Air cooling structure of outer rotor electric roller

A technology of electric drum and air-cooled structure, which is applied in the direction of electric components, magnetic circuit shape/style/structure, electrical components, etc., and can solve the problem of long distance between the shaft hole and the heating part of the motor stator, high equipment manufacturing cost, and slow heat transfer, etc. problem, to achieve the effect of improving heat dissipation, saving manufacturing cost and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

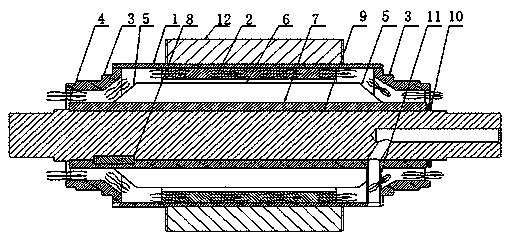

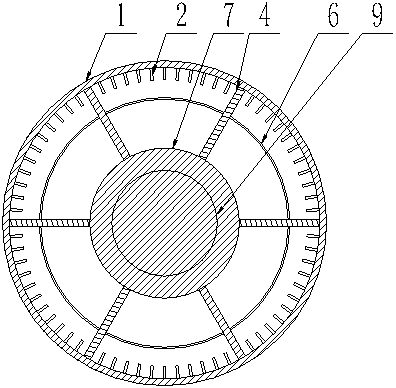

[0032] Below in conjunction with accompanying drawing, describe this description in detail:

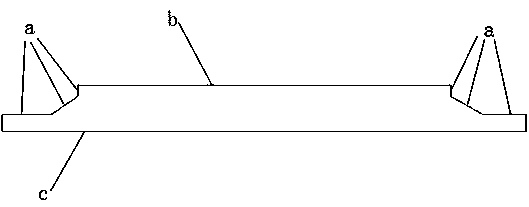

[0033] like Figure 1-8 As shown, the present invention includes a fixing seat 27, an end cover assembly, and a stator assembly. The fixed seat 27 includes an intermediate shaft sleeve 26, an axial support rib 22, and a fixed outer ring 24. The end cover assembly includes an end cover 15, an oil cover assembly, a bearing 17, and a sealing device. The stator assembly includes a stator sleeve 1, an axial Rib 4 , wind deflector structure, bearing seat 3 , main shaft 9 , stator coil core assembly 12 . The fixed seat 27 is fixed together through the key connection or shrink fit between the intermediate shaft sleeve 26 and the main shaft 9 , and the stator assembly and the end cover assembly are welded together with the outer ring of the bearing seat 3 through the stator sleeve 1 .

[0034] like Figure 8 As shown, in the preferred embodiment of the air-cooled structure of the outer roto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com