Vehicle headlight

A technology for headlights and vehicles, which is applied in the directions of headlights, vehicle parts, lighting devices, etc., to achieve the effect of high position accuracy and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0098] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

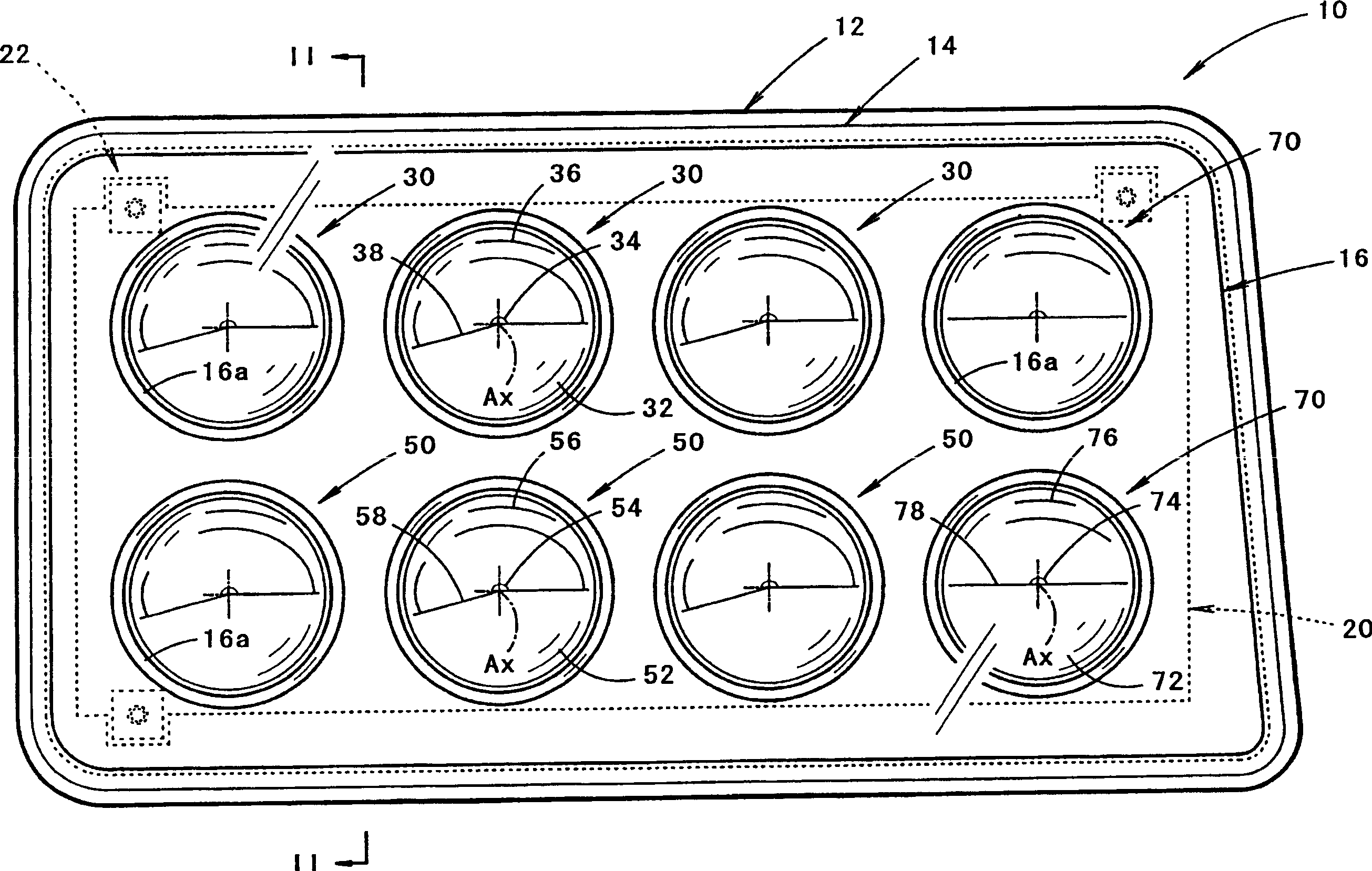

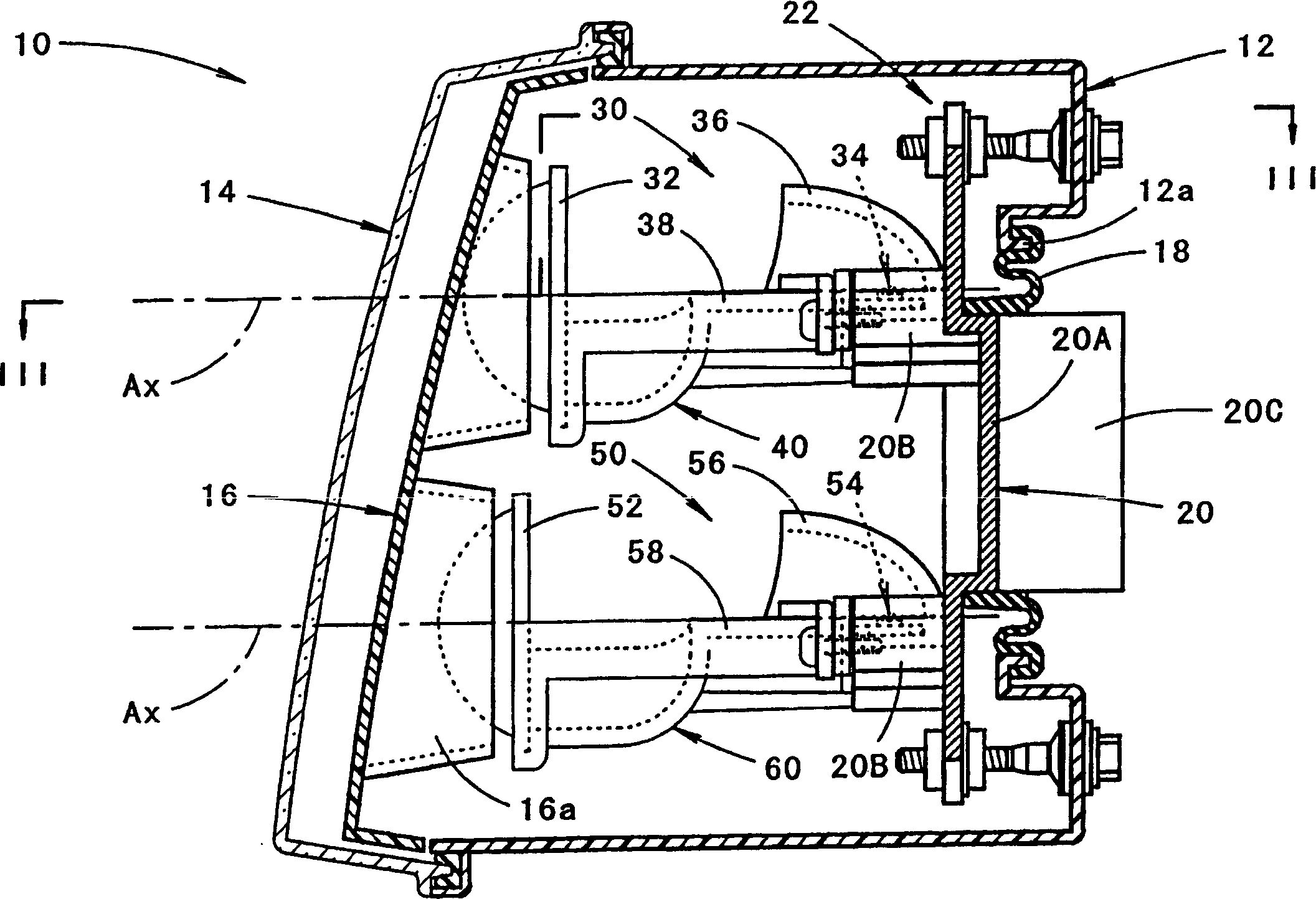

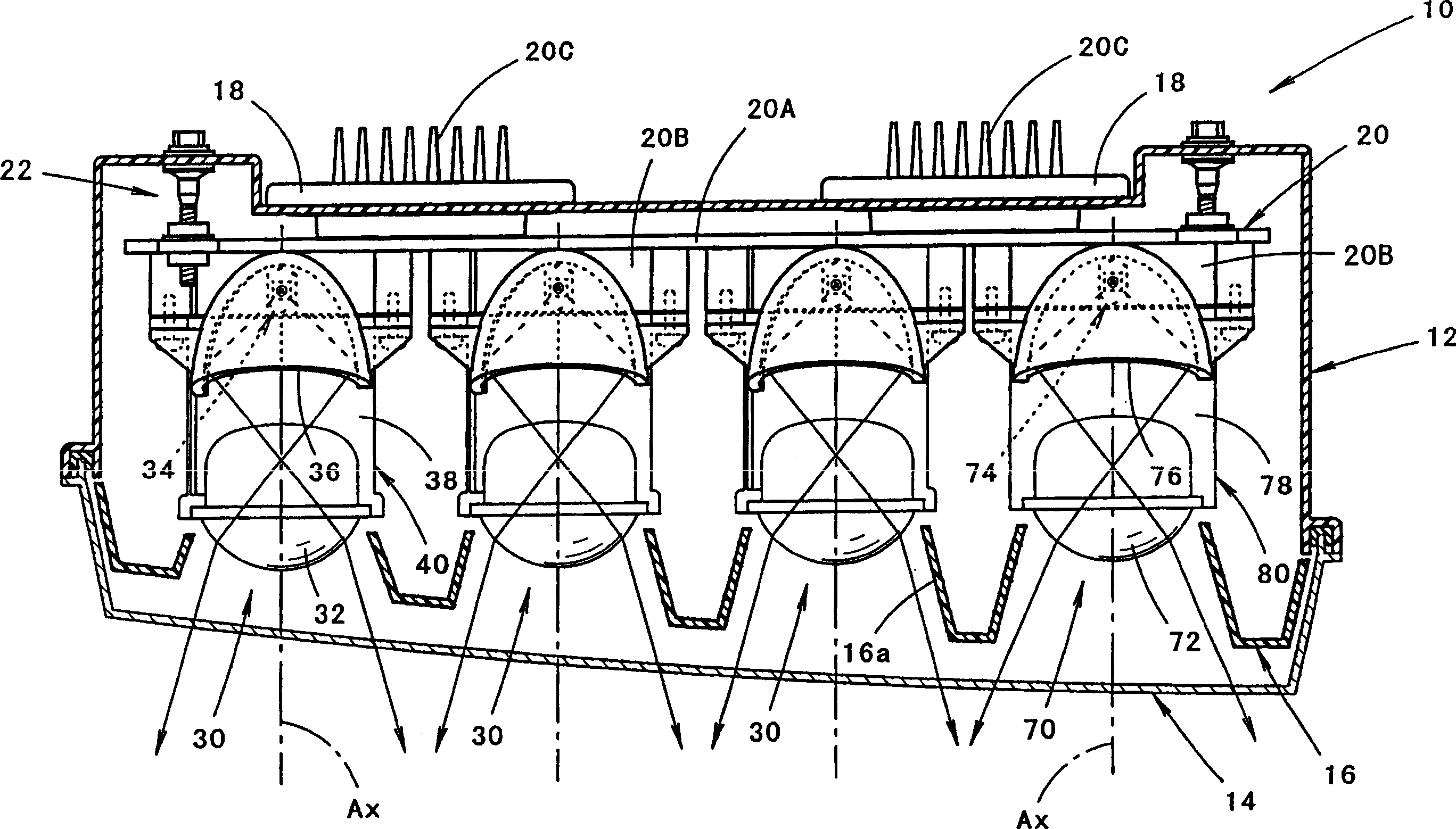

[0099] figure 1 is a front view of a vehicle headlamp according to an embodiment of the present invention, figure 2 yes figure 1 The II-II line profile, image 3 yes figure 2 Sectional view of line III-III.

[0100] As shown in these figures, the vehicle headlamp 10 of this embodiment is a lamp installed on the right side of the front end of the vehicle. Eight lamp units 30, 50, 70 are accommodated, and each floor has two upper and lower floors and each floor has four configurations. In addition, in this vehicle headlamp 10 , light irradiation from these eight lamp units 30 , 50 , and 70 forms a low beam light distribution pattern.

[0101] In the light chamber, an inner panel 16 is provided along the translucent cover 14, and cylindrical openings 16a surrounding each lamp unit are formed at positions corresponding to the lamp units 30, 50, 70 in the inner panel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com