Motor vehicle heating system and method for pre-heating liquid fuel

A technology for heating systems and motor vehicles, applied in the field of preheating liquid fuels, can solve problems such as increasing and decreasing viscosity, achieve the effects of effective heat transfer, increase sealing force, and avoid unintentional opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

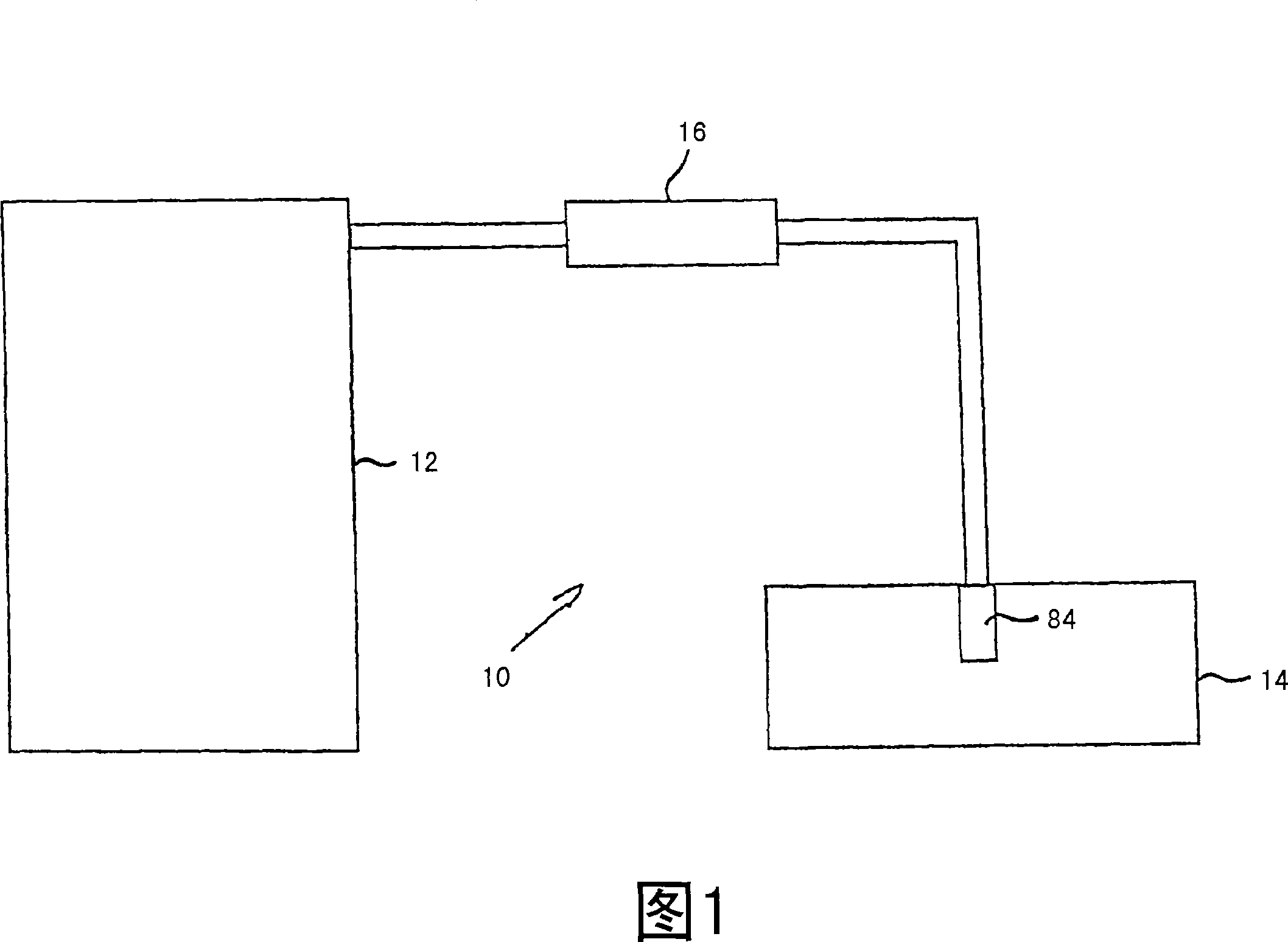

[0022] FIG. 1 is a schematic block diagram of one embodiment of the motor vehicle heating system of the present invention. This system 10 is operable, for example, for substantially supplemental heating, or for providing heating in stationary situations (when the vehicle is parked). The illustrated heating system 10 includes a piston fuel pump 16 for pumping liquid fuel from a fuel tank 12 to a burner and heat exchanger unit 14 . Depending on whether air or water is being heated, the burner and heat exchanger 14 may communicate with air and water lines (not shown) in a manner well known to those skilled in the art. The burner and heat exchanger 14 also has a fuel valve 84 that can throttle or shut off the fuel supply. It is not necessary for the fuel valve 84 to be integrated in the burner and heat exchanger 14 ; instead, it may be arranged between the piston fuel pump 14 and the burner and heat exchanger 14 . The heating system shown in FIG. 1 does not have a separate heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com