Modified hydrocarbon resin prepolymer, copper-clad plate and preparation method of copper-clad plate

A hydrocarbon resin and prepolymer technology, applied in the field of copper clad laminates and their preparation, and modified hydrocarbon resins, can solve the problems of fast polymerization speed, explosive aggregation, cracking, damage stress, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0077] Preparation of the prepreg: put the reinforcing material in the combined material solution (full) dip it, take it out, and then bake it at 120°C-185°C for 1-10min to prepare the modified hydrocarbon resin prepreg;

[0078] Preparation of modified hydrocarbon resin copper-clad laminate: cut and laminate the modified hydrocarbon resin prepreg and metal copper foil according to the requirements of length, width and thickness, and then place them in a hot press, keeping the heating rate at 1~ 3°C / min, after reaching the temperature, press at a pressure of 0.2-1MPa and a temperature of 80-150°C for 1-3 hours, then continue to heat up, keeping the heating rate at 1-3°C / min, after reaching the temperature, press at 2-7MPa It is prepared by pressing under pressure and temperature of 180-250°C for 1-6 hours;

[0079] The modified hydrocarbon resin copper-clad laminate prepared by the present invention and the comparison of some technical performances of the comparative sample bo...

Embodiment 3

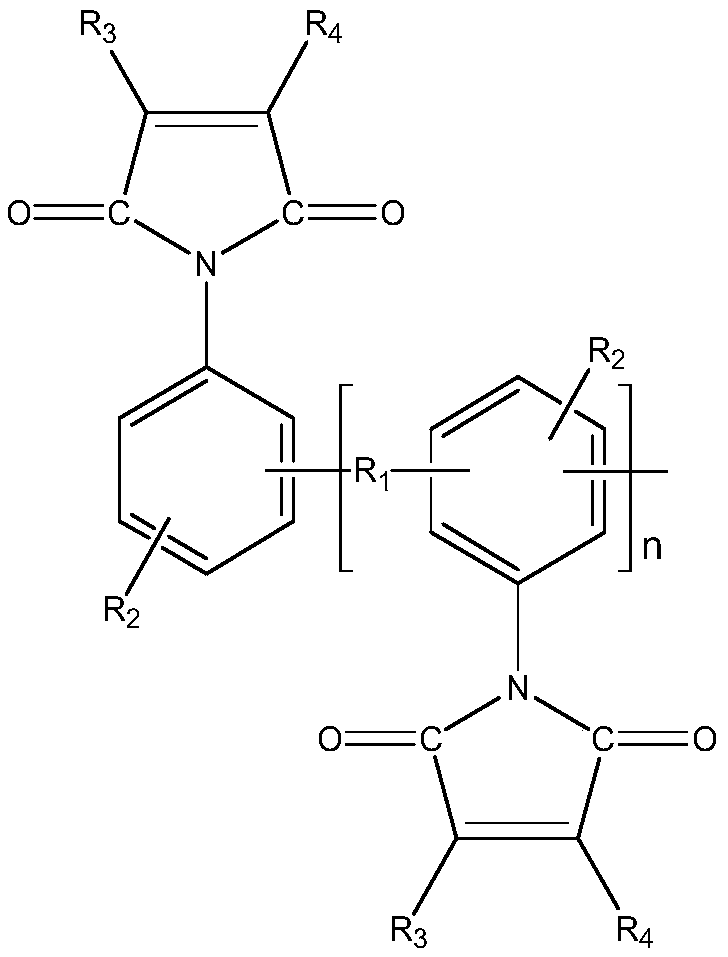

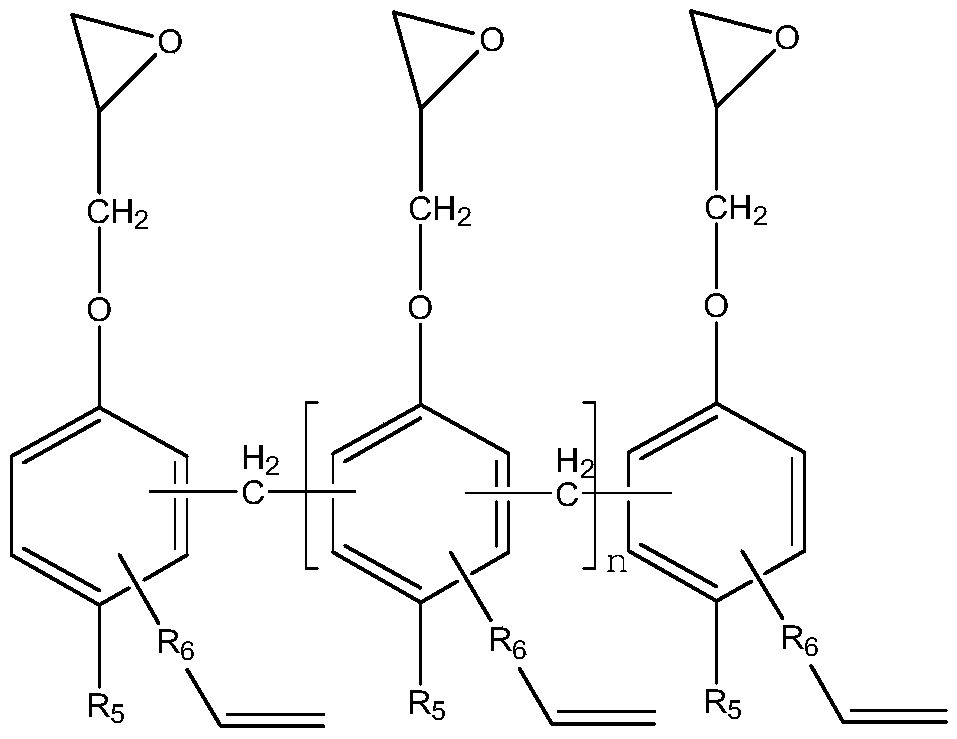

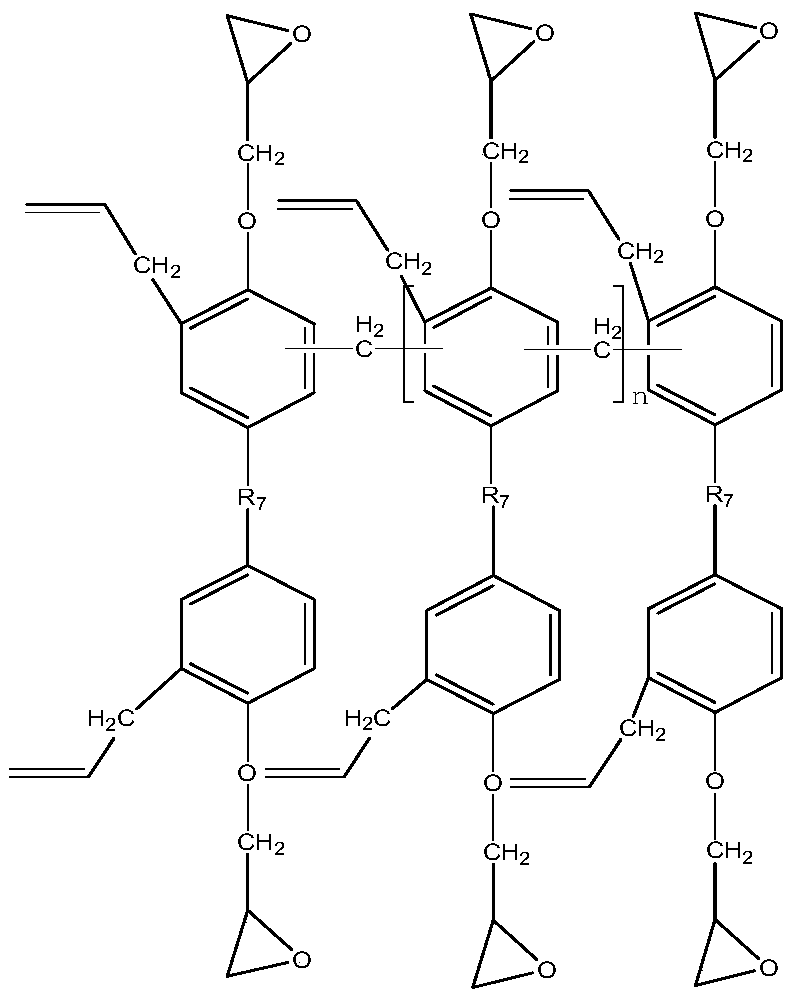

[0096] A modified hydrocarbon resin prepolymer, the modified hydrocarbon resin prepolymer consists of 50 parts by mass of hydrocarbon resin, 50 parts by mass of a mixture of double bond epoxy resin / maleimide resin, 1 part by mass of initiator The composition ① of A and 180 parts by mass of solvent A is prepared by mixing and reacting in a microchannel reactor and removing part of the solvent.

Embodiment 4

[0098] A modified hydrocarbon resin prepolymer, the modified hydrocarbon resin prepolymer consists of 450 hydrocarbon resins, 50 mass parts mixture of double bond epoxy resin / maleimide resin, 5 mass parts initiator The composition ① of A and 280 parts by mass of solvent A is prepared by mixing and reacting in a microchannel reactor and removing part of the solvent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com