Fuel oil atomization device of smelting furnace burner

A fuel atomization and burner technology, applied in the direction of combustion method, combustion type, etc., can solve the problems of insufficient combustion of heavy oil, high cost of heavy oil use, and poor atomization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

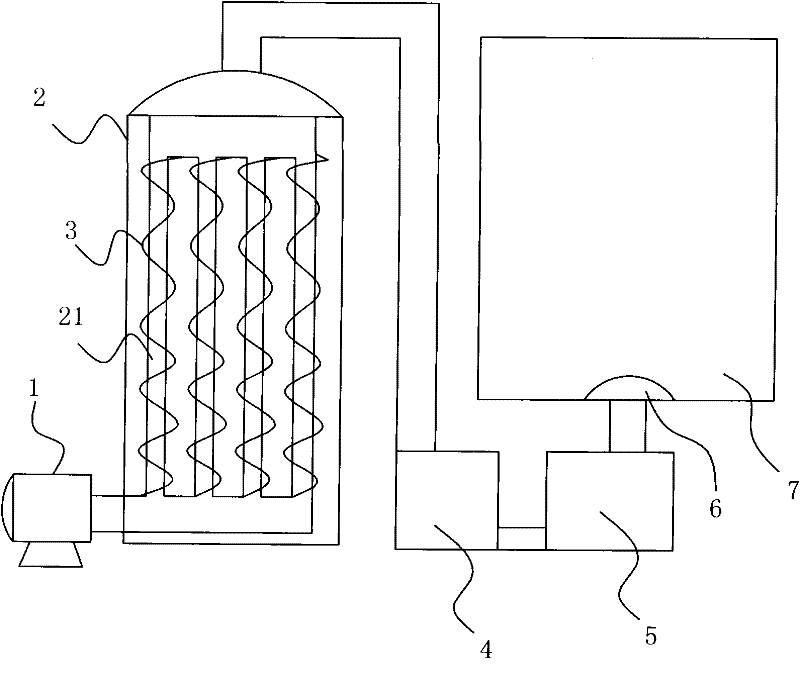

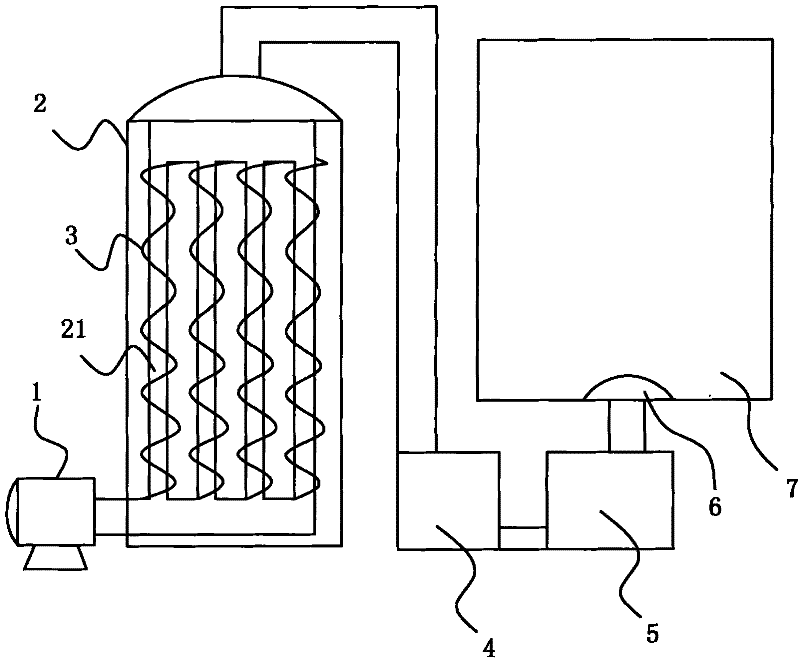

[0014] Example 1, such as figure 1 As shown, a fuel atomization device for a furnace burner includes an air intake fan 1, an air heater, an air dryer 4, an atomizing nozzle 6, a supercharger 5 and a furnace burner 7 connected together through pipelines, and the air The heater includes an air heating chamber 2 and a heater arranged in the air heating chamber 2 , and the heater is composed of a heating air pipe 21 and an electric heating wire 3 wound on the heating air pipe 21 .

[0015] The working principle is: the external air passes through the air intake fan 1 and enters the heating air pipe 21 in the air heater. After being heated by the electric heating wire 3, it enters the air dryer 4 for drying, and then enters the atomization after being pressurized by the supercharger 5 The nozzle 6 atomizes the heavy oil, and then ignites the atomized heavy oil sprayed into the furnace burner 7 to start the production of the furnace.

Embodiment 2

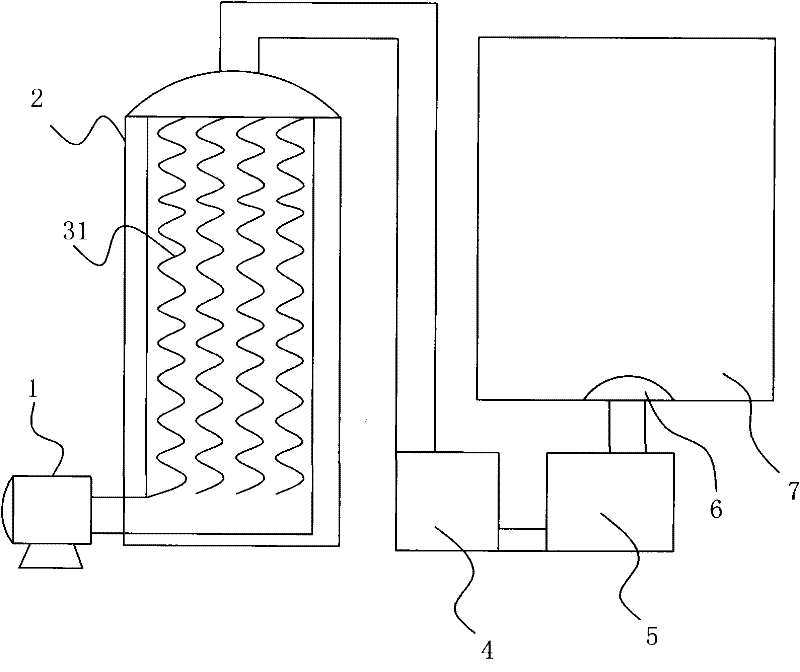

[0016] Example 2, such as figure 2 As shown, others are the same as in Embodiment 1, except that the heater is a heating tube 31 placed in the air heating chamber 2, and the heating tube 31 heats the air passing through the air intake fan 1 into the air heater , the heated air enters the air dryer 4 to dry, then pressurizes through the supercharger 5 and enters the atomizing nozzle 6 to atomize the heavy oil, and then ignites the atomized heavy oil sprayed into the furnace burner 7 to start the production of the furnace. The heating pipe 31 is composed of an insulating jacket and an electric heating wire passing through the insulating jacket, and the insulating jacket may be a ceramic tube or an asbestos coiled tube.

[0017] In the above embodiment, the external air can also be passed into the dryer 4 by the intake fan 1 for drying, then enter the air heating chamber 2 for heating, and finally enter the atomizing nozzle 6 to mist the heavy oil after being pressurized by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com