Fuse elements and fuse devices

A fuse and component technology, applied in electrical components, emergency connection, emergency contact form, etc., can solve the problems of low current rating and poor fast breaking, and achieve the effect of increasing current rating, reducing conductor resistance, and excellent fast breaking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

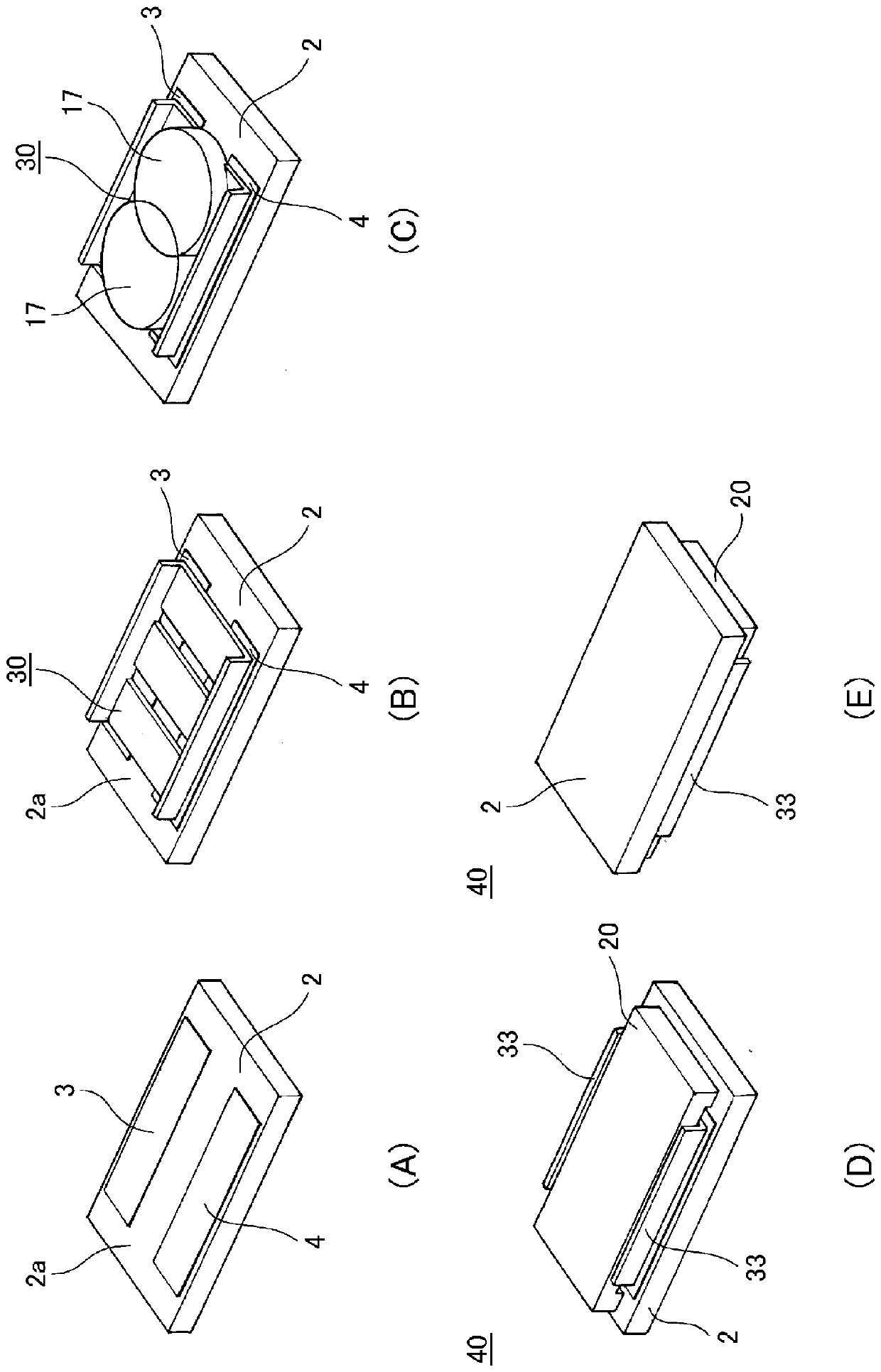

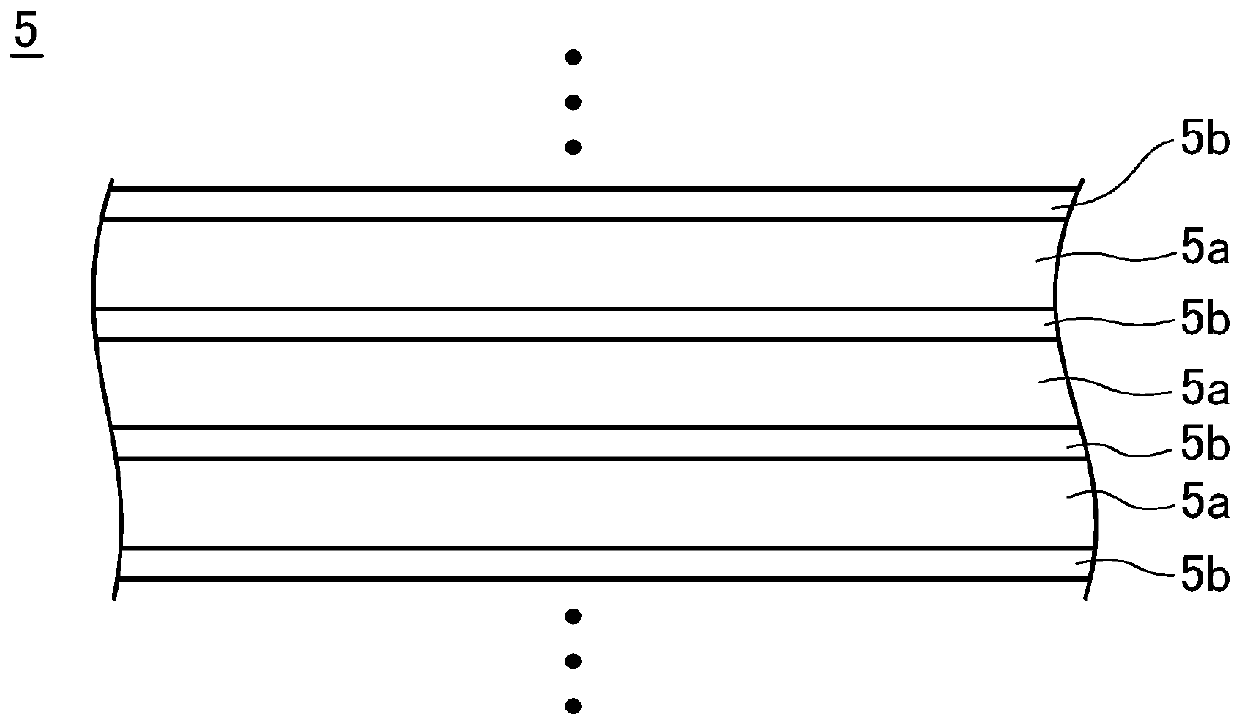

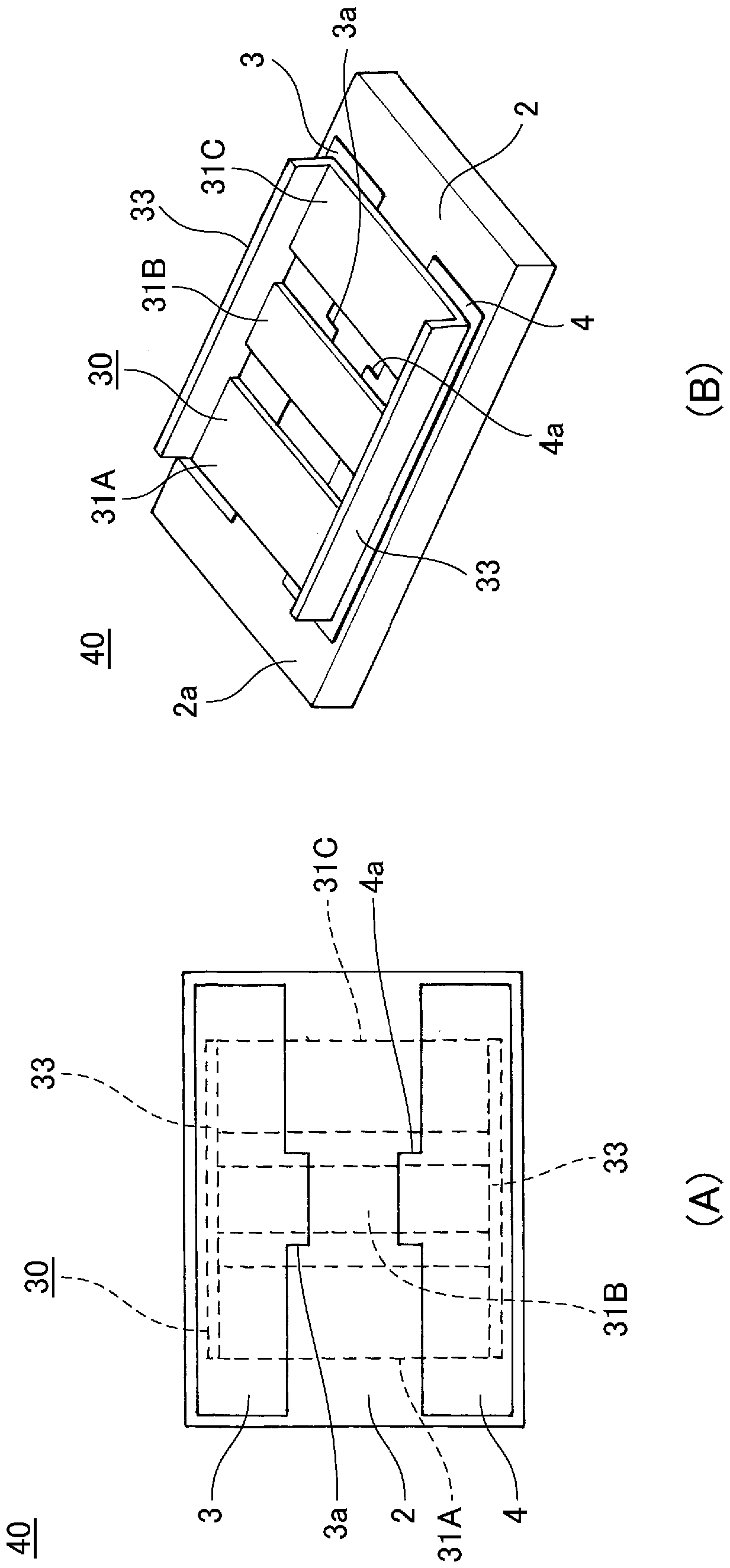

[0038] [Fuse device]

[0039] The fuse device 1 of the present invention is as figure 1 As shown, it is provided with: an insulating substrate 2, first and second electrodes 3, 4 provided on the insulating substrate 2, and installation between the first and second electrodes 3, 4, and self-heating due to the conduction of a current exceeding the rated current. The fuse element 5 is blown to cut off the current path between the first electrode 3 and the second electrode 4 .

[0040] The insulating substrate 2 is formed in a square shape by an insulating member such as alumina, glass ceramics, mullite, or zirconia, for example. In addition, as the insulating substrate 2 , materials used for printed wiring boards such as glass epoxy substrates and phenol substrates may be used.

[0041] First and second electrodes 3 and 4 are formed on opposite end portions of the insulating substrate. The first and second electrodes 3 and 4 are each formed of a conductive pattern such as Cu w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com