply amount in relation to the fuel supply amount to obtain an excess air factor corresponding to a predetermined rich air-fuel ratio, a part of the air-fuel mixture in the fuel vaporizer (6) is partially oxidized, and the remaining fuel vapor is heated by the oxidation heat. As a result, the partial oxidation reaction and steam reforming reaction in the fuel reformer (2) are performed with a favorable balance.

Owner:NISSAN MOTOR CO LTD

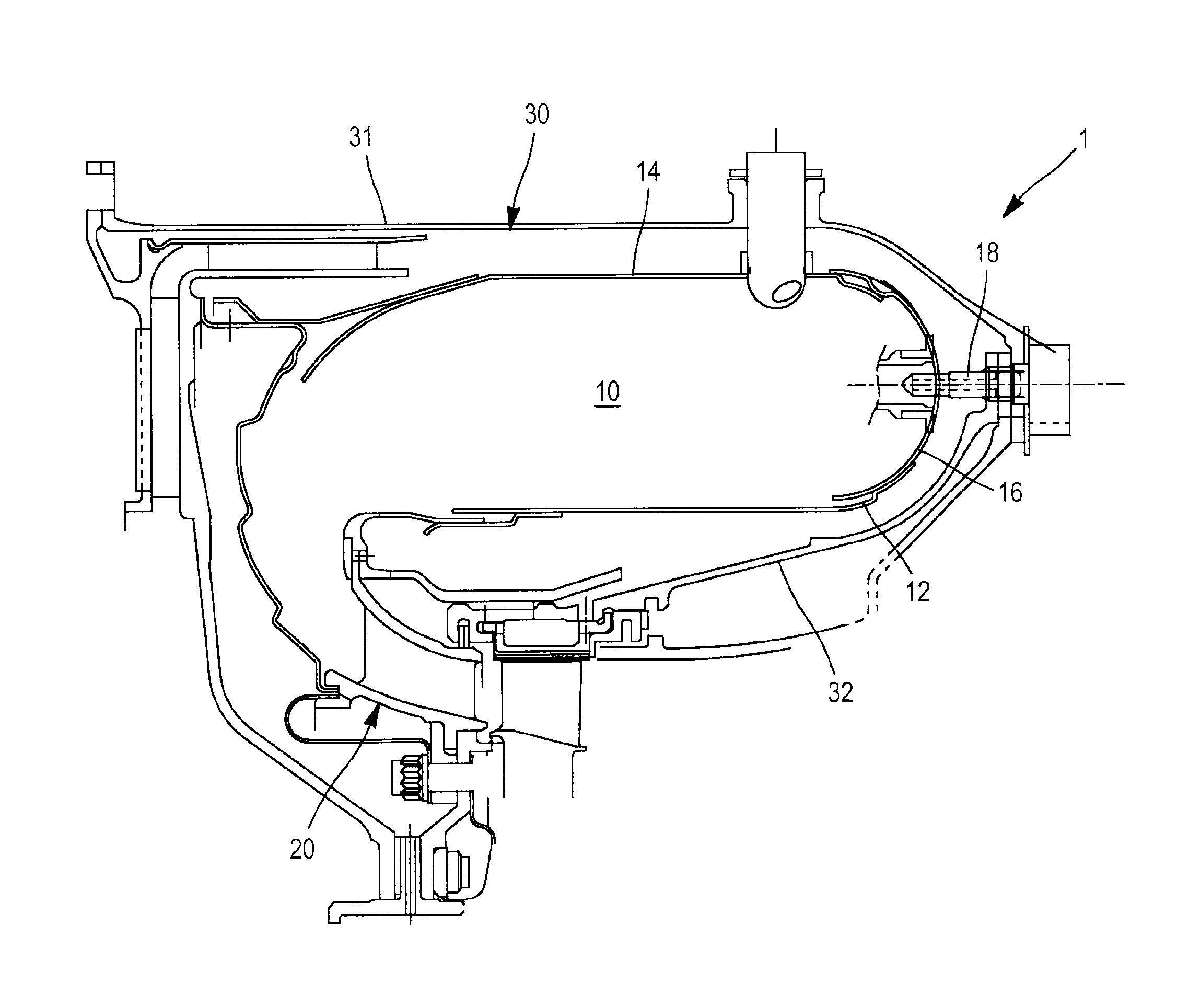

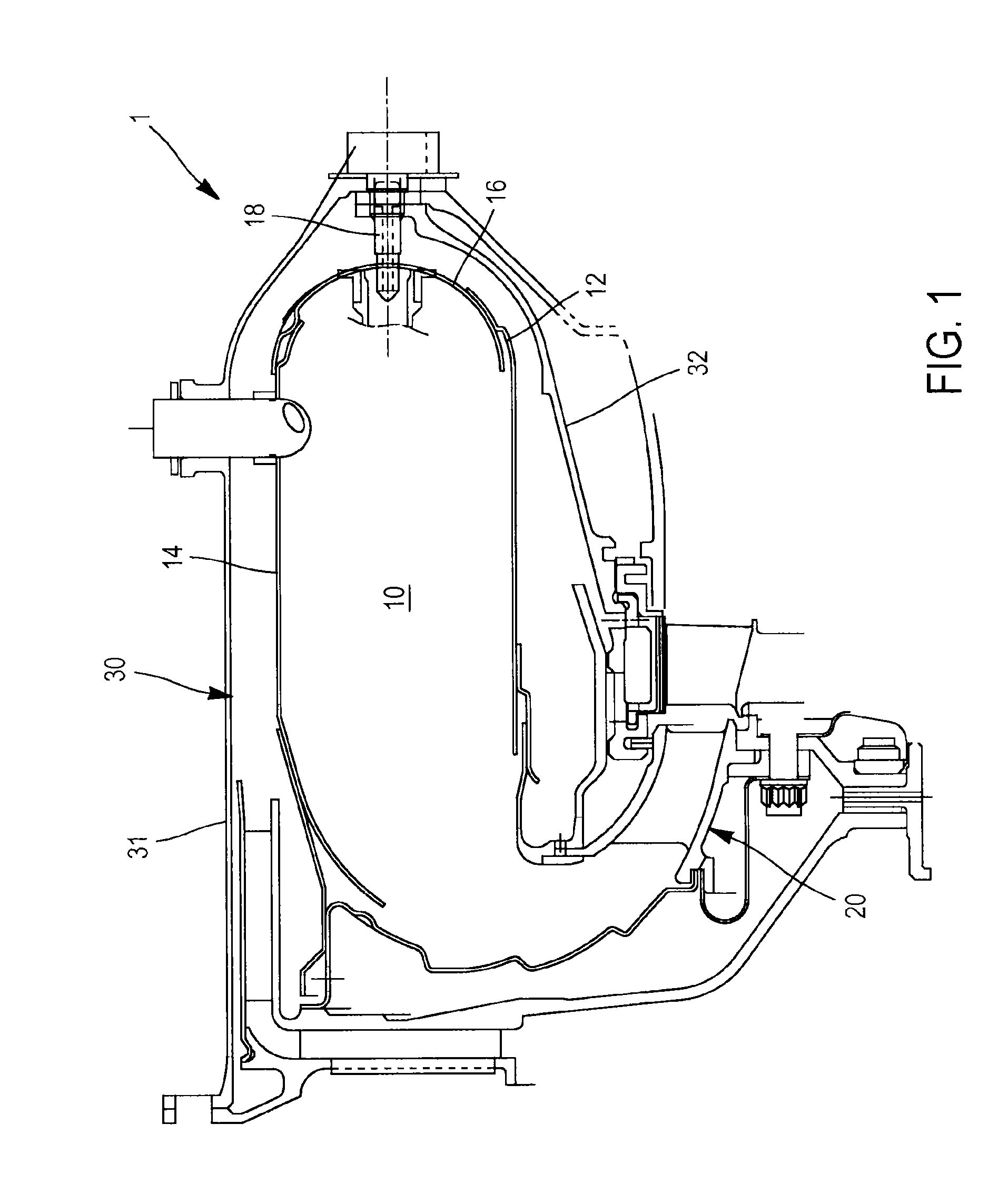

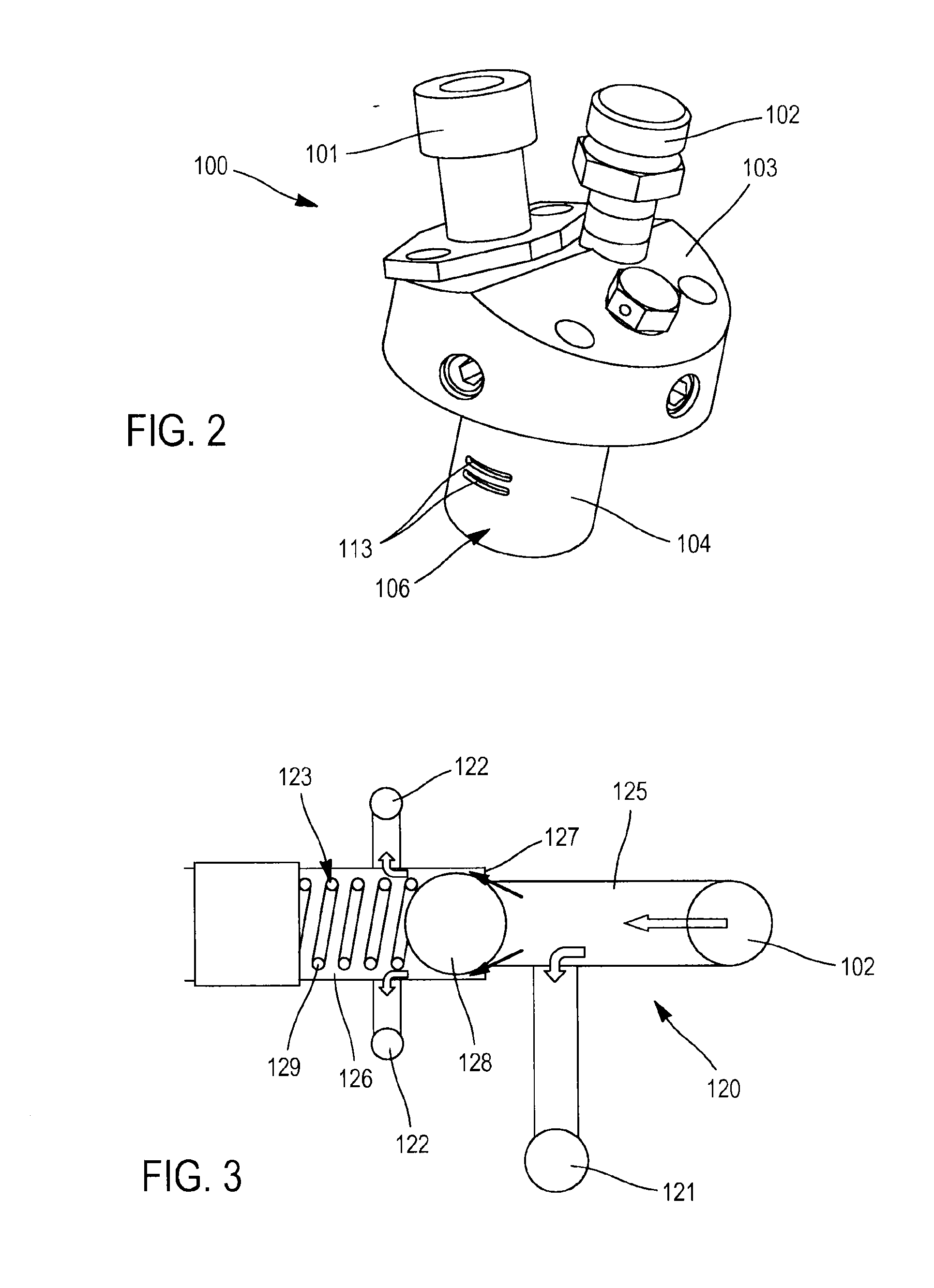

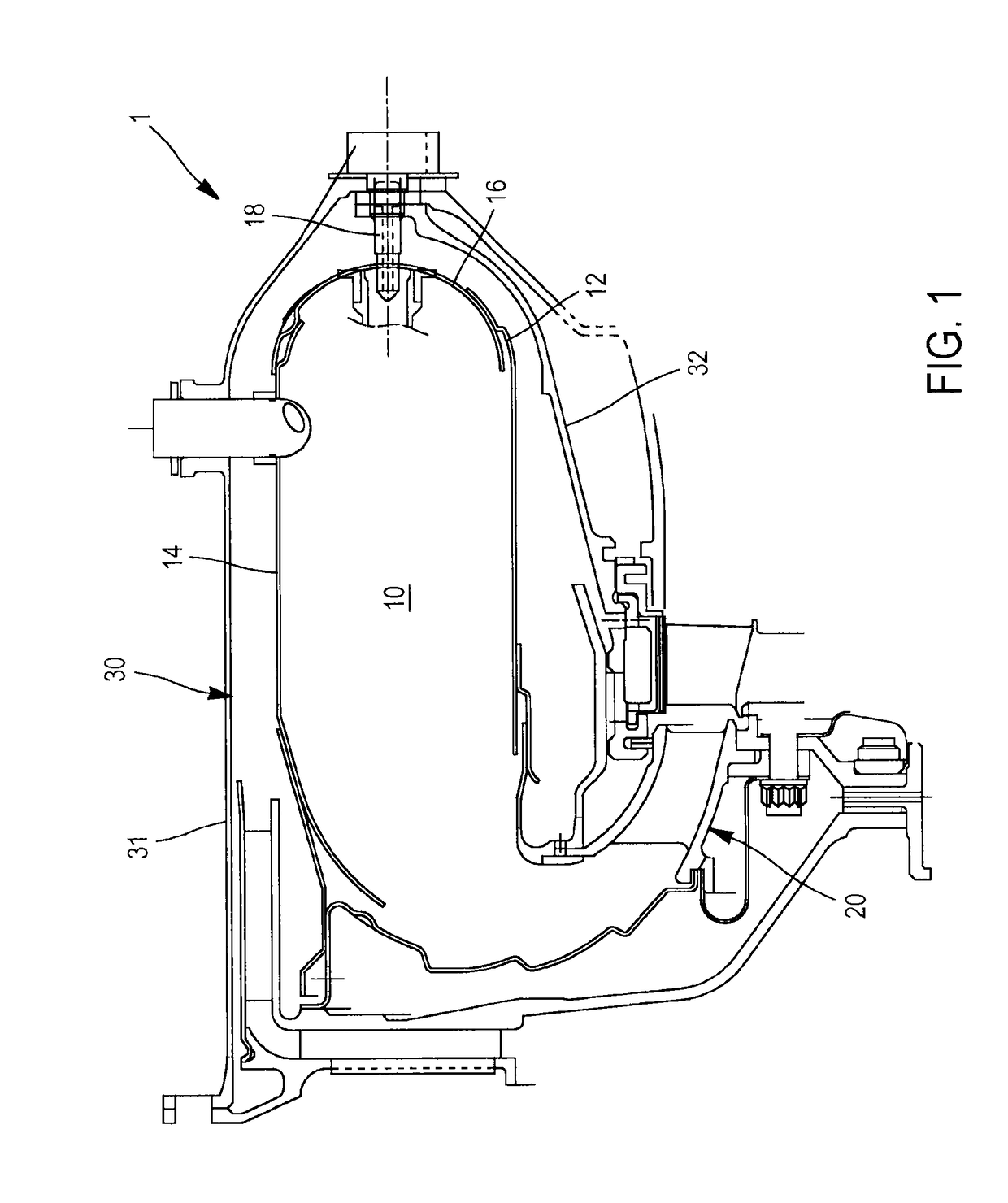

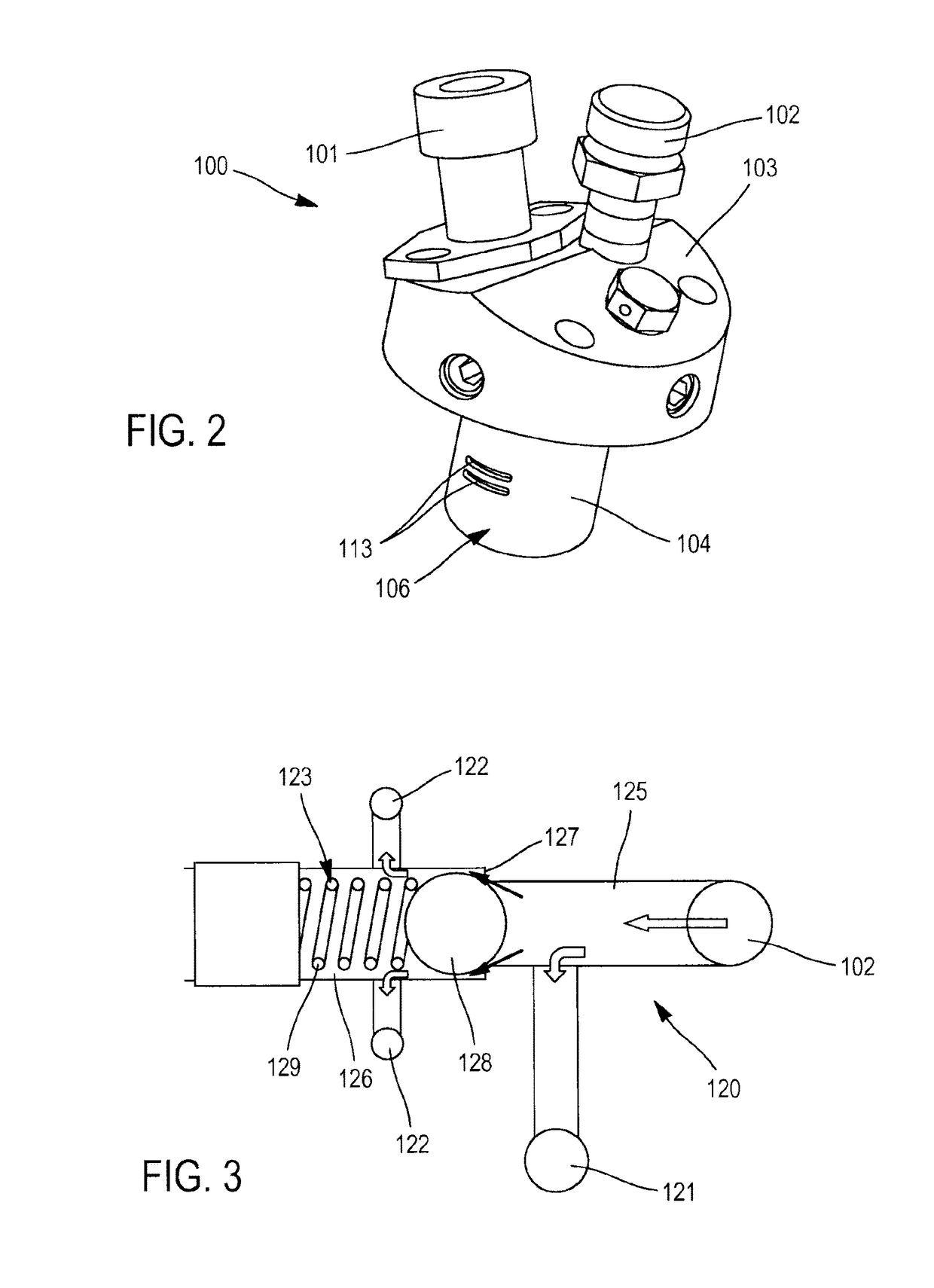

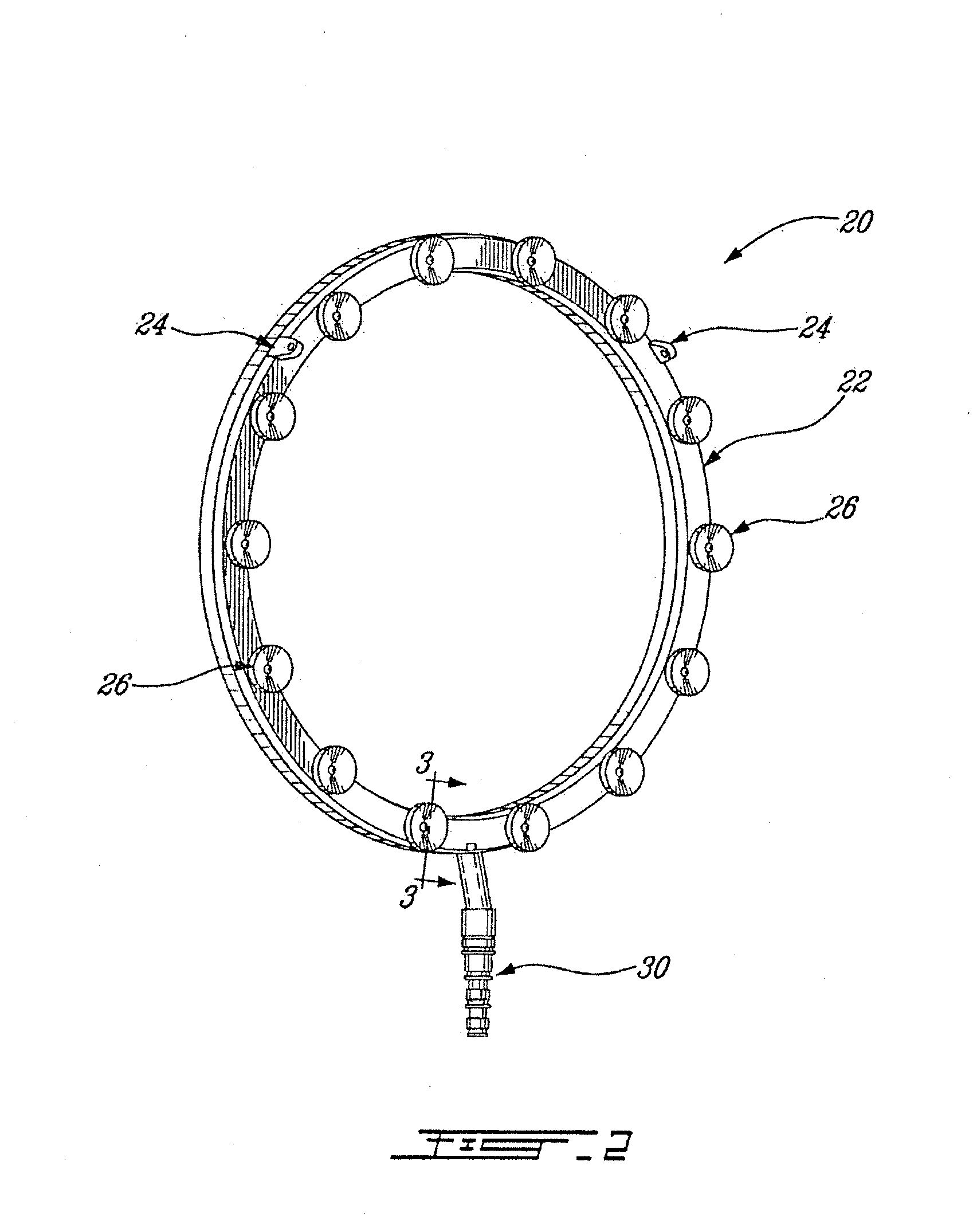

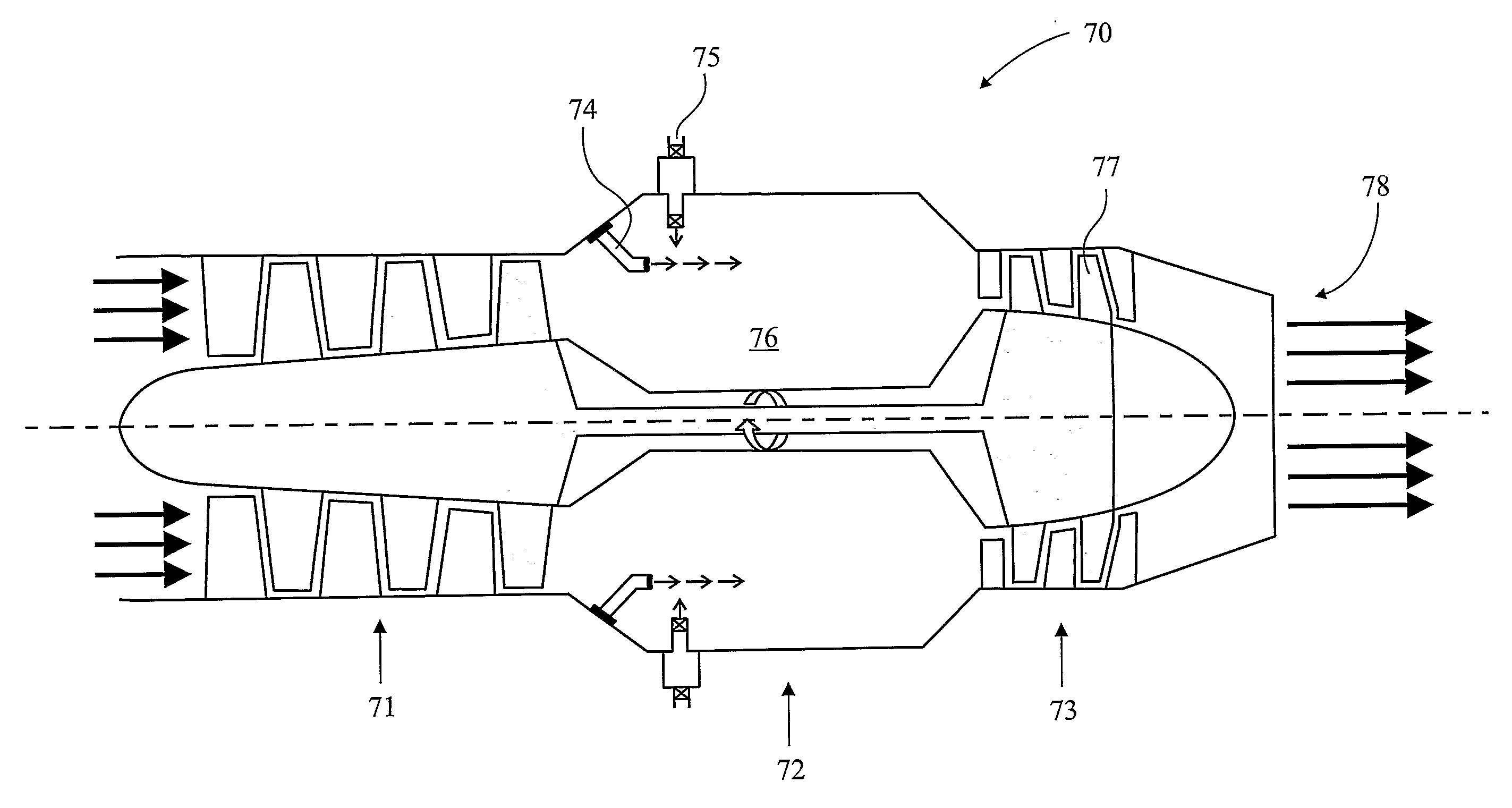

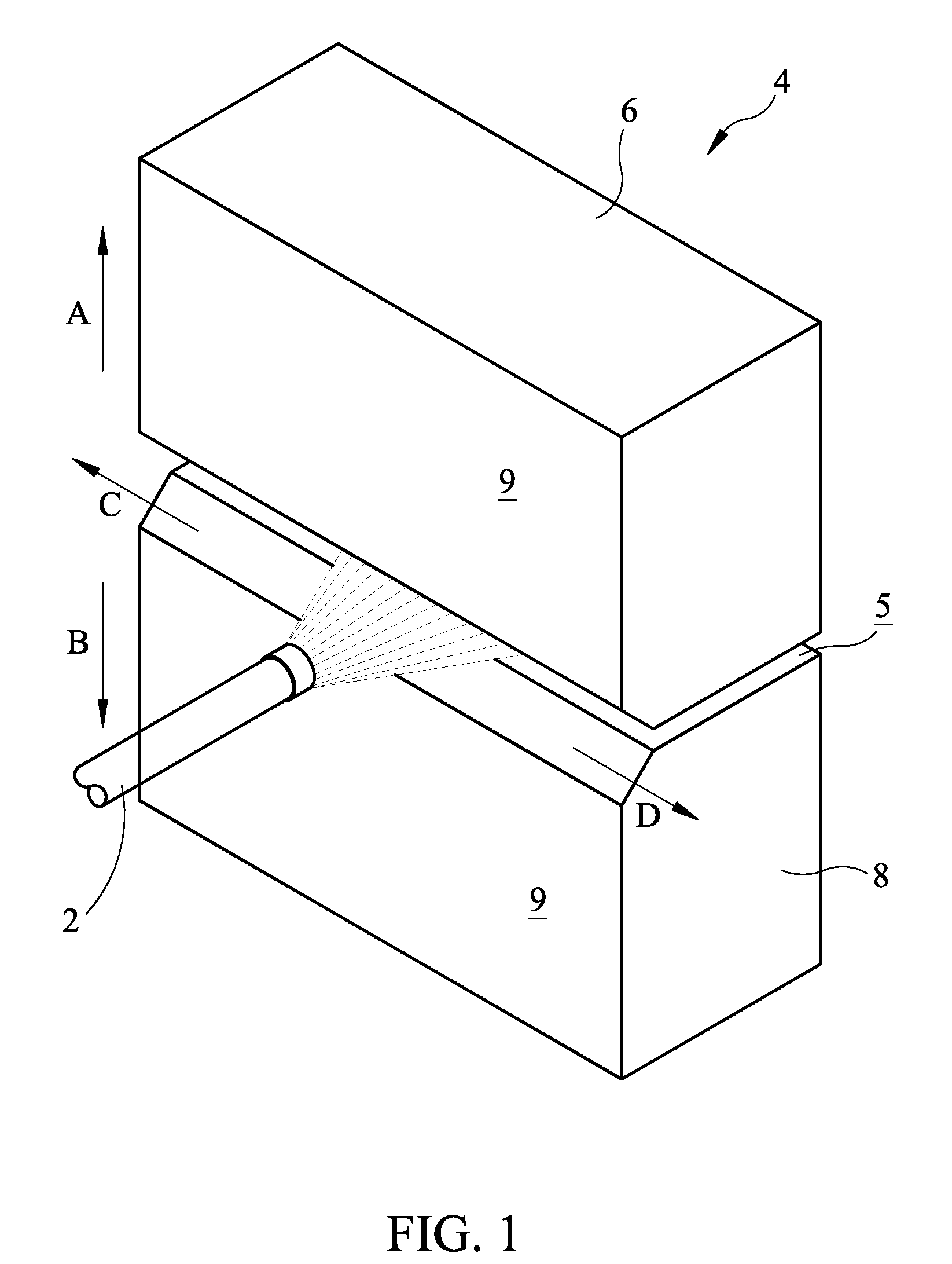

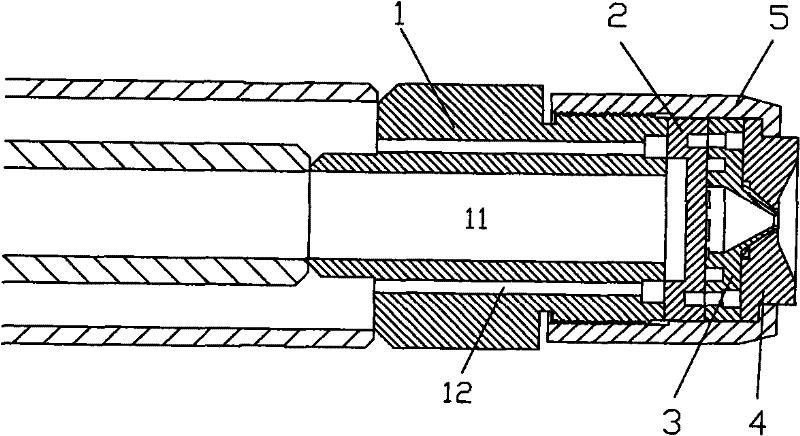

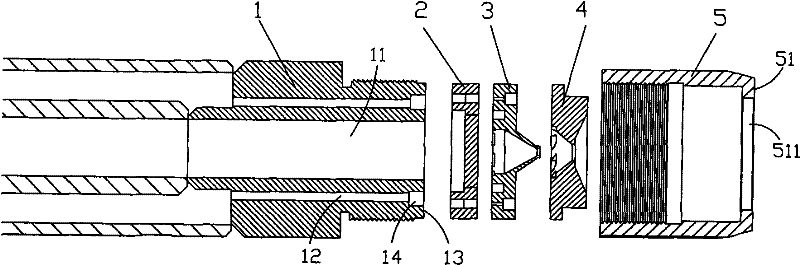

Two-circuit injector for a turbine engine combustion chamber

ActiveUS20150260406A1Fast ignitionFuel economyContinuous combustion chamberCombustion typesCombustion chamberTurbine

A start-up injector for a turbine engine combustion chamber, said injector including a fuel injection circuit; and a fuel ignition circuit including a fuel injector supplied by the fuel injection circuit and a spark plug for igniting the injected fuel. The start-up injector also includes a partitioned enclosure including a first compartment in which the fuel is ignited by the spark plug and a second compartment separated from the first compartment by a thermally conductive partition; and a main combustion start-up circuit which includes at least one fuel injector supplied by the fuel injection circuit and opens into the second compartment of the enclosure such as to inject the fuel against the wall.

Owner:SAFRAN HELICOPTER ENGINES

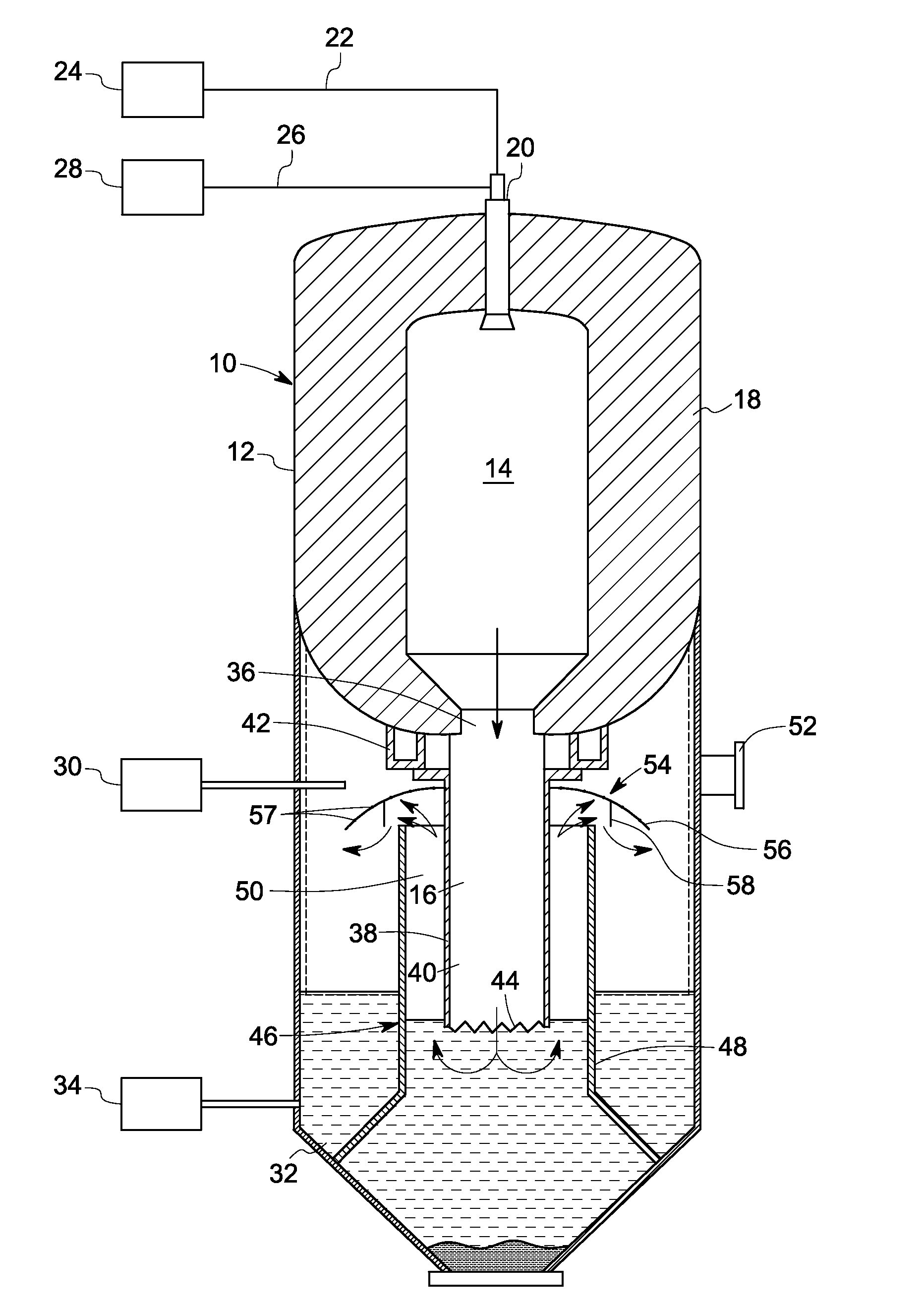

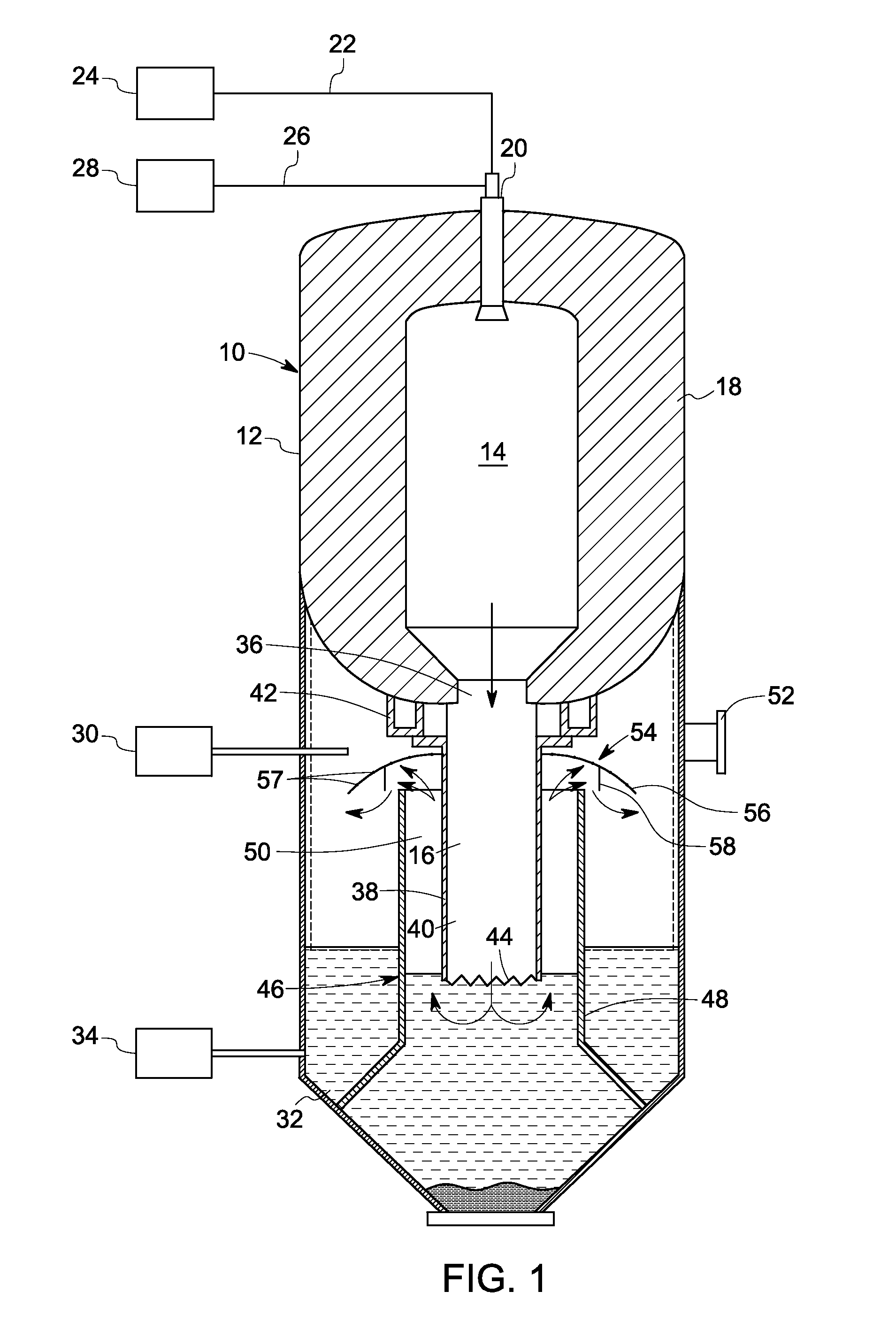

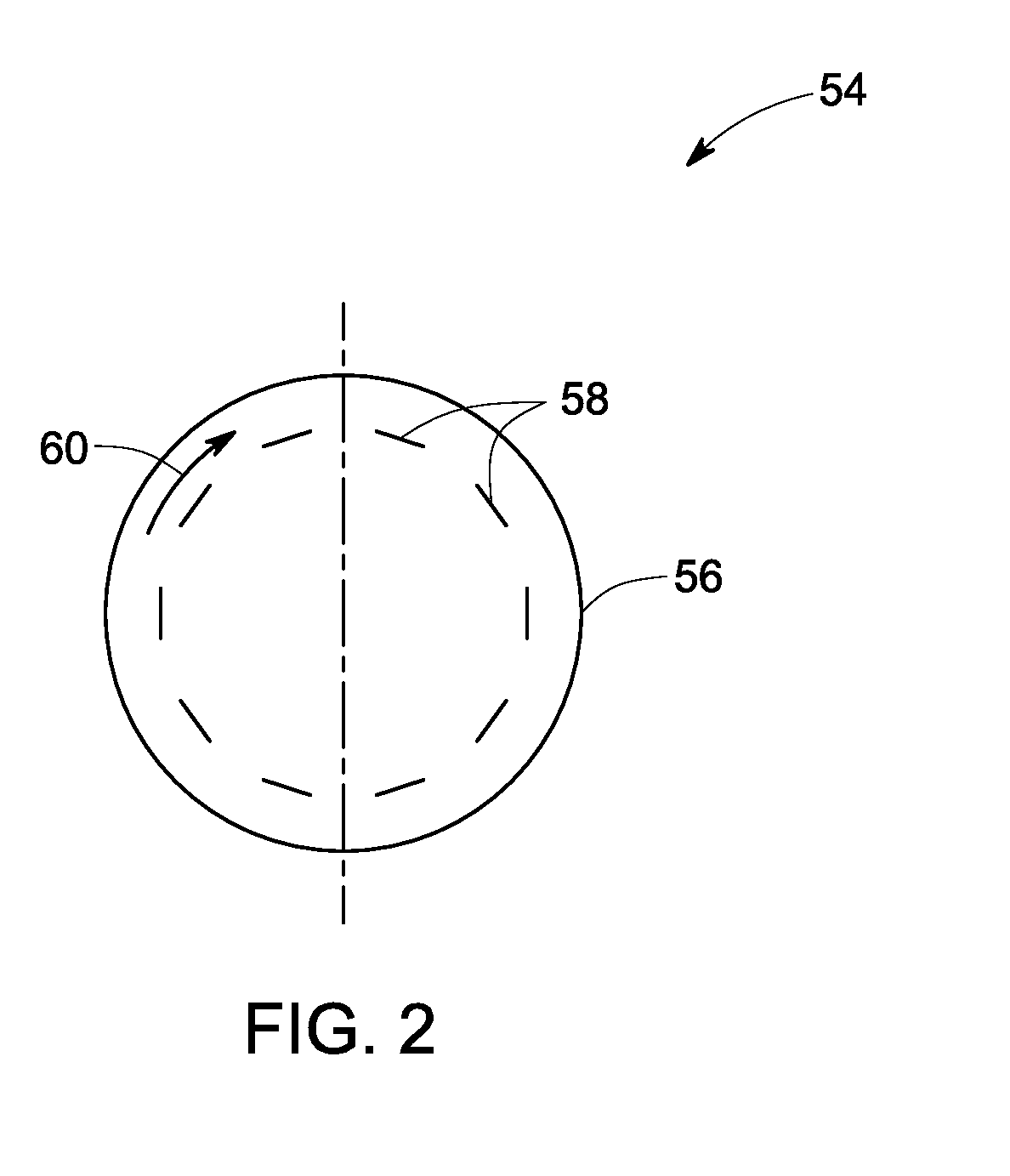

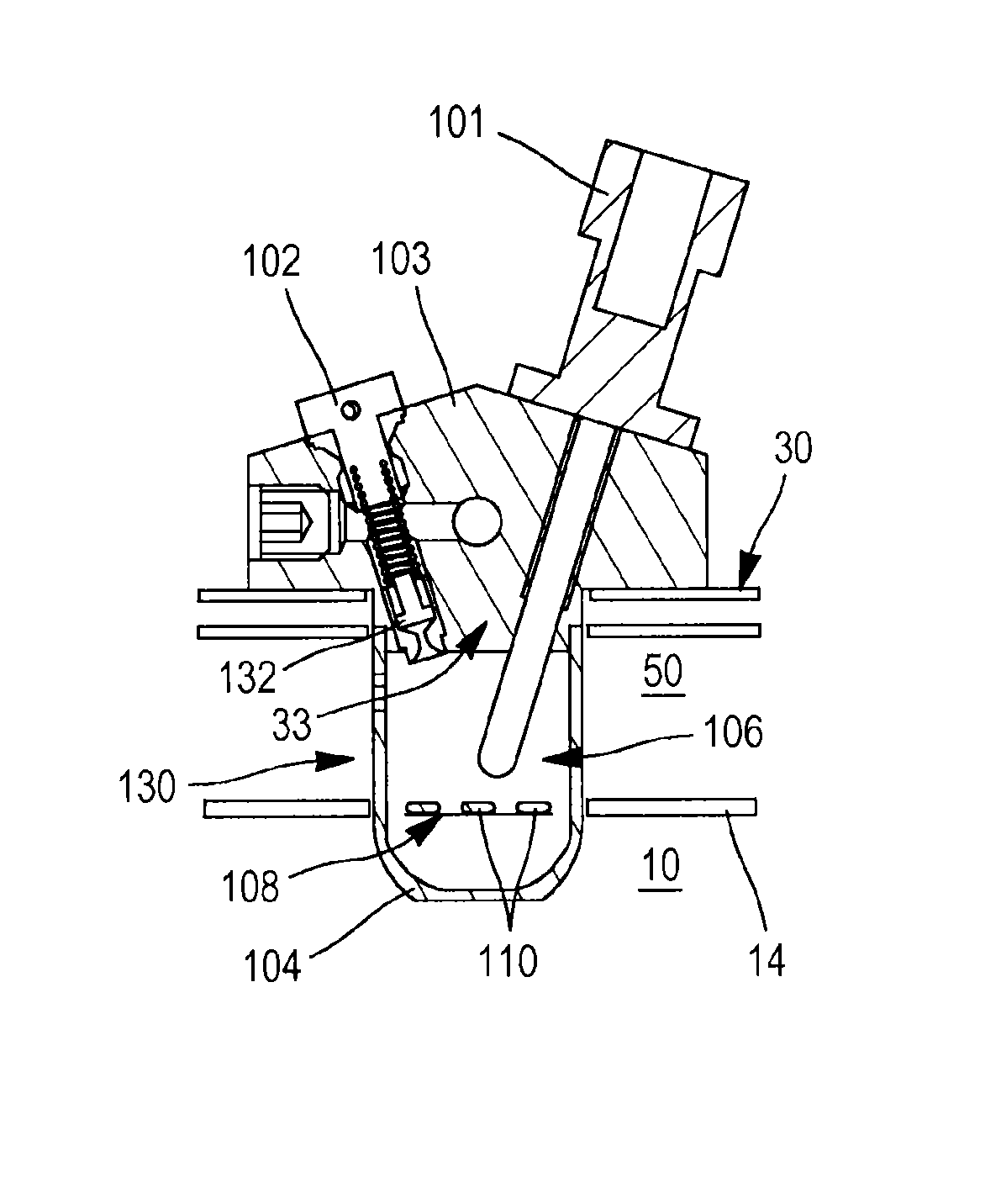

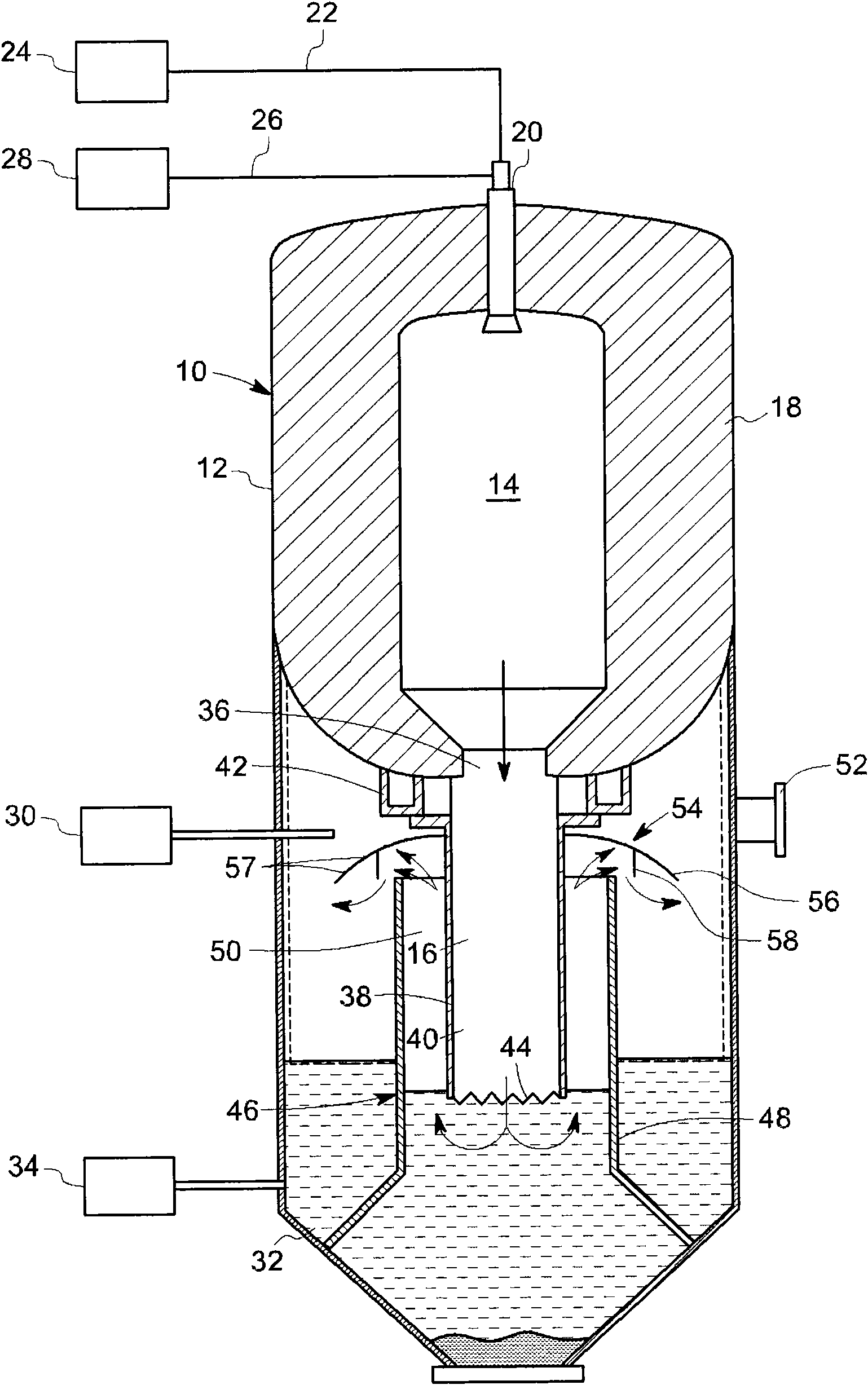

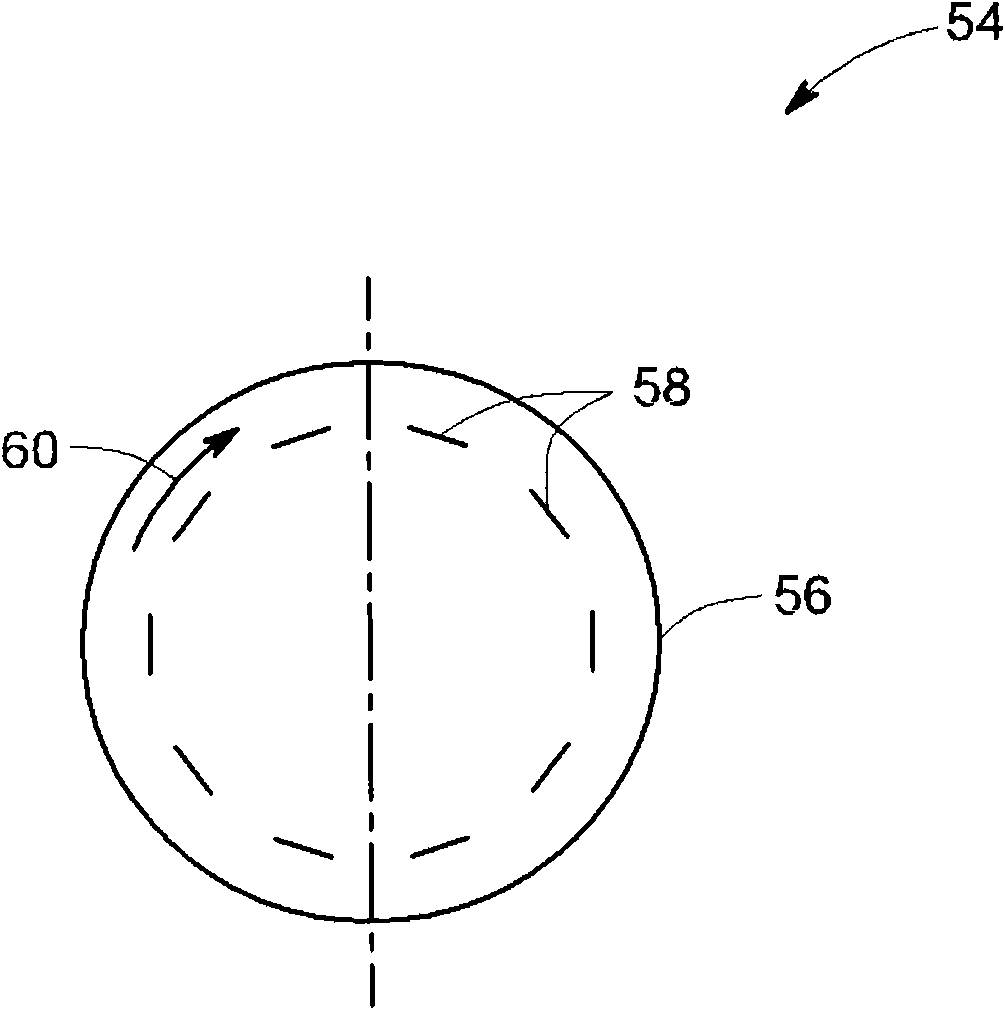

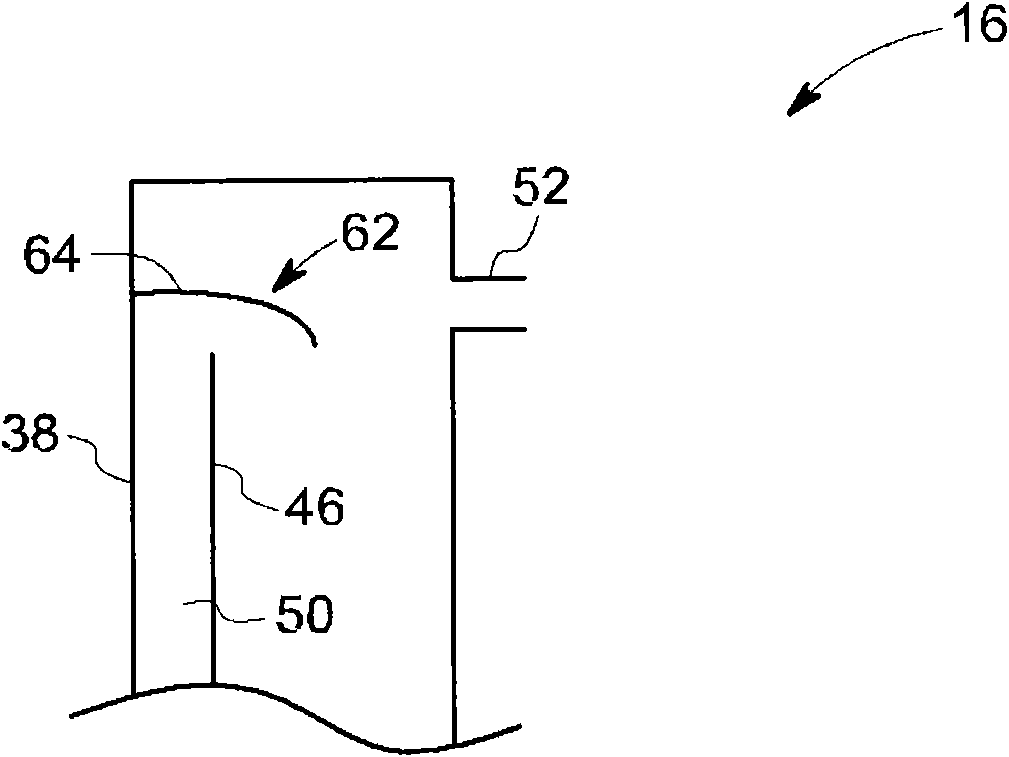

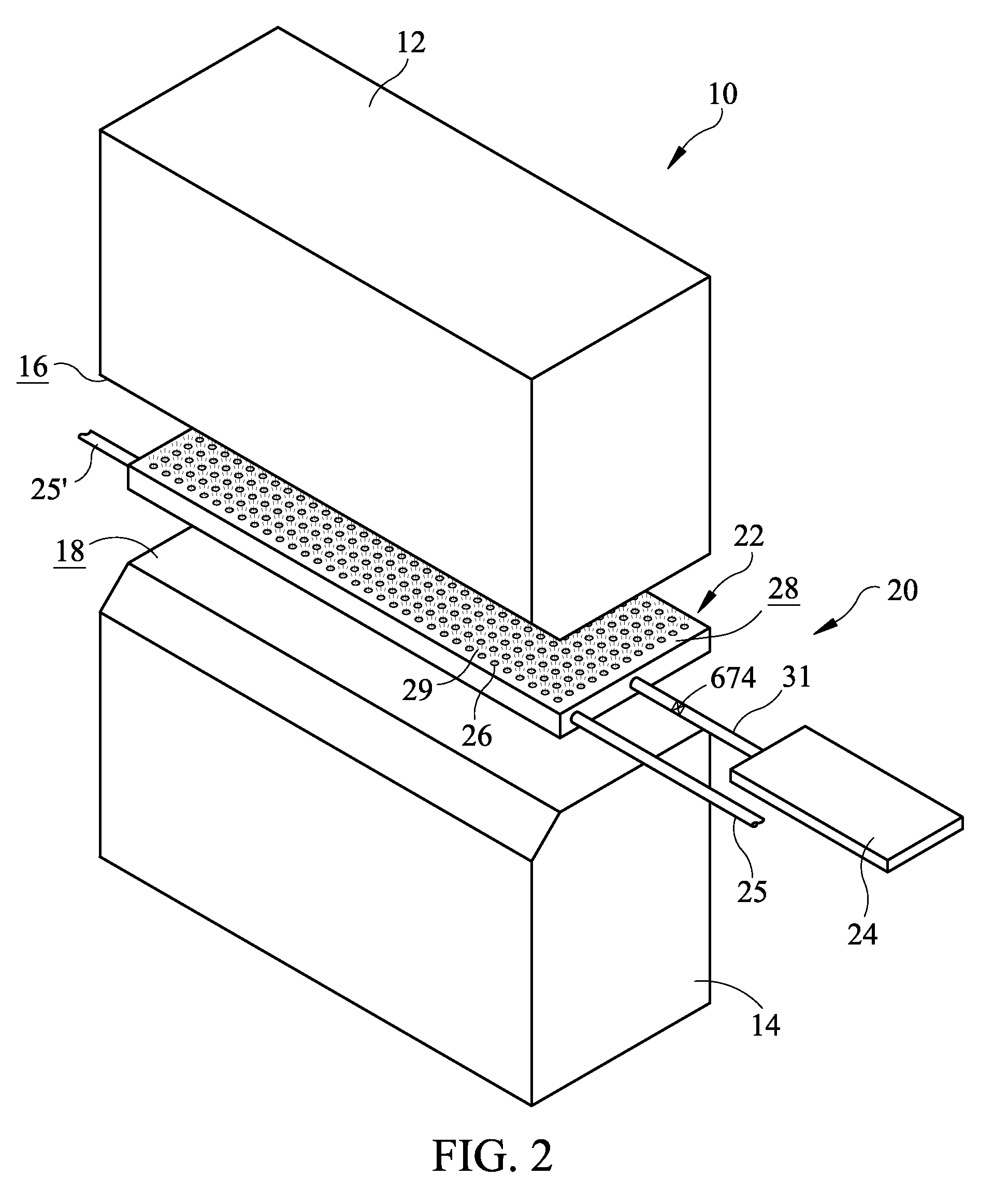

Cooling chamber assembly for a gasifier

InactiveUS20100325956A1Easy to assembleCombustion typesAuxillary pretreatmentSyngasCombustion chamber

A gasifier includes a combustion chamber in which a combustible fuel is burned to produce a syngas and a particulated solid residue. A cooling chamber having a liquid coolant is disposed downstream of the combustion chamber. A dip tube is disposed coupling the combustion chamber to the cooling chamber. The syngas is directed from the combustion chamber to the cooling chamber via the dip tube to contact the liquid coolant and produce a cooled syngas. An asymmetric or symmetric liquid separator is disposed proximate to an exit path of the cooling chamber and configured to remove entrained liquid content from the cooled syngas directed through the annular passage to the exit path.

Owner:GENERAL ELECTRIC CO

Two-circuit injector for a turbine engine combustion chamber

ActiveUS9927125B2Fast ignitionFuel economyContinuous combustion chamberCombustion typesCombustion chamberTurbine

A start-up injector for a turbine engine combustion chamber, said injector including a fuel injection circuit; and a fuel ignition circuit including a fuel injector supplied by the fuel injection circuit and a spark plug for igniting the injected fuel. The start-up injector also includes a partitioned enclosure including a first compartment in which the fuel is ignited by the spark plug and a second compartment separated from the first compartment by a thermally conductive partition; and a main combustion start-up circuit which includes at least one fuel injector supplied by the fuel injection circuit and opens into the second compartment of the enclosure such as to inject the fuel against the wall.

Owner:SAFRAN HELICOPTER ENGINES

Integral heater for fuel conveying member

ActiveUS20090084108A1Combustion typesTurbine/propulsion fuel flow conduitsMechanical engineeringPyrolysis

A fuel conveying member for an engine, the fuel conveying member having heating means integrated therein to permit pyrolysis of carbonaceous deposits.

Owner:PRATT & WHITNEY CANADA CORP

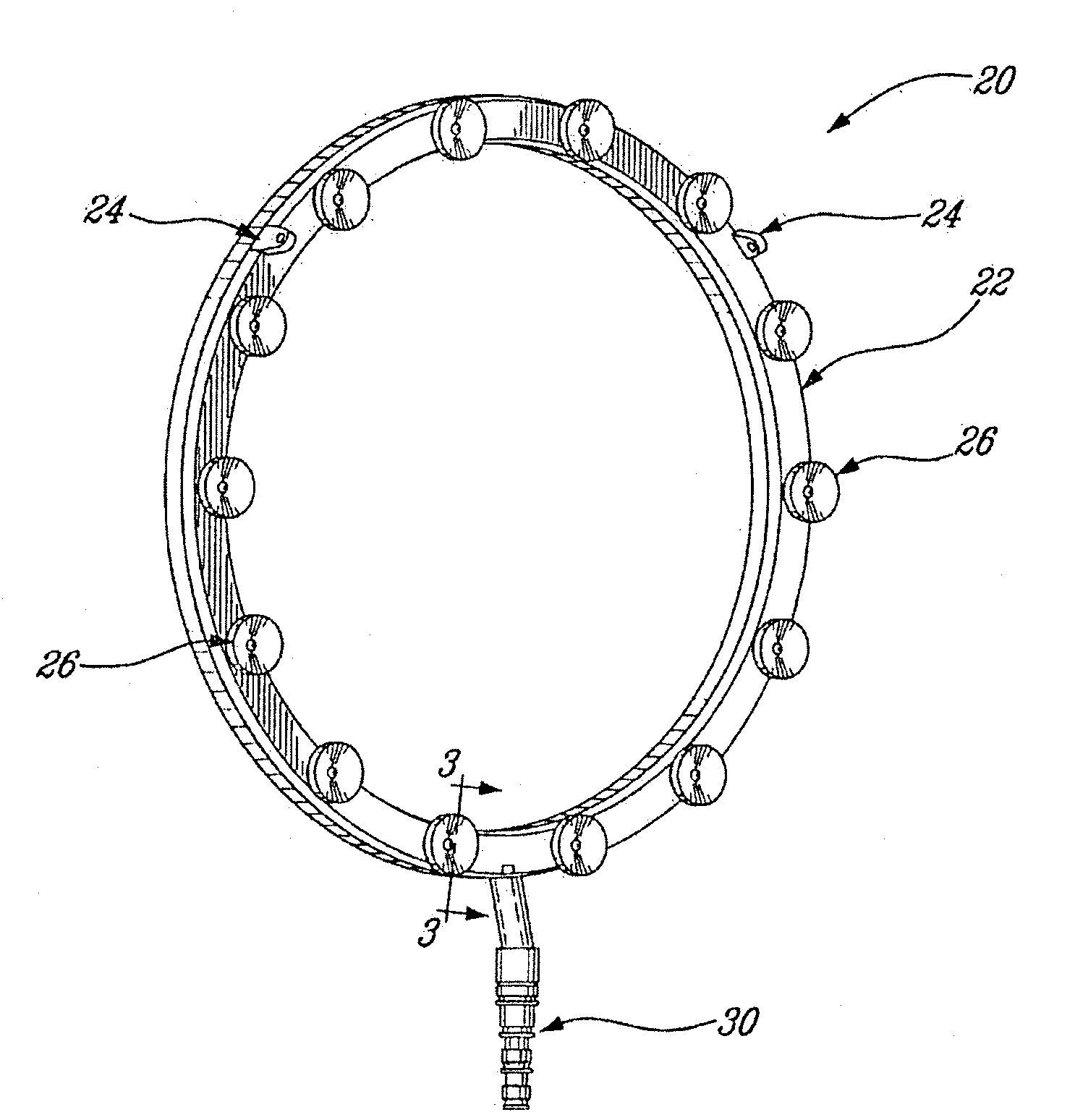

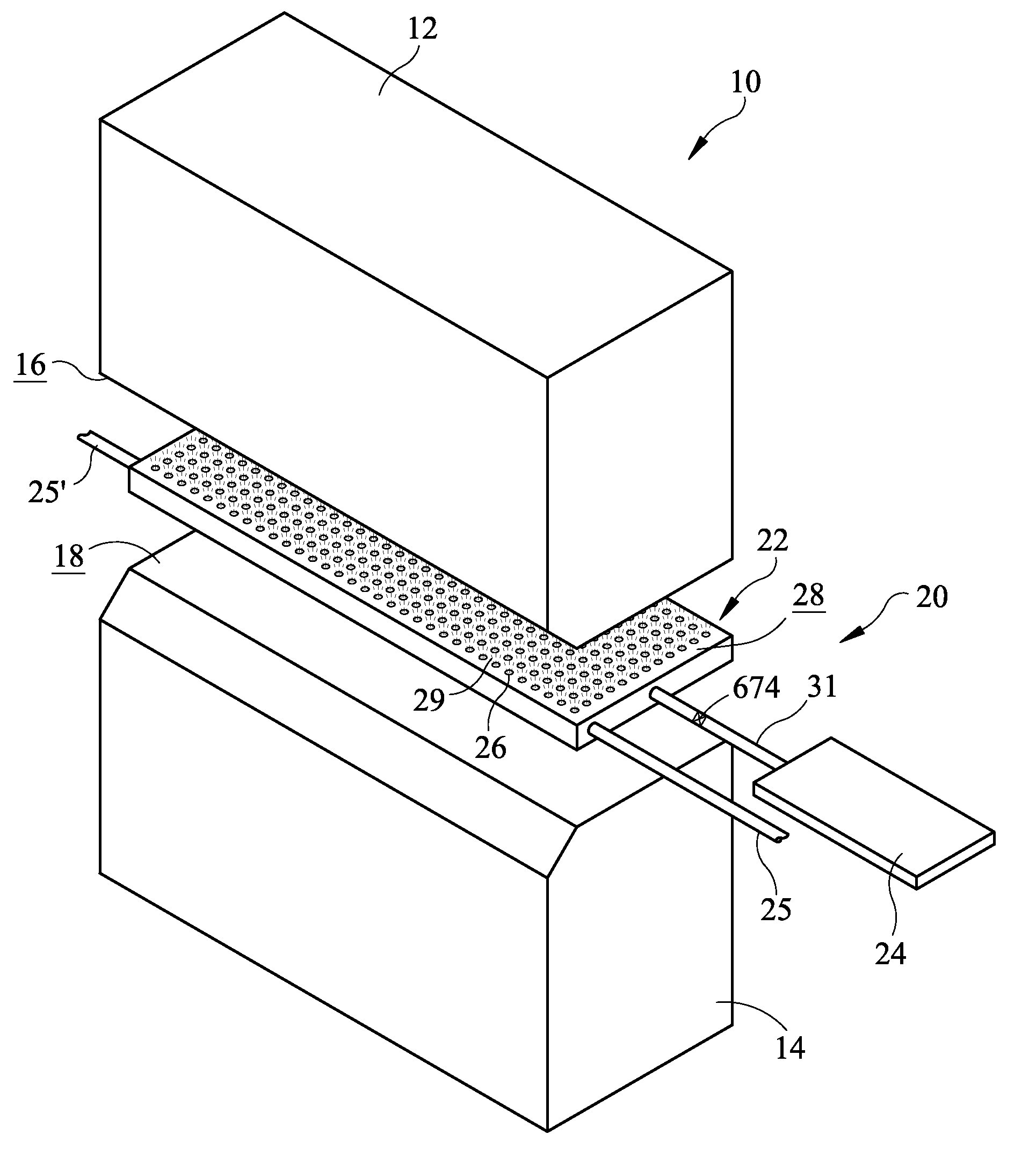

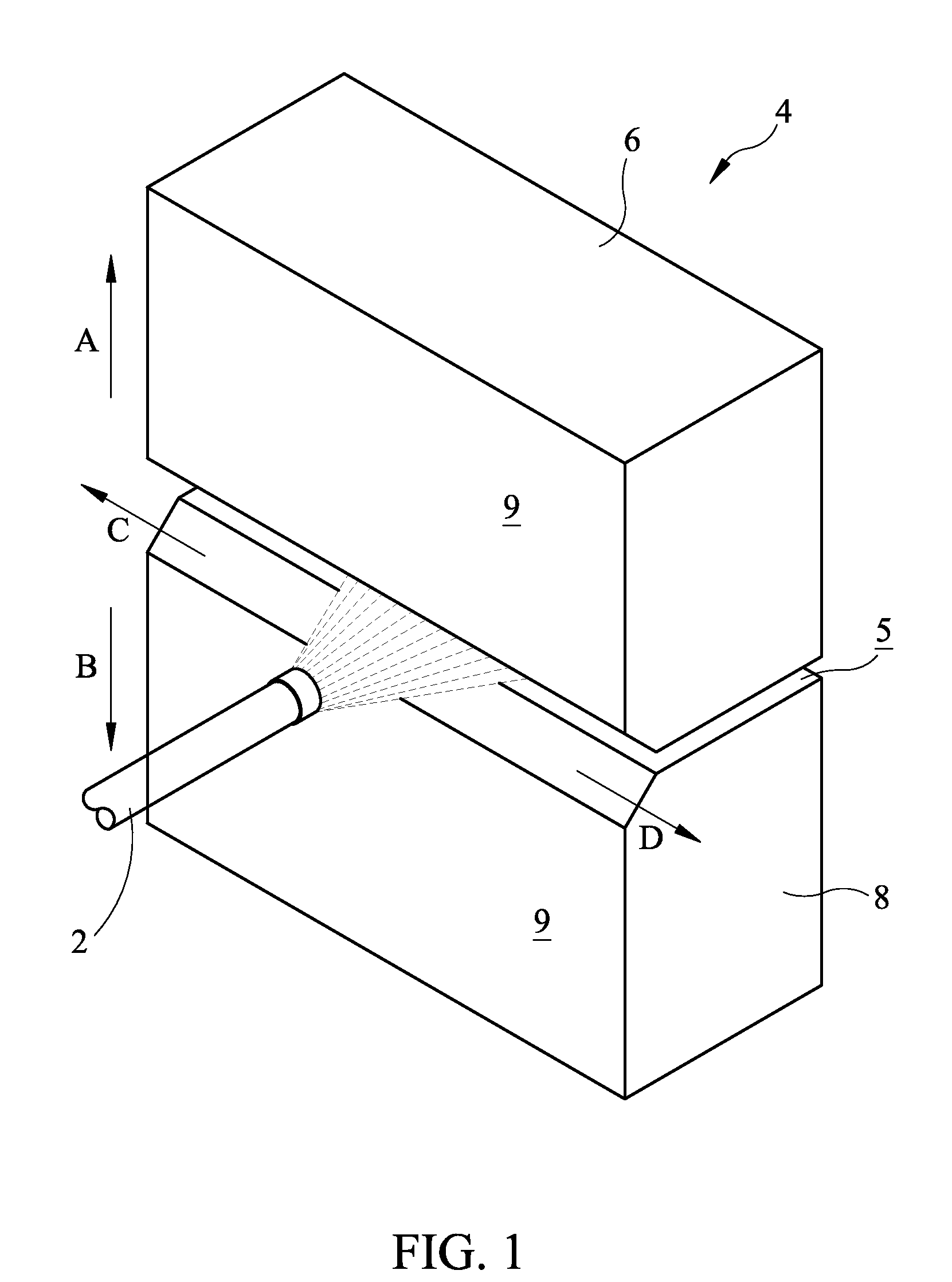

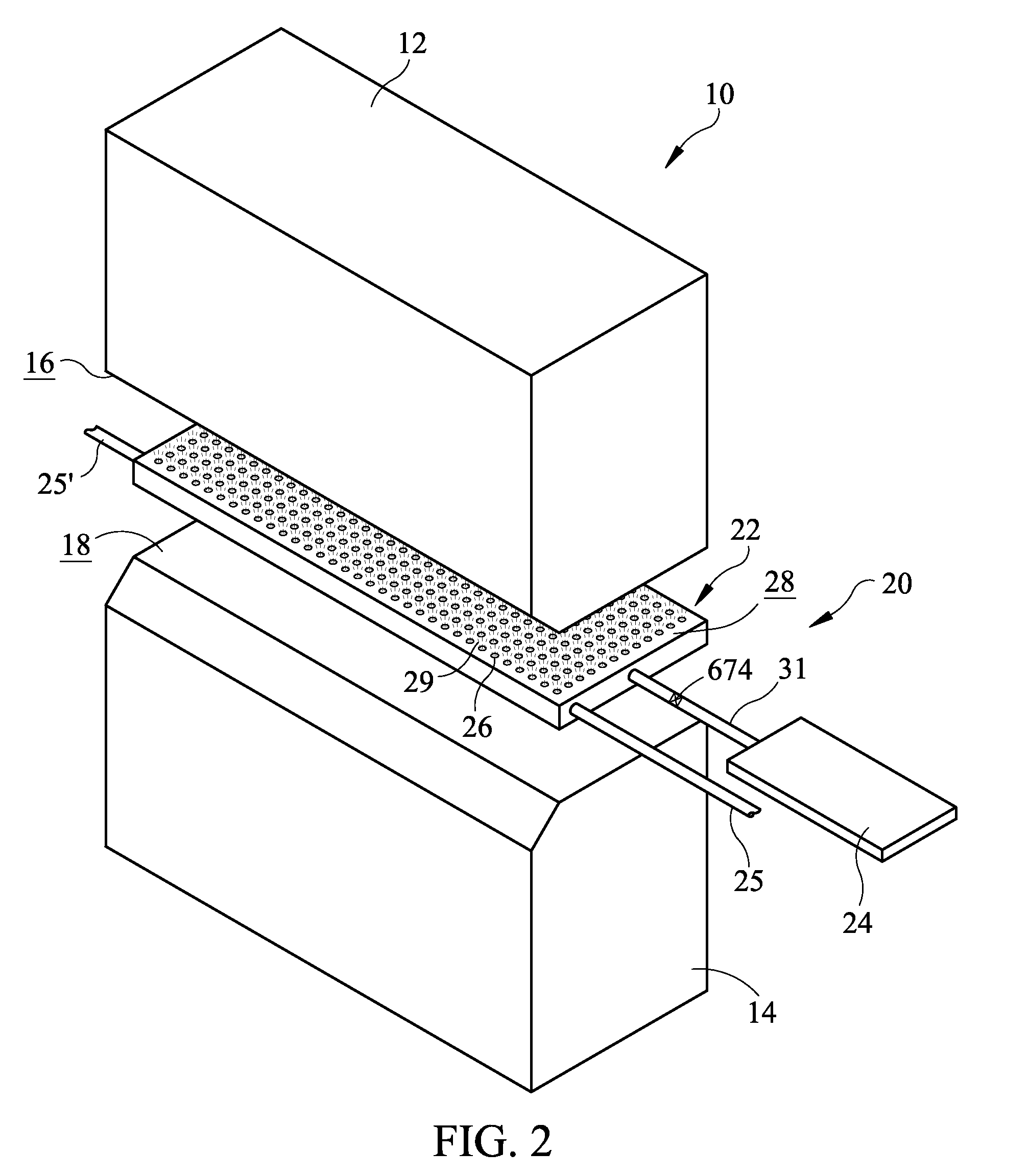

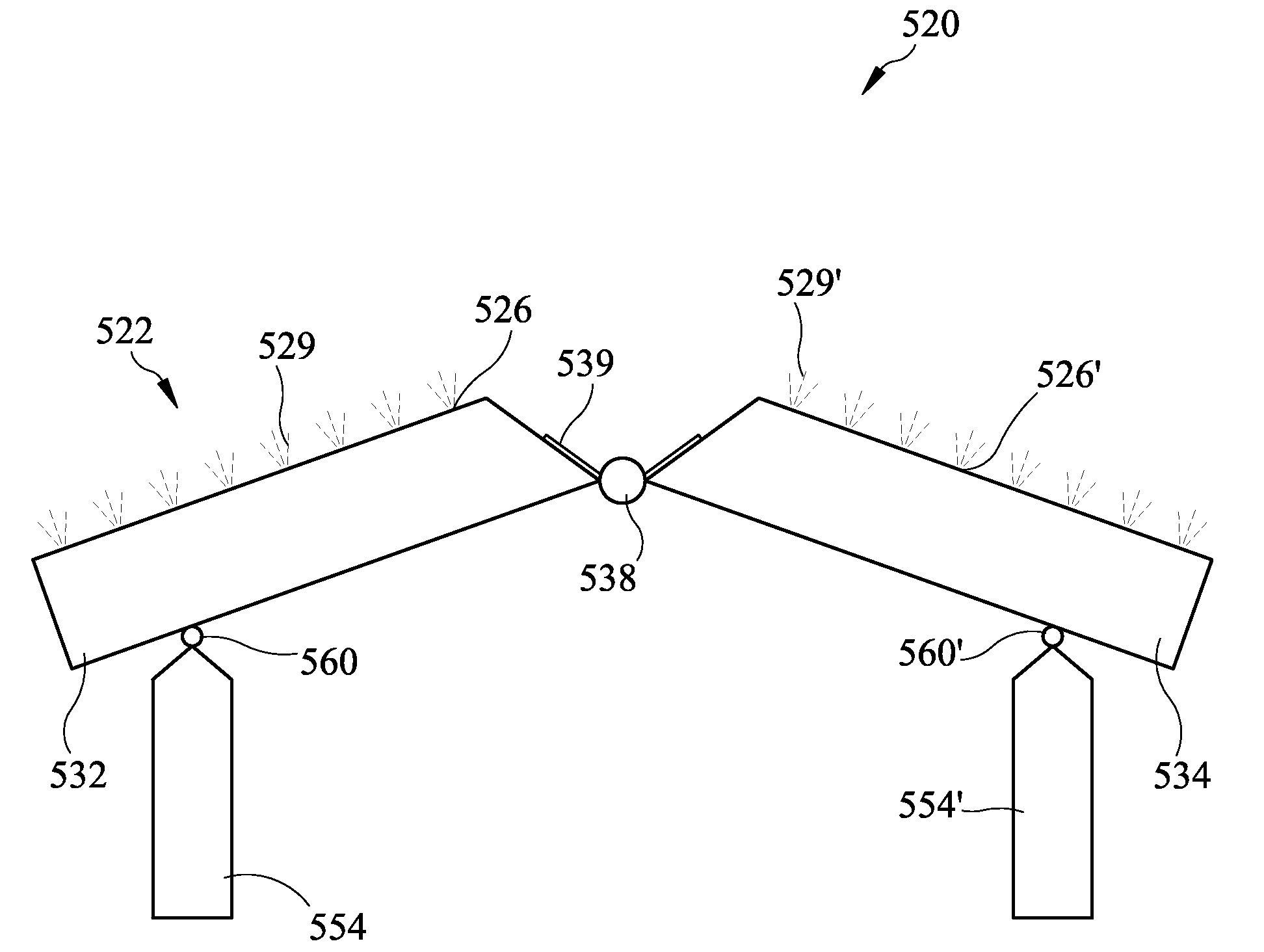

Forging die heating apparatuses and methods for use

A forging die heating or preheating apparatus comprises a burner head comprising a plurality of flame ports. The burner head is oriented to compliment an orientation of at least a region of a forging surface of a forging die and is configured to receive and combust a supply of an oxidizing gas and a supply of a fuel and produce flames at the flame ports. The plurality of flame ports are configured to impinge the flames onto the forging surface of the forging die to substantially uniformly heat at least the region of the forging surface of the forging die.

Owner:ATI PROPERTIES LLC

Cooling chamber assembly for a gasifier

The invention relates to a cooling chamber assembly for a gasifier. A gasifier includes a combustion chamber in which a combustible fuel is burned to produce a syngas and a particulated solid residue. A cooling chamber having a liquid coolant is disposed downstream of the combustion chamber. A dip tube is disposed coupling the combustion chamber to the cooling chamber. The syngas is directed from the combustion chamber to the cooling chamber via the dip tube to contact the liquid coolant and produce a cooled syngas. An asymmetric or symmetric liquid separator is disposed proximate to an exit path of the cooling chamber and configured to remove entrained liquid content from the cooled syngas directed through the annular passage to the exit path.

Owner:GENERAL ELECTRIC CO

Fire extinguisher

ActiveUS20100032176A1Easy to operateEasy to useLiquid fuel feeder/distributionContinuous combustion chamberFire extinguisherCivil engineering

A method and apparatus is disclosed for ejecting material. The ejected material is ejected as liquid and / or liquid vapour via an explosive process which can provide a very fast ejection as well as an ejection which has a large throw. The material can be water or other fire suppressant material to provide a successful fire extinguishing system.

Owner:FAURECIA SYST DECHAPPEMENT

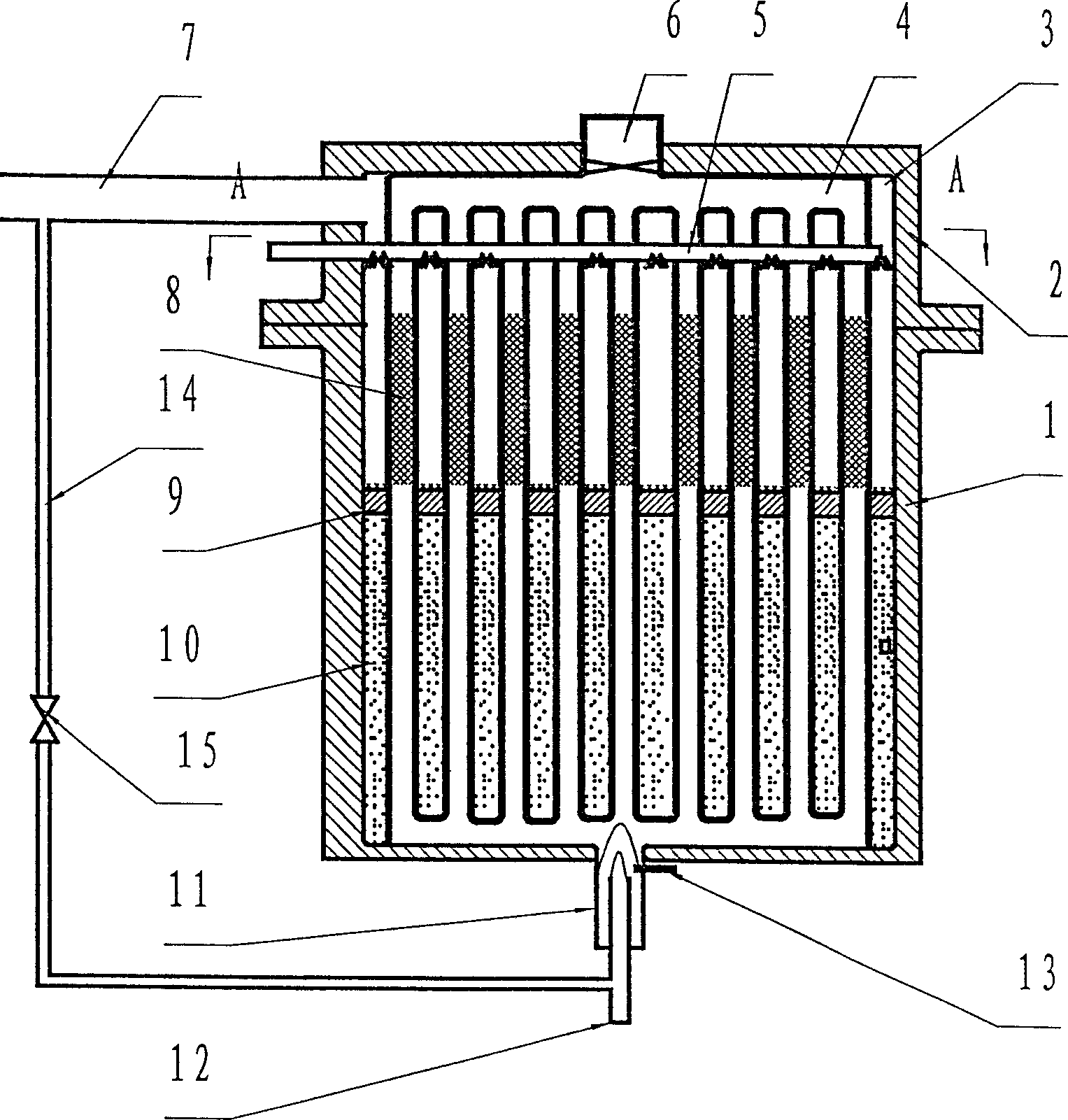

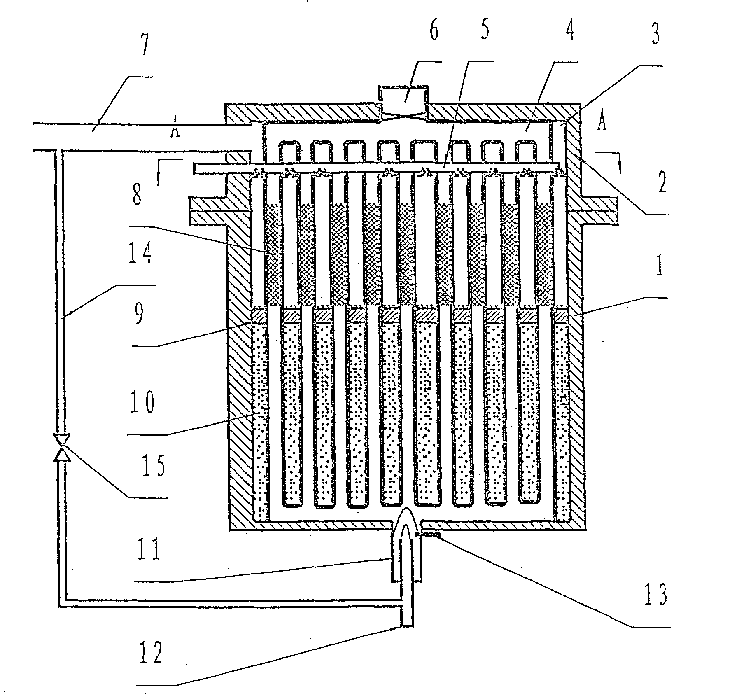

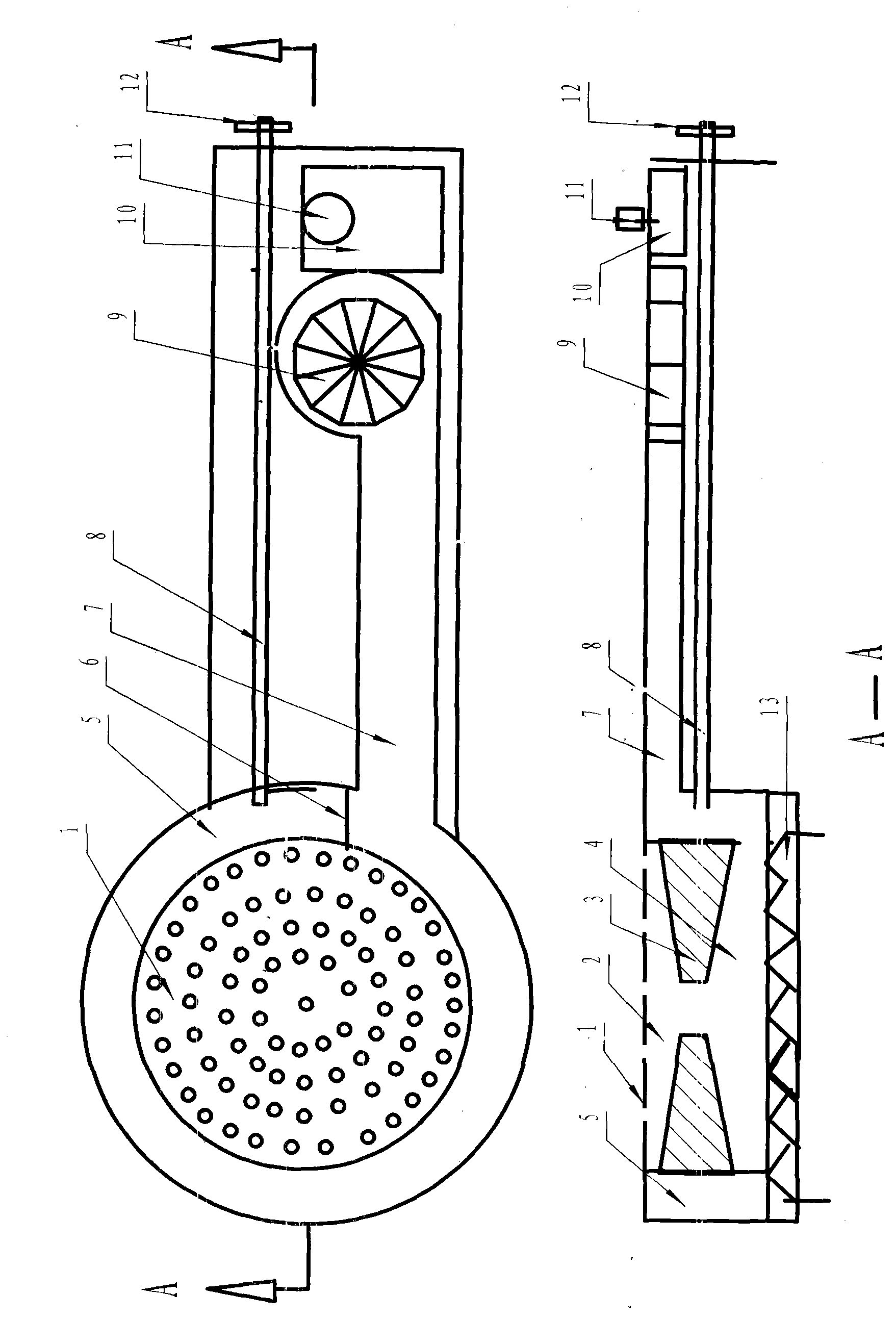

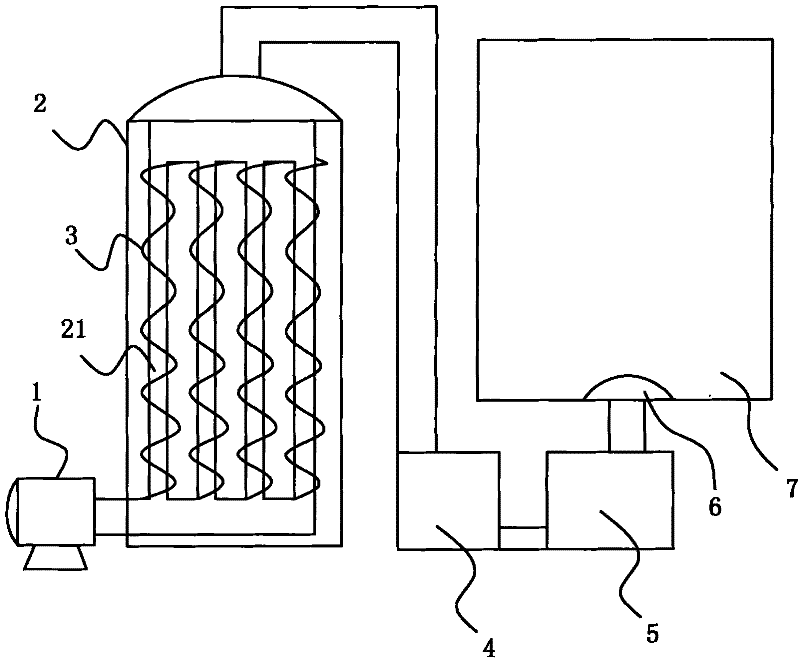

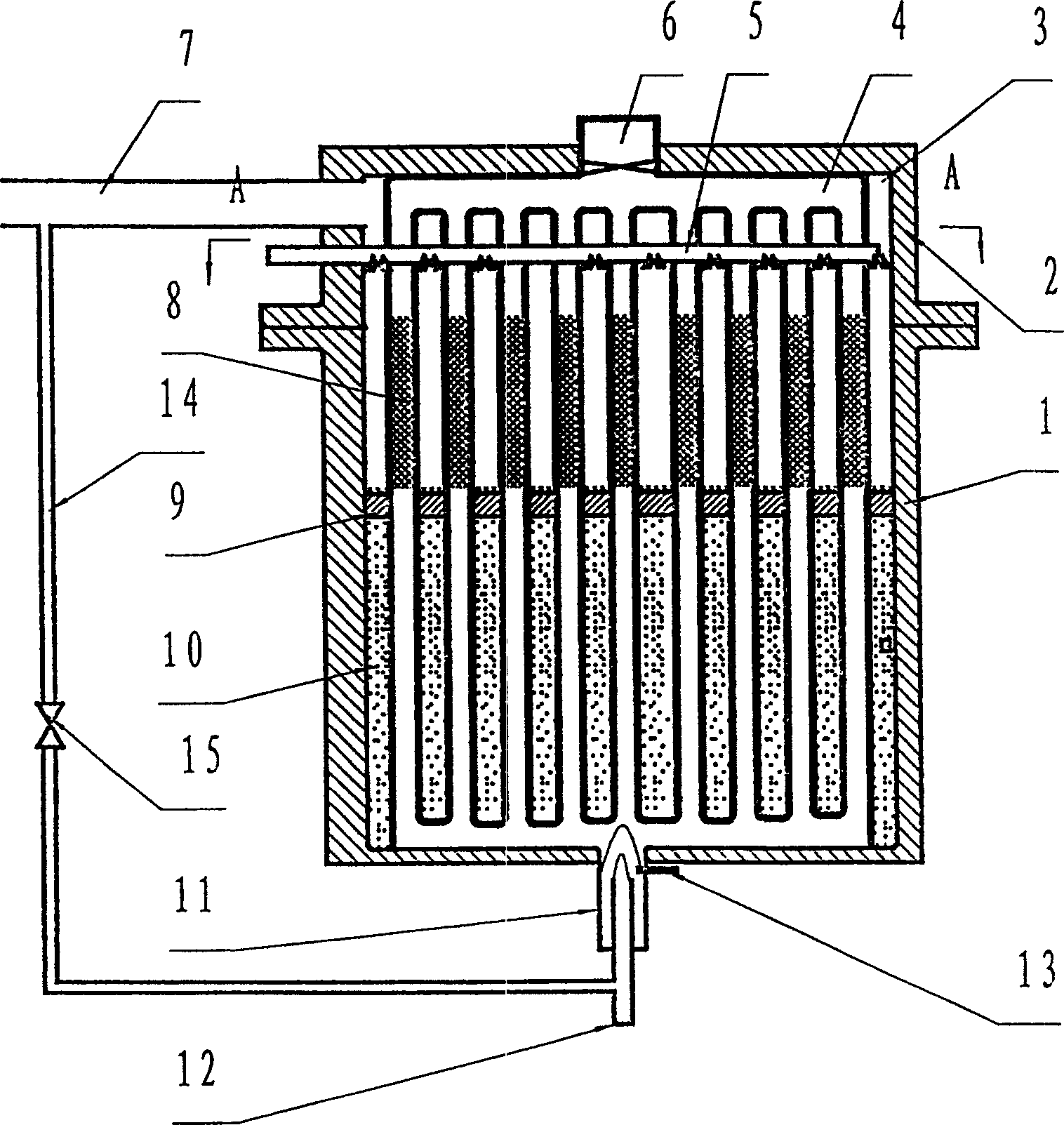

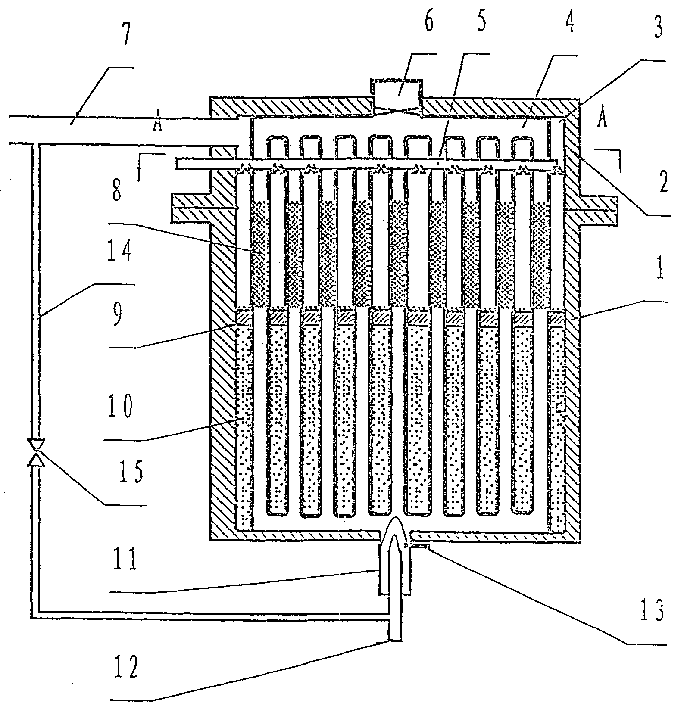

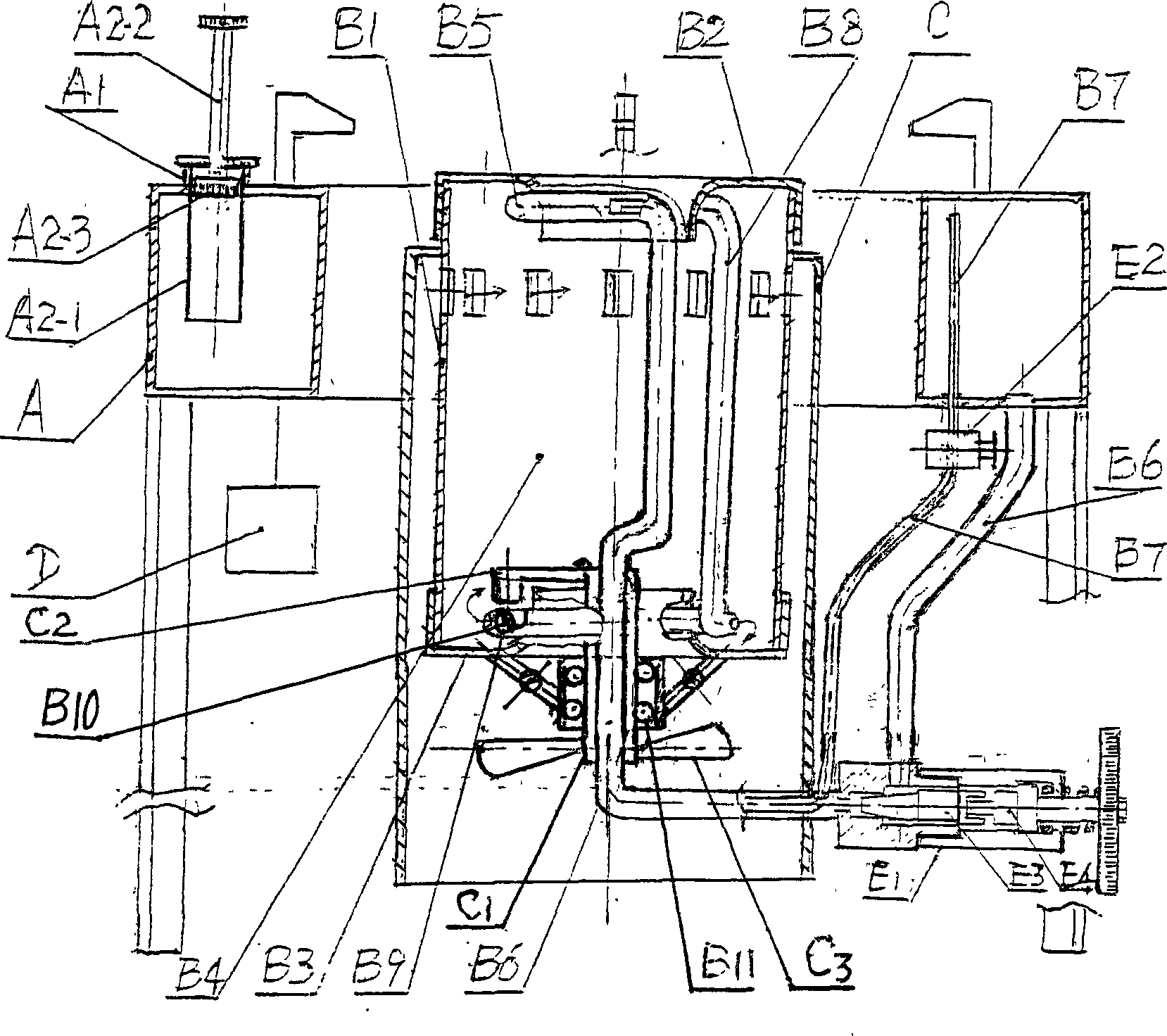

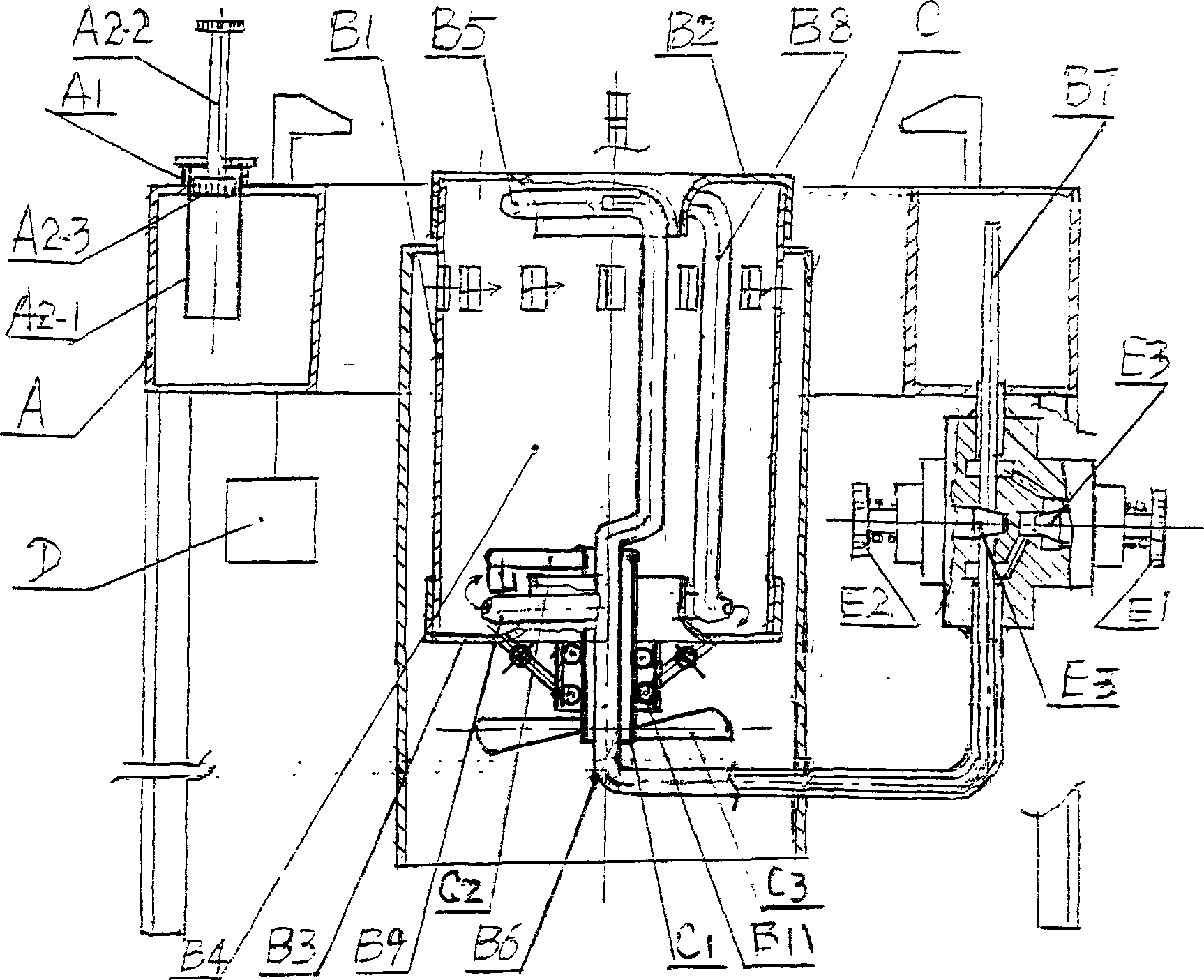

Heats torage of gasifier liquefied natural gas

InactiveCN1510337ACreate pollutionGet over workLiquid fuel feeder/distributionCombustion typesThermal energyCombustion

A heat accumulating gasifier for liquefied natural gas is disclosed. The natural gas generated by evaporation of liquefied natural gas in storage tank is burning at the bottom of gasifier. The heat generated by said combustion is transferred via heat exchanger to the heat accumulating medium. The accumulated heat is then used to gasify the liquefied natural gas. Said gasifier is composed of a heat exchanger, an insulating gasifying case containing said heat exchanger and divided into the gasifying cavity containing showering tube of liquefied natural gas and natural gas collecting tube and the heat accumulating cavity full of heat accumulating medium, and an igniter.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

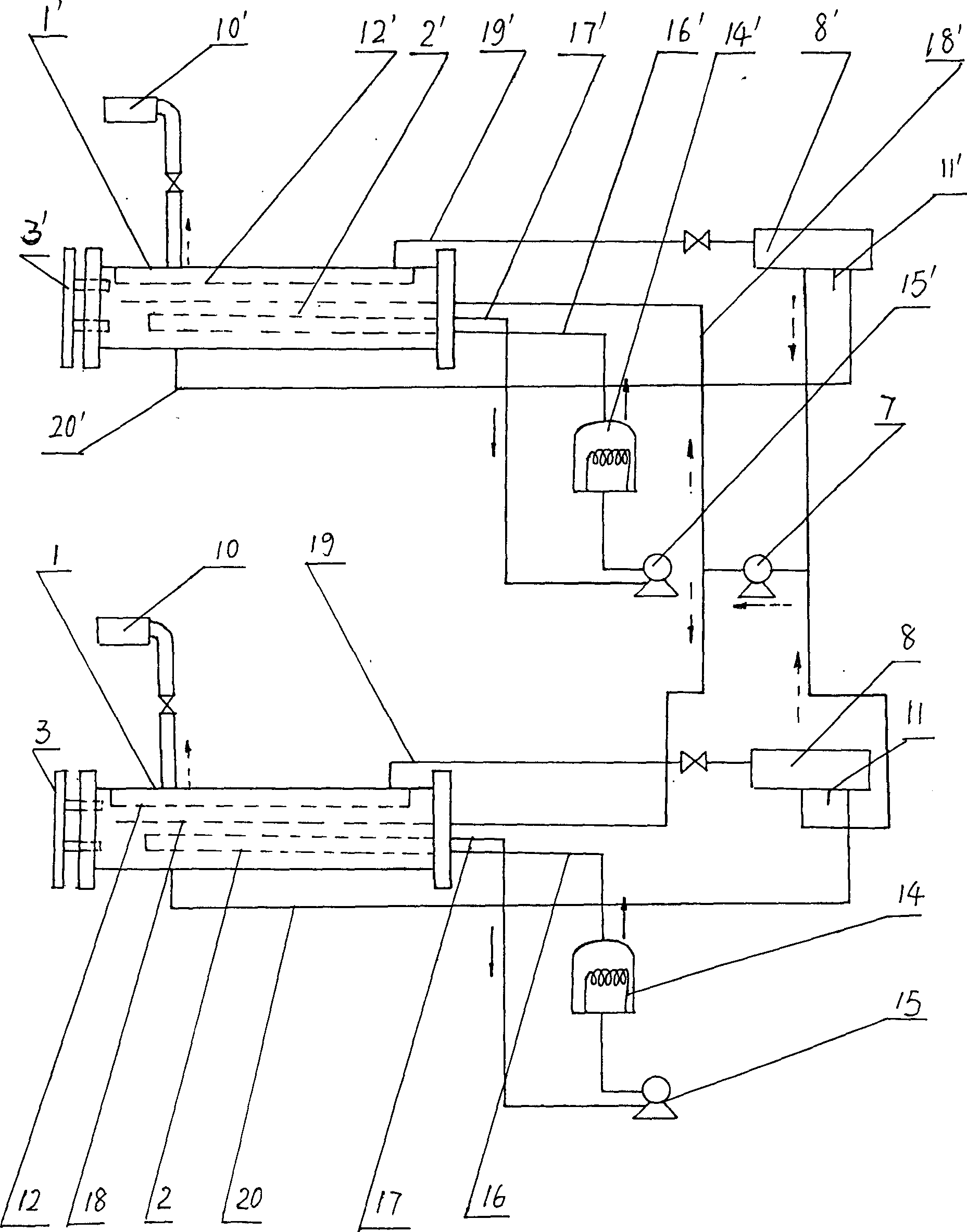

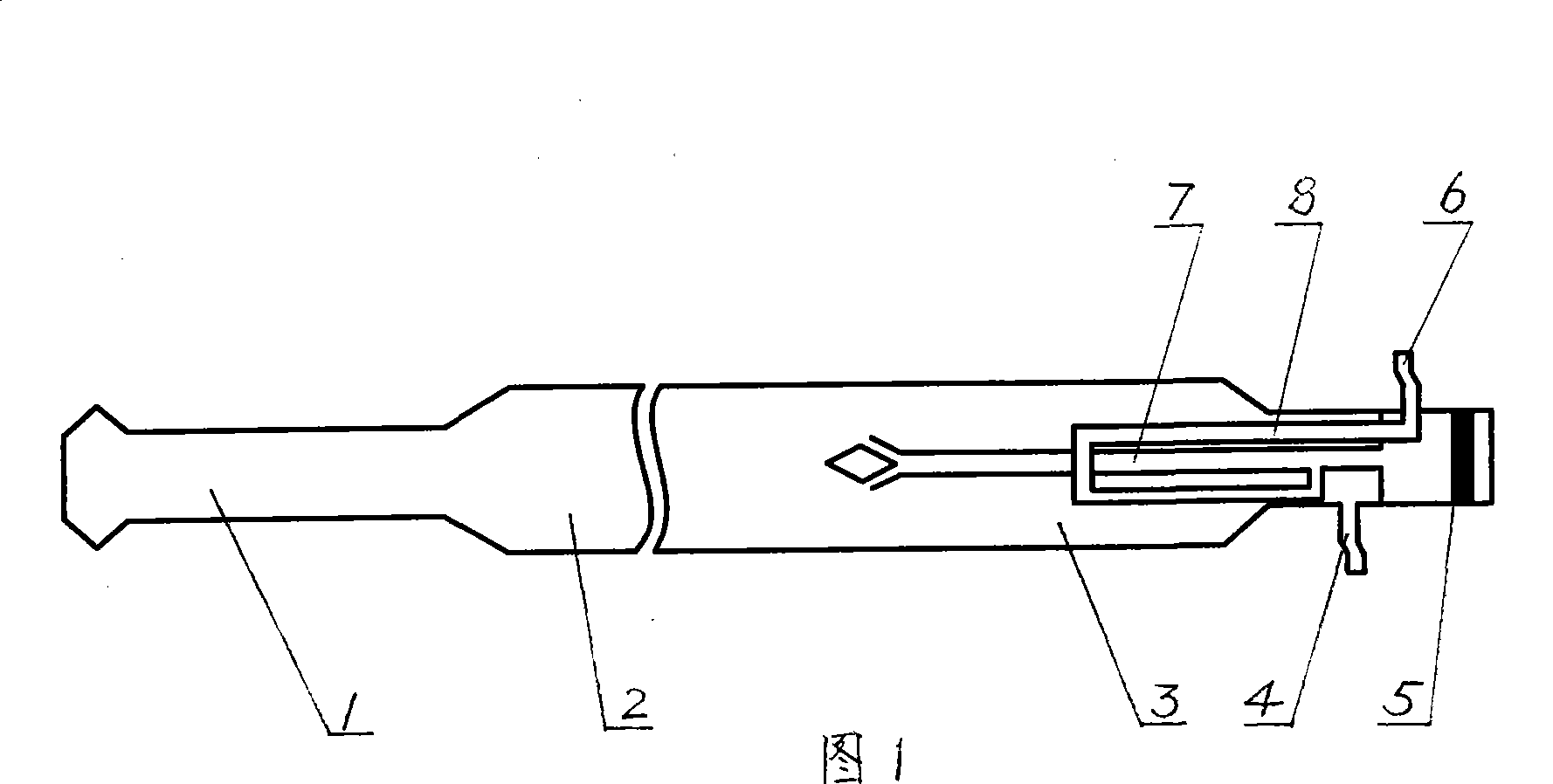

Tube type vaporization device for liquefied gas for industrial use

InactiveCN1789816ABurn fullyContinuous and stable combustionLiquid fuel feeder/distributionCombustion typesCombustorAutomatic control

This invention relates to one industry oiling tube evaporation device, which comprises Evaporation part, heating part, automatic control part, burst part and liquid supply part, wherein, the evaporation tube is one hollow tube with its inside located with heating medium recycling tube; the said evaporation tube two ends are sealed with one end located with liquid level meter connected to the evaporation tube and with the other end located with heating medium entrance, exhaust mouth and gas liquid entrance; the heating medium entrance and exhaust mouth are separately connected to the heating medium recycling tube entrance and exhaust mouth.

Owner:肖杰

Forging die heating apparatuses and methods for use

A forging die heating or preheating apparatus comprises a burner head comprising a plurality of flame ports. The burner head is oriented to compliment an orientation of at least a region of a forging surface of a forging die and is configured to receive and combust a supply of an oxidizing gas and a supply of a fuel and produce flames at the flame ports. The plurality of flame ports are configured to impinge the flames onto the forging surface of the forging die to substantially uniformly heat at least the region of the forging surface of the forging die.

Owner:ATI PROPERTIES LLC

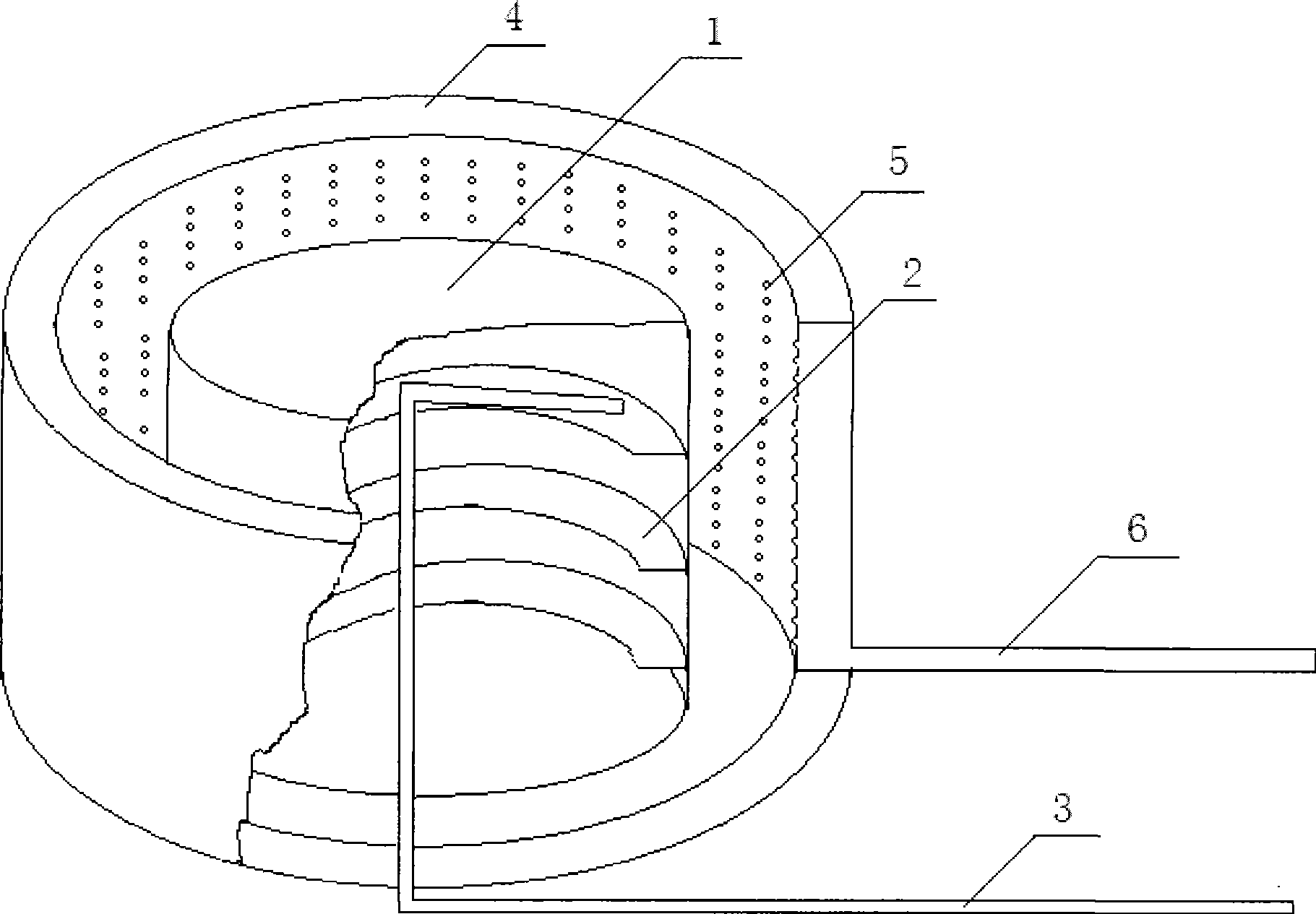

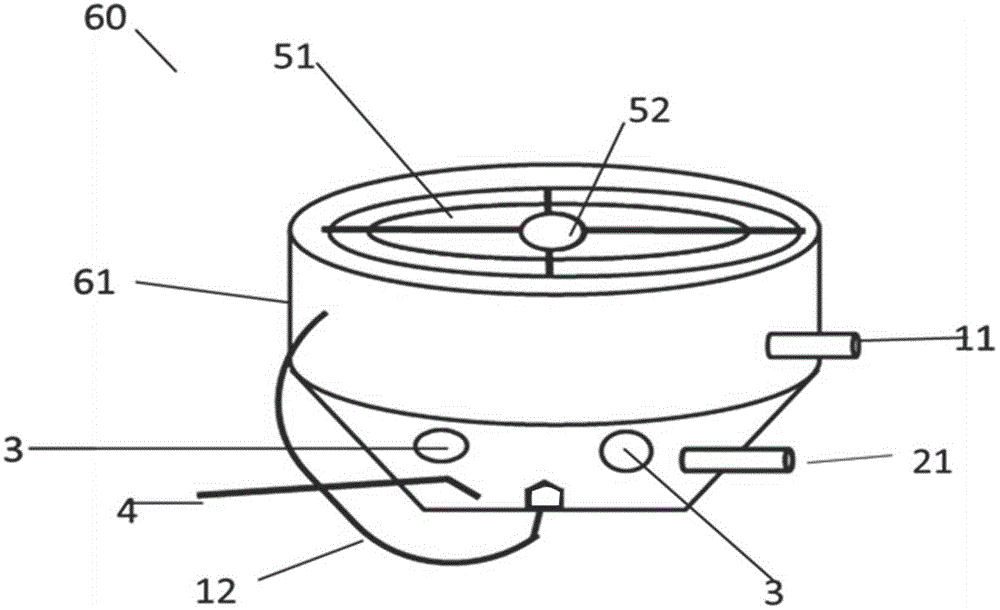

Alcohol-based fuel vaporizing combustion furnace

ActiveCN104848269AAvoid enteringAvoid exclusionCombustion typesDomestic stoves or rangesCombustionAlcohol

The invention provides an alcohol-based fuel vaporizing combustion furnace, which belongs to the technical field of a combustion furnace and aims at solving the problems that in the prior art, the blockage can easily occur, and the heated temperature difference is great, so that the furnace is damaged, the starting time is long, and the noise is great. The alcohol-based fuel vaporizing combustion furnace comprises a backflow heat-resistant filtering unit, a vaporizing unit, a fire intensity control unit, a heating starting unit, a fire spraying unit and a preheating unit, wherein the vaporizing unit is communicated with the backflow heat-resistant filtering unit through a material supply pipe; the fire intensity control unit is communicated with a vaporizing cavity branch pipe vaporizing unit; the heating starting unit and the fire spraying unit are communicated with the fire intensity control unit; the fire spraying unit comprises a fire spraying head and a fire spraying cavity; the fire spraying head comprises a fire distribution cap and a connecting rod; the fire distribution cap is in contact with a conical surface arranged at the upper end of the fire spraying cavity, so that the lower part of the cavity forms a gas spraying chamber, and the upper part of the cavity forms an annular spray nozzle; the lower end of the connecting rod is connected with the lower end of the fire spraying cavity through screw threads; a plurality of fire spraying grooves are uniformly distributed in the circumference of the lower end of the fire distribution cap; a gap is formed in the fire spraying cavity and the vaporizing cavity for forming an air distribution opening; an ignition needle is arranged in any position of the air distribution opening; the preheating unit is connected with the lower end of the fire spraying cavity of the fire spraying unit through screw threads.

Owner:闫云恒

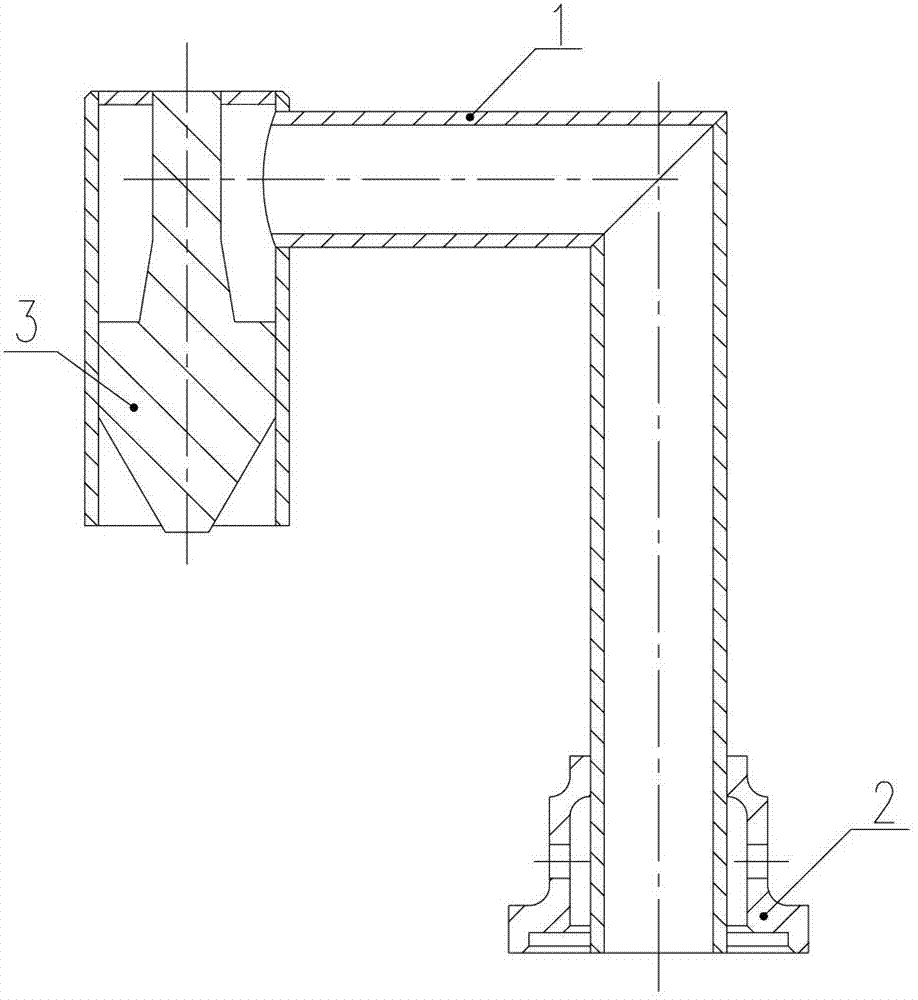

Fuel oil atomizing device

InactiveCN102889615AReduce axial jet velocityIncrease the average areaContinuous combustion chamberCombustion typesCombustionFuel oil

The invention relates to a fuel oil atomizing device which comprises an evaporation pipe, an air cup and an oil rotating device, wherein the evaporation pipe is formed by three sections of reversed-L-shaped pipes which form angles of 90 degrees; the oil rotating device is arranged at the inner part of a fuel oil outlet of the evaporation pipe; 4-6 spiral grooves are arranged on the outer surface of the oil rotating device; the air cup is mounted at the outer part of the evaporation pipe at the fuel oil inlet; a cup opening of the air cup is leveled with the fuel oil inlet of the evaporation pipe; and an air outlet is arranged on the side wall of the air cup. The fuel oil atomizing device disclosed by the invention realizes the aim of sufficiently atomizing under the condition of a very short oil mist range so that the evaporation rate is improved and good conditions are provided for stable and efficient combustion.

Owner:HARBIN DONGAN ENGINE GRP

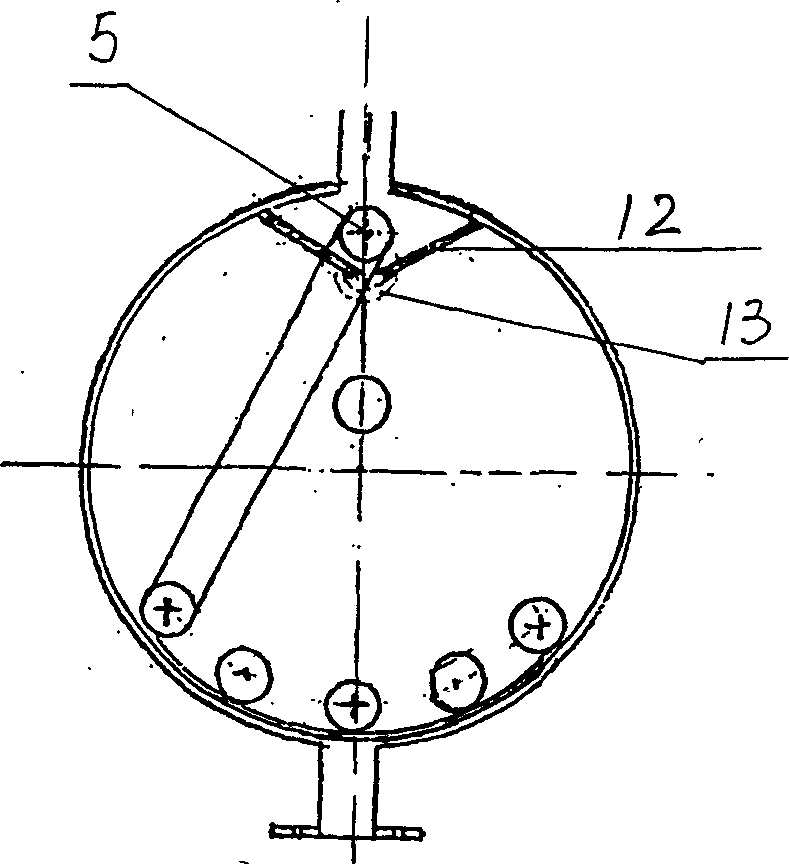

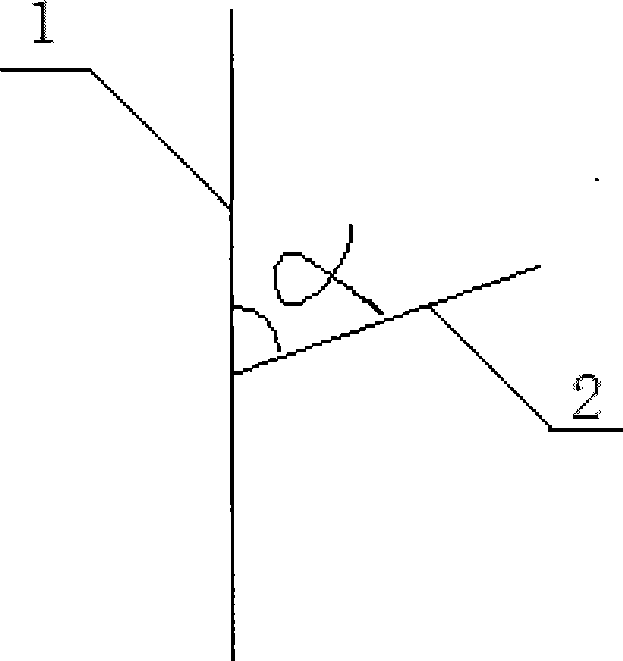

Gasification oil range

InactiveCN101435599AFully vaporizedSave energyCombustion typesDomestic stoves or rangesTO-18Combustion

The invention belongs to a kitchen appliance and relates to a gasified oil furnace. The problem to be solved by the invention is to provide the gasified oil furnace capable of using waste engine oil and diesel fuel with large viscosity for combustion. The gasified oil furnace is characterized in that a gasified cover (1) is arranged inside a furnace hearth (4), and the inner wall of the gasified cover (1) is provided with a guide plate (2); an oil pipe (3) is arranged inside the gasified cover (1); the inner wall of the furnace hearth (4) is provided with a plurality of ventholes (5); the guide plate (2) in the gasified cover (1) is an integral plate which rotates downwards or 2 to 18 plates which are not connected with one another; and the included angle of the guide plate (2) in the gasified cover (1) and the inner wall of the gasified cover (1) is between 85 and 50 DEG. The gasified oil furnace has the advantages of energy conservation, full gasification of fuel oil in the furnace, high heat utilization rate and capability of using the waste engine oil and diesel fuel with larger viscosity for combustion.

Owner:宋玉林

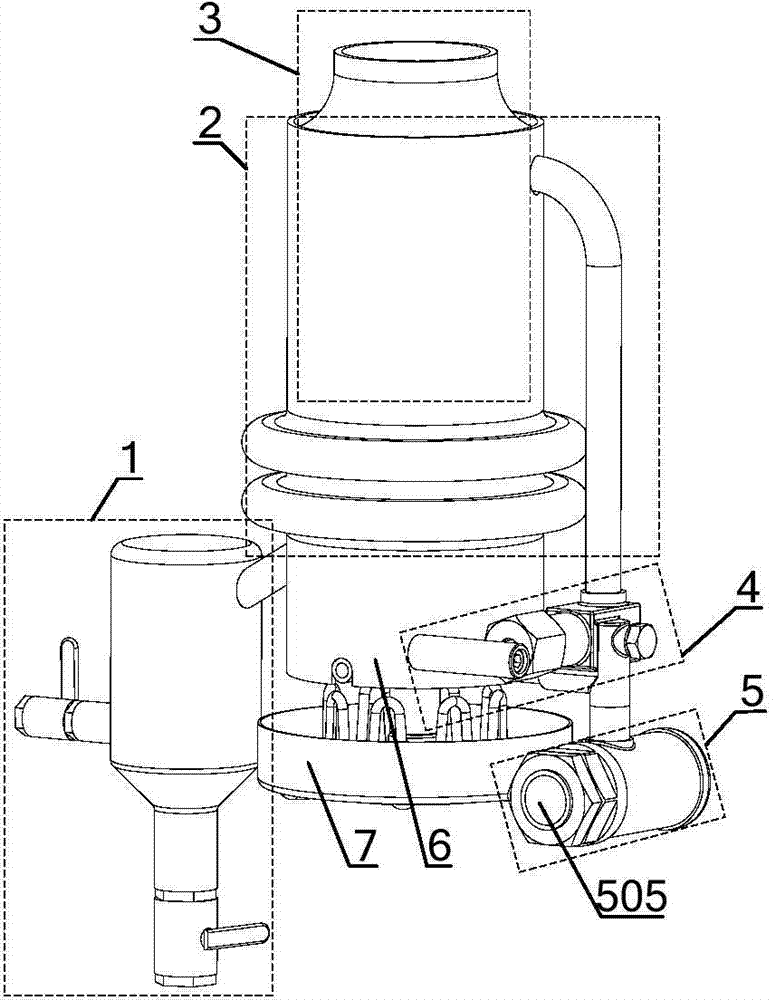

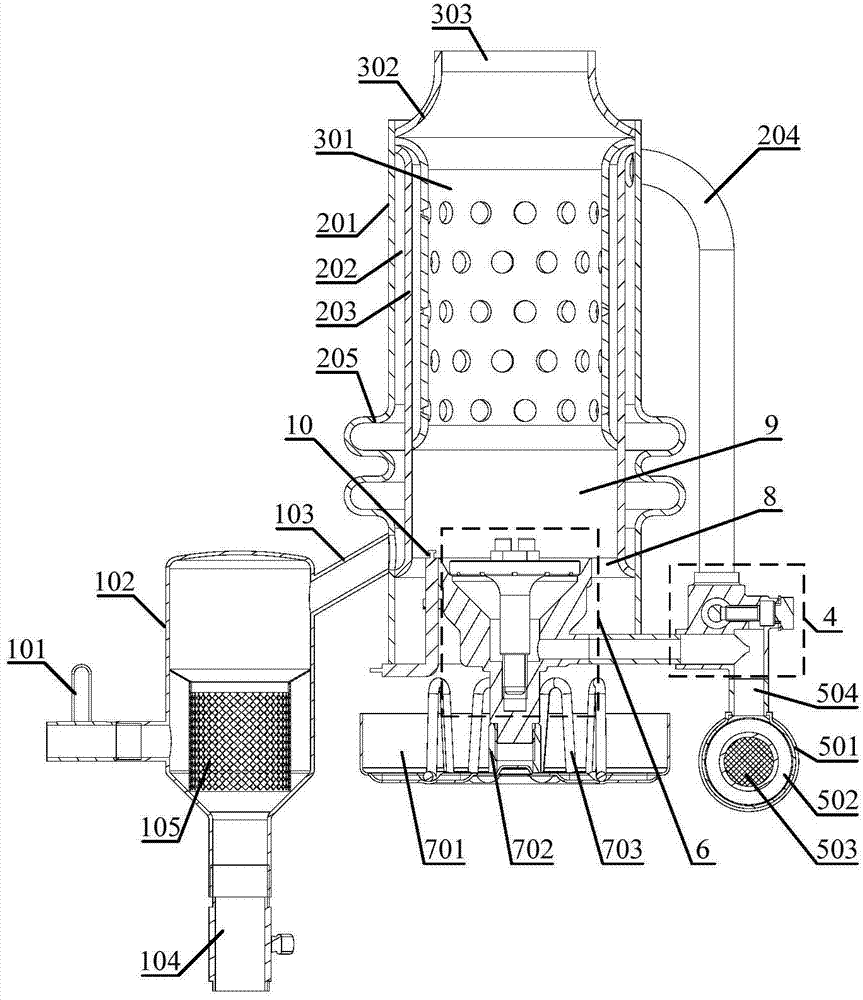

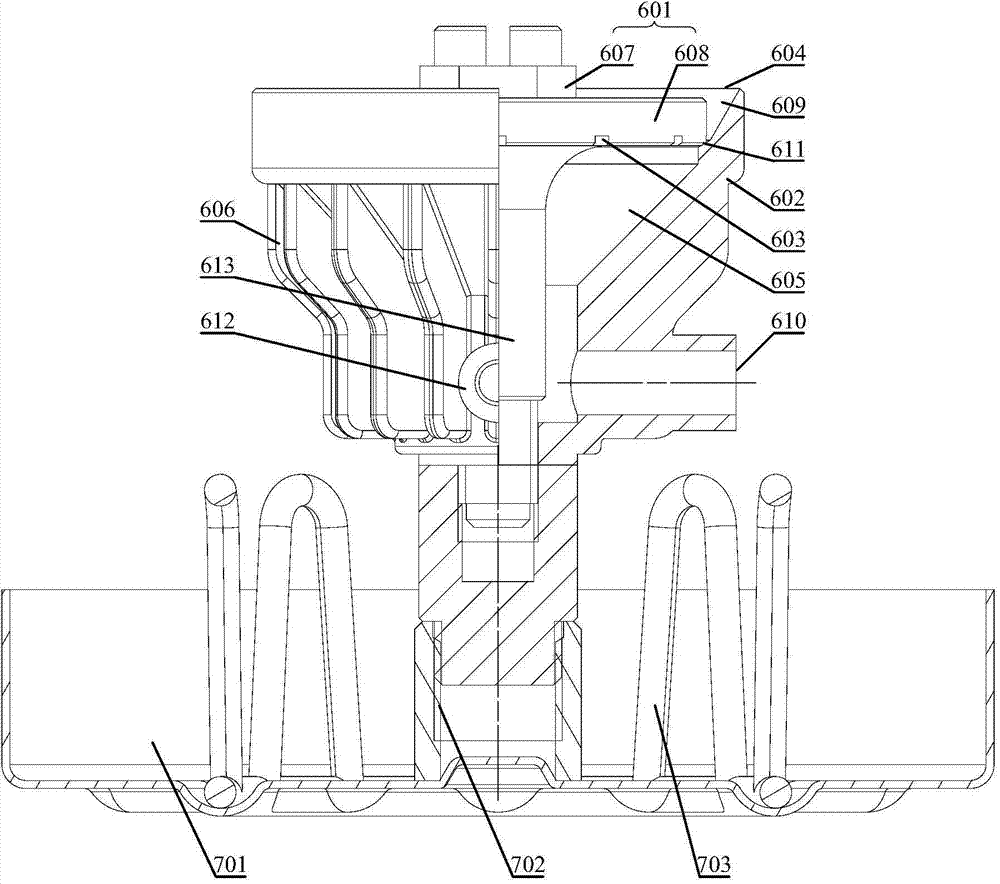

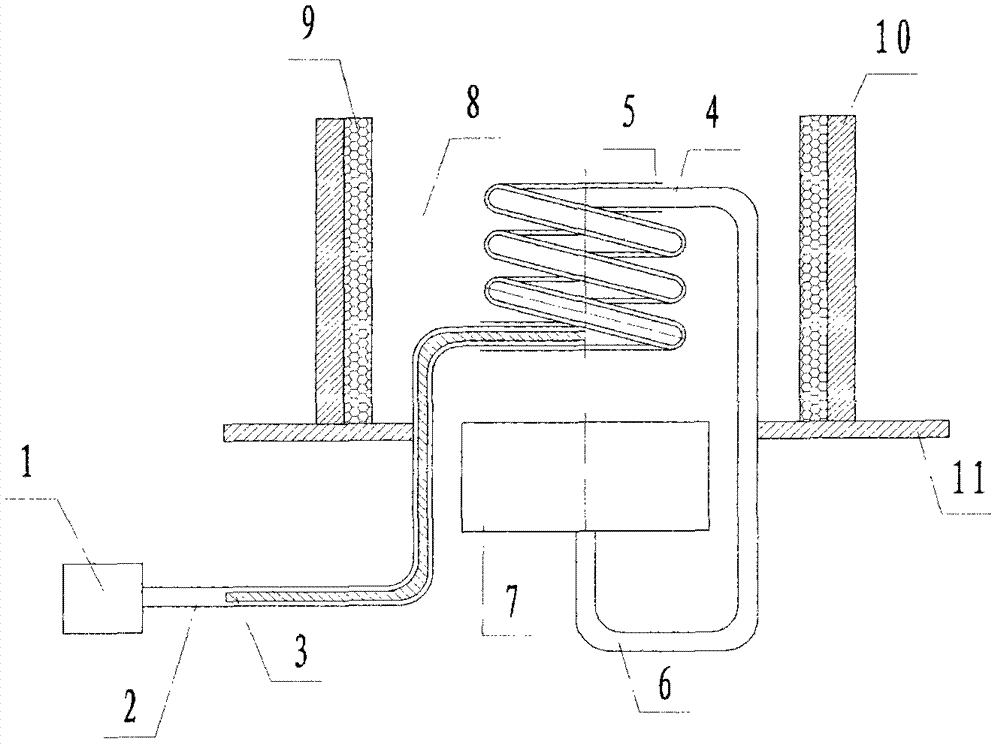

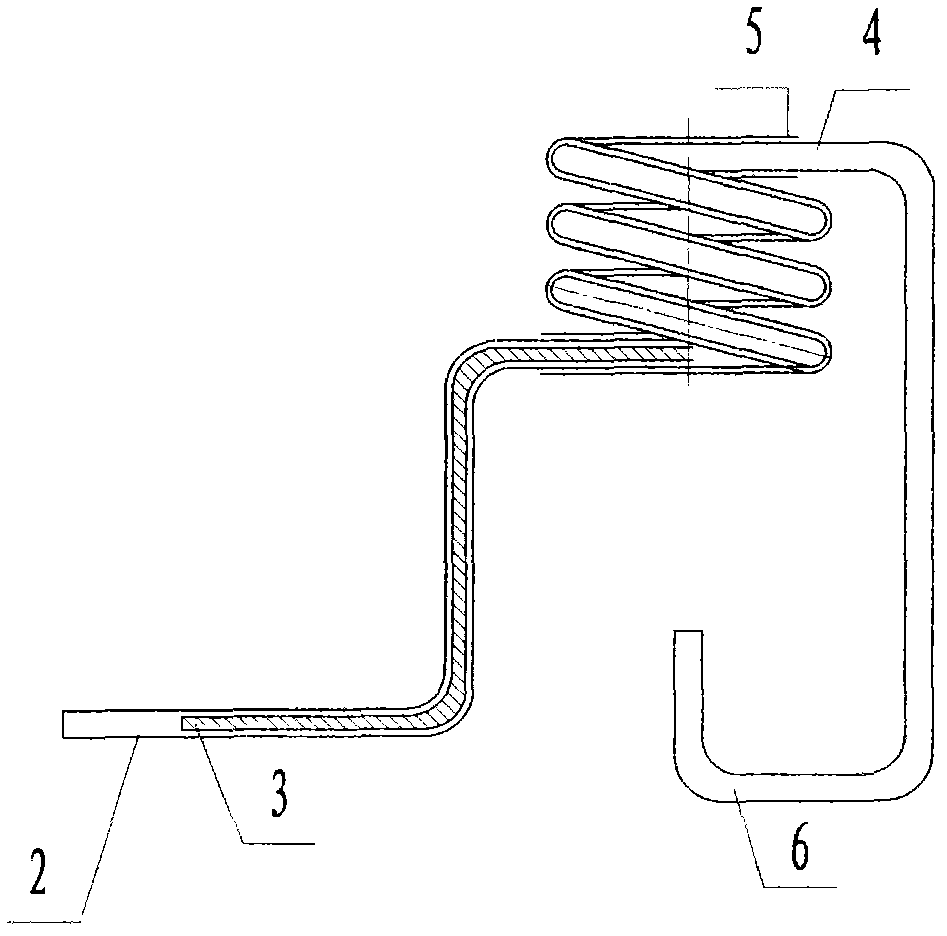

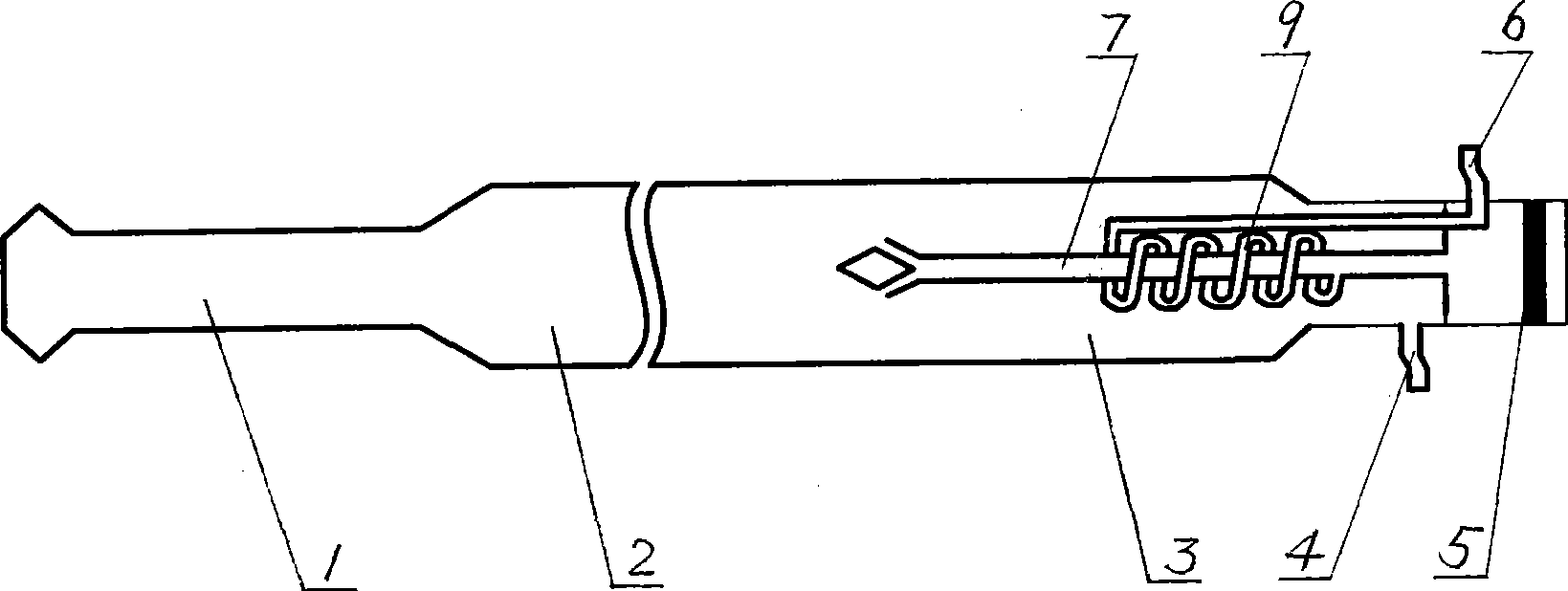

Liquid fuel gasifier

InactiveCN103090382AComplete gasificationReduce energy consumptionCombustion typesElectricityFixed frame

The invention provides a liquid fuel gasifier which is composed of a gasifying device, a burning device, a sound reducing device, a fire ring, a valve body assembly and a fixed frame. The gasifying device is placed above the burning device and is arranged in the sound reducing device. The burning device is partially or completely arranged in the sound reducing device. The gasifying device is composed of a gasifying pipe, a heat insulation pipe and a gas resistor. The gasifier is structurally characterized in that the gasifying pipe is arranged in the heat insulation pipe, the gas resistor is inserted in the gasifying pipe, the gasifying pipe and the gas resistor are combined and inserted to form a combination piece which is wound to form a spiral spring column body or a conical body, the gasifying pipe is a metal hollow pipe or a non-metal high temperature resistant hollow pipe, the heat insulation pipe is a metal hollow pipe, the length of the gas resistor and the heat insulation pipe is shorter than that of the gasifying pipe, the sound reduction device is of an annular columnar structure or a conical structure, and the sound reduction device is placed in the fire ring and surrounds the gasifying device and the burning device. The liquid fuel gasifier resolves the problem that the liquid fuel is completely gasified, enables burning to be complete, is low in energy consumption, saves energy by over 60% with flame temperature higher than 1200 DEG C, does not require a fan, is complete, convenient, electricity-saving, strong in fire and high in heating speed, simultaneously effectively controls gasifying temperature, resolves the problem of carbon accumulation and changes popularization of the liquid fuel especially alcohol group liquid fuel from ideal to reality.

Owner:李小辉

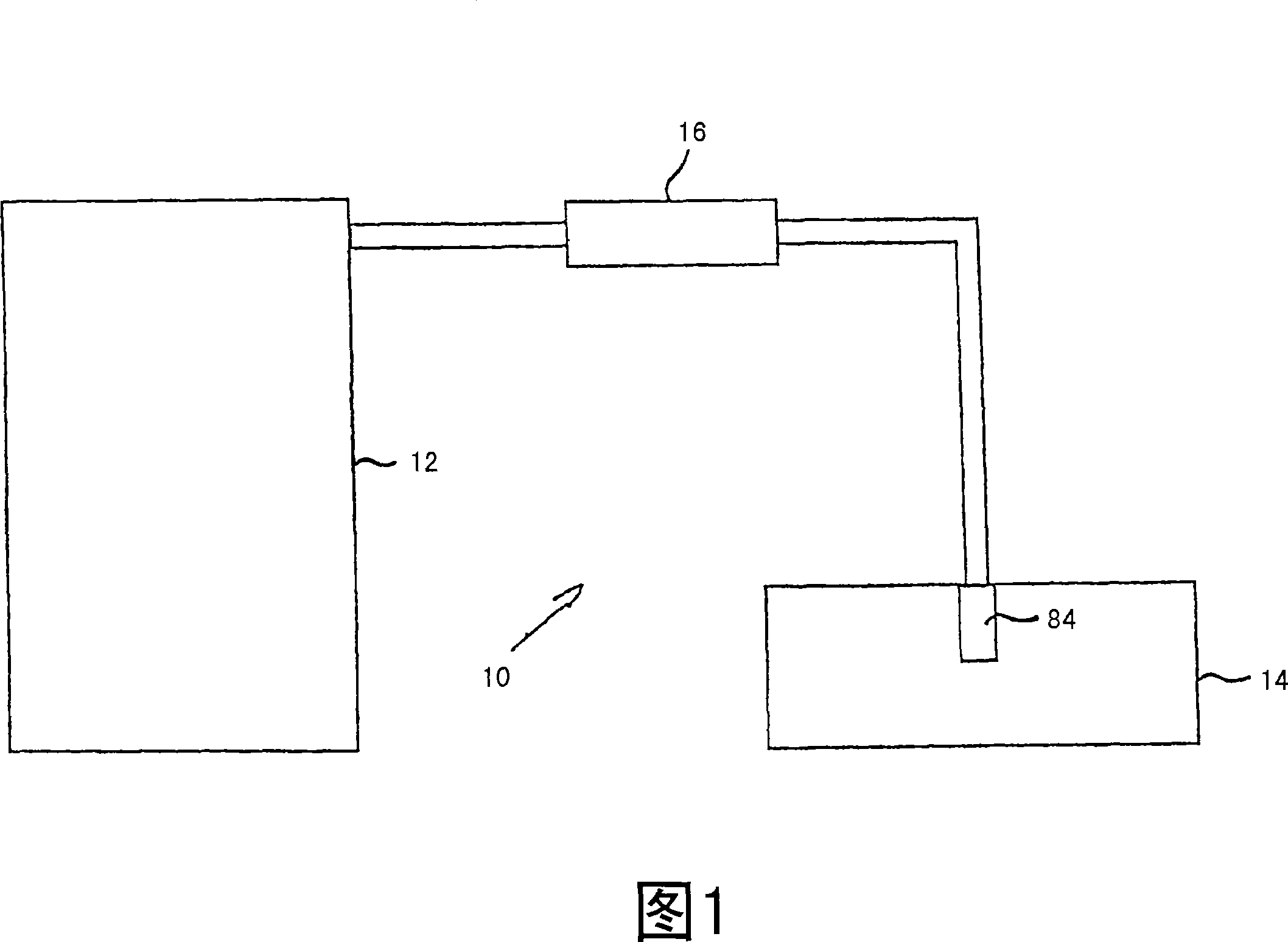

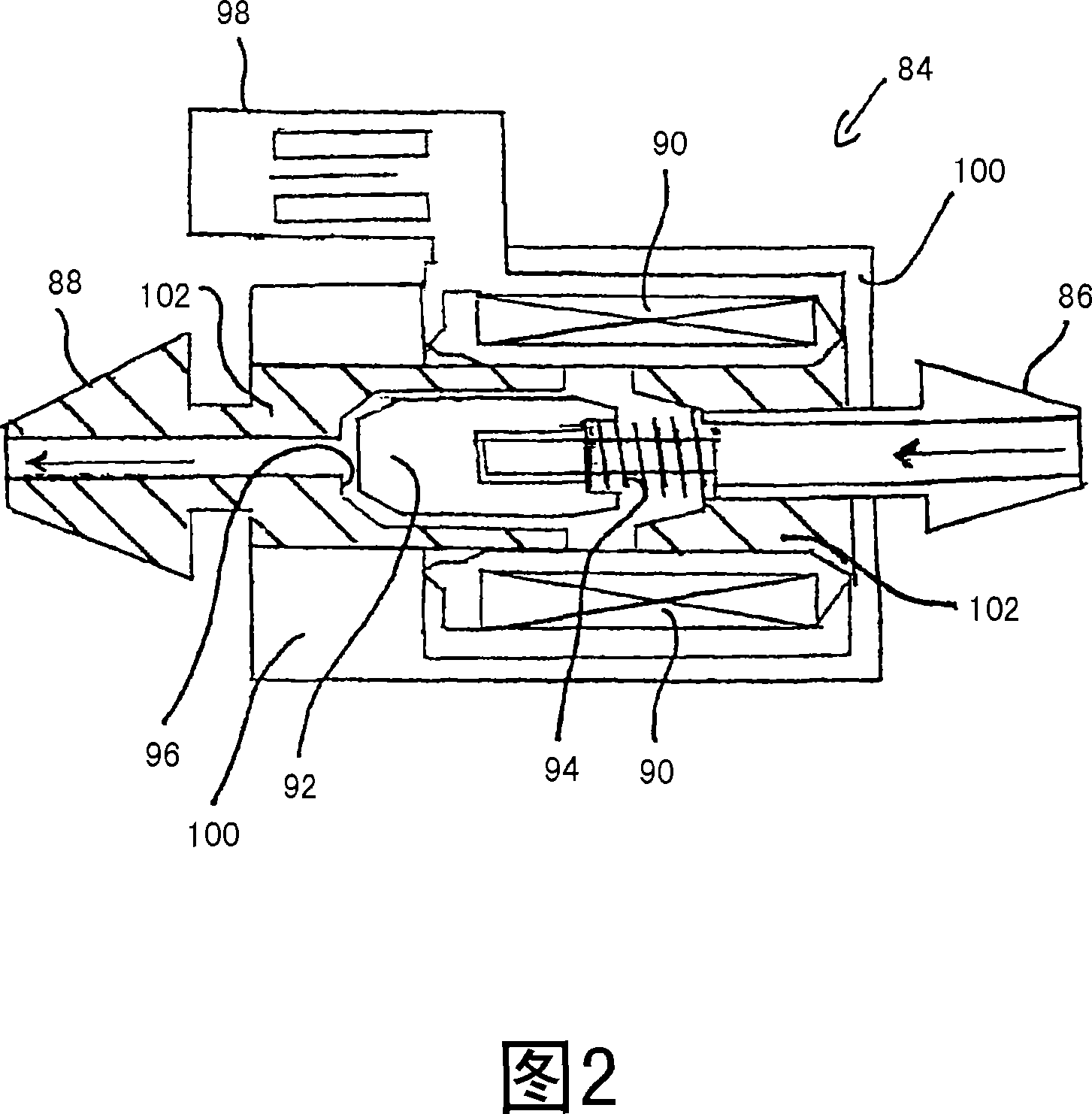

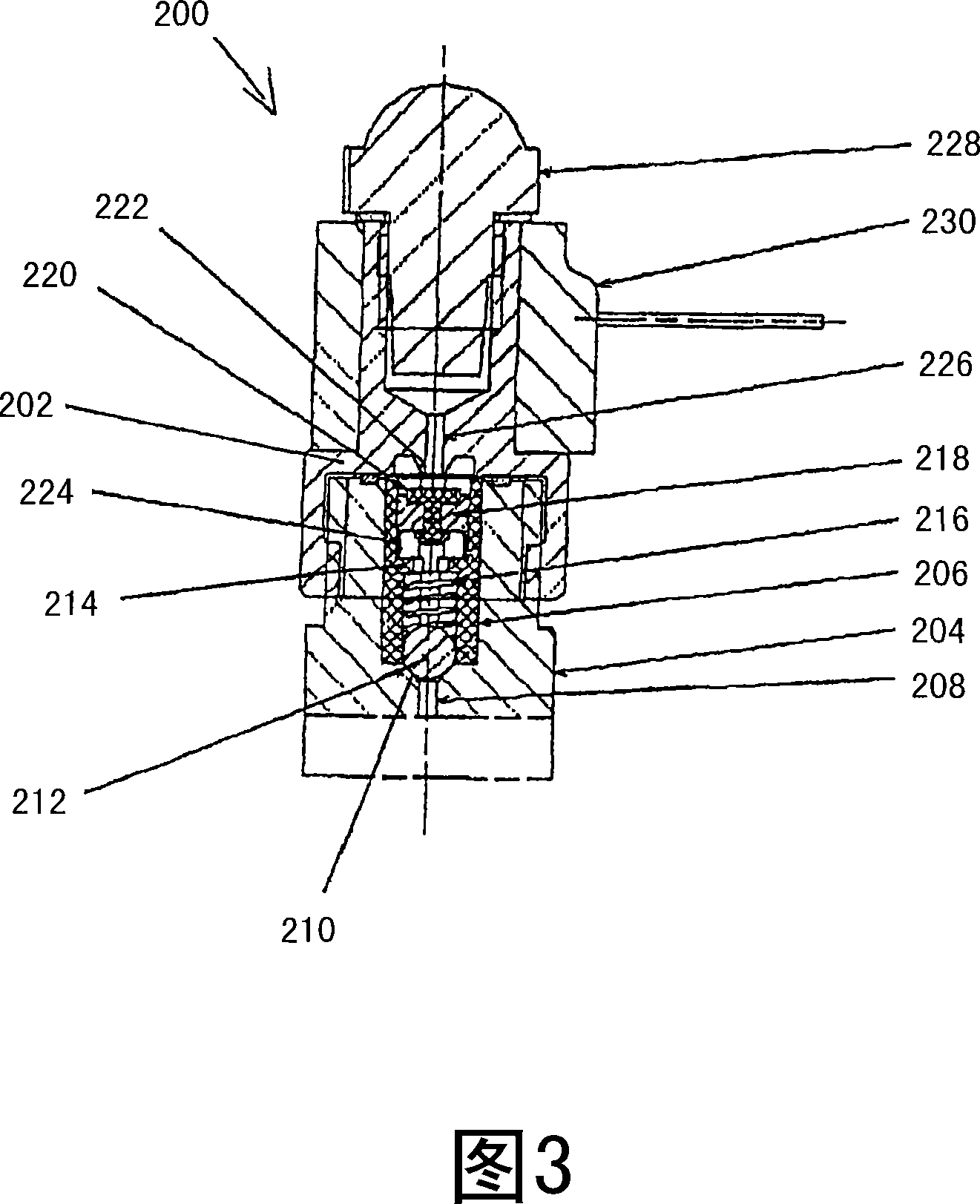

Motor vehicle heating system and method for pre-heating liquid fuel

InactiveCN101184642AEffective heat transferAvoid unintentional openingAir-treating devicesOperating means/releasing devices for valvesMobile vehicleEngineering

The invention relates to a motor vehicle heating system (10) which is embodied in such a way as to be operated by liquid fuel, and comprises a fuel pump (16) and an electromagnetically actuated fuel valve (84; 200) which is arranged downstream from the fuel pump. According to the invention, the electromagnetically actuated fuel valve (84; 200) is embodied in such a way as to pre-heat fuel. The invention also relates to a method for pre-heating liquid fuel for a motor vehicle heating system, whereby the waste heat of an electromagnetically actuated fuel valve (84; 200) is used to pre-heat the fuel.

Owner:WEBASTO AG

Infrared flameless gasification stove

InactiveCN104251500APollution-free combustionHigh calorific valueCombustion typesDomestic stoves or rangesCombustion chamberFuel gasification

The invention provides an infrared flameless gasification stove able to burn various liquids and gases. The infrared flameless gasification stove includes: a ceramic infrared combustion disc, a combustion chamber, a ceramic fire gather ring, a fuel gasification chamber, an annular preheat air duct, a wind shield, an air inlet duct, a fuel regulating valve, a fan, a fan speed regulator, a speed regulation knob, a fuel adjustment knob, and a preheat device. The infrared flameless gasification stove provided by the invention can crack oil products that are refined from waste and are difficult to ignite under room temperature into flammable gas and realize efficient and pollution-free combustion immediately, and the heat value and safety factors are greatly larger than those of natural gas and liquefied gas. The instrument provided by the invention saves resources and also protects the environment, and has the advantages of simple structure, easy processing and manufacturing, and convenient popularization.

Owner:杨福光

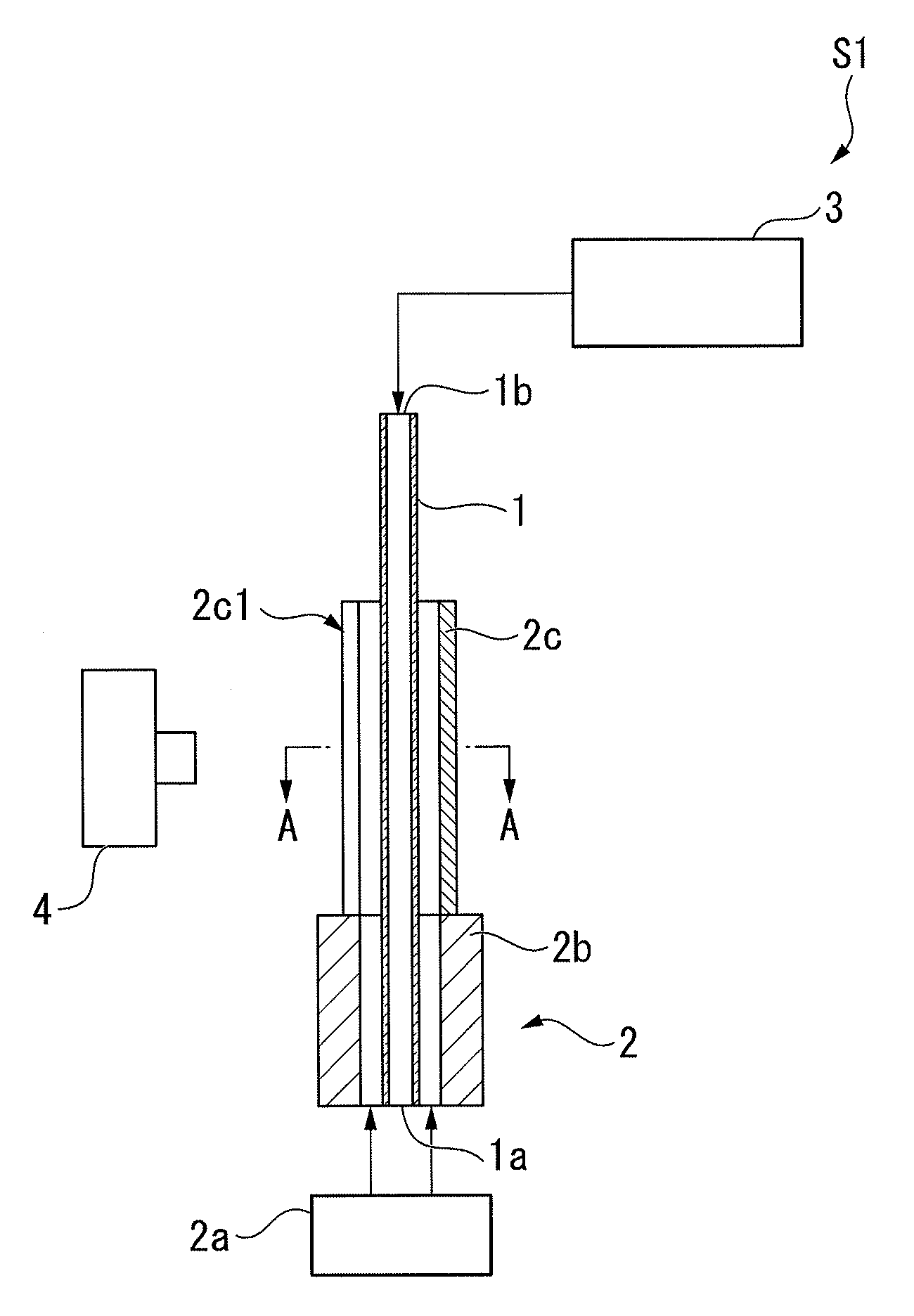

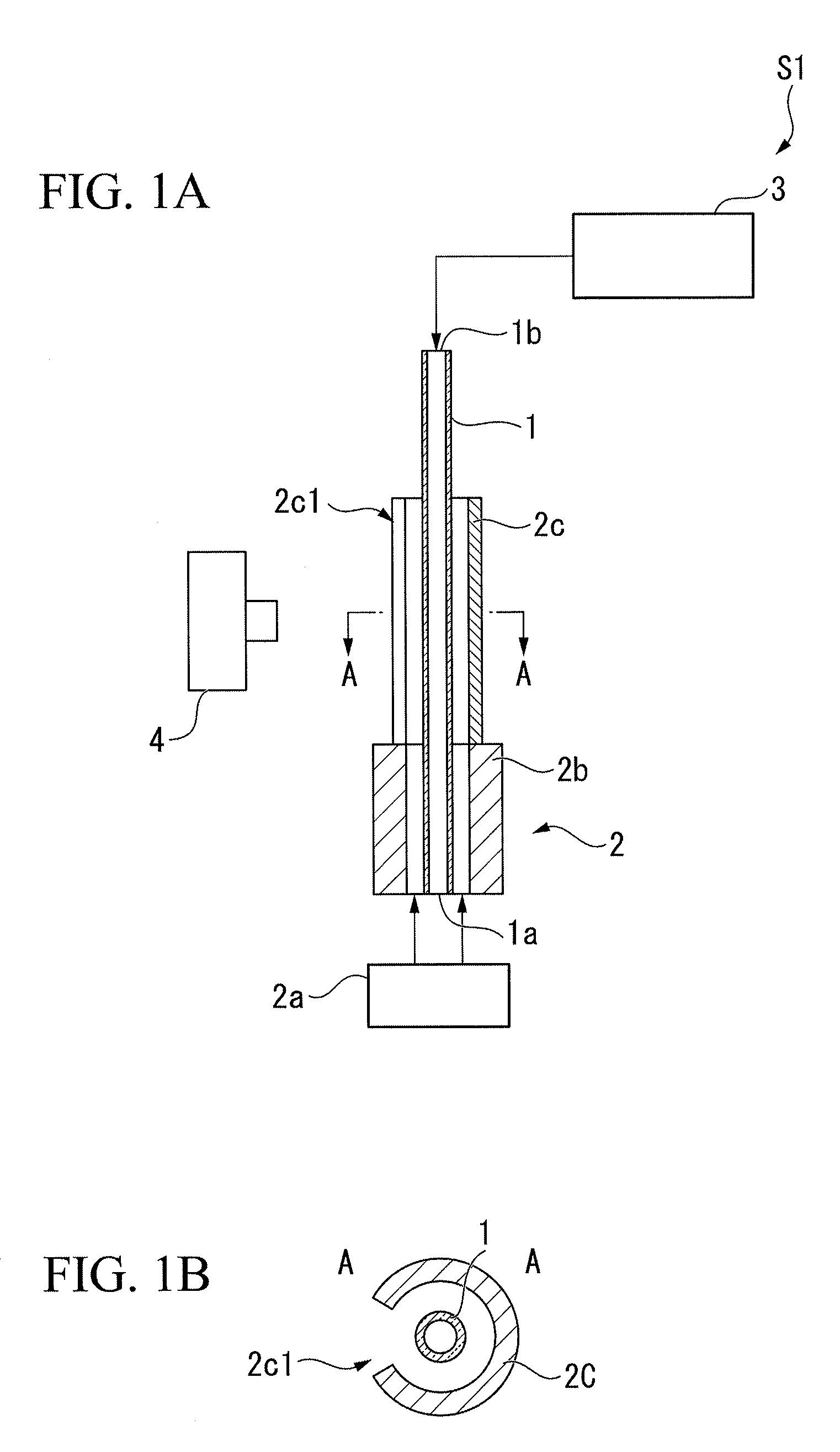

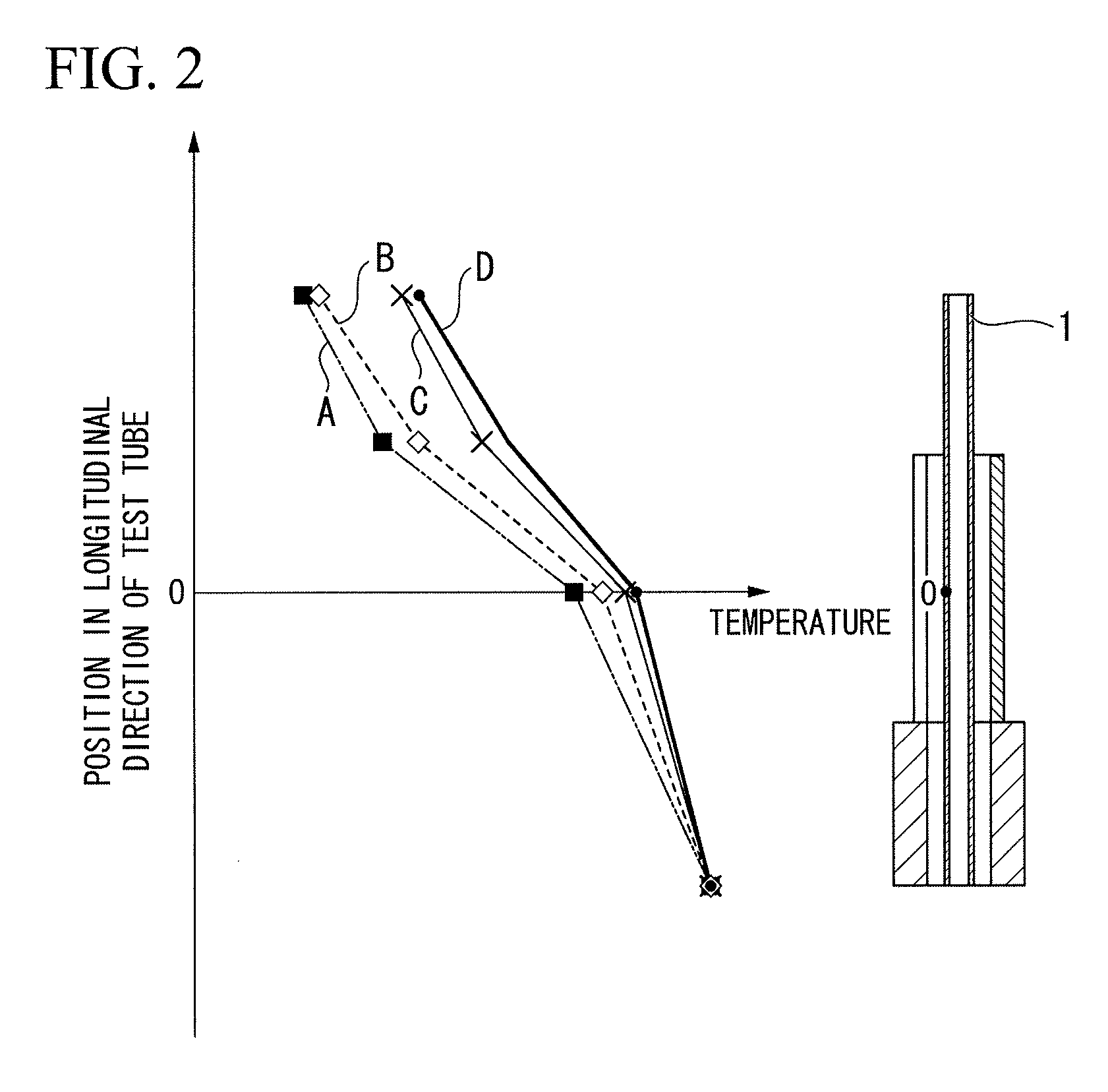

Combustion experimental apparatus

Owner:TOHOKU UNIV +1

Sulfur-nitrogen crystalline silica cracking tube

InactiveCN101439308ASmooth entryImprove accuracyCombustion typesLaboratory glasswaresCombustionSulfur

The invention discloses a sulphur nitrogen quartz cracking tube used for an analyzing instrument which uses a cracking method to detect the contents of the sulphur nitrogen elements in a sample; the middle section of the cracking tube is a combustion cavity; the two ends are respectively a gasification end and a stable end; the inside of the gasification end is provided with a gasification cavity which is communicated with a gas loading opening; the inner wall of the gasification end and the outer wall of the gasification cavity are provided with a bent gas loading pre-heating tube; one end of the pre-heating tube is communicated with the gasification cavity and the other end is communicated with the gas loading opening. When the sulphur nitrogen quartz cracking tube works, the loaded gas enters the preheating tube at first and then enters the gasification cavity; the temperature of the loaded gas after preheating achieves the requirement of complete gasification of the sample, thereby avoiding the problems of leading the sample to generate carbon distribution or residua due to the lower temperature of the loaded gas, thereby improving the detection accuracy.

Owner:泰州市中环分析仪器有限公司

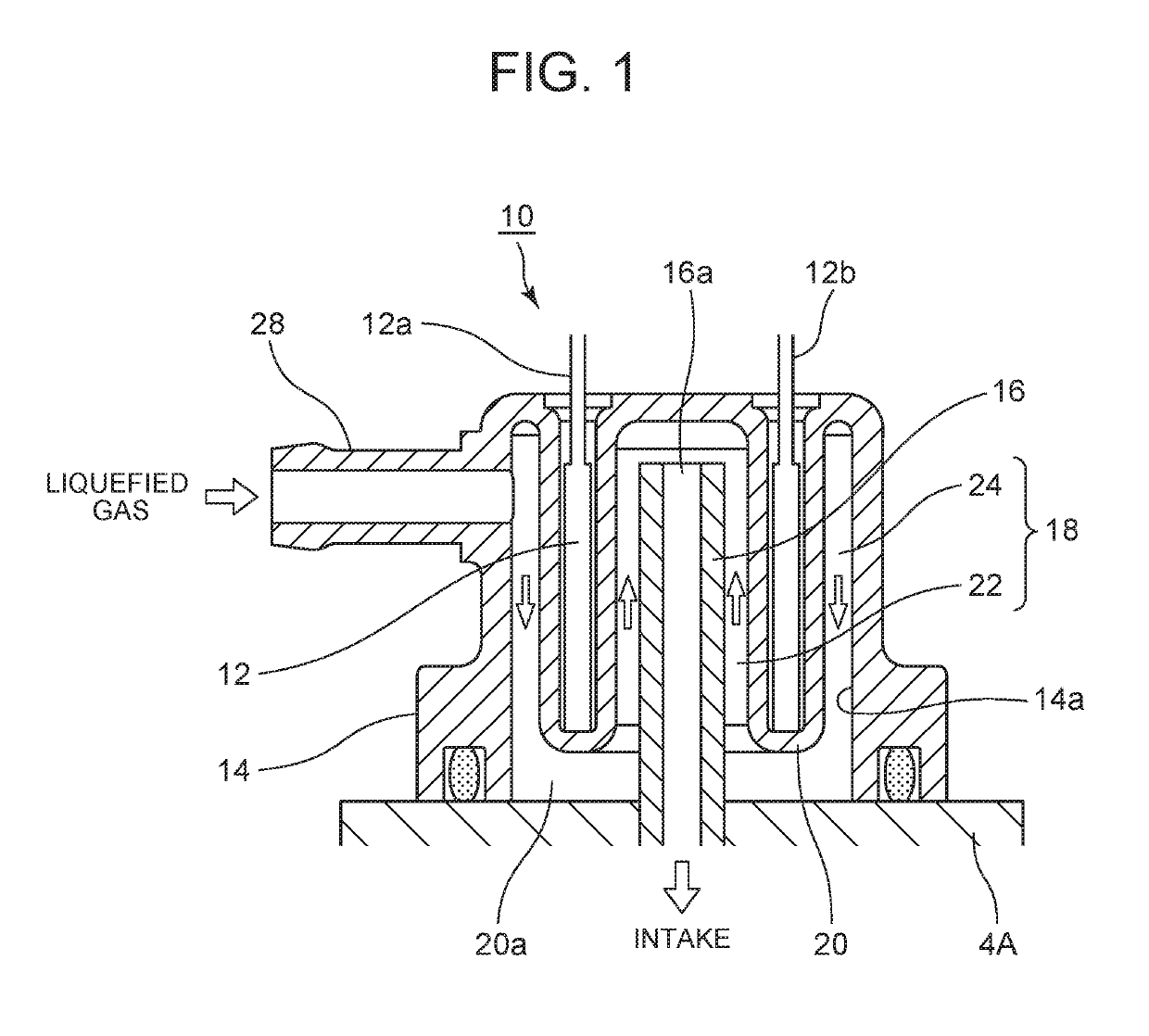

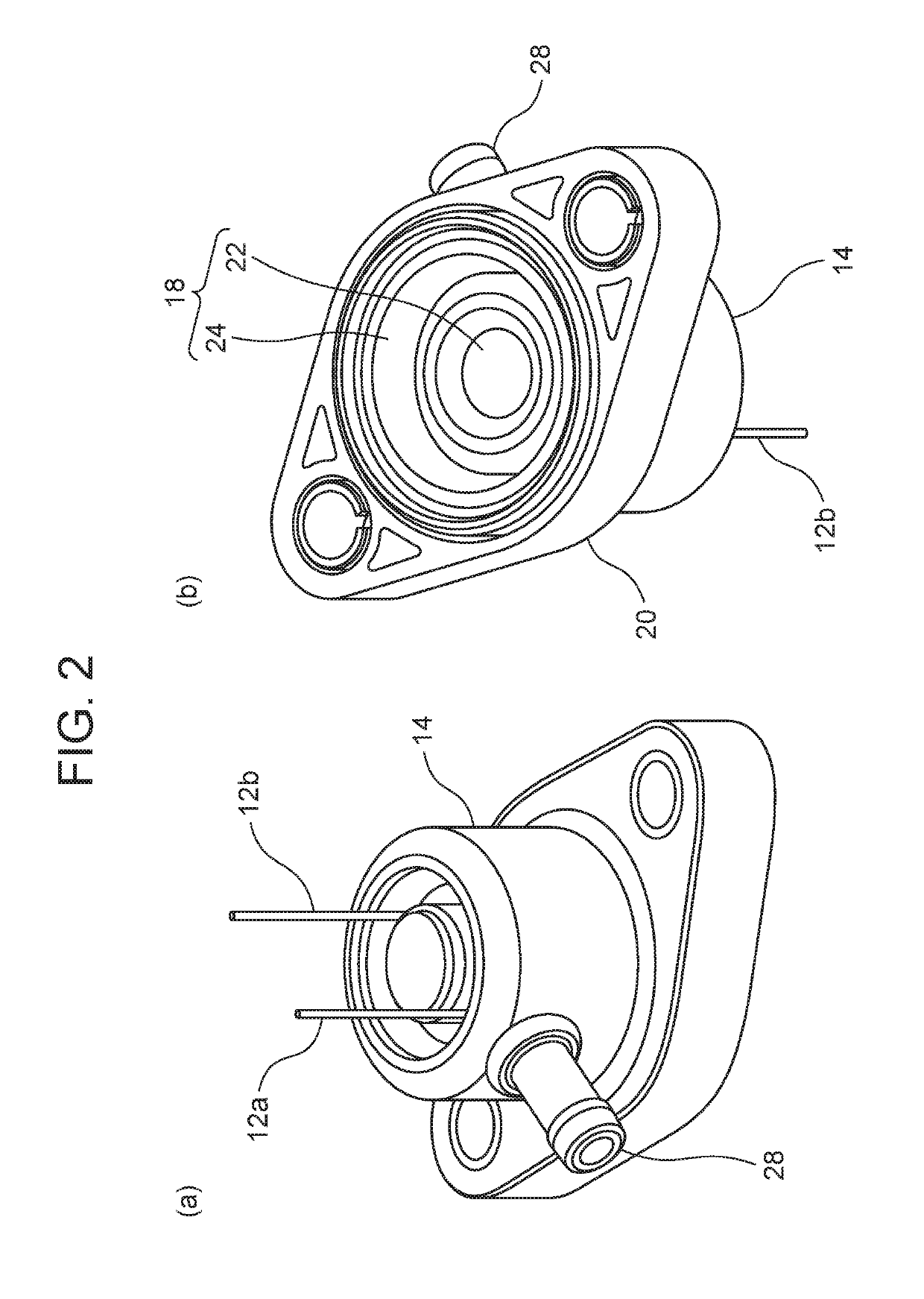

Heater device for heating liquefied gas

ActiveUS10520185B2Inhibition heightReduce component countCombustion typesInternal combustion piston enginesLiquid gasInstrumentation

Owner:NIPPON THERMOSTAT CO LTD

Fuel oil atomization device of smelting furnace burner

The invention discloses a fuel oil atomization device of a smelting furnace burner, comprising an atomization nozzle and a supercharger as well as an air inflow fan, an air heater and an air dryer connected together by pipelines, wherein the air heater comprises an air heating chamber and a heater arranged in the air heating chamber, and the heater comprises a heating air pipe and an electric heating strip wound on the heating air pipe or a heating pipe arranged in the air heating chamber. By adopting the technical scheme, the fuel oil atomization device has the beneficial effects that as air after being heated and dried is adopted for atomizing heavy oil, the atomizing effect is better, the heavy oil can be burned more completely, the unit heat conversion rate of the heavy oil is enhanced, and the using cost of the heavy oil is lower.

Owner:必成玻璃纤维(昆山)有限公司

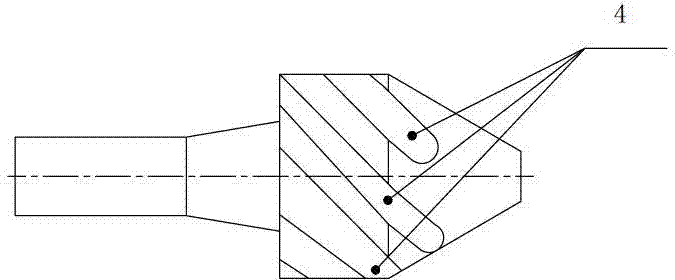

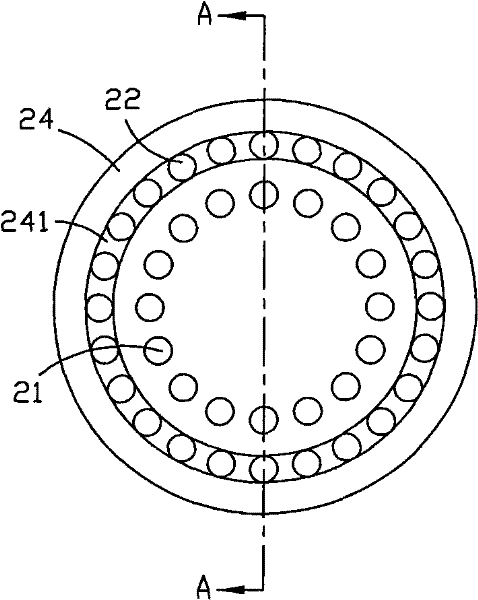

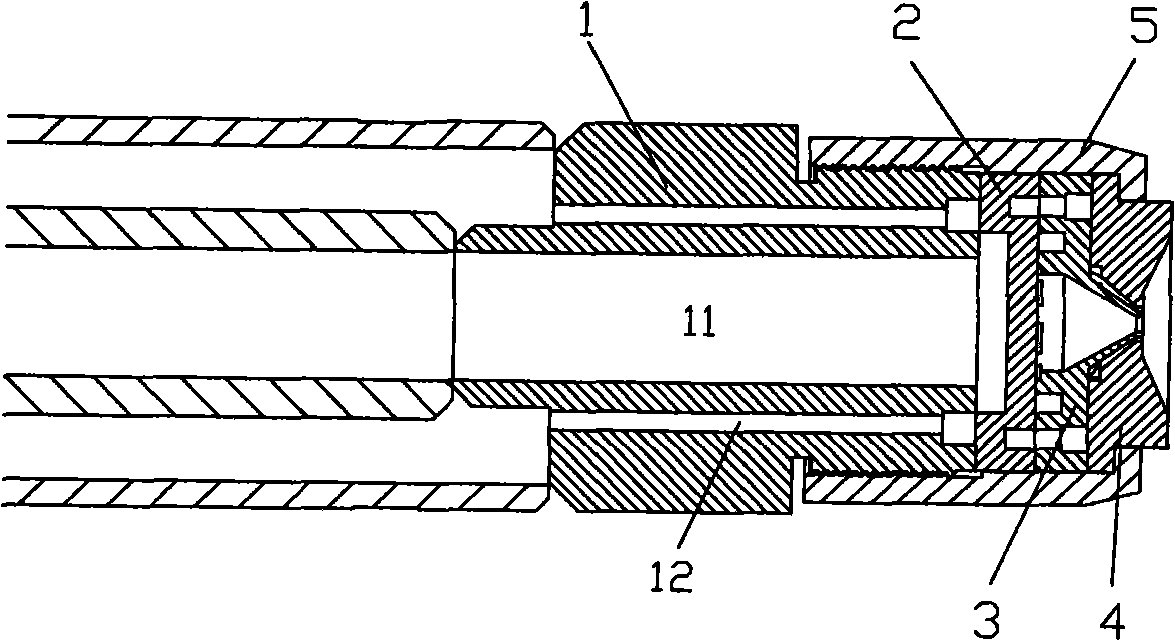

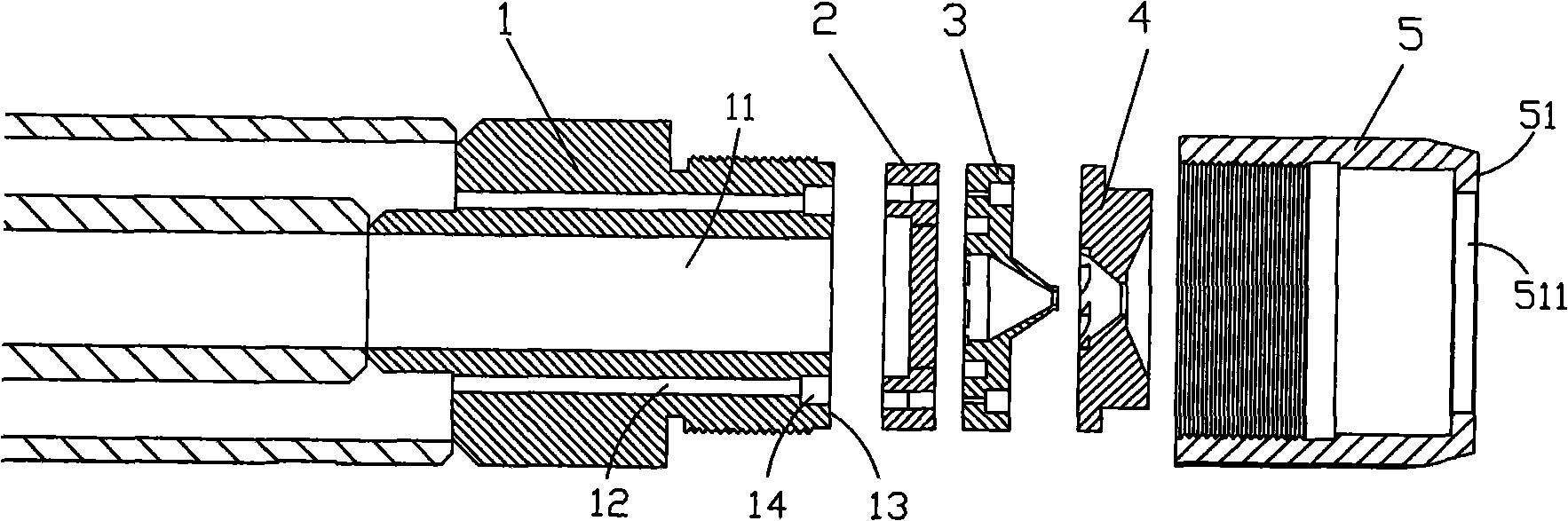

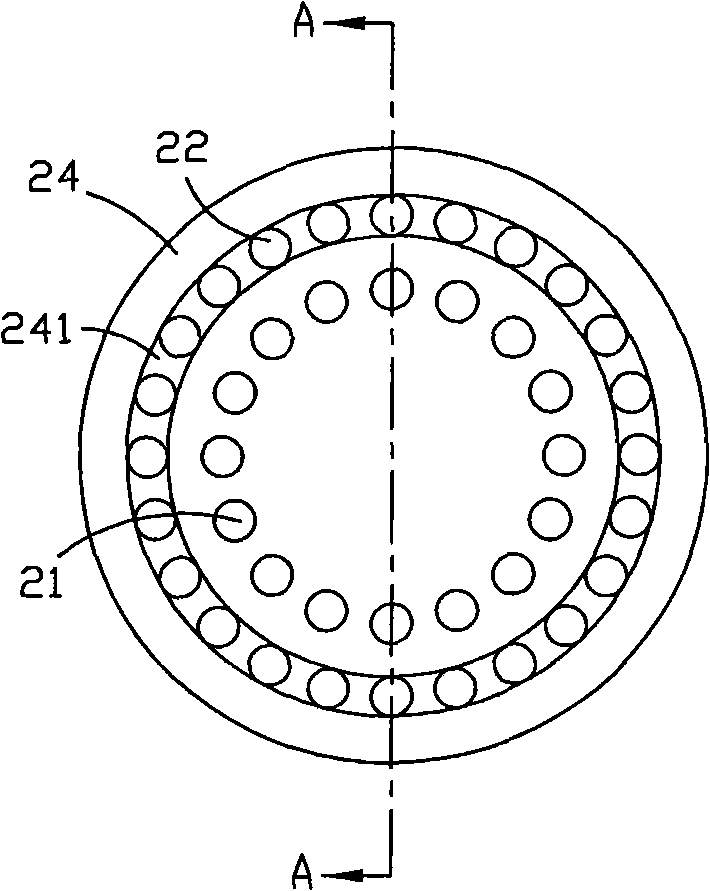

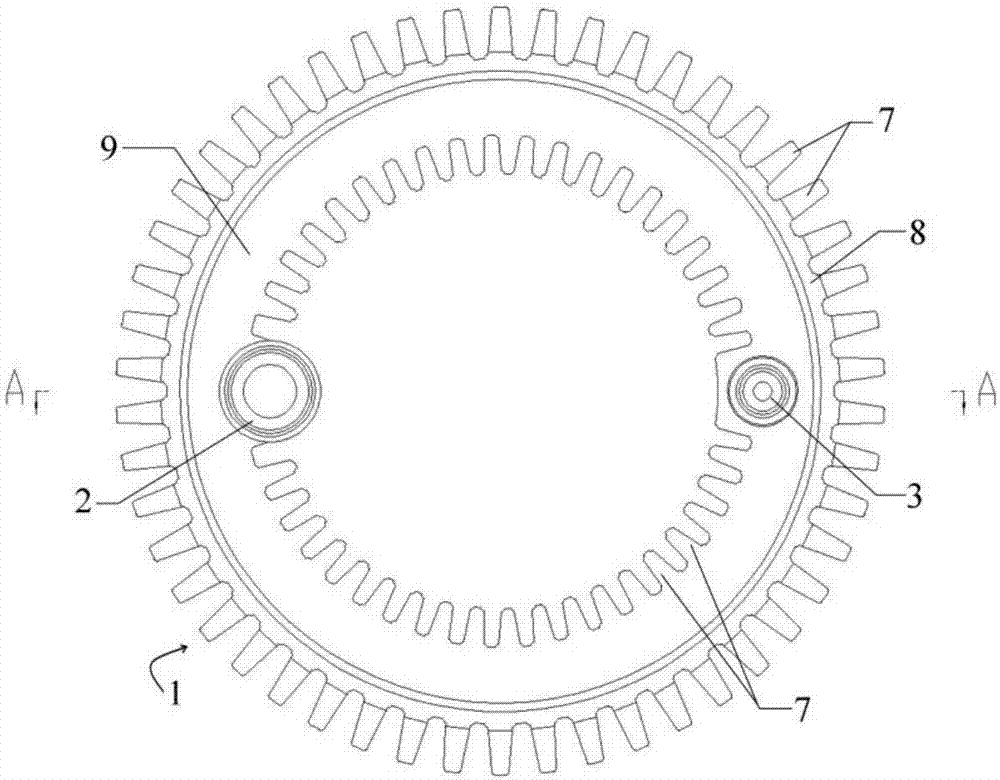

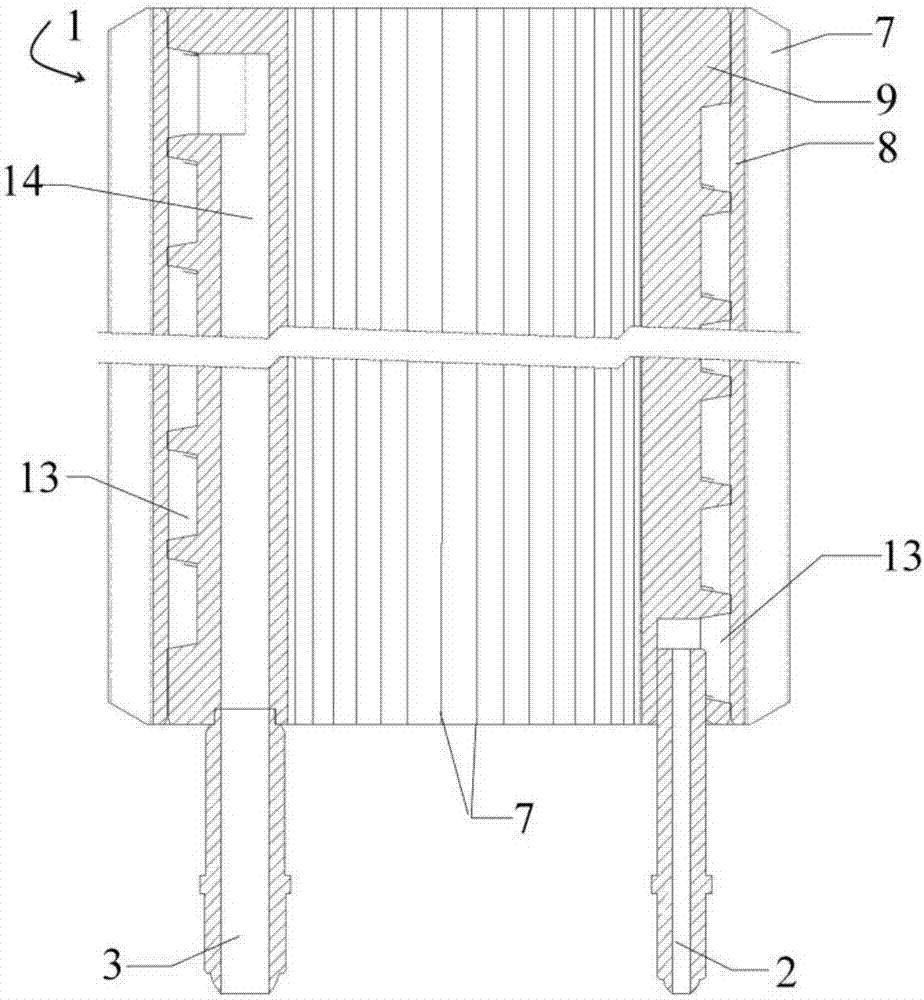

Dual-output atomizer

The invention relates to a dual-output atomizer, which comprises a body, a splitter vane, an atomizer A and an atomizer B, wherein the splitter vane, the atomizer A and the atomizer B are sequentially propped against the body and are sheathed and fixed by an end cover; the body is cylindrical, and a channel A and a channel B are formed at the center; one side of the splitter vane is propped against the body, for corresponding to the channel A and the channel B of the body, an inner circle of through holes and an outer circle of through holes are formed on the splitter vane; an annular oil balancing groove and a spin chamber, as well as a tangential groove around the spin chamber are formed on the side surface of the atomizer A, which is propped against the splitter vane; third oil inlet holes are arranged on the outer side of the annular oil balancing groove along the circumference of the atomizer A; a spin chamber corresponding to the spin chamber of the atomizer A is arranged on theside surface of the atomizer B, which is propped against the atomizer A, and the tangential groove is further arranged around the spin chambers; and a horn-shaped spout, which is communicated with the spin chamber and inwards concave, is arranged on the other side surface of the atomizer B. The two atomizers using a same set of program and mechanism used for controlling advance and retreat can simultaneously perform advance and retreat, and a variety of energy can be accurately and timely supplied under complex and emergency working conditions, thereby meeting complex combustion requirements of energy supply under the different working conditions.

Owner:西斐(上海)工业控制有限公司

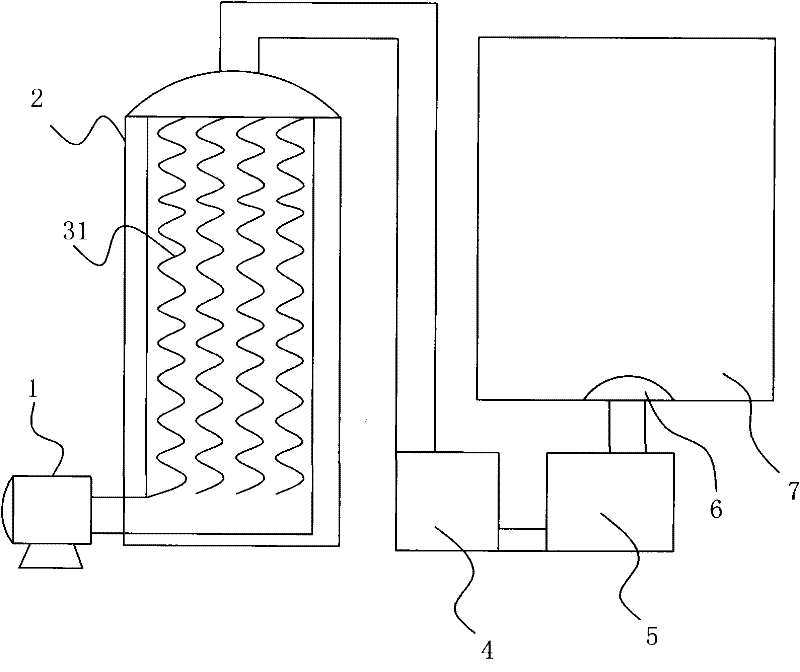

Heat storage type liquefied natural gas gasifier

InactiveCN1214209CCreate pollutionOvercome dependenceLiquid fuel feeder/distributionCombustion typesThermal energyCombustion

A heat accumulating gasifier for liquefied natural gas is disclosed. The natural gas generated by evaporation of liquefied natural gas in storage tank is burning at the bottom of gasifier. The heat generated by said combustion is transferred via heat exchanger to the heat accumulating medium. The accumulated heat is then used to gasify the liquefied natural gas. Said gasifier is composed of a heat exchanger, an insulating gasifying case containing said heat exchanger and divided into the gasifying cavity containing showering tube of liquefied natural gas and natural gas collecting tube and the heat accumulating cavity full of heat accumulating medium, and an igniter.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Dual-output atomizer

The invention relates to a dual-output atomizer, which comprises a body, a splitter vane, an atomizer A and an atomizer B, wherein the splitter vane, the atomizer A and the atomizer B are sequentially propped against the body and are sheathed and fixed by an end cover; the body is cylindrical, and a channel A and a channel B are formed at the center; one side of the splitter vane is propped against the body, for corresponding to the channel A and the channel B of the body, an inner circle of through holes and an outer circle of through holes are formed on the splitter vane; an annular oil balancing groove and a spin chamber, as well as a tangential groove around the spin chamber are formed on the side surface of the atomizer A, which is propped against the splitter vane; third oil inlet holes are arranged on the outer side of the annular oil balancing groove along the circumference of the atomizer A; a spin chamber corresponding to the spin chamber of the atomizer A is arranged on the side surface of the atomizer B, which is propped against the atomizer A, and the tangential groove is further arranged around the spin chambers; and a horn-shaped spout, which is communicated with the spin chamber and inwards concave, is arranged on the other side surface of the atomizer B. The two atomizers using a same set of program and mechanism used for controlling advance and retreat can simultaneously perform advance and retreat, and a variety of energy can be accurately and timely supplied under complex and emergency working conditions, thereby meeting complex combustion requirements of energy supply under the different working conditions.

Owner:西斐(上海)工业控制有限公司

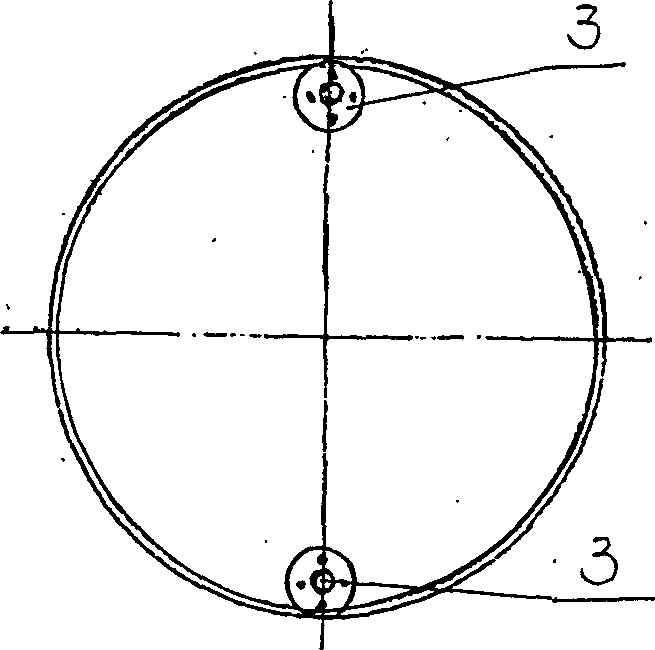

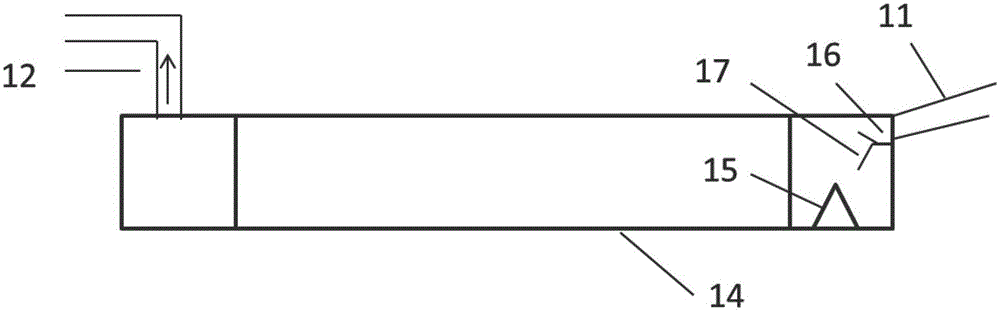

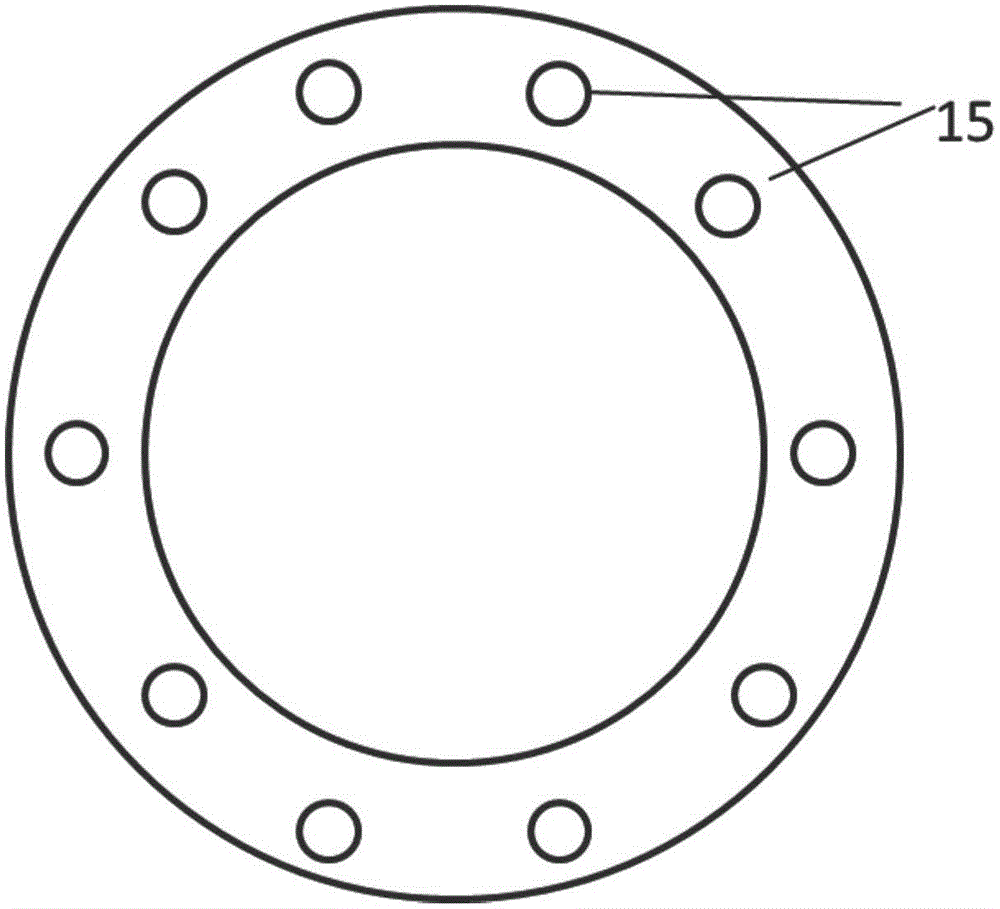

Liquid fuel vaporization combustion device

InactiveCN105485730APrevent separationAvoid enteringDomestic stoves or rangesCombustion typesTO-18Engineering

The invention relates to a liquid fuel vaporization combustion device which comprises a vaporization device (1), a vaporization device liquid inflow pipe (11) and a vaporization device gas outflow pipe (12) which are connected with the vaporization device (1), a preheating device (2), a preheating device liquid inflow pipe (21) connected with the preheating device (2), and a vaporization nozzle (13) connected with the gas outflow pipe (12), wherein the vaporization device (1) is annular, and a bottom wall (14) of the vaporization device (1) is recessed inwards to form 2 to 18 conic or truncated-cone-shaped bottom wall protrusions (15); a circle of liquid inflow groove (16) is fixed to the upper half portion of the side wall of the vaporization device (1) and the position, corresponding to each bottom wall protrusion (15), of the liquid inflow groove (16) is provided with a chute (17); and the gas outflow pipe (12) is connected to the top of one end of the vaporization device (1). By the adoption of the liquid fuel vaporization combustion device, liquid fuel can be completely vaporized and fully burnt, and combustion efficiency is improved.

Owner:XUZHOU LIFANG MECHANICAL & ELECTRICAL EQUIP MFG CO LTD

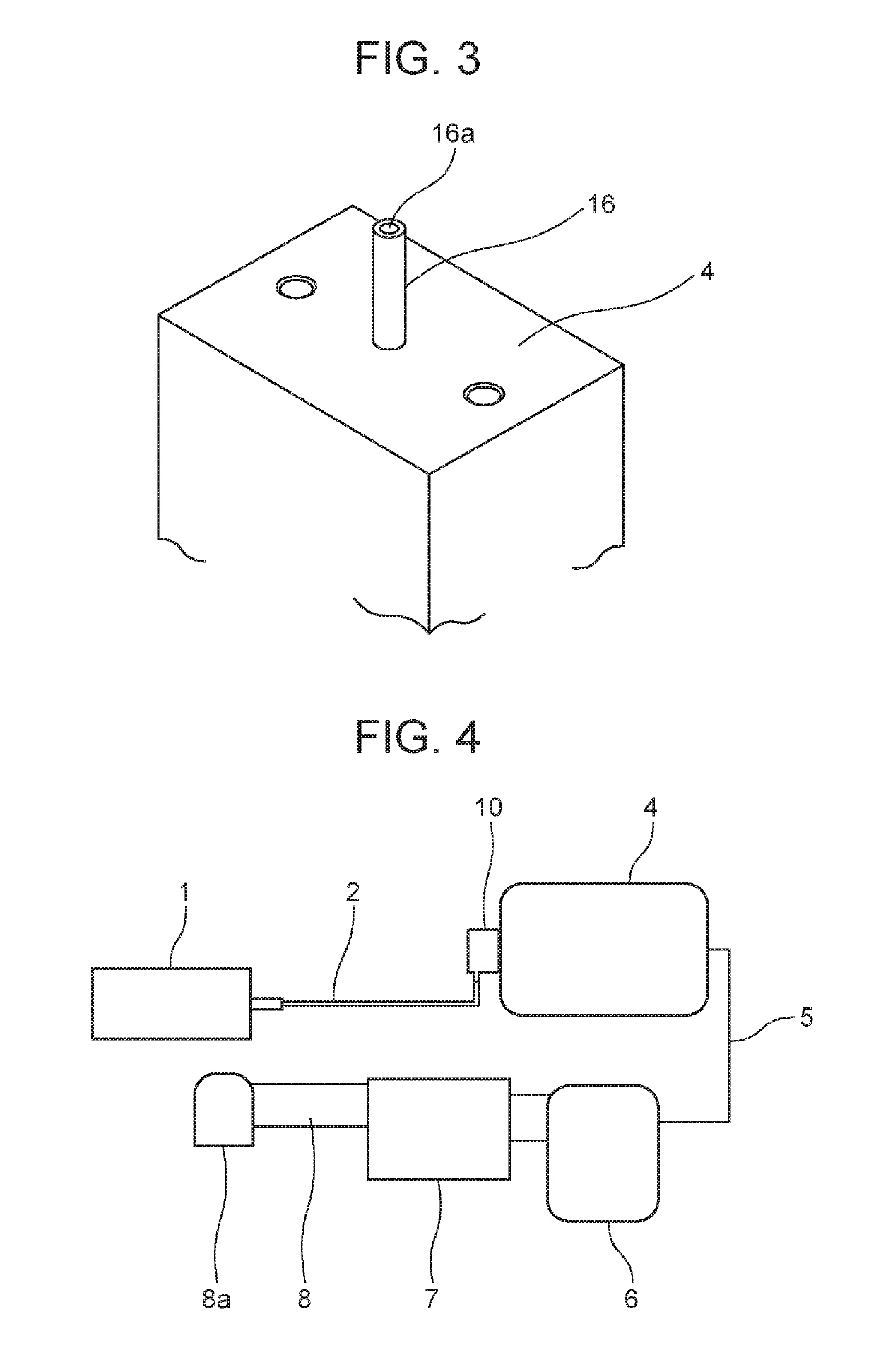

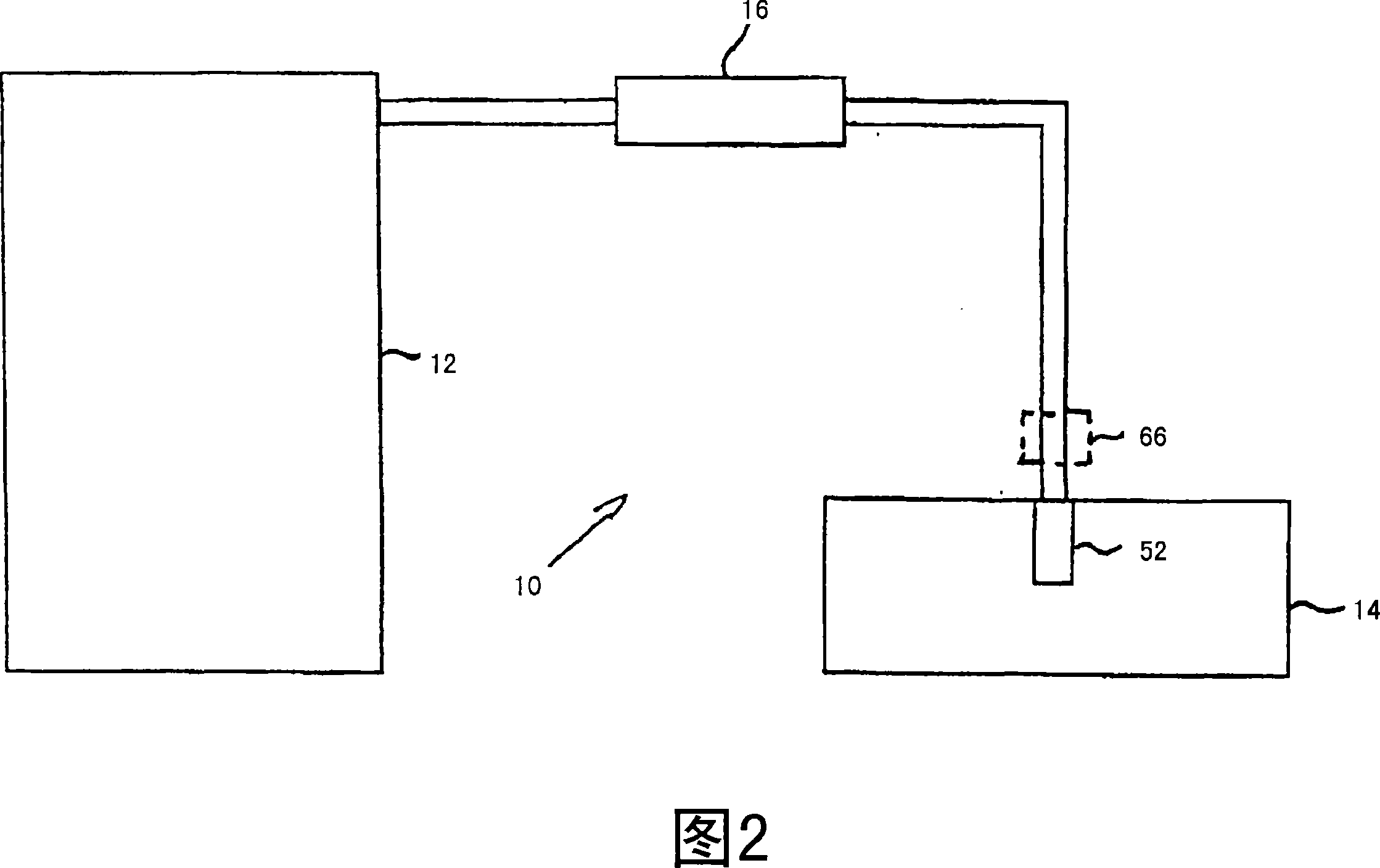

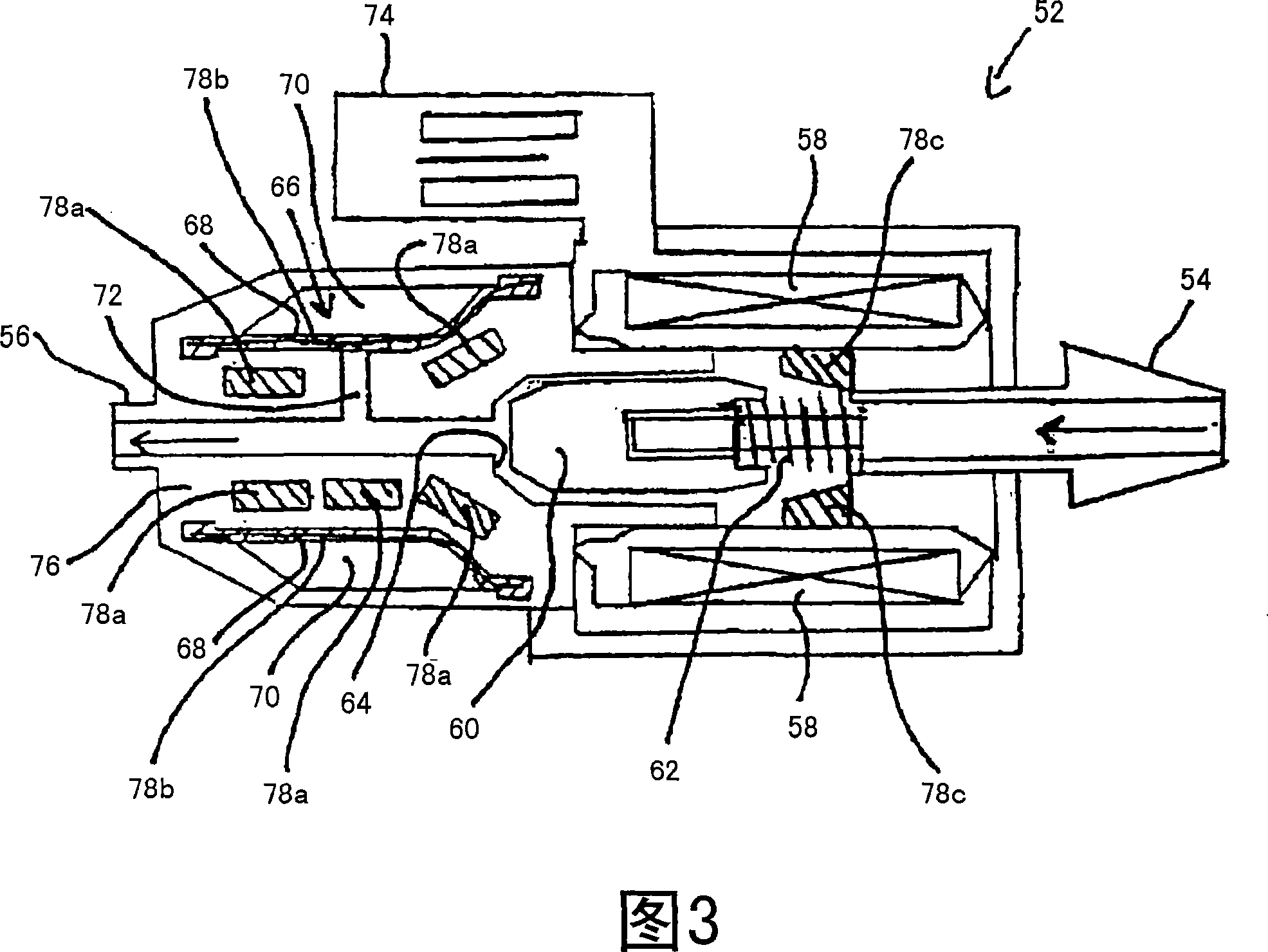

Motor vehicle heating system

InactiveCN101203394AReduce the numberFuel supply regulationLiquid fuel feeder/distributionElastomerLiquid fuel

The invention relates to a motor vehicle heating system (10) which is embodied in such a way as to be operated by liquid fuel, and comprises a fuel pump (16 ; 16) and a damping element (34; 66) which is provided with an elastomer (36; 68) and used to damp pulsations generated by the fuel pump (16'; 16). According to the invention, means (58, 78a, 78b, 78c, 80, 82) are provided for heating the elastomer (68). Preferably, the motor vehicle heating system comprises an electromagnetically actuated fuel valve (52), and the damping element (66) is provided in the region of the electromagnetically actuated fuel valve (52) and especially integrated into the same.

Owner:WEBASTO AG

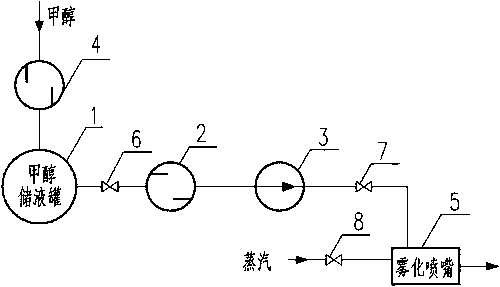

Methyl alcohol based boiler ignition system

InactiveCN103742905AReduce ignition investmentLow running costCombustion typesAlcoholAtomizer nozzle

The invention discloses a methyl alcohol based boiler ignition system. The system comprises a methyl alcohol coarse filter, wherein an inlet of the methyl alcohol coarse filter is connected with a methyl alcohol raw material main pipe, and an outlet is connected with a methyl alcohol liquid storage tank, a methyl alcohol fine filter, a methyl alcohol pump and an atomization nozzle. A steam inlet is further arranged at the atomization nozzle and is connected with a steam main pipe. By means of the system, initial investments and operating costs are reduced, the operating responding speed is improved, combustion products are pollution-free to the atmosphere, and the energy-saving and environment-friendly purpose is achieved.

Owner:陕西大唐新能电力设计股份有限公司

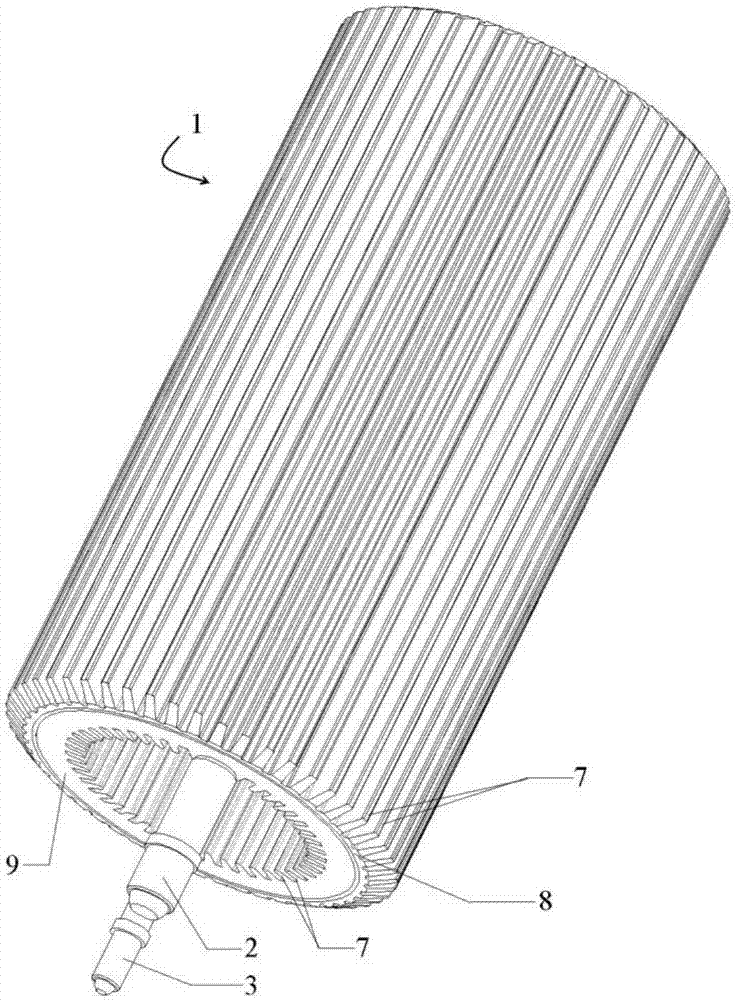

Reasonably-structured special power vaporizer for high-efficiency methanol burner

PendingCN107448935AReasonable structureCompact structureCombustion typesCombustorMechanical engineering

The invention discloses a reasonably-structured special power vaporizer for a high-efficiency methanol burner. The special power vaporizer comprises a power vaporizer body. The bottom of the power vaporizer body is provided with a methanol inlet and a methanol vaporization outlet. The power vaporizer body comprises a vaporization outer sleeve and a vaporization inner sleeve. A spiral channel and an output channel are formed between the vaporization outer sleeve and the vaporization inner sleeve. One end of the spiral channel is connected with the methanol inlet and extends upwards from the bottom of the power vaporizer body. The spiral channel extends to the top of the power vaporizer body along the power vaporizer body and is connected with the output channel. The output channel is connected with the methanol vaporization outlet. The special power vaporizer is simple and reasonable in structure. A fuel inlet is formed in the bottom, and a fuel outlet is formed in the top. The size of the methanol inlet is smaller than that of the output channel and that of the methanol vaporization outlet. The heat exchange area is increased. Besides, the power vaporizer is light in overall weight. The heat storage capacity is greatly increased. The service life of the power vaporizer is greatly prolonged.

Owner:中润海精密科技有限公司

Liquid fuel gasifier with self-driven fan

A liquid fuel gasifier with a self-driven fan consists of a pressurizable fuel tank, a tubular gasifier-cyclone burner, a self-driven fan, a balance valve, an oil supply valve and an electronic igniter, wherein a burner and a gasifier are integrated to be cylindrical; the cylinder is provided with a fire head on the upper part and a burning disc on the lower part; a cylinder space defined by the fire head and the burning disc is a combustion chamber; the gasifier is arranged inside the combustion chamber; an annular sealing opening for accommodating the burner is formed in the upper part of an air supply tube, and an opening for accommodating the fan is formed in the lower part of the air supply tube; a gasifier pipeline consists of an oil supply pipe, a gasifying ring, a gas conveying pipe, a balance pipe and a gas spraying ring, and is communicated with the fuel tank through the oil supply pipe and the balance pipe for implementing oil supplying; by virtue of heat of the burner, oil is gasified, gasified gas is directly supplied to the combustion chamber through the gas spraying ring, and the gasifier is used under the conditions of air supply and ignition of the igniter; the fan consists of the air supply tube, a rotating shaft, fan blades, a transmission arm, and a magnetic ball arranged inside the gas spraying ring; the magnetic ball rotates inside the gas spraying ring under the pushing of fuel gas and pulls the transmission arm to enable the fan to operate.

Owner:袁宏文

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com