Patents

Literature

88results about "Material flash-point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Open flash point detection device for petroleum and petroleum products

InactiveCN101451969ARealize automated detectionSimple and fast operationMaterial flash-pointPetroleum productControl circuit

The invention discloses an open flash point detection device of petroleum and petroleum products, mainly comprising a high voltage ignition anode, a gas ignition arm, a sample detection cap, a flash point detection anode and cathode, a sample temperature sensor and a control circuit, wherein the ignition anode and the ignition arm are arranged above the panel, a cup rim of the detection cap is arranged on the panel, the detection anode and the detection cathode are respectively arranged at the center and the circumference of the cup rim of the detection cap, three uniformly distributed detection heads are arranged on the detection cathode, an ignition detection sensor is arranged nearby the ignition anode. The device is used for detecting the open flash point of the petroleum and the petroleum products, realizes automatic detection through an electronic circuit and a program control, operation is convenient, detection is reliable, detection precision is high, which satisfies requirement of international rules.

Owner:JIANGSU JIANGFEN ELECTROANALYTICAL INSTR

Testing system and method for testing oil sample closed flash point

InactiveCN106483164AEmission reductionReduce physical damageMaterial flash-pointHeating furnaceFlash point

The invention relates to a testing system and method for testing an oil sample closed flash point, wherein the testing system includes a sample cup for containing the oil sample, a micro heater for heating the oil sample in the sample cup, a high frequency micro arc for carrying on ignition of the oil sample and a flash point detection module for detecting the oil sample flash point. The testing system and method for testing an oil sample closed flash point further relates to a testing method for testing an oil sample closed flash point.

Owner:北京润道油液监测技术有限公司

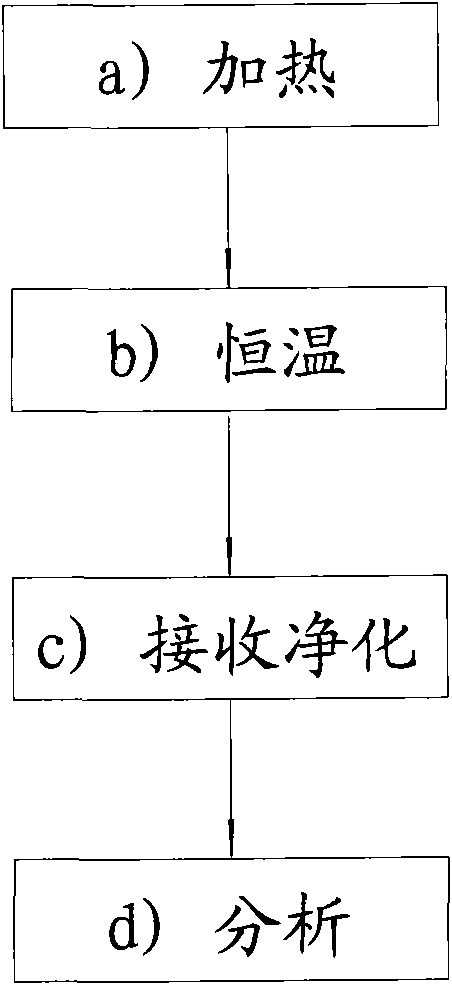

Method for analyzing coal pyrolysis

InactiveCN101598644AUniform pyrolysisFully pyrolyzedComponent separationMaterial heat developmentGas passingOil water

The invention discloses a method for analyzing coal pyrolysis, which comprises the following steps: a) under a condition isolated from the air, heating more than or equal to 0.5 kilogram of coal, and stirring the coal in the heating process, wherein the rate of temperature rise is less than or equal to 5 DEG C per minute; b) keeping the temperature constant when the temperature is raised to a set value; c) passing the generated product through an oil-water receiving bottle and an absorption bottle set in turn; and d) analyzing the collected product in the oil-water receiving bottle, and analyzing the gas passing through the absorption bottle. Compared with the prior art, the method for analyzing the coal pyrolysis performs more thorough analysis on the coal and the pyrolysis product, and the data obtained by the analysis is also more informative and credible. The method for analyzing the pyrolysis of the coal is applicable to the detailed analysis of various coals and the pyrolysis products thereof.

Owner:CHINA COAL ENERGY HEILONGJIANG COAL CHEM

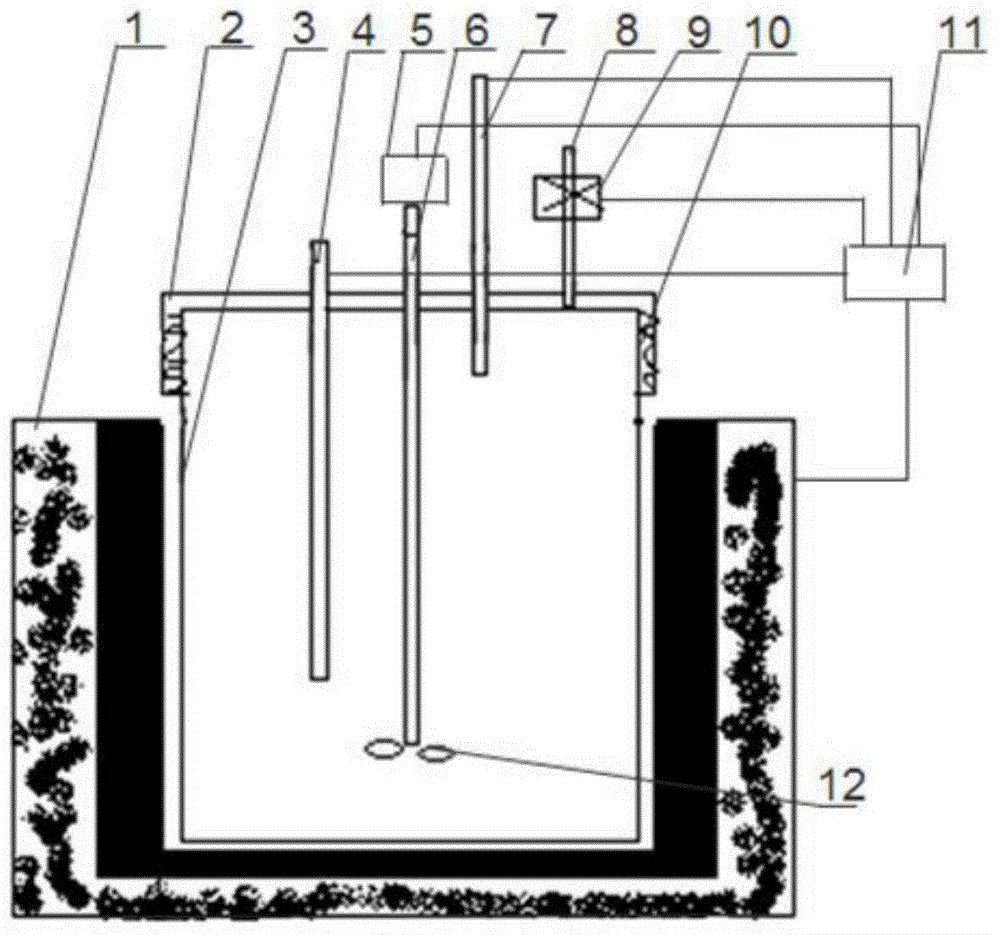

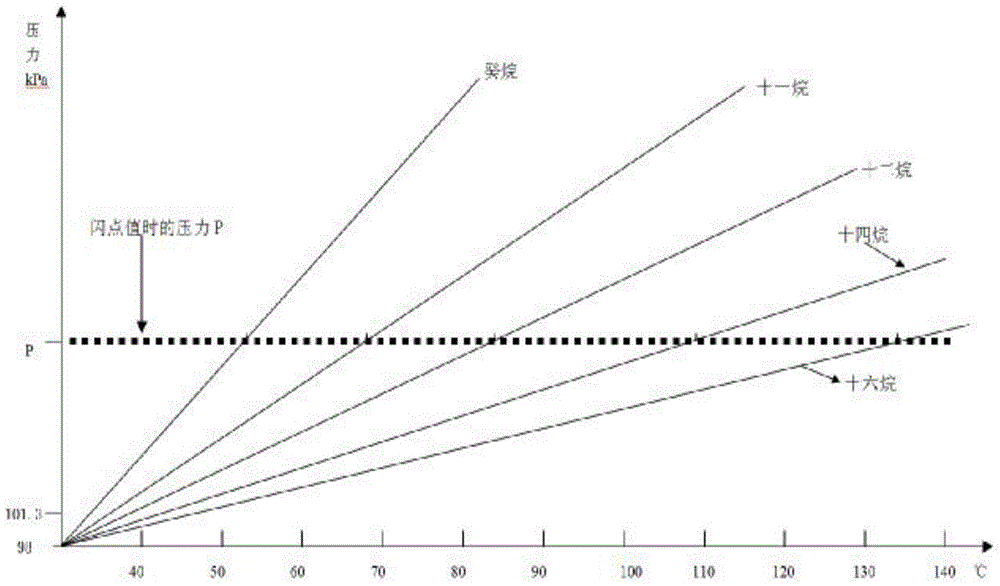

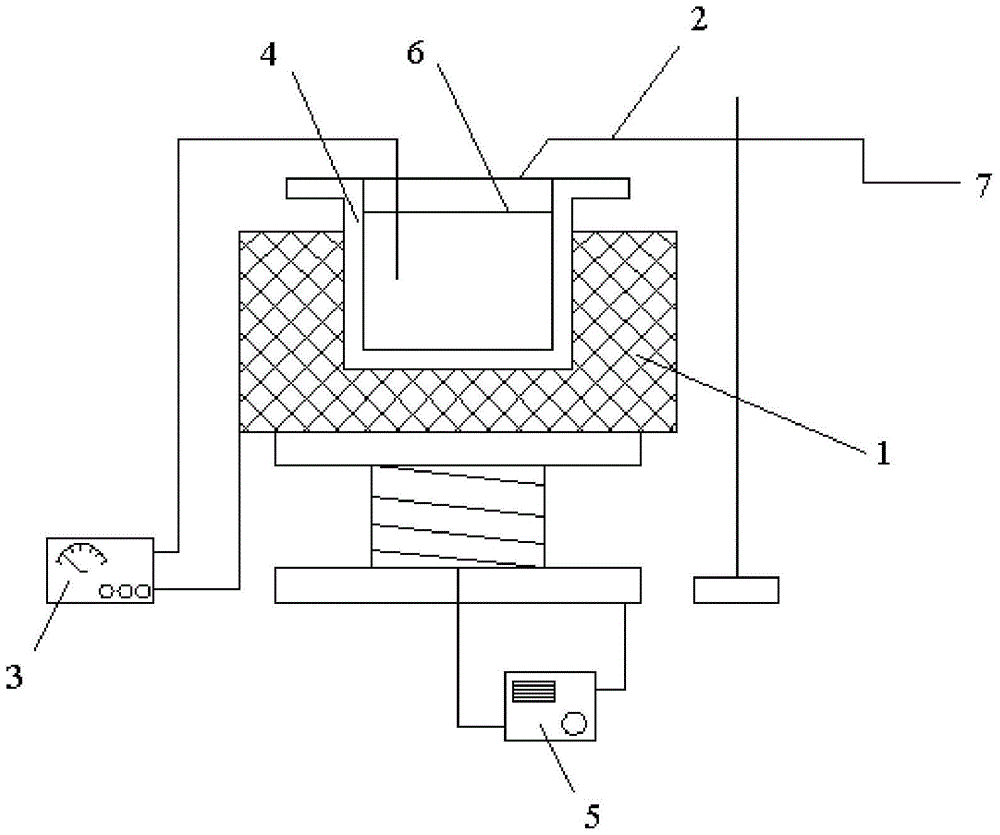

Automatic measuring device and method for flash point of insulating oil special for electric power

InactiveCN104535614AHigh detection sensitivityHigh degree of automationMaterial flash-pointPlatinum resistanceElectric power system

The invention relates to an automatic measuring device for the flash point of insulating oil special for electric power. The device comprises a concave heating groove connected with a control main machine, a sealing oil cup in the concave heating groove, and an oil cup cover on the sealing oil cup, wherein the oil cup cover is provided with a platinum resistance thermometer, a stirring rod, a pressure sensor and a burning exhaust pipe through holes in an inserting mode, the top end of the stirring rod is provided with a motor, the bottom end of the stirring rod is provided with blades, the pressure sensor is connected with the control main machine, and the burning exhaust pipe is provided with a solenoid valve. A determining method for the flash point comprises the steps that (1) a pressure and temperature change relationship of each standard substance is built in the control main machine; (2) a work standard curve of the flash points and the pressure relationship is built according to the known flash points of the standard substances; (3) the device is started to heat a tested oil product; (4), the flash point temperature of the tested oil product is determined. The device and method are high in detection sensitivity, high in degree of automation, free of open fire, safe, reliable and capable of avoiding the problem of environmental pollution in the experiment process.

Owner:STATE GRID CORP OF CHINA +1

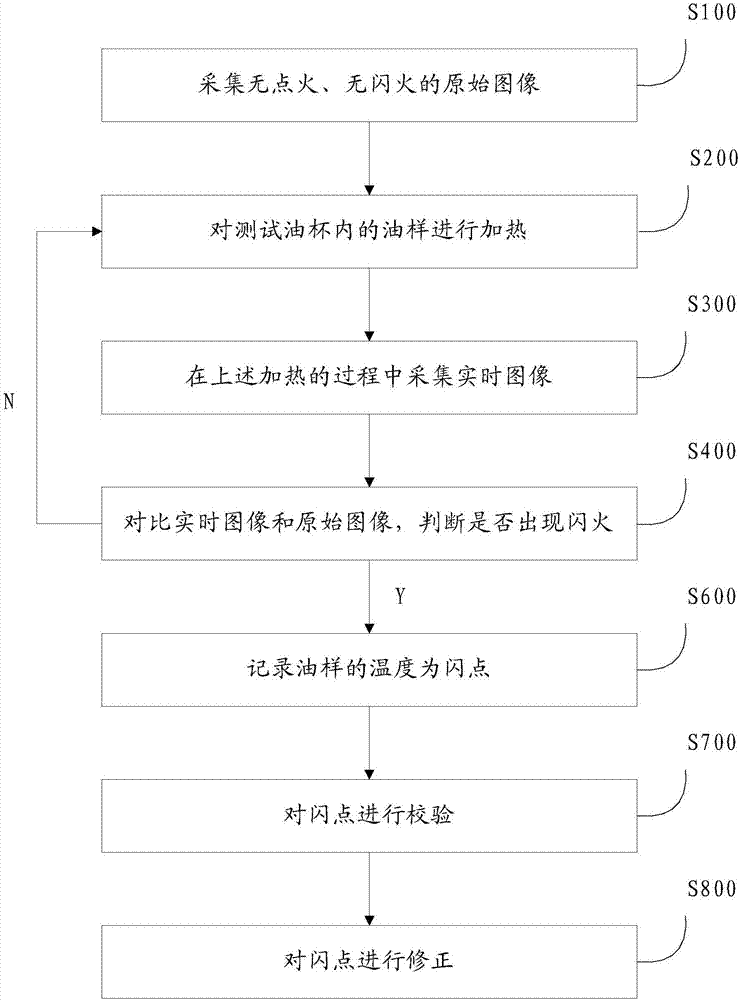

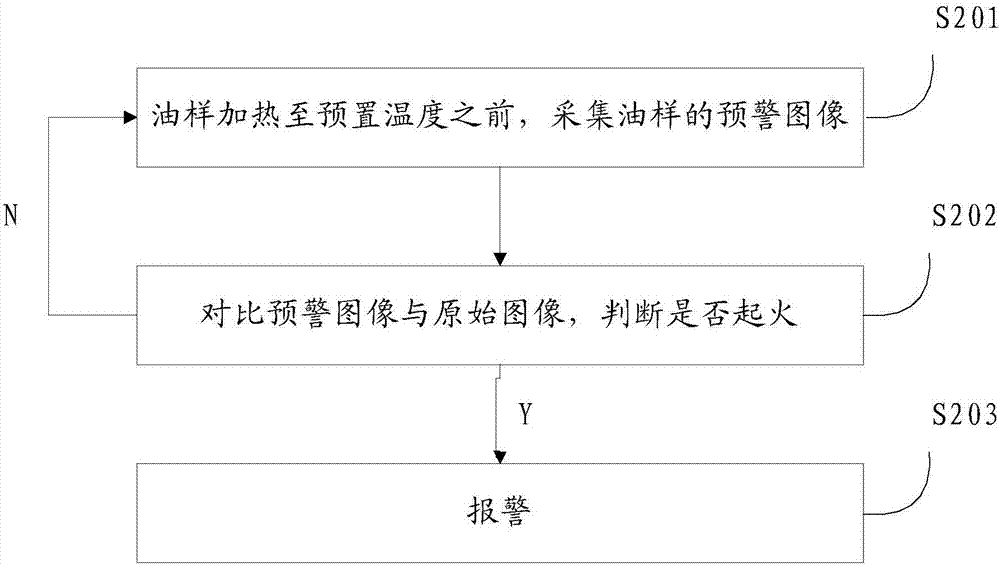

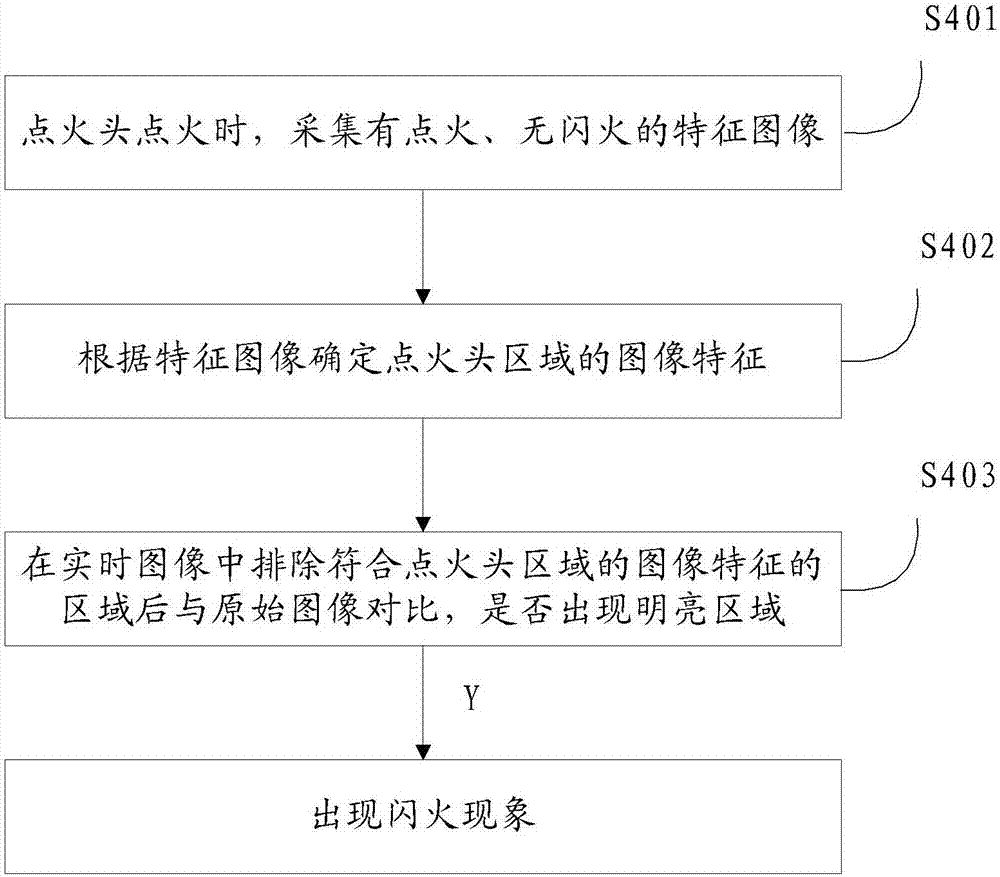

Method and system for determining open flash point by using CCD mode

The invention discloses a method and a system for determining the open flash point by using a CCD mode. The method comprises: (1) acquiring an original image with no ignition and no flash fire; (2) heating the oil sample in a test oil cup; (3) acquiring real-time images during the heating process; (4) comparing the real-time images to the original image, and determining whether flash fire occurs; (5) repeatedly performing the steps (2)-(4) if the flash fire does not occur; and (6) recording the temperature of the oil sample as the flash point if the flash fire occurs. The system comprises a heating device, a CCD acquisition device, a temperature acquisition device, and a processor. According to the present invention, whether the flash fire occurs is automatically recognized by using the CCD technology, such that the labor force is liberated, the labor cost is saved, and the eyes of operators are protected; 2, the feature of the ignition head area image is eliminated, such that the blue light interference of the ignition flame can be effectively removed, and the accuracy of the determination result can be improved; and 3, with the firing pre-warning step, the setting of the too high preset temperature (exceeding the flash point) can be prevented.

Owner:HKY TECH

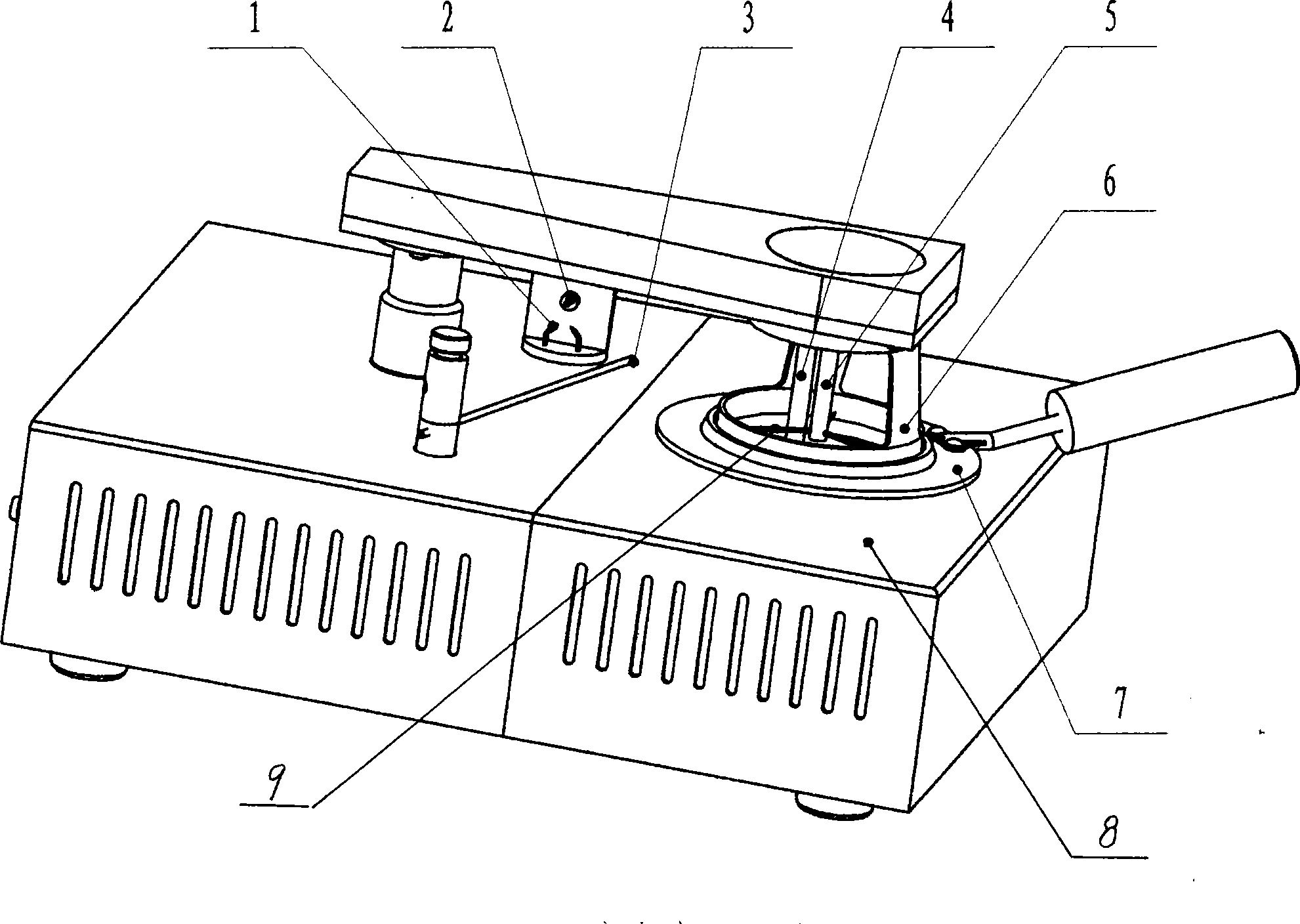

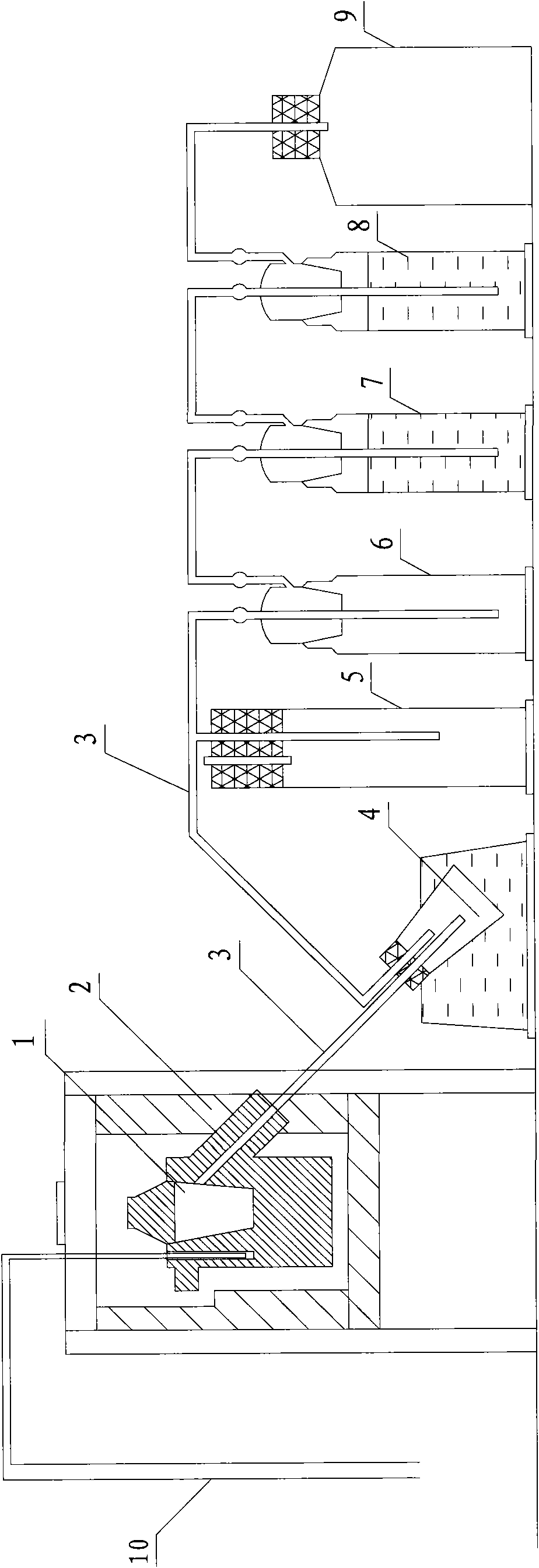

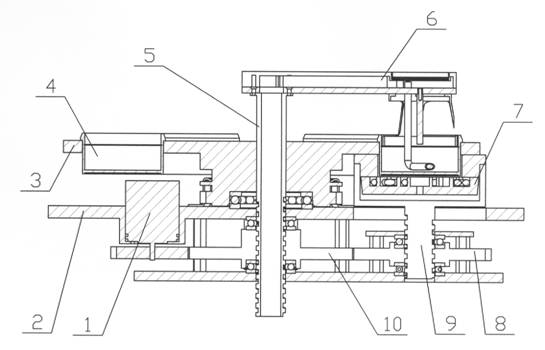

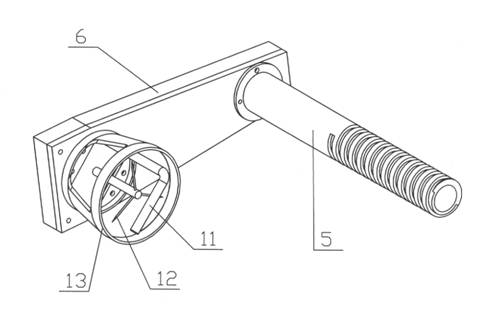

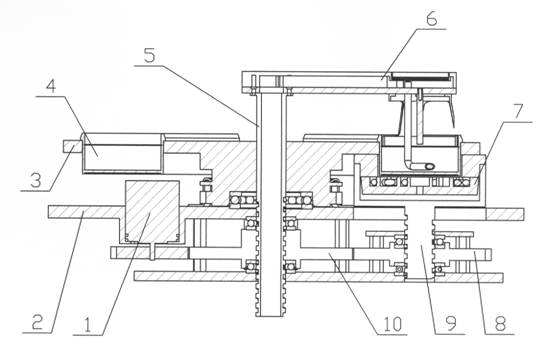

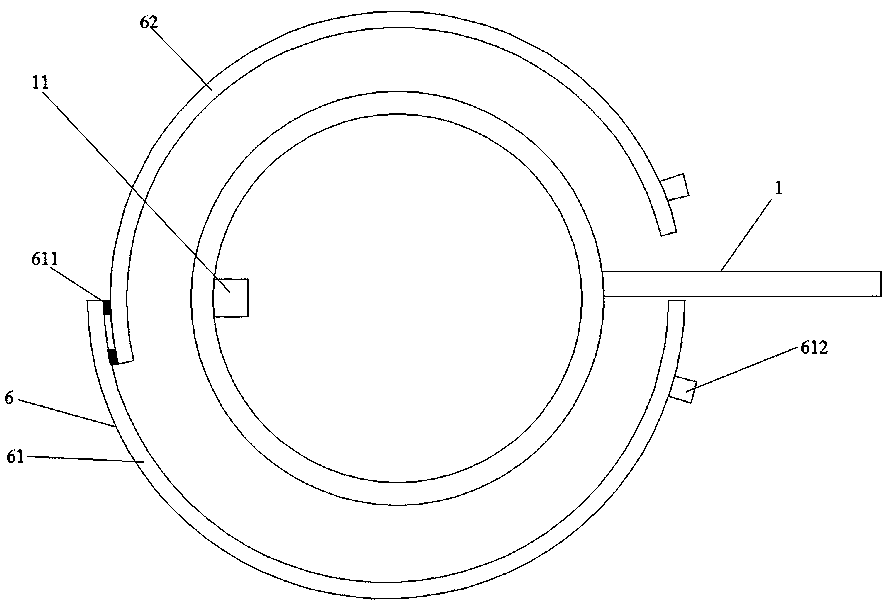

Open flashing point automatic detection device for petroleum and petroleum products

InactiveCN102565127ASimple and fast operationHigh degree of automationMaterial flash-pointPetroleum productFlash point

The invention discloses an open flashing point automatic detection device for petroleum and petroleum products, mainly comprising an automatic detecting arm, a sequence feeding disc, sample detecting cups, a heating device, a power-driven device and a control and detection circuit, wherein the automatic detecting arm is provided with a lifting screw at the tail end, with a temperature sensor, a flashing point detecting anode and cathode at the head end, and with a gas ignition arm, a high voltage ignition anode and an ignition detecting sensor; there are 6-10 sample detecting cups circumferentially and uniformly arranged on the feeding disc; the heating device is arranged below the feeding disc and provided with a lifting mechanism. The device is used for automatic detection of the petroleum and petroleum products open flashing point, has simple operation, high degree of automation, accurate and reliable measurement, and has obvious improvement compared to the existing artificial detection device.

Owner:JIANGSU JIANGFEN ELECTROANALYTICAL INSTR

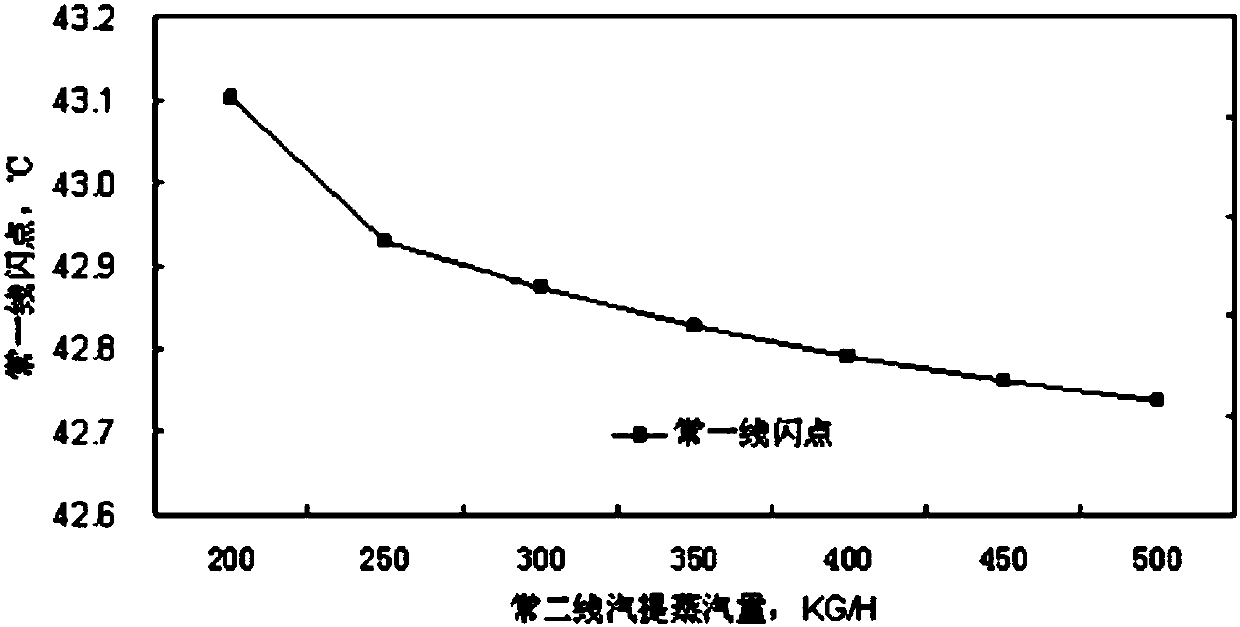

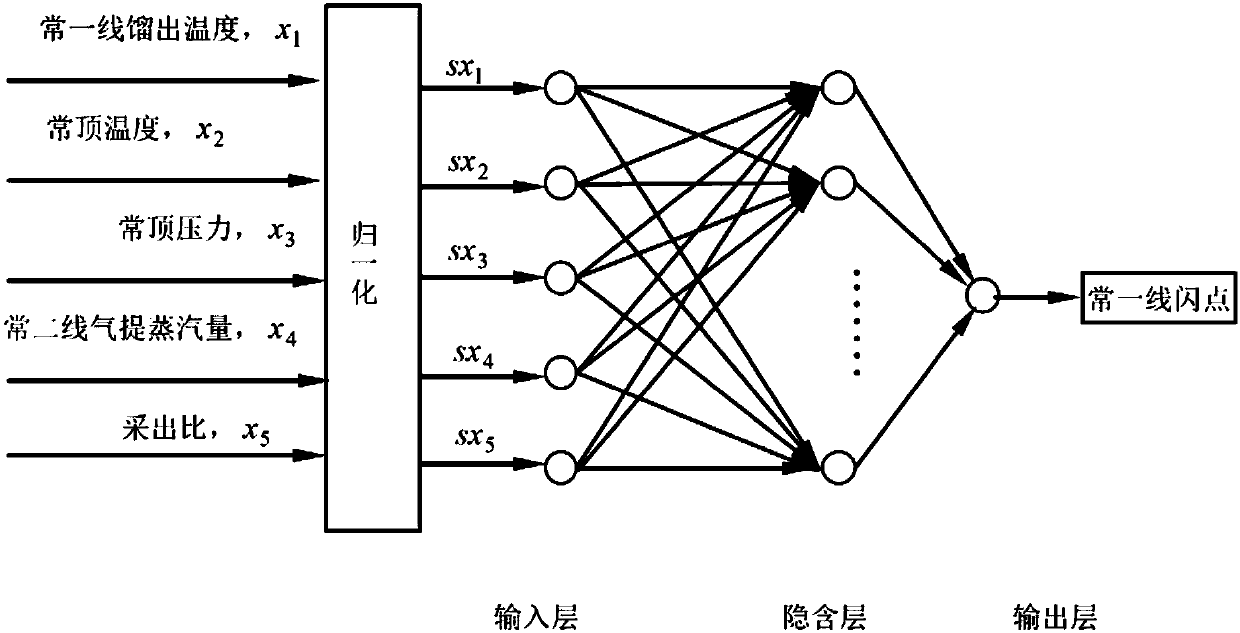

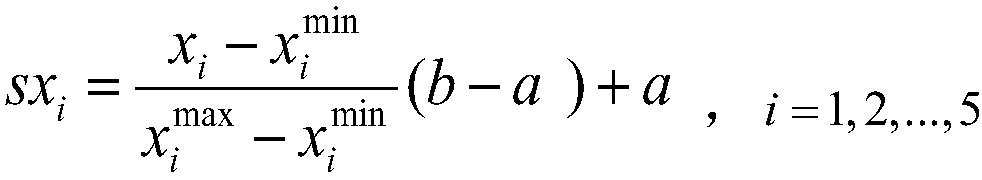

On-line soft measuring method of regular first-line oil flash point

InactiveCN108204997AReduce training timeSmall amount of calculationMaterial flash-pointNetwork modelMonitoring and control

The invention relates to an on-line soft measuring method of a regular first-line oil flash point. The method comprises selecting and constructing key variables such as a regular first-line distillation temperature, a regular top temperature, regular top pressure, a regular second-line stripping steam flow and a regular first-line extraction-feeding ratio total amount as neural network model inputvariables for influencing the regular first-line oil flash point, building a regular first-line oil flash point soft meter based on an artificial neural network model through the regular first-line oil flash point as a corresponding output, and correcting a model output through a manual analysis value to realize the real-time monitoring and control of the quality of the regular first-line productin the atmospheric tower. The method can guide an operator to timely adjust the operation process. The flash point estimated value provided by the soft meter can provide basis for the process control, optimize the operation process and improve the crude oil extraction rate of the atmospheric and vacuum distillation unit.

Owner:PETROCHINA CO LTD

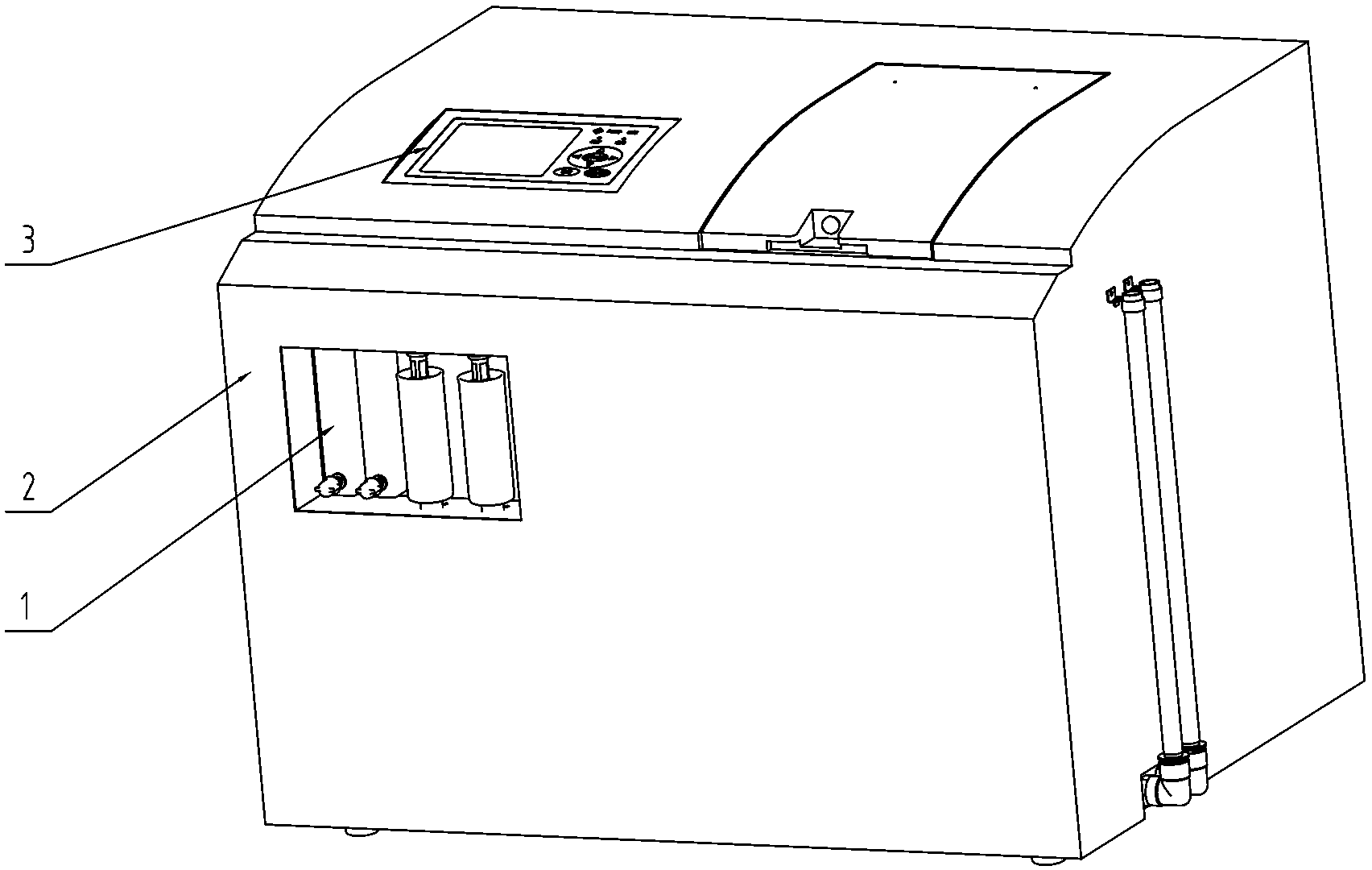

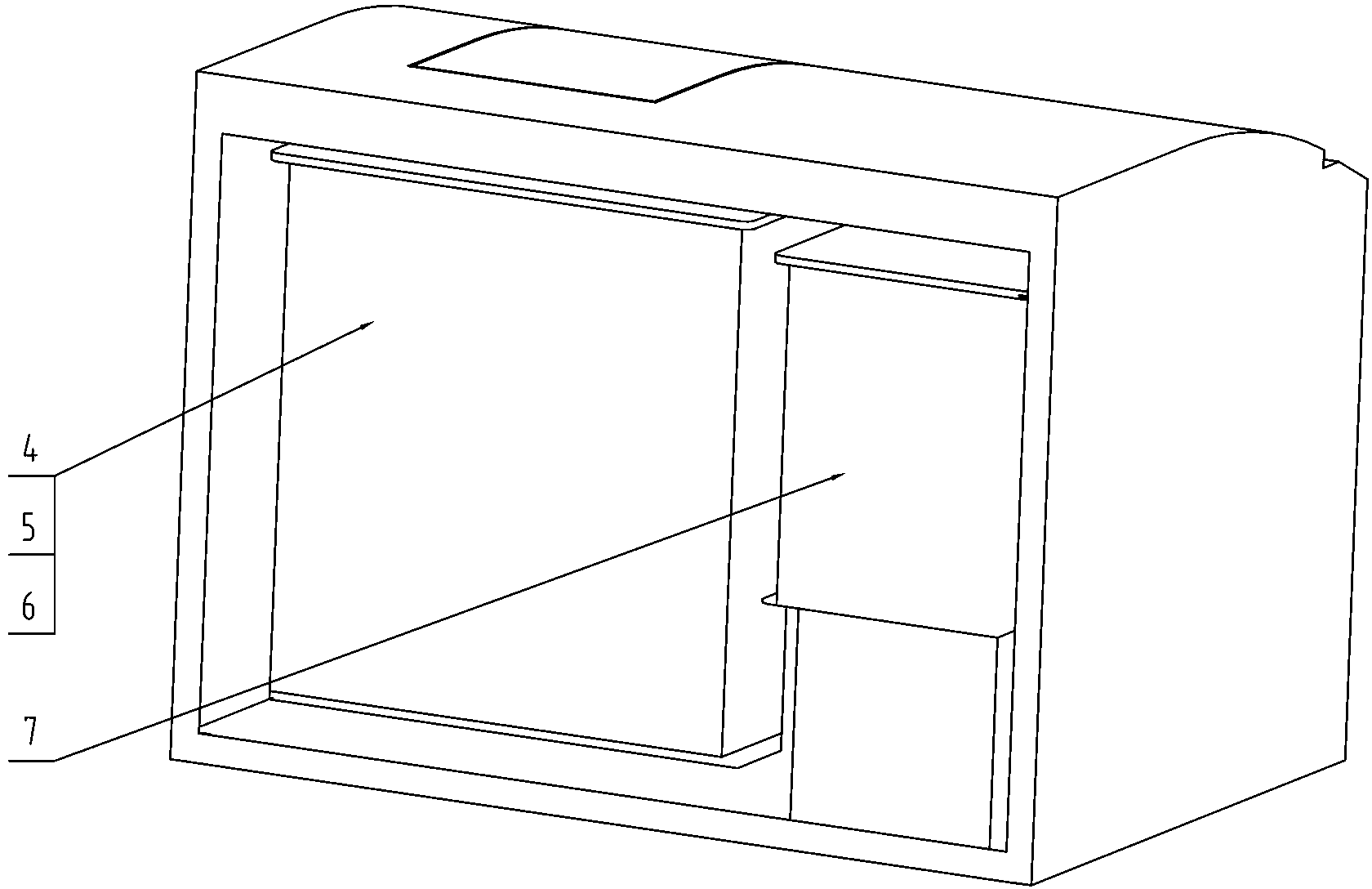

Heat insulation type spontaneous combustion testing equipment

ActiveCN103235004ACompact structureLow costMaterial heat developmentMaterial flash-pointSpontaneous combustionWater baths

The invention discloses heat insulation type spontaneous combustion testing equipment which comprises a water bath component, a heating component, a preheating component, a reactor, a gas circuit system and a control system, wherein the reactor is used for containing a coal sample to be detected and arranging the coal sample in the water bath component; the heating component is communicated with the water bath component and is used for heating a water environment in the water bath component; the reactor is communicated with an external air supply part through the gas circuit system; and the preheating component is arranged on the gas circuit system. The heat insulation type spontaneous combustion testing equipment has the advantages of simple and compact structure, low cost, easiness and convenience in operation, high degree of automation, high testing precision and the like.

Owner:HUNAN SUNDY SCI & TECH DEV

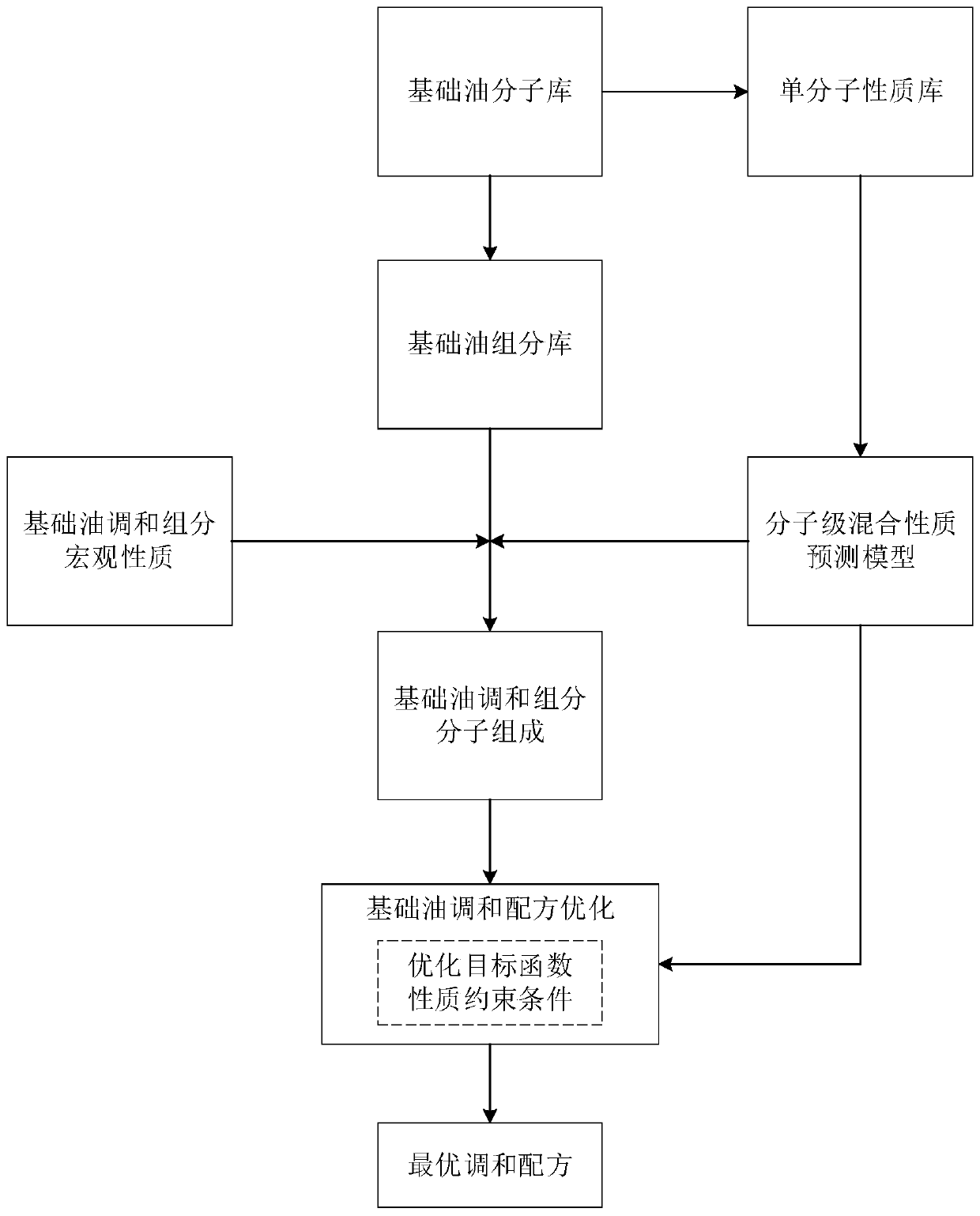

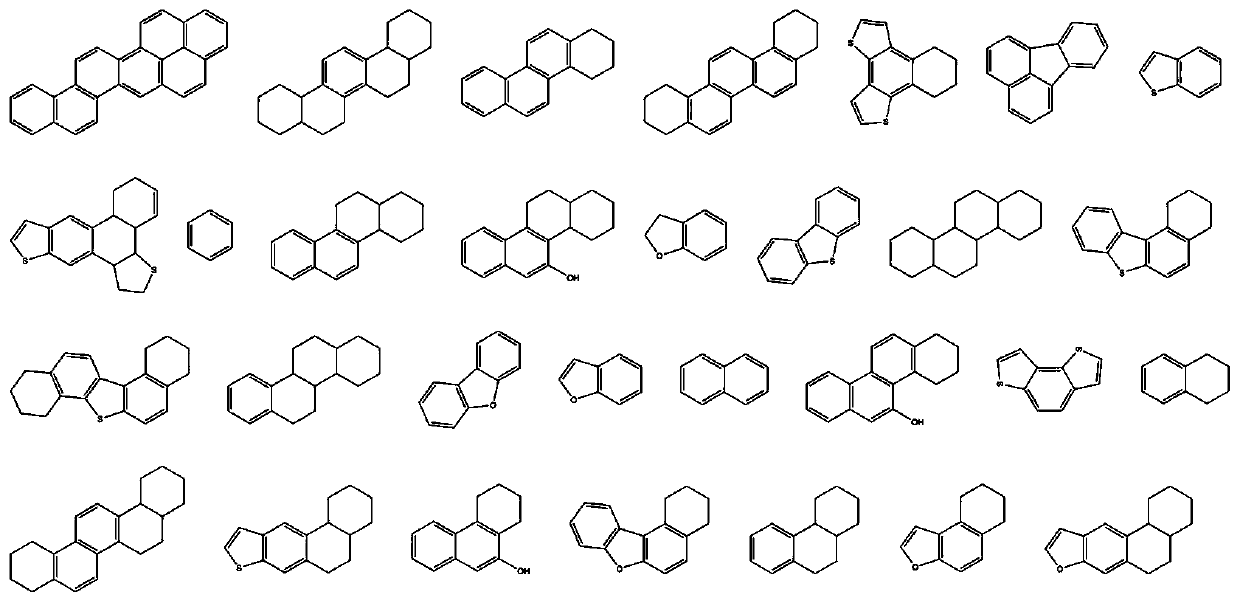

Molecular-level base oil blending optimization method

ActiveCN109949870AImprove accuracyReduce the amount of experimentsFlow propertiesMaterial flash-pointEconomic benefitsMaterial resources

The invention relates to a molecular-level base oil blending optimization method. According to the molecular-level base oil blending optimization method, a molecular-level physical property model is used for calculating base oil components and product property. Compared with methods such as traditional empirical formula, the molecular-level base oil blending optimization method has advantages of effectively improving accuracy in property predicting, and furthermore changing a condition of incapability of simultaneously satisfying multiple property indexes or overhigh property margin in blending, realizing accurate control to product quality and production cost, effectively improving economic benefit in blending production, preventing a large amount of experiment working required in a traditional method, saving manpower and material resources and greatly reducing time required in determining a blending formula.

Owner:SYSPETRO TECH CO LTD

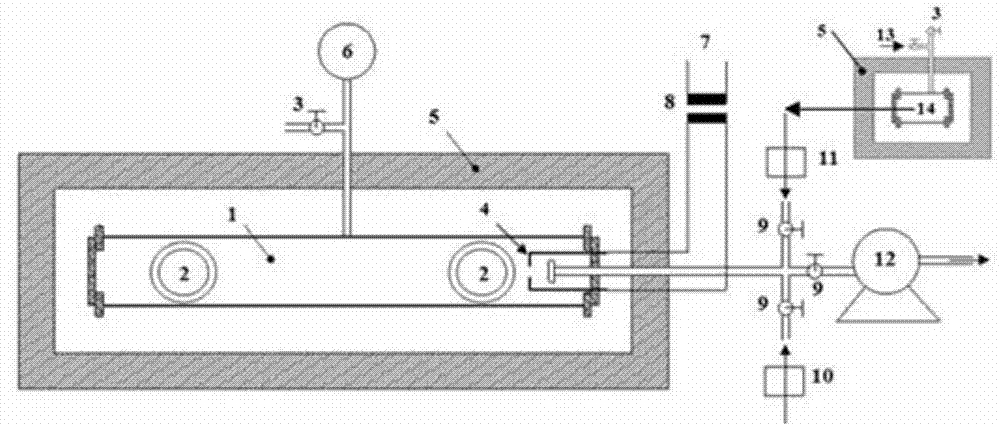

Liquid gasifying and flow control device for measuring combustion limit of combustible liquid steam

InactiveCN103616411AFlammability limitGuaranteed feasibilityMaterial flash-pointInvestigating phase/state changeTemperature controlCombustion

The invention provides a liquid gasifying and flow control device for measuring the combustion limit of combustible liquid steam. The liquid gasifying and flow control device comprises a liquid storage pipe, a gas storage pipe, a measuring pipe, a heating and temperature-control device, ignition equipment, a high-temperature-resistant pipeline, a vacuum pressure gauge, a high-temperature-resistant valve and a vacuum pump, wherein the liquid storage pipe, the gas storage pipe and the measuring pipe are connected in sequence by pipelines; the liquid storage and the measuring pipe are respectively provided with a safety valve. The liquid gasifying and flow control device provided by the invention has the advantages that the promotion is high, not only can multiple combustible liquid steam be measured, but also the measurement under different pressures can be carried out simultaneously.

Owner:UNIV OF SCI & TECH OF CHINA

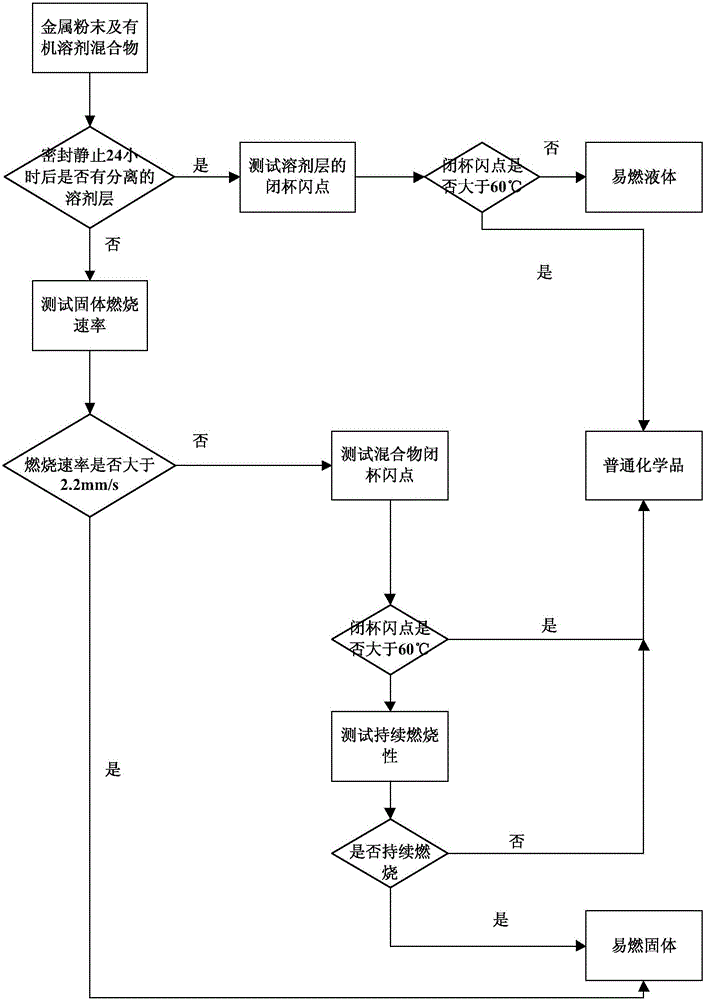

Combustibility evaluation method of metal powder and solvent mixture thereof

InactiveCN105136852AAccurately assess safetyEliminate the risk of accidentsMaterial heat developmentMaterial flash-pointEvaluation resultGeneral chemist

The invention discloses a combustibility evaluation method of metal powder and a solvent mixture thereof. The method comprises the following steps: firstly, standing a mixture and observing whether the mixture has a solvent layer or not; if so, testing a closed cup flash point of the solvent layer; if a measured closed cup flash point value is more than 60 DEG C, determining that the mixture is a common chemical; if the measured closed cup flash point value is smaller than 60 DEG C, determining that the mixture is flammable liquid; secondly, combusting metal powder without the solvent layer; testing a solid combustion speed of the metal powder; if a measured combustion speed value is more than 2.2mm / s, determining that the metal powder is a flammable solid; then, measuring a closed cup flash point of a mixture with the measured combustion speed value smaller than 2.2mm / s; if the measured closed cup flash point value is more than 60 DEG C, determining that the mixture is the common chemical; finally, continuously combusting the mixture with the closed cup flash point value smaller than 60 DEG C and observing whether the mixture is continuously combusted or not; if so, determining that the mixture is the flammable solid; otherwise, determining that the mixture is the common chemical. The method disclosed by the invention has the advantages of reliable evaluation results and stable utilization conditions.

Owner:CHINA PETROLEUM & CHEM CORP +1

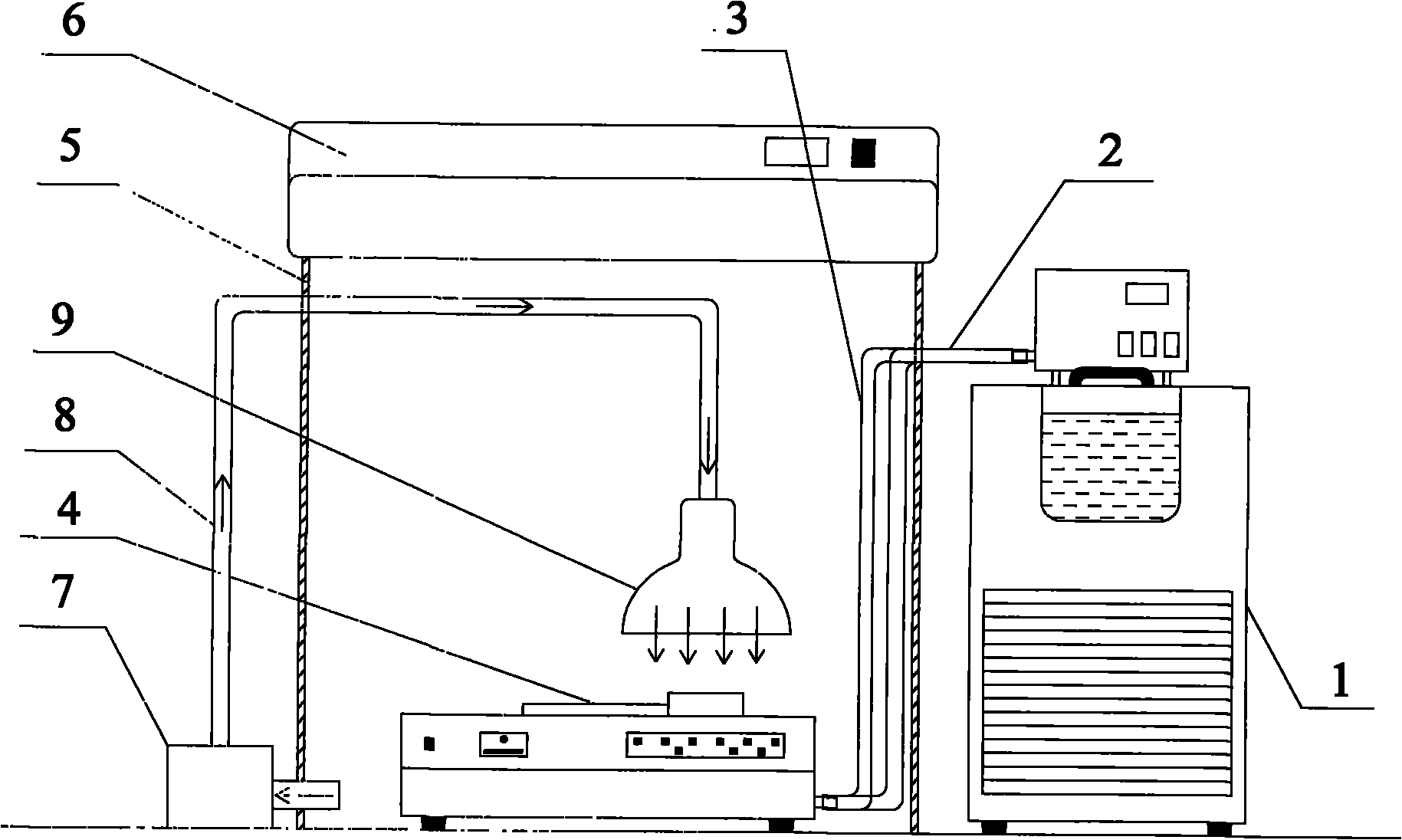

Combined type refrigerant low-temperature flash point testing system

ActiveCN101839877AExtended Low Temperature Test RangeConserve waterMaterial flash-pointFiltrationThermal insulation

The invention relates to a combined type refrigerant low-temperature flash point testing system. In the primary refrigeration (external cooling), a Freon compressor (heat pump) is utilized to reduce the temperature of a flow medium, and the medium is in closed cycle; and in the secondary refrigeration (internal cooling), a semiconductor cold reactor is utilized, the heat dissipation end of the cold reactor is cooled by the low-temperature flow medium so as to greatly reduce the temperature of the refrigeration end. The testing system consists of an external cooling device, a flash point testing device, an isolation hood and an air drying and filtering device, wherein the flash point testing device is connected with the external cooling device via a thermal insulation pipeline, and is isolated from the environment by an organic glass cover, and an air opening of the air drying and filtering device is arranged in the cover. Compared with the prior art, the invention extends the low-temperature testing range of the existing rapid equilibrium closed cup flash point instrument, eliminates the tap water cooling method when being used, and saves water, gas drying avoids the defects of frosting and condensation, and the exhaust gas is adsorbed and discharged via filtration, which has certain energy saving and environment protection value.

Owner:SHANGHAI RES INST OF CHEM IND

Method for testing closed-cup flash point of water-containing lubricating oil

The invention relates to a method for testing a closed-cup flash point of water-containing lubricating oil, which mainly solves the technical problems of long water removal time, low efficiency and influence on flash point testing timeliness in the prior art. The method comprises the following steps: (a) enabling the water-containing lubricating oil with the water content being 0.5%-8% by weight to be in full contact with a dryer, wherein the water removal efficiency is 0.0001-0.001min<-1> and refers to the weight of the water-containing lubricating oil passing through the unit weight of the dryer within a unit time; and (b) enabling the lubricating oil after water removal to enter a flash point test instrument for flash point testing. According to the technical scheme for flash point testing, the method well solves the problems and can be used for testing the closed-cup flash point of the water-containing lubricating oil during industry practice.

Owner:CHINA PETROLEUM & CHEM CORP

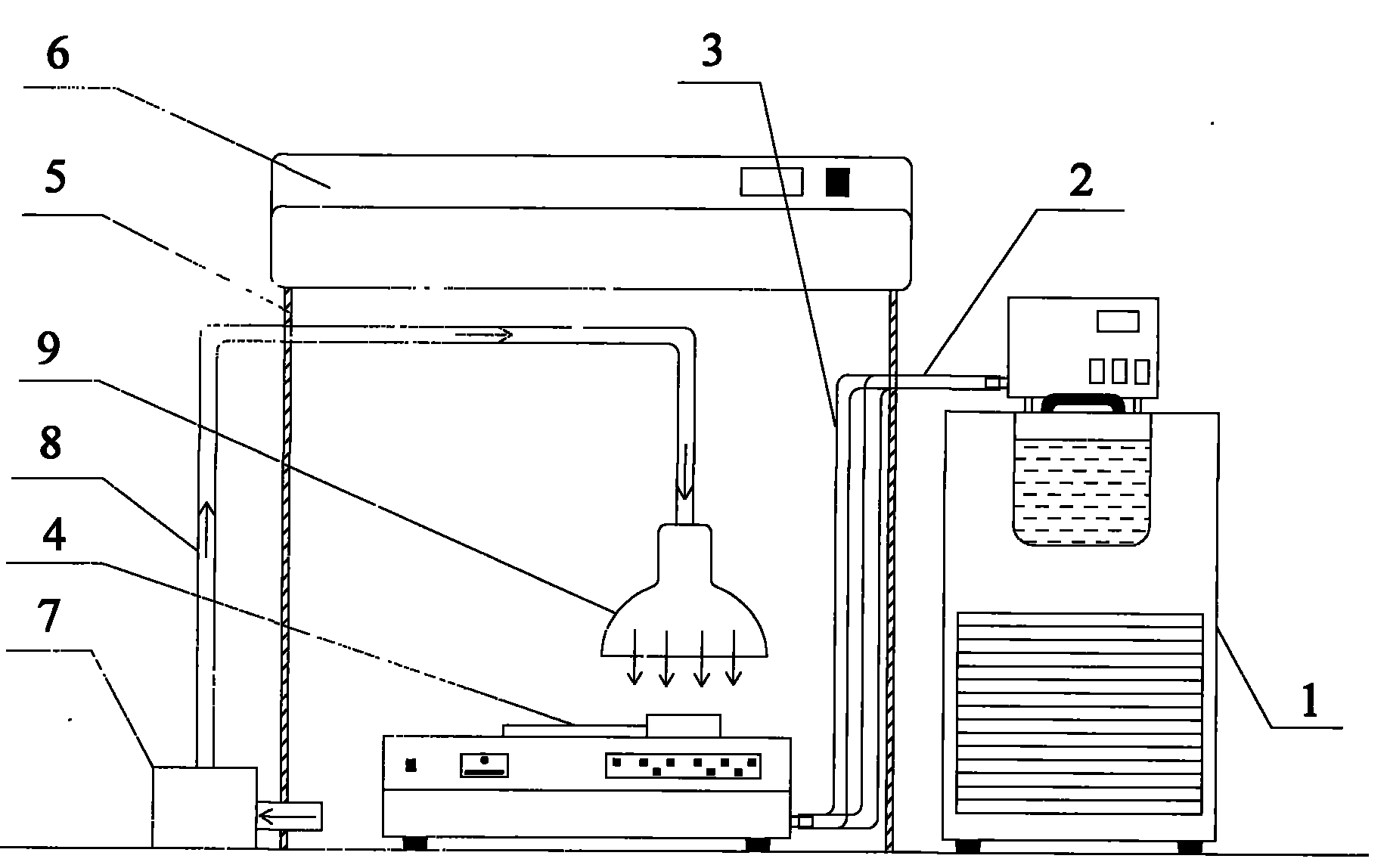

Method for testing flash point of combustible liquid in high-pressure environment

PendingCN112083040ASolving Flashpoint Testing ProblemsHigh precisionMaterial flash-pointTemperature controlLiquid fuel

The invention discloses a method for testing a flash point of combustible liquid in a high-pressure environment. The method comprises the steps of opening an end cover and taking out a sample cell; adding liquid fuel into the sample cell; putting the sample cell filled with the sample into a tank body and sealing the container; inflating high-pressure gas into the sealed pressure-resistant container to reach the test pressure by using a diaphragm compressor,and then closing; setting a temperature rise program through a temperature controller, and heating the liquid fuel in the sample cell by an electric heating ring; continuously igniting fractions at the upper part of the liquid fuel through a high-voltage electric spark igniter, and recording whether the sample fractions are ignited or not by using a high-speed video recorder; determining the flash point value of the liquid fuel sample under the pressure; and taking out the sample cell after the test, and calculating the reaction amount of the sample. The method can be used for testing the flash point of a substance in a high-pressure environment, and is simple to operate, good in pressure resistance and corrosion resistance, high in precision, high in safety and good in visuality.

Owner:NANJING UNIV OF SCI & TECH

Closed-cup flash point instrument

InactiveCN104880485ASimple structureImprove general performanceMaterial flash-pointEngineeringProtection ring

The invention discloses a closed-cup flash point instrument. The closed-cup flash point instrument comprises a horizontal working plane, a vertical working plane, a machine head, a lifting table, a sweeping slide way, a fixing ring, a flash point protection ring, an instrument box, an oil cup opening, an ignition cover fixing hole, a bolt and connecting holes, wherein the horizontal working plane is perpendicular to the vertical working plane; the instrument box is provided with a workbench, and is fixedly arranged on the workbench via the bolt; the horizontal working plane is provided with the oil cup opening which is provided with the flash point protection ring; the flash point protection ring is provided with the fixing ring; the lifting table is arranged at one side of the workbench on the instrument box; one end of the lifting table is fixedly arranged on the instrument box, and the other end surface is provided with the connecting holes. The closed-cup flash point instrument is simple in structure; the opened-cup mode and the closed-cup mode are convenient to switch, and are high in universality; the production and detection costs are reduced; the closed-cup flash point instrument is high in output signal, flexibility and anti-interference capability, and cannot generate leakage detection and misinformation.

Owner:苏州华安普电力科技股份有限公司

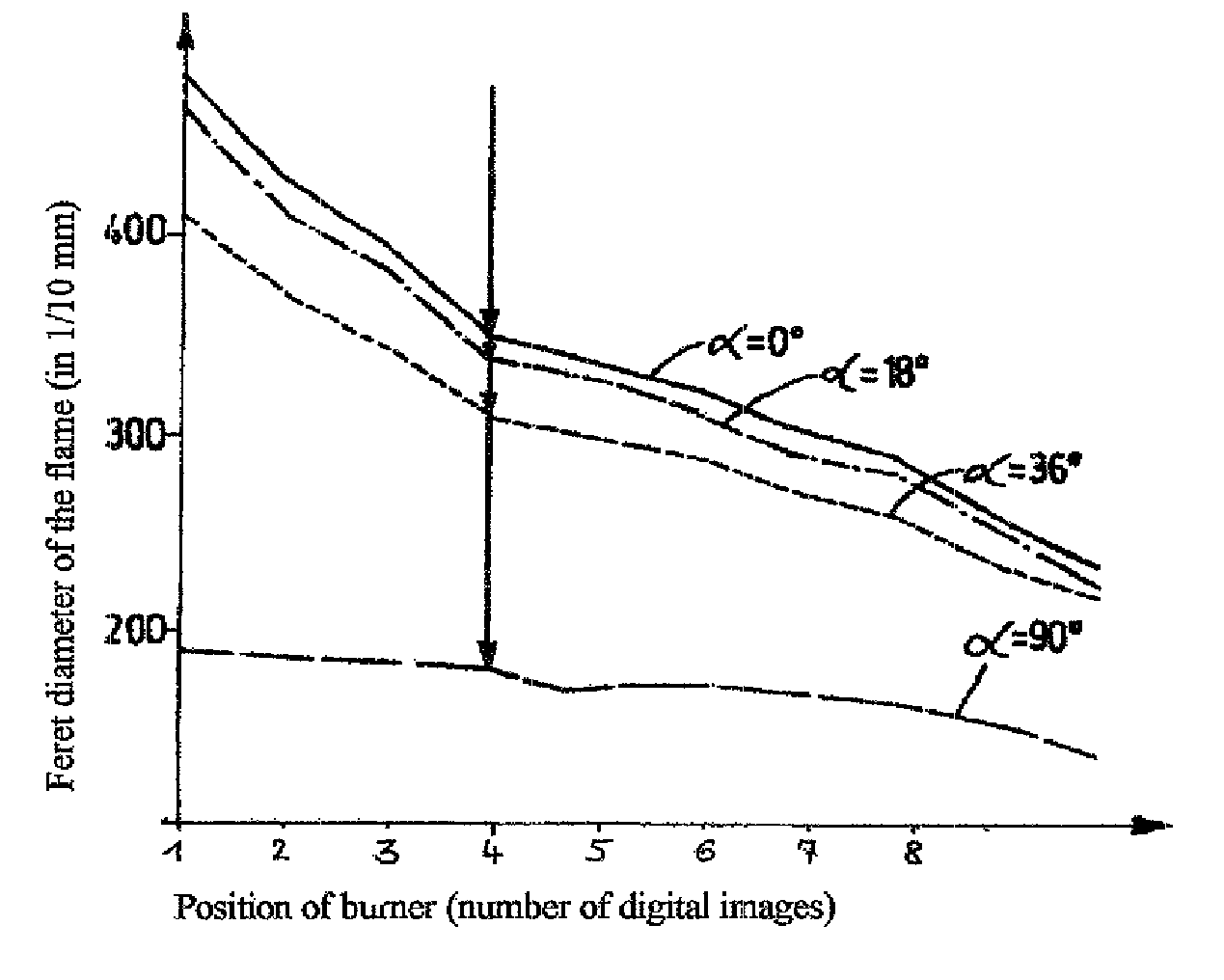

Method and device for determining the smoke point of hydrocarbons

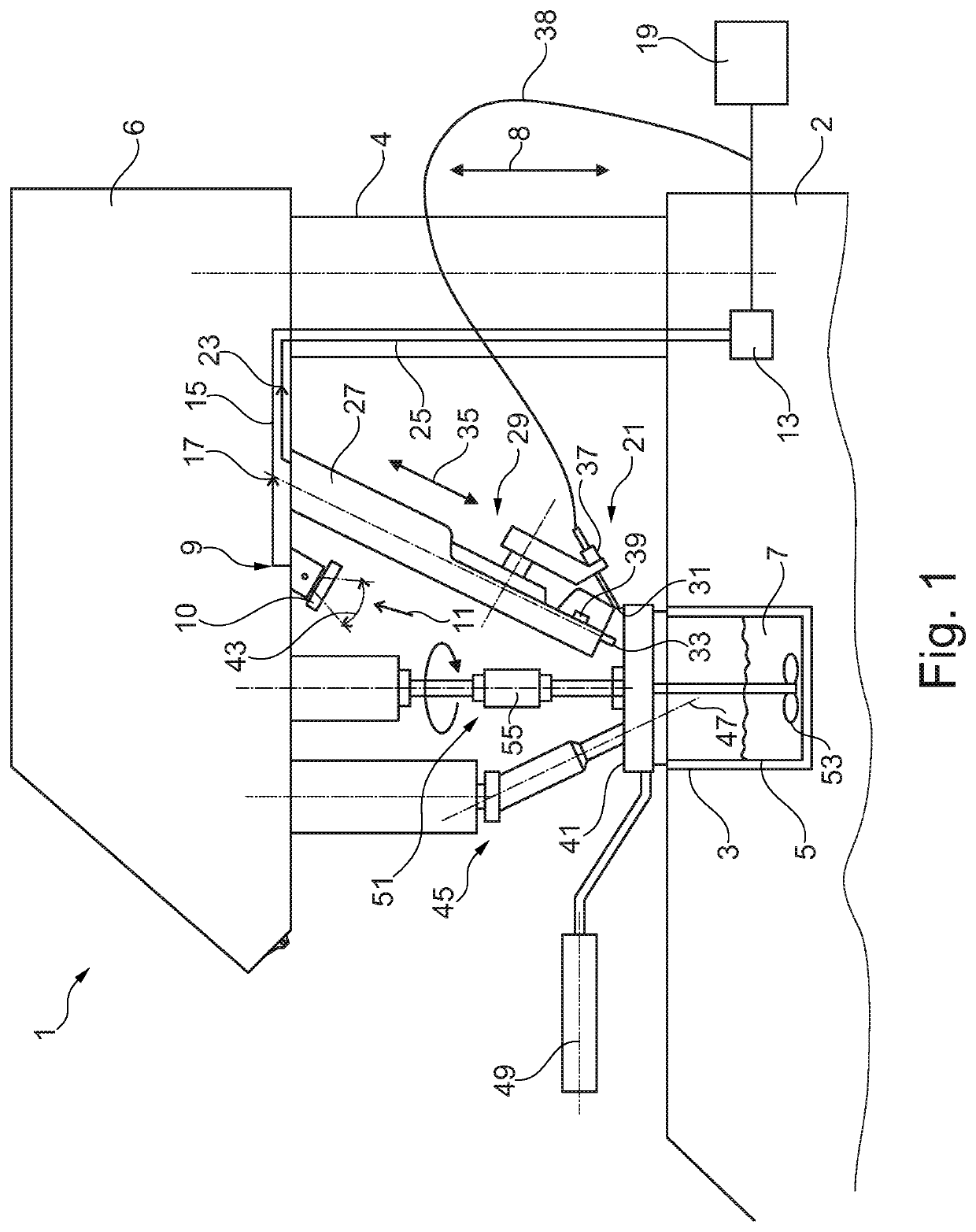

ActiveUS7829343B2Chemical analysis using combustionMicrobiological testing/measurementCombustorSmoke point

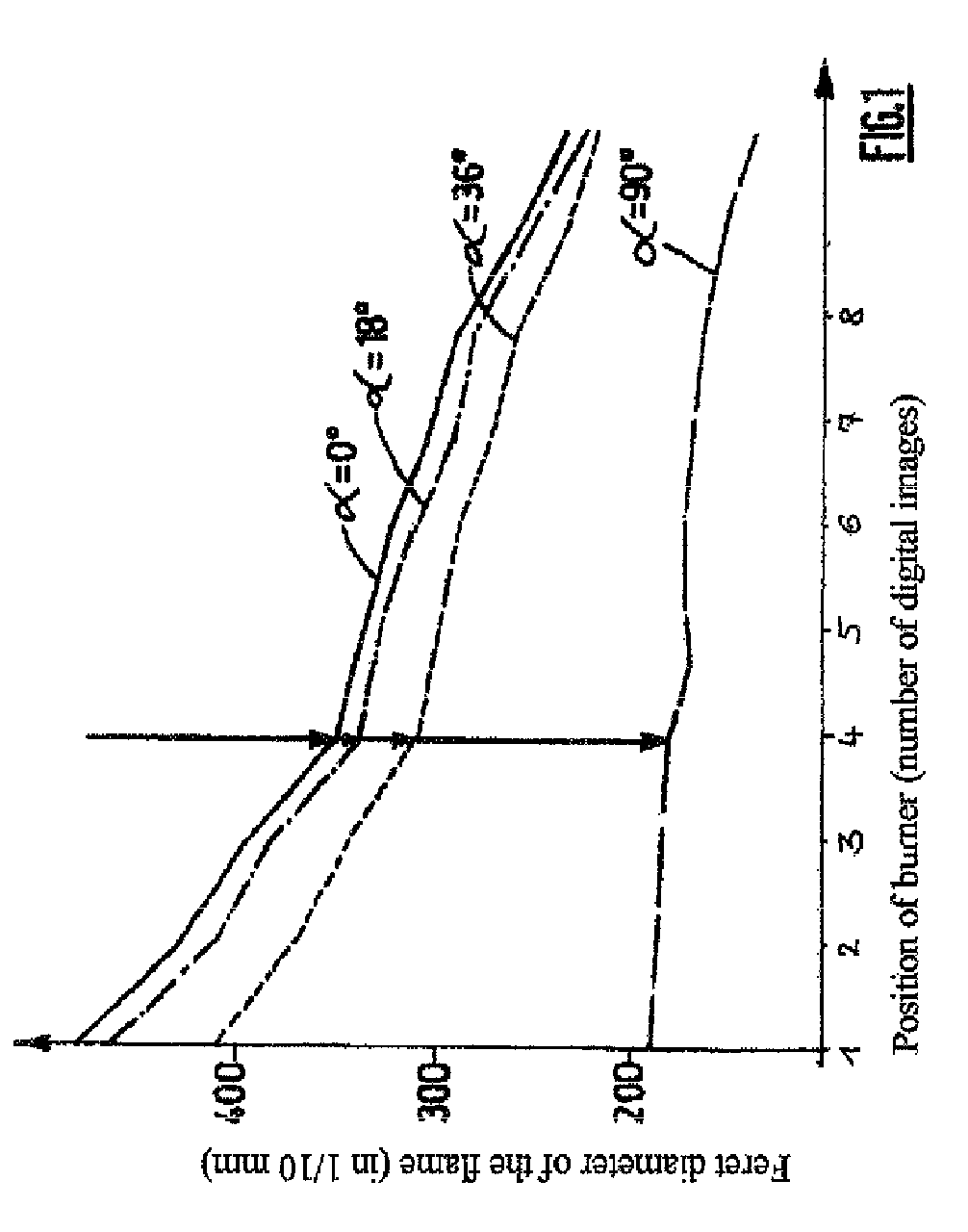

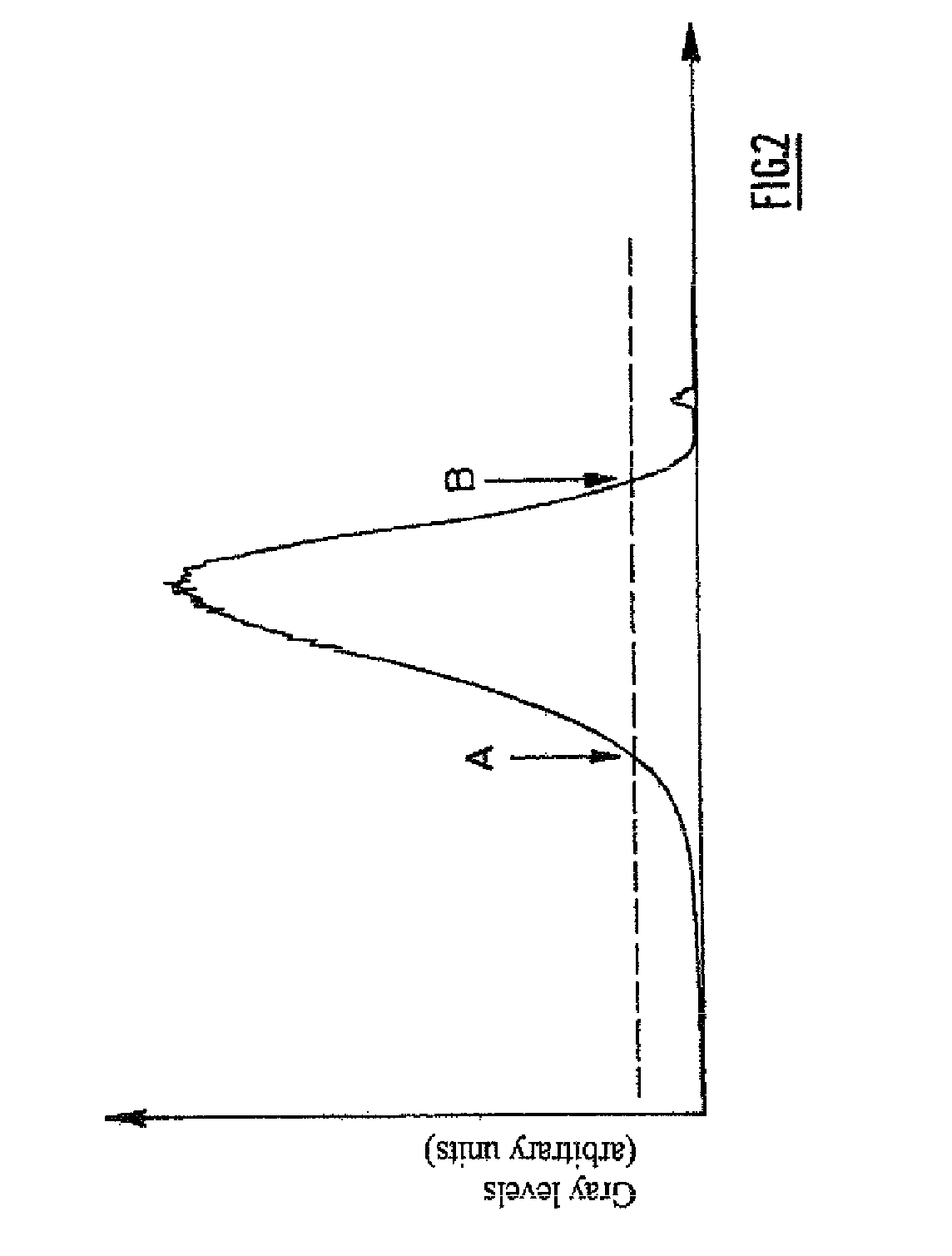

The invention relates to a method for determining the smoke point of a hydrocarbon, comprising, among the different steps defined in the ASTM D 1322 standard or equivalents thereof, the identification, among different aspects of the flame according to the position of the burner in the lamp, of a particular aspect of the flame and the reading of the height of this flame on a graduated scale in mm. The invention is characterized by the fact that a series of digital images of the flame is taken and recorded with the aid of a digital camera or the like at intervals sufficiently close for permitting, by analyzing these digital images, the detection of a sudden change in the shape of the flame, and that the height of this flame is measured at the moment of this sudden change in its shape, said height being considered as the smoke point of the tested hydrocarbon.

Owner:TOTAL RAFFINAGE MARKETING

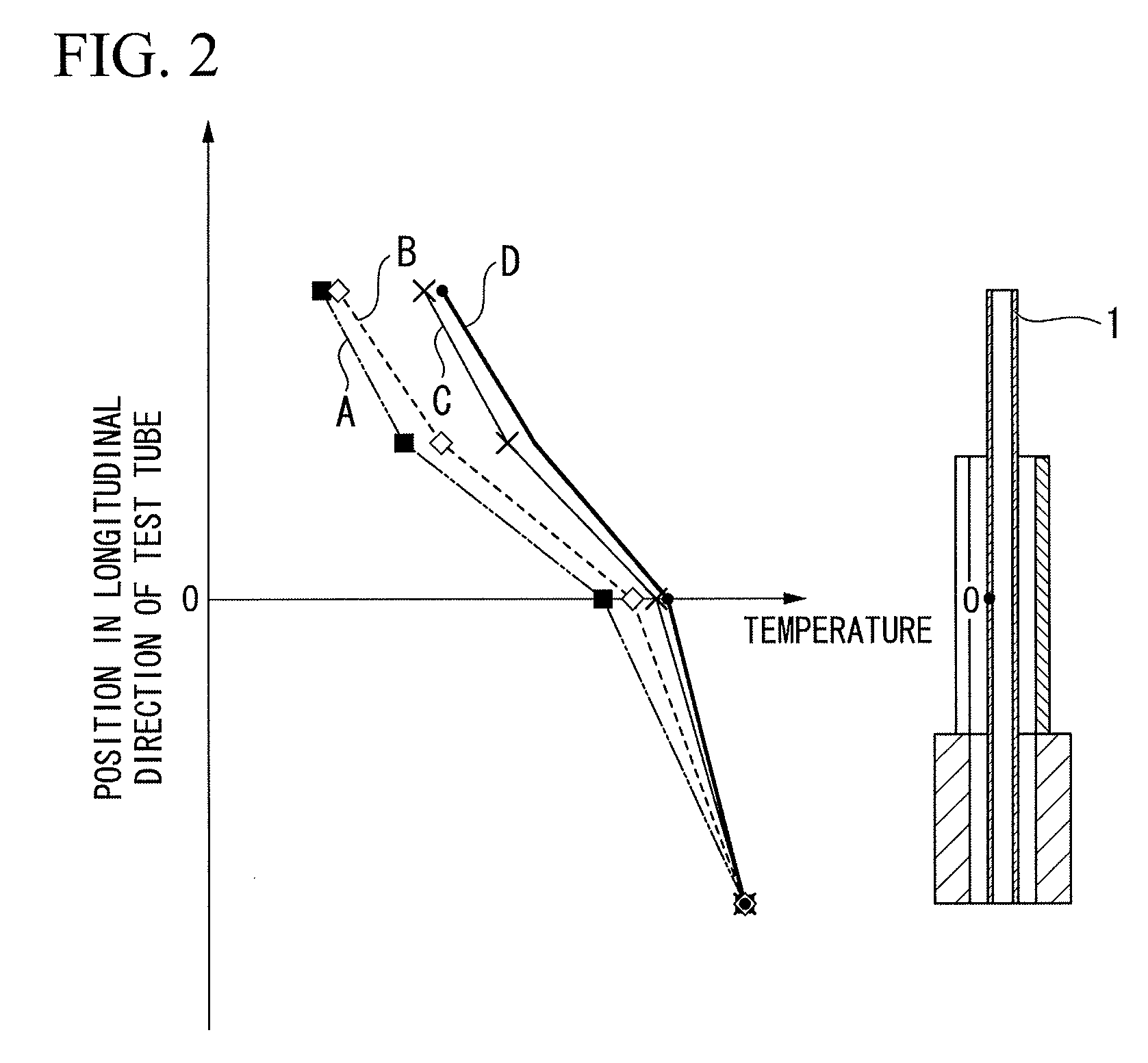

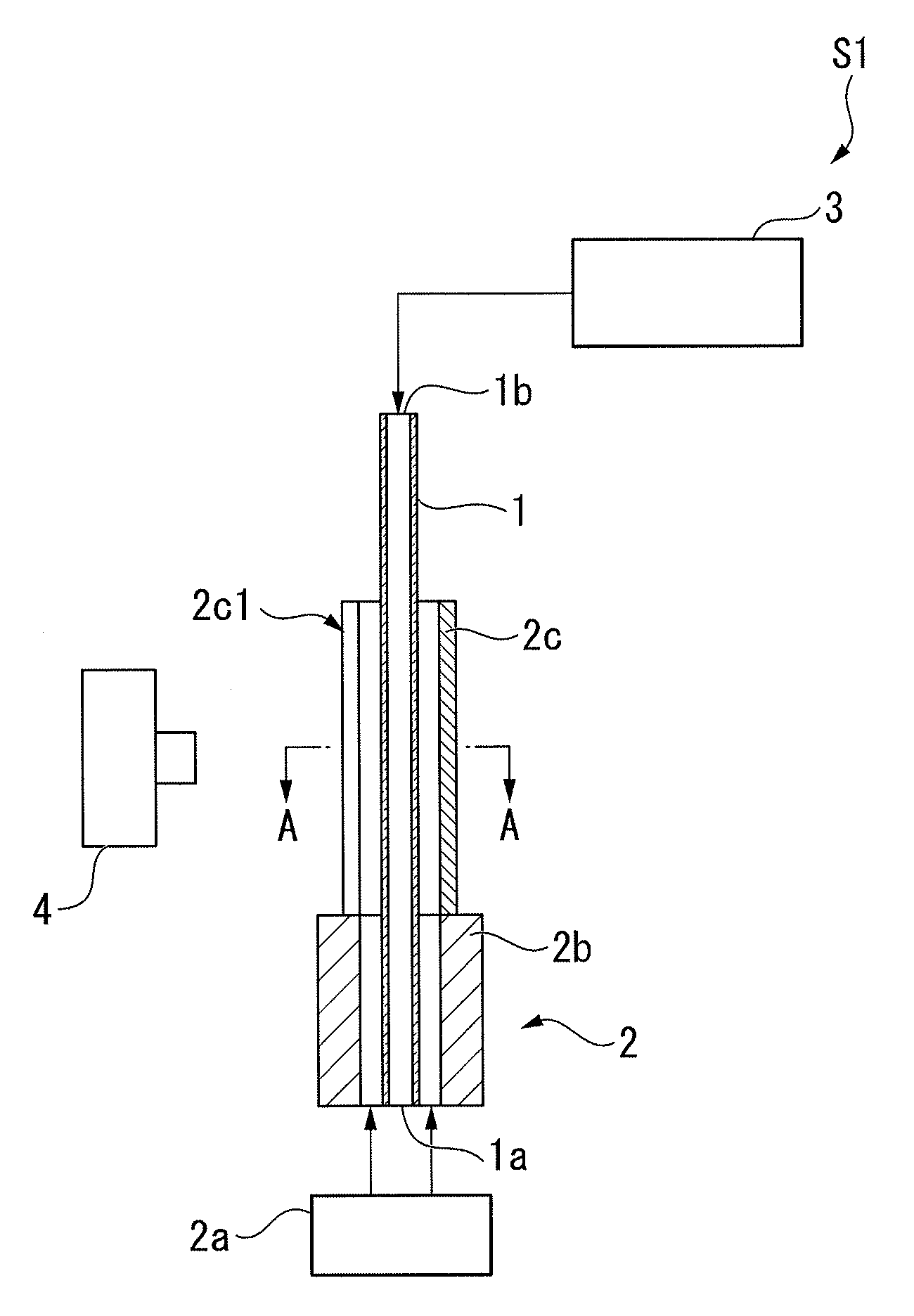

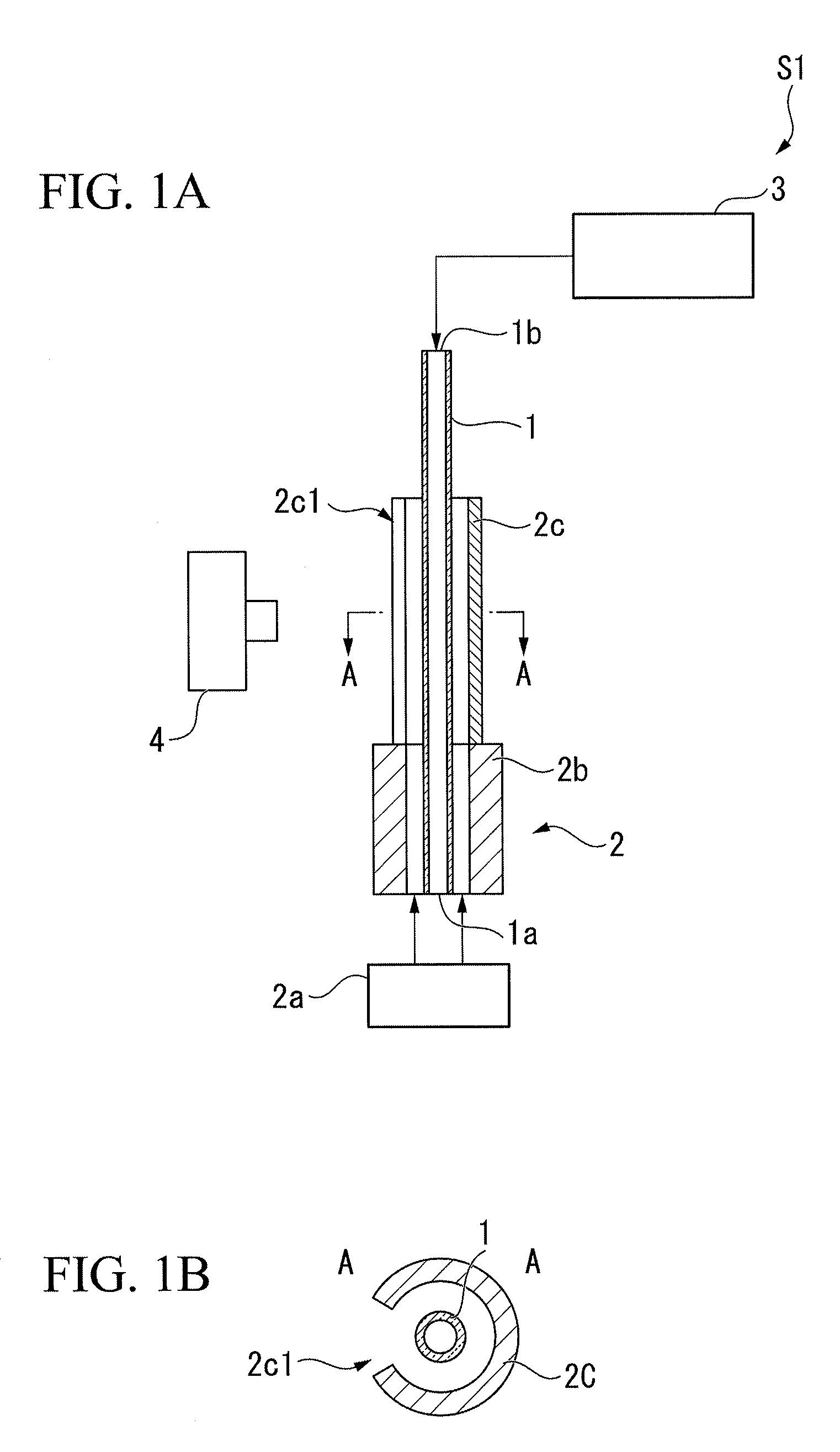

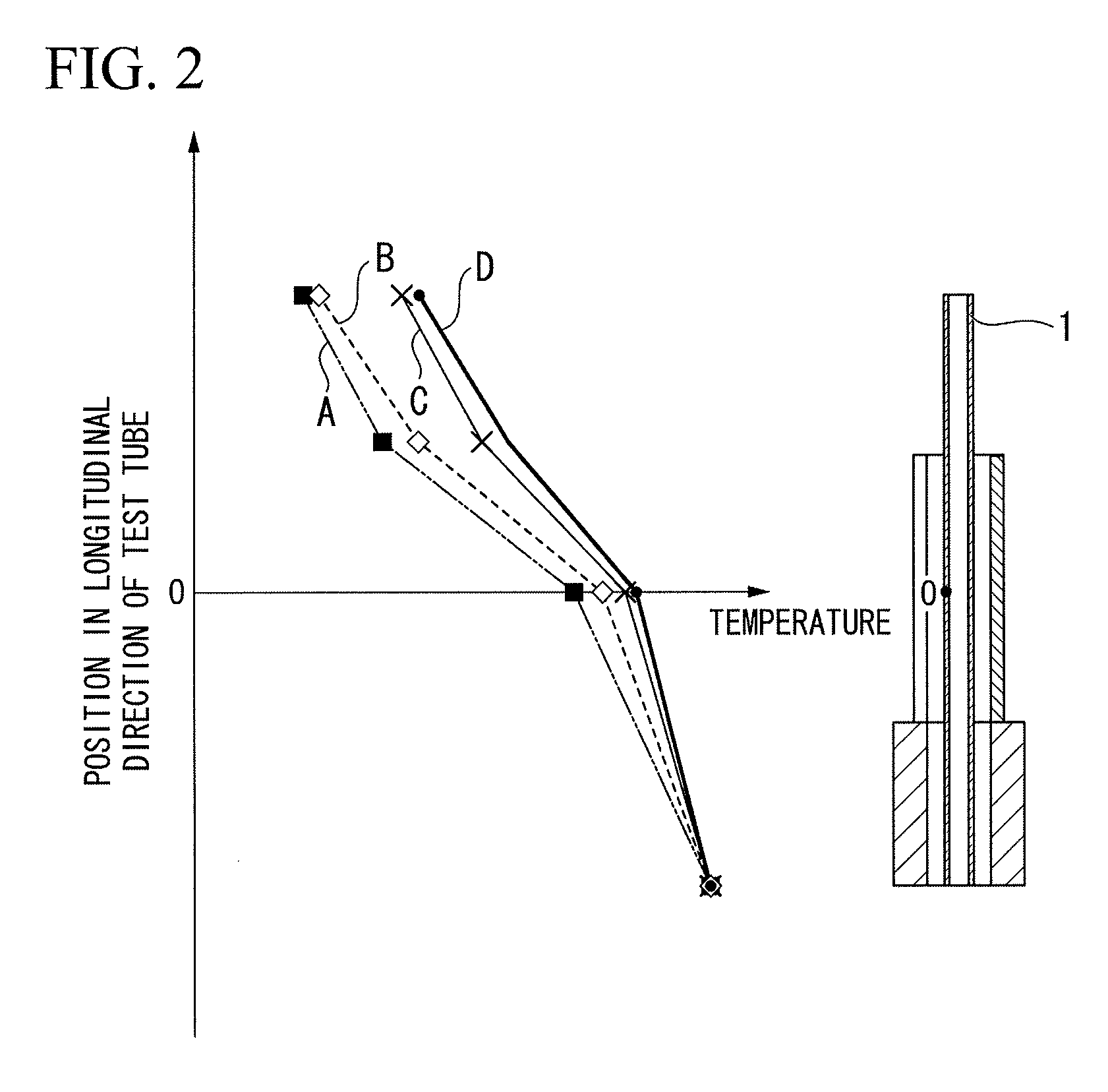

Combustion experimental apparatus

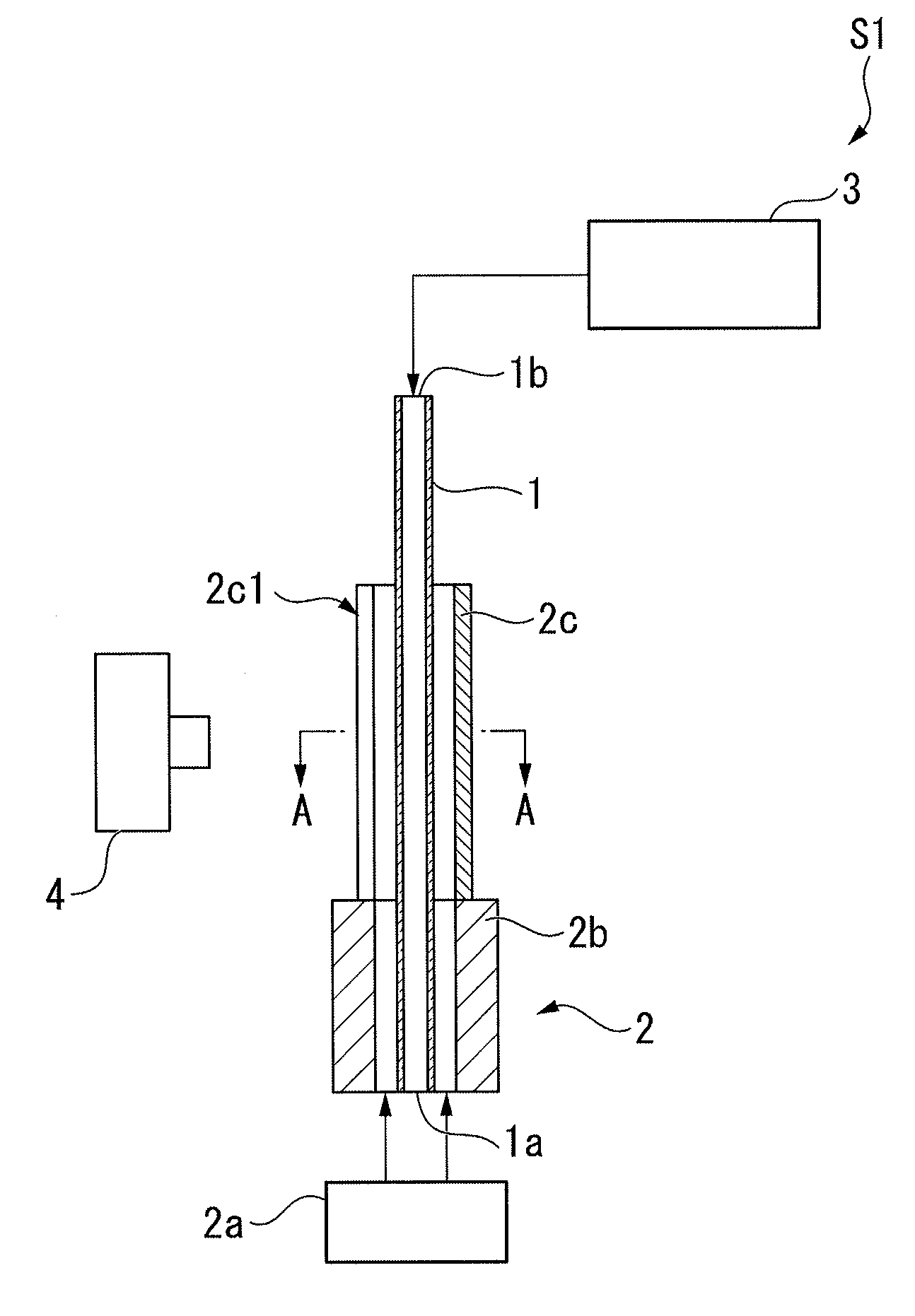

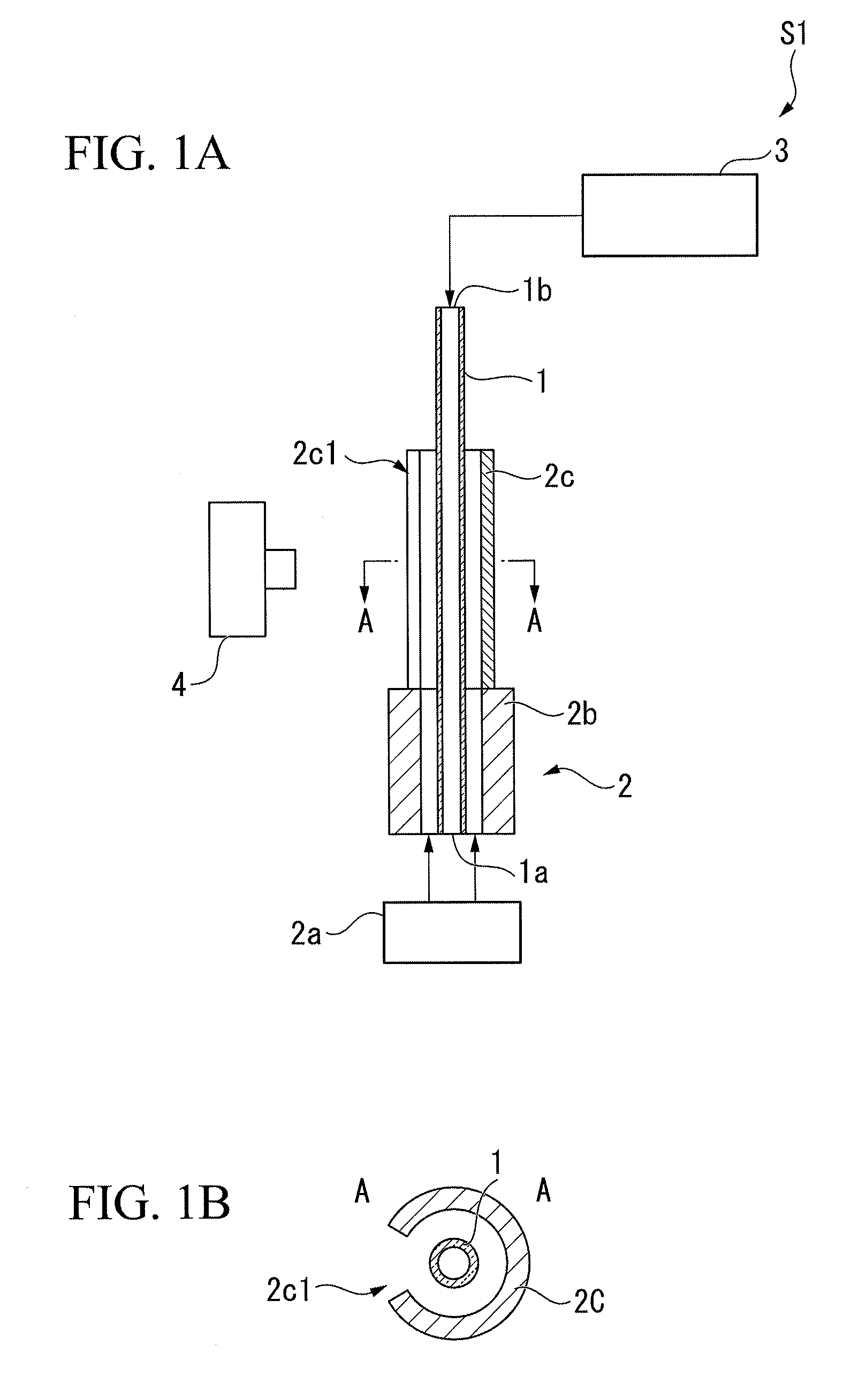

In a combustion experimental apparatus to obtain the positions of flames formed inside a tube (1), it is possible to adjust a temperature gradient in a longitudinal direction applied to the tube, by including a temperature-adjusting fluid supply device (2) to cause a temperature-adjusting fluid to flow along the tube.

Owner:TOHOKU UNIV +1

Method for determining open cup flash point of oil product

The invention relates to a method for determining open cup flash point of oil product, which comprises the following steps: determining boiling range distribution of oil product by using a gas chromatography method, and calculating the open cup flash point of the oil product according to the obtained boiling range distribution result by using a correlation formula. According to the invention, the method for determining open cup flash point of oil product can accurately determine open cup flash point of oil product with small deviation of detection result.

Owner:CHINA PETROLEUM & CHEM CORP +1

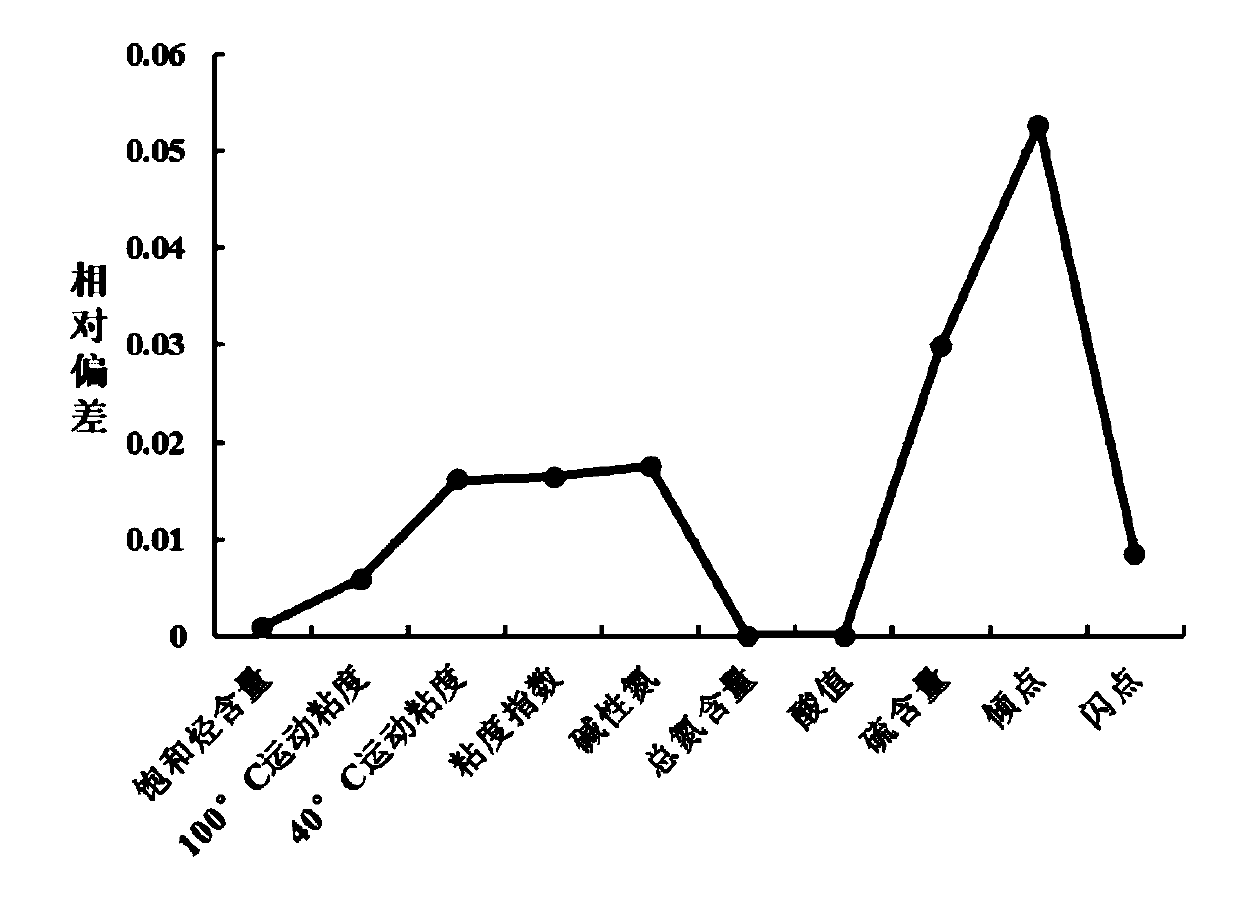

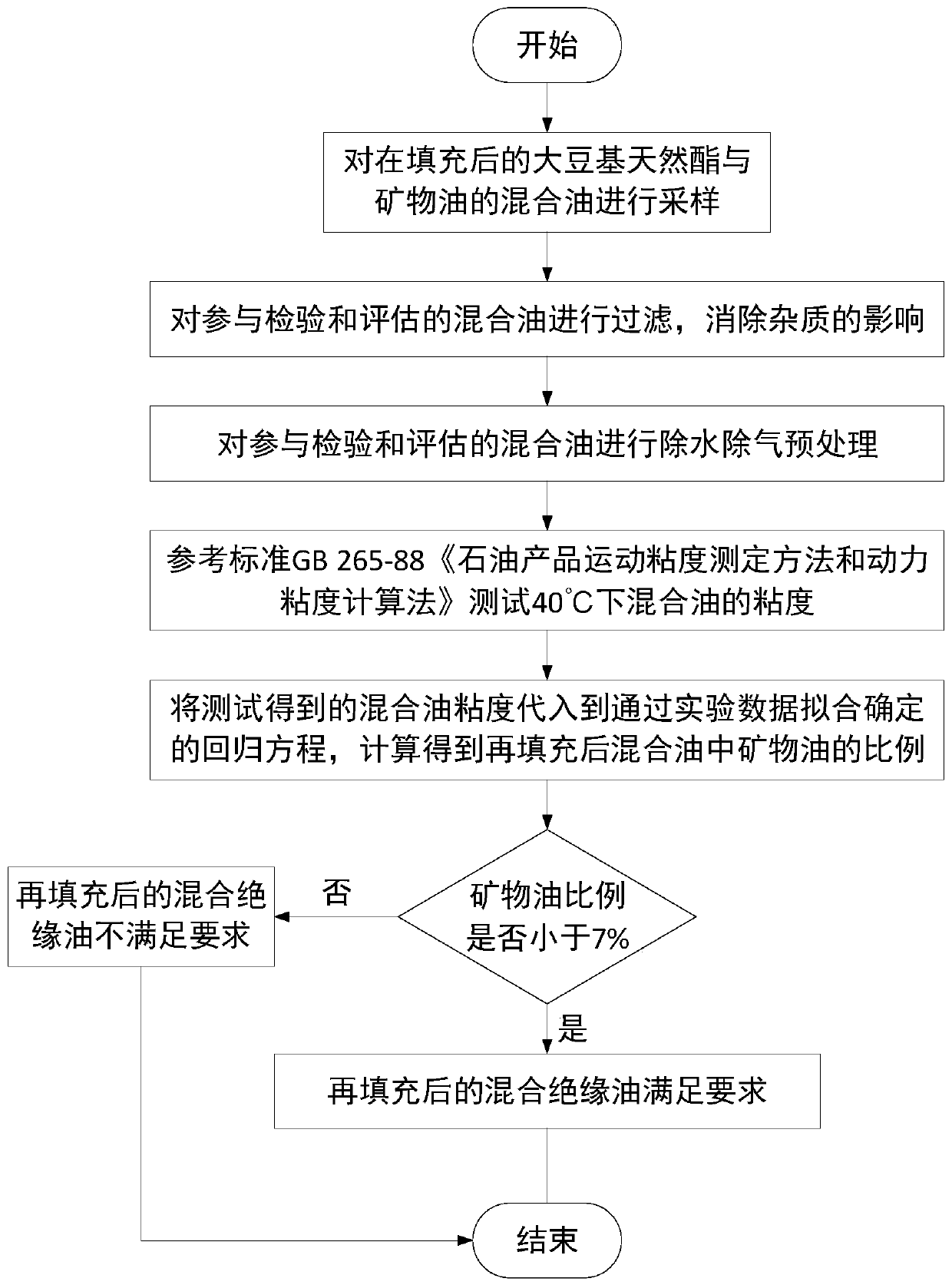

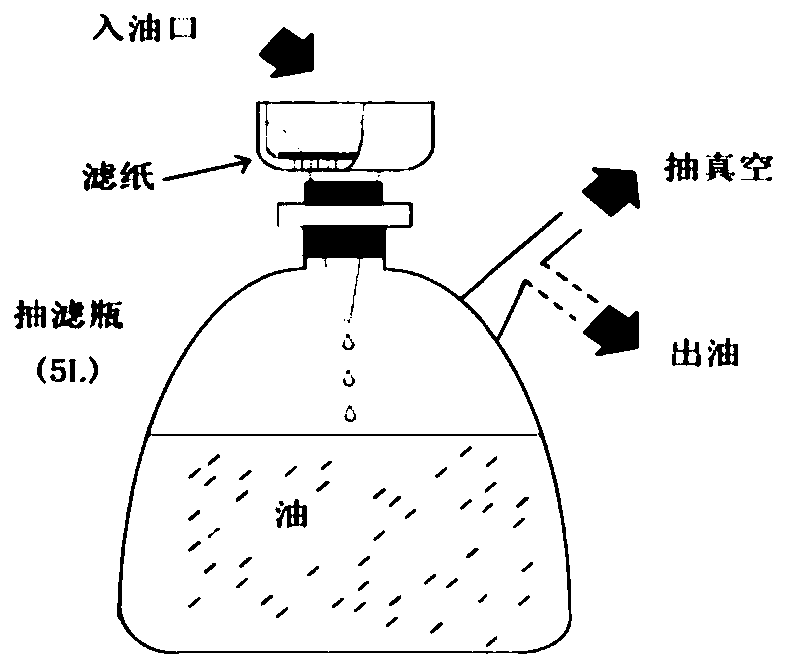

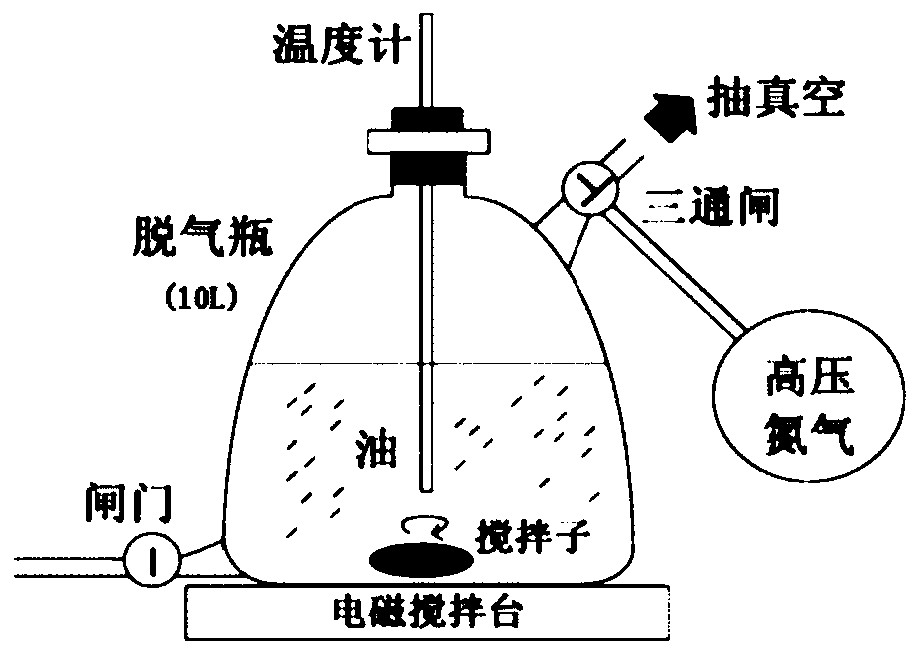

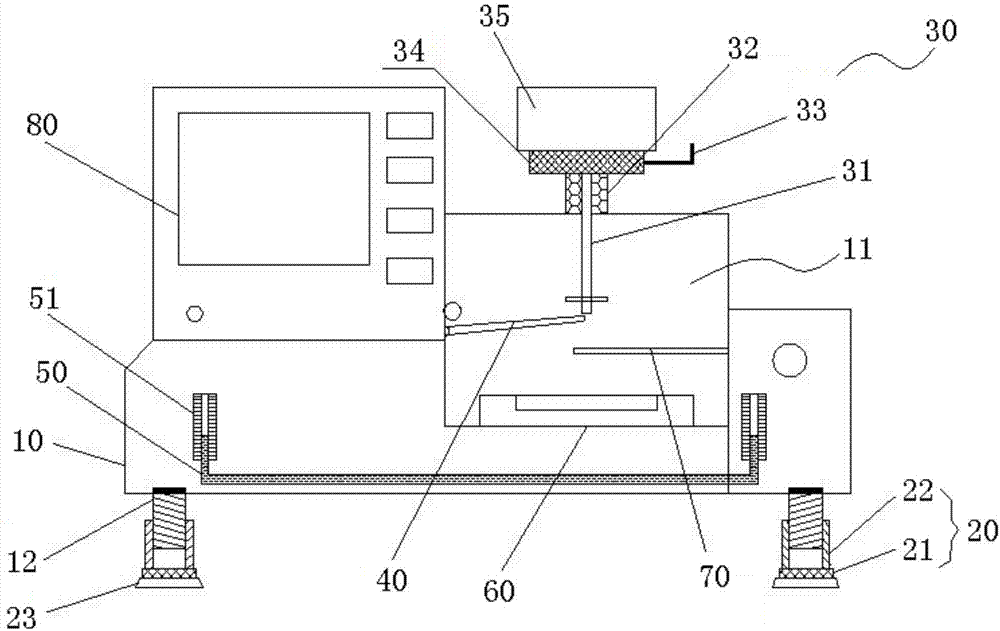

Method for judging proportion of residual mineral oil after refilling transformer with soybean-based natural ester

InactiveCN111308053AReduce sensitivityFlow propertiesMaterial flash-pointPhysical chemistryMineralogy

The invention discloses a method for judging the proportion of residual mineral oil after refilling a transformer with soybean-based natural ester. The method comprises the following steps: performingsoybean-based natural ester refilling on a mineral oil transformer; sampling mixed oil, then carrying out filtering and water and gas removal pretreatment; ; testing the viscosity of the mixed oil pretreated at a temperature of 40 DEG C according to related standards; calculating the proportion of mineral oil in the refilled mixed oil according to a regression equation determined through experimental data fitting; and evaluating the refilled mixed insulating oil. The proportion of the refilled mineral oil generally does not exceed 10%, and the linear relationship between the viscosity of themixed oil and the proportion of the mineral oil is very obvious in an interval of 0-10% of the proportion of the mineral oil, so that an equation model of the viscosity of the mixed oil of the soybean-based natural ester and the mineral oil and the proportion of the mineral oil can be accurately obtained. In addition, the physical and chemical properties of the viscosity of the mixed oil are low in sensitivity to moisture, so that the influence of environmental factors on a measurement result is effectively reduced.

Owner:STATE GRID SHAANXI ELECTRIC POWER +3

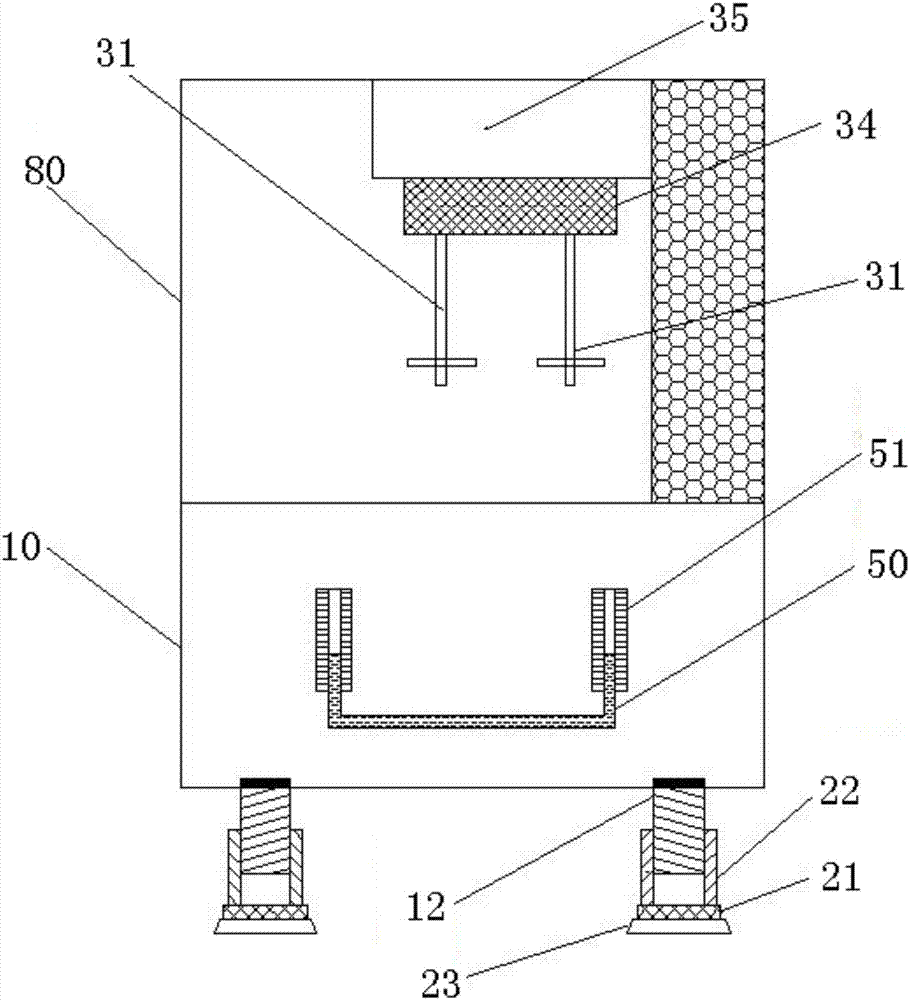

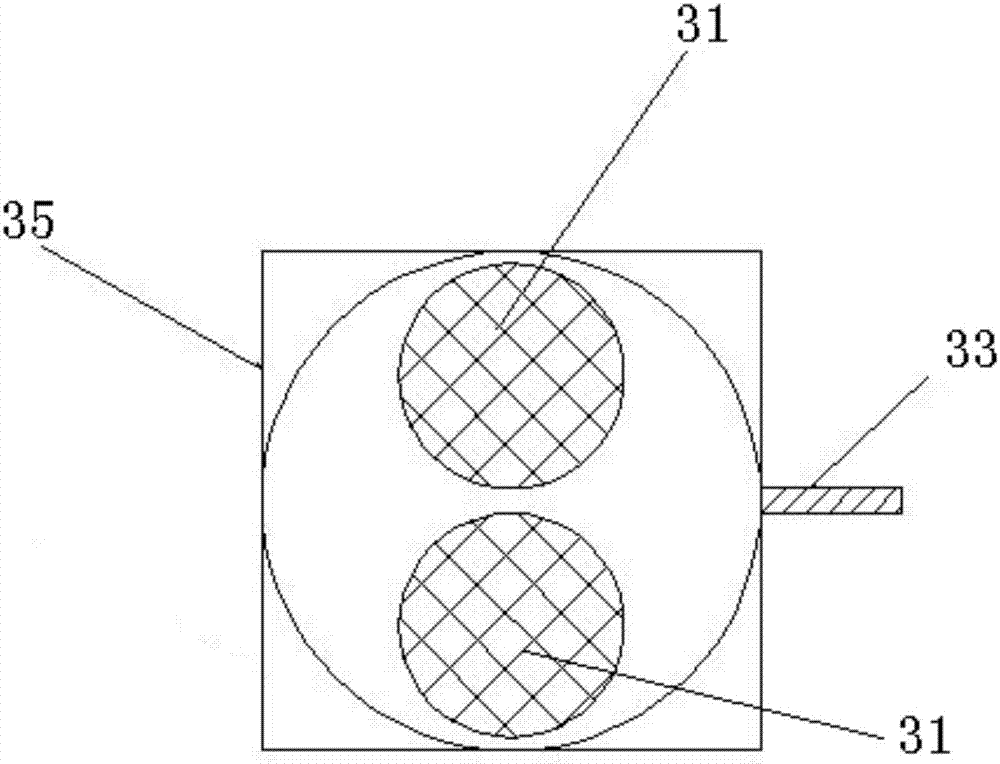

Flash point detection device

The invention provides a flash point detection device. The flash point detection device comprises a detection table and support parts, wherein a detection chamber used for detecting the flash point of a combustible liquid is formed in the detection table; the support parts are connected with the detection table and can move relative to the detection table, so that the height of the detection table in the vertical direction is adjustable. With application of the technical scheme, the support parts movable relative to the detection table are arranged, so that the flash point detection device can be placed horizontally by adjusting the support parts, and the reliability of experimental detection values is improved.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

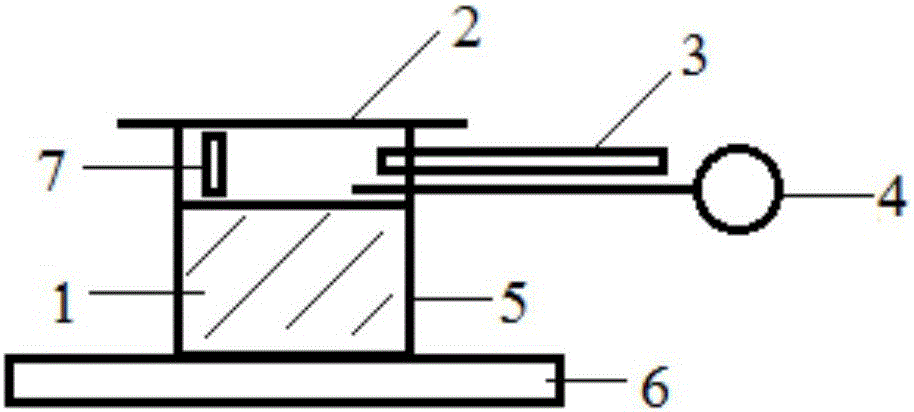

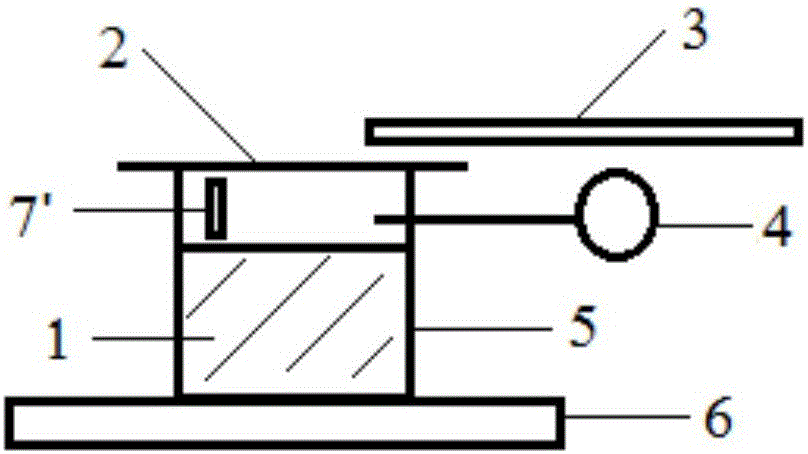

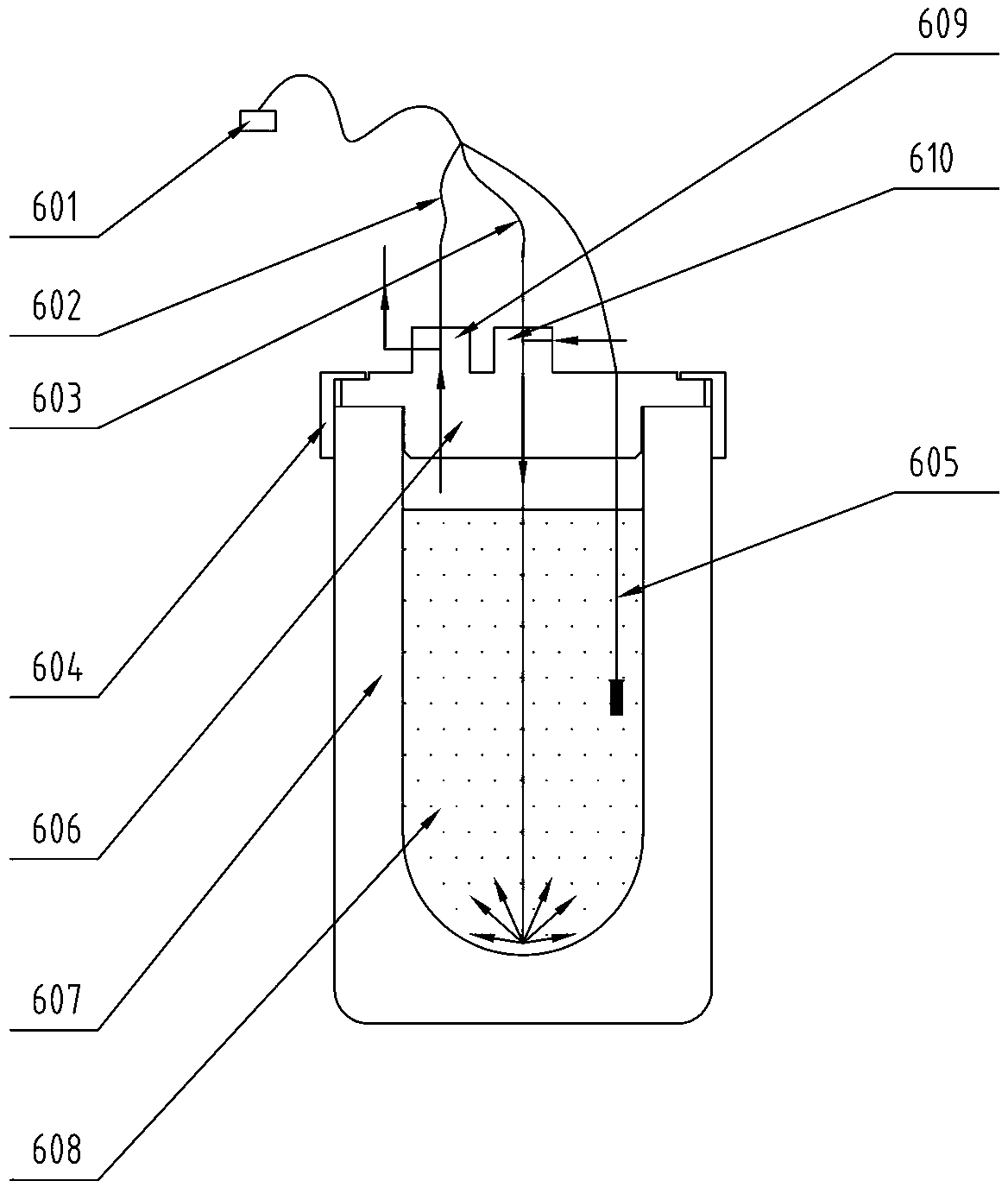

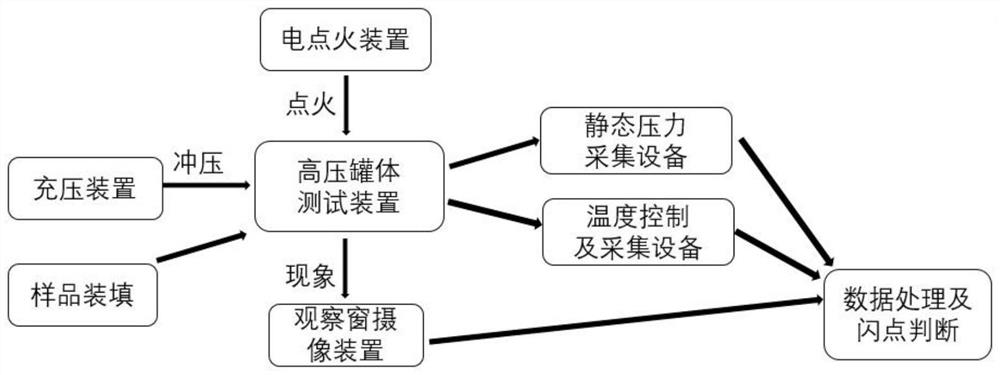

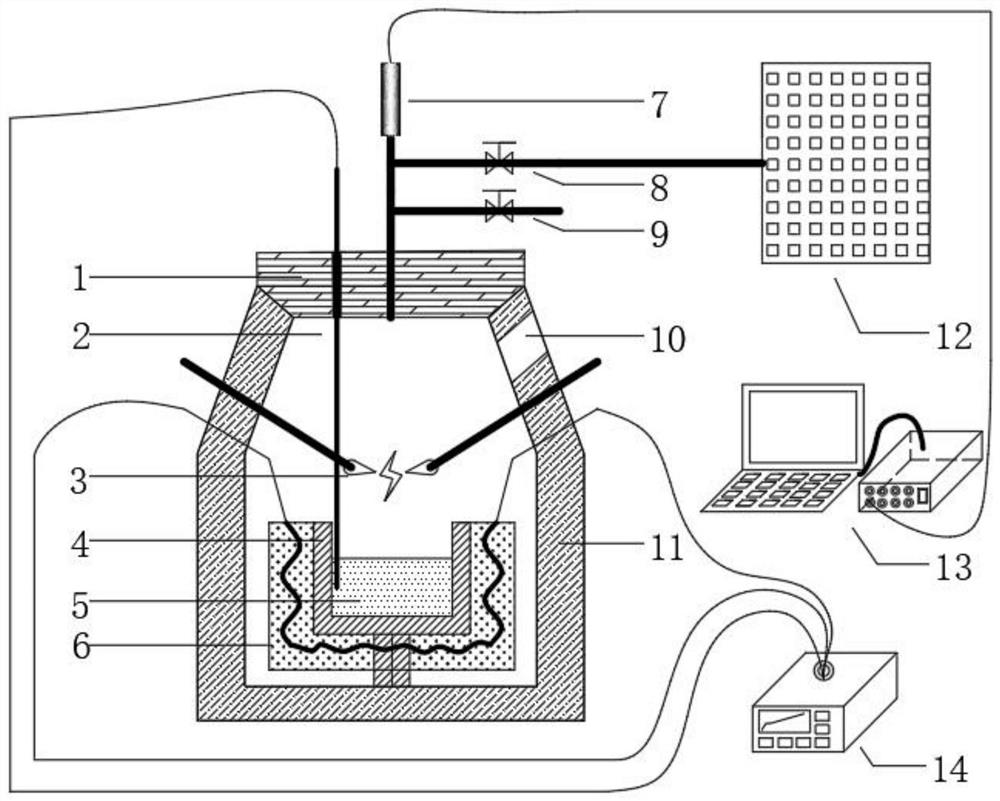

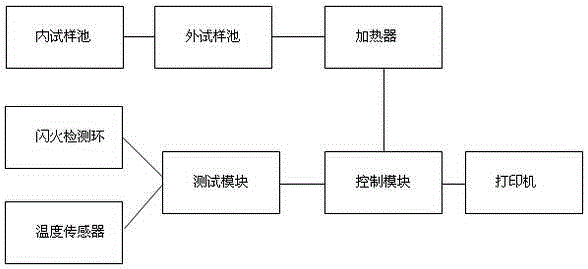

Energetic material flash point test method and equipment thereof

InactiveCN106610391AReduce dosageGuarantee the safety of lifeMaterial flash-pointIntrinsic safetyTest sample

The invention relates to an energetic material flash point test method and equipment thereof. The method comprises the steps of placing an energetic material to be tested into an inner sample tank, and placing the inner sample tank into an outer sample tank; placing the outer sample tank on a heater; forming a test system through the heater, the sample tanks, a temperature sensor, a flash fire detection ring and a test module jointly, wherein the test module is connected with a control module through a data flat cable. The test system is separated from the control module, and the test system and the control module are separately arranged in different rooms and are separated through an explosion-proof wall. By means of separation operation and reducing the test sample amount, the energetic material flash point test is achieved; the essential security of a test process is improved through separated operation and by reducing the test sample amount, the casualty in a dangerous process is effectively avoided, and the damage to the equipment in the test process is also effectively reduced.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

Flash point standard substance

The invention provides a flash point standard substance, which is dimethyl silicon oil with a structure as shown in a formula I, wherein the purity of the dimethyl silicon oil is 100%, and the viscosity is not more than 50mm<2> / s. The flash point standard substance is a siloxane polymer; according to different polymerization degrees, flash point values are also different; and the viscosities are different in a range of 5-500,000mm2 / s. The flash point standard substance has the advantages of physiological inertness, good chemical stability, electric insulativity and weather resistance, wide viscosity range, low freezing point, high flash point, good hydrophobicity and high shearing resistance.

Owner:JIANGSU INST OF METROLOGY

Combustion experimental apparatus

Owner:TOHOKU UNIV +1

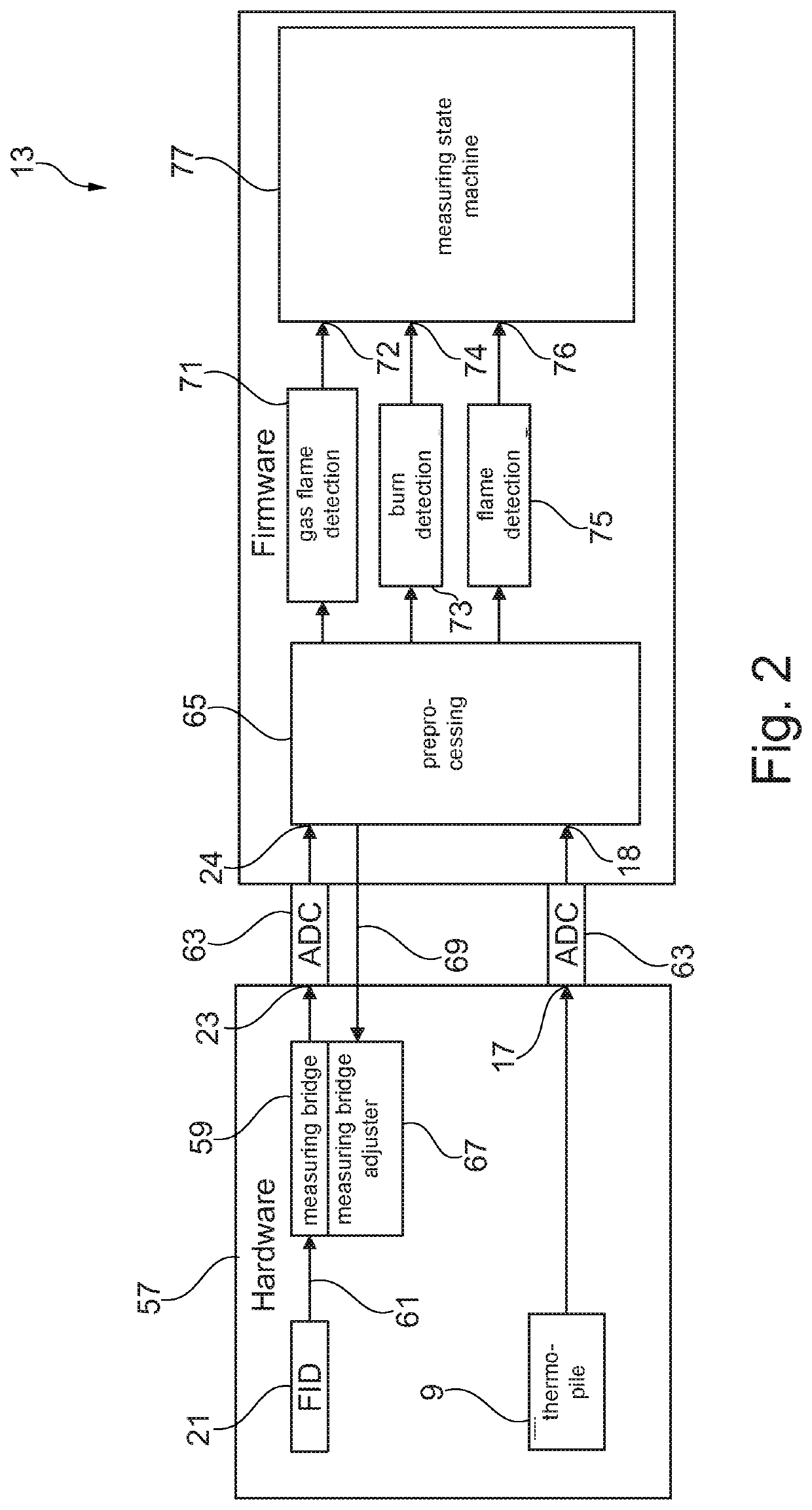

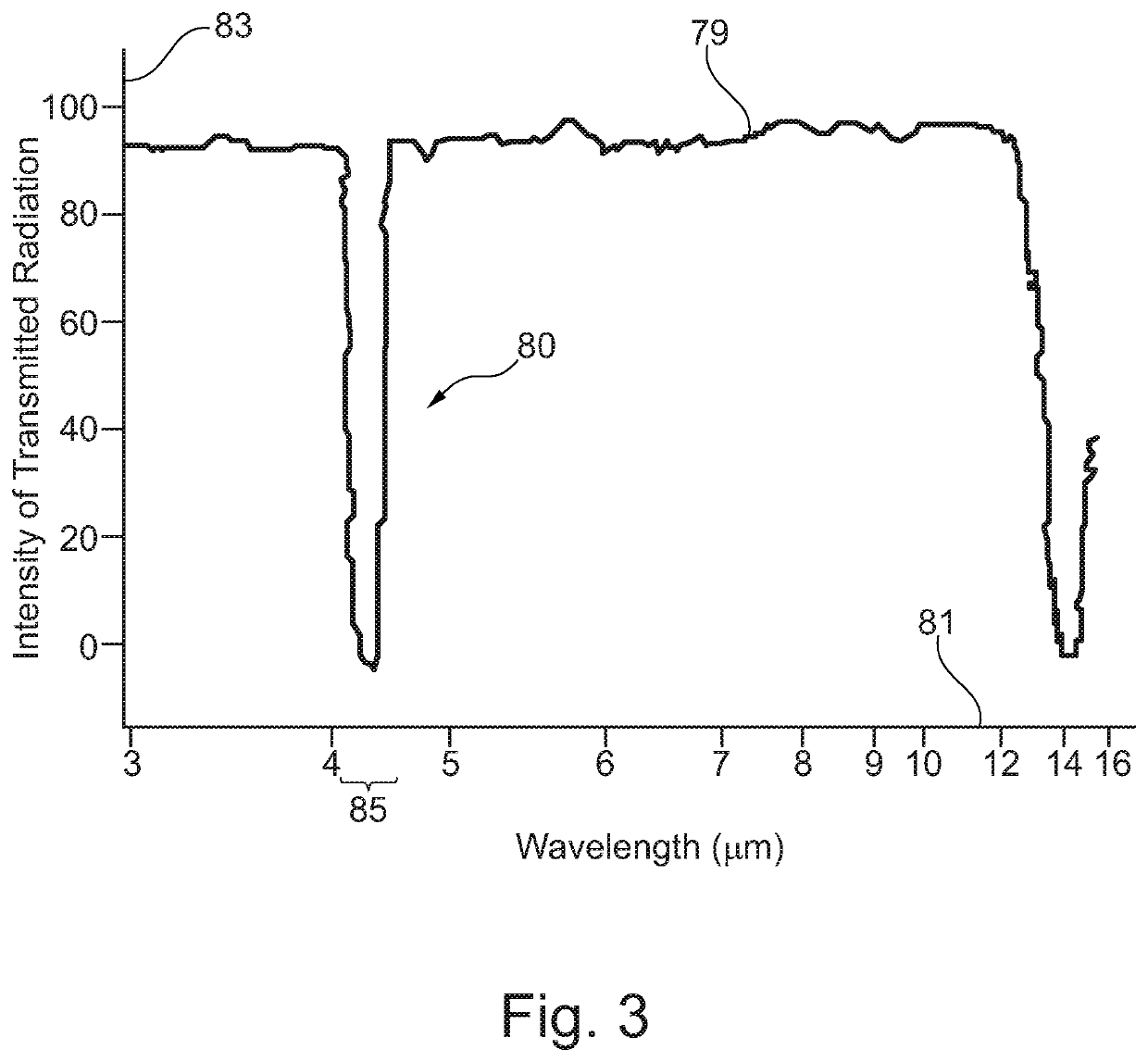

Flame monitoring in a flash point determination or combustion point determination

PendingUS20220349849A1High sensitivityImprove manageabilityMaterial flash-pointFuel testingInfraredCombustion

A device for a flash point: determination and / or combustion point determination of a liquid sample which is receivable in a container and for a flame detection is described, comprising: a container reception for receiving the container; an infrared sensor which is arranged to detect light which is generated by a flame in a region around or within the container; an evaluation system which is coupled with the infrared sensor and is configured to evaluate infrared sensor data of the infrared sensor, to indicate a fire or a burn based on the evaluation.

Owner:ANTON PAAR PROVETEC

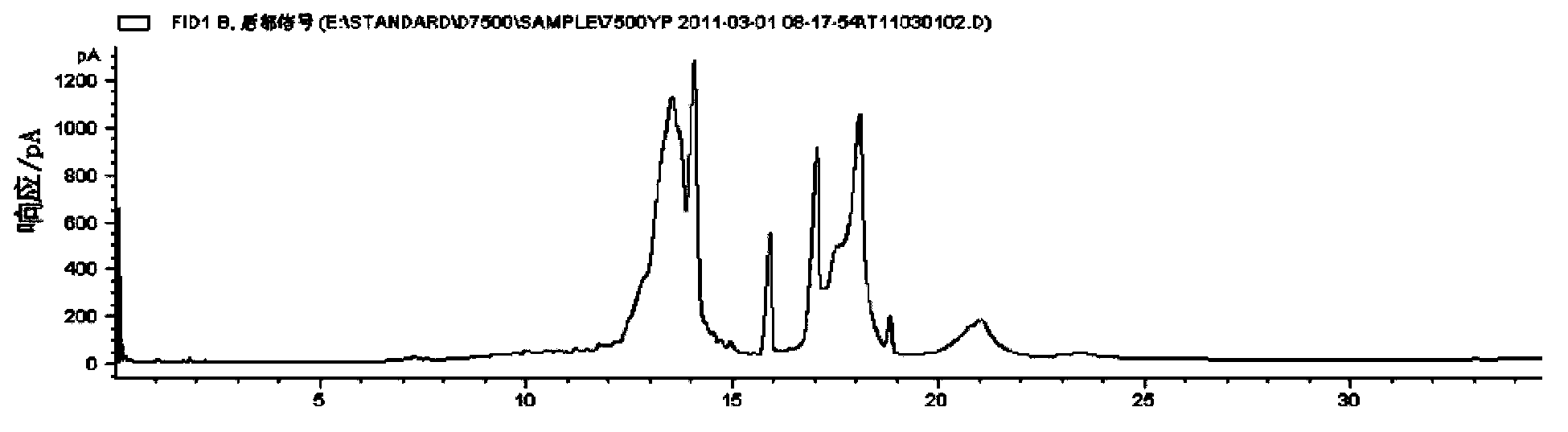

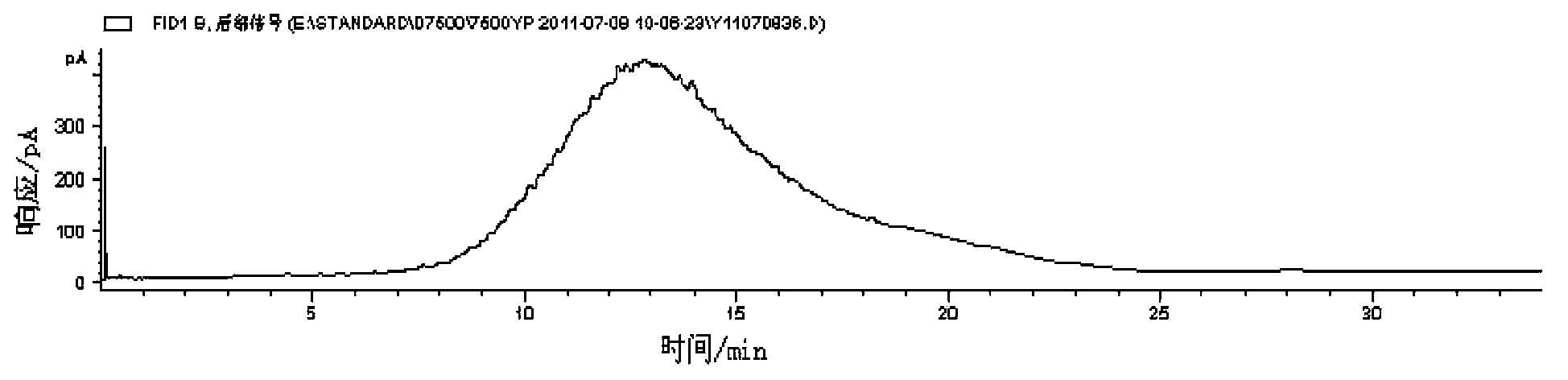

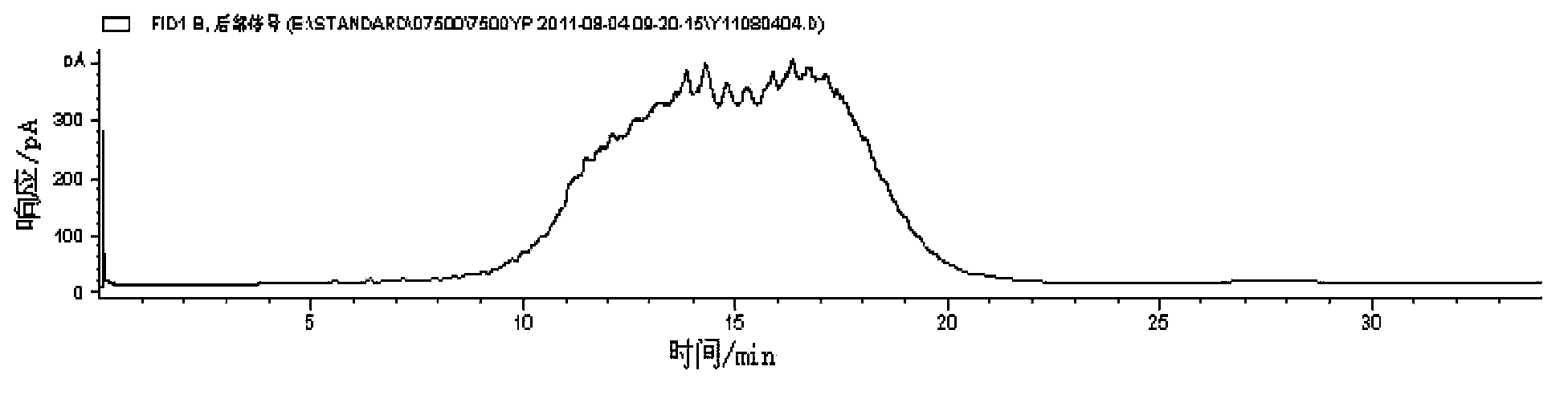

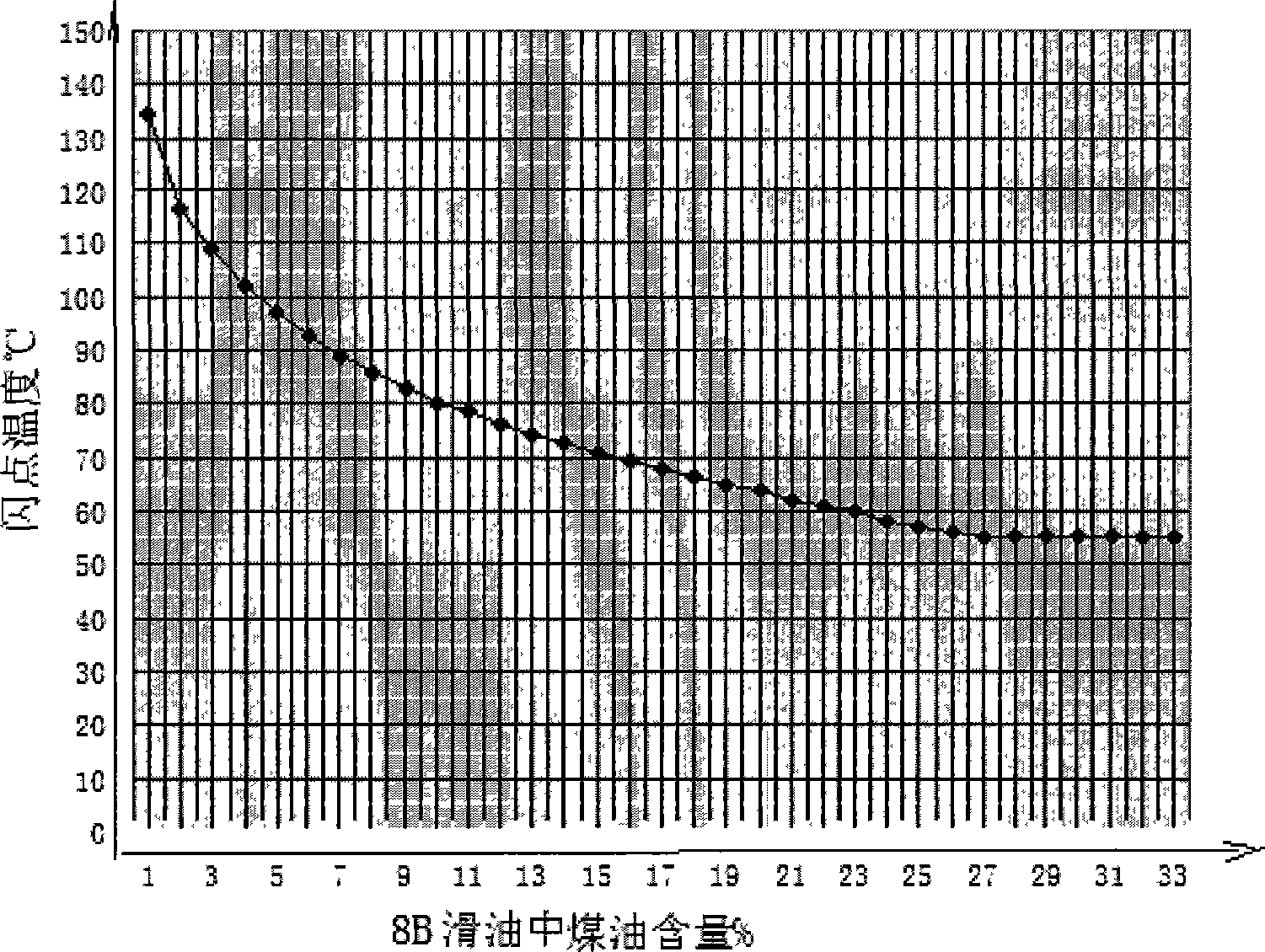

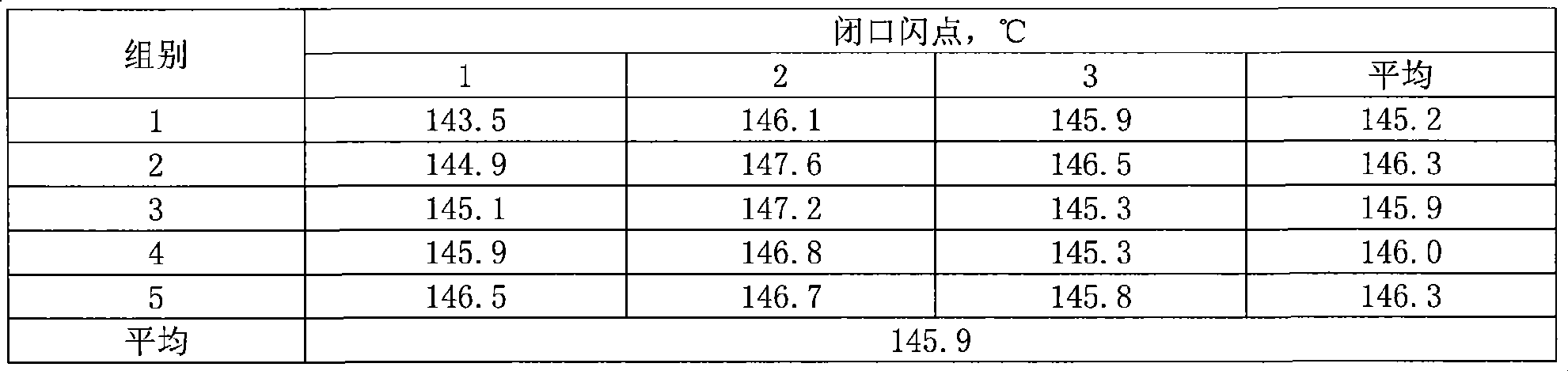

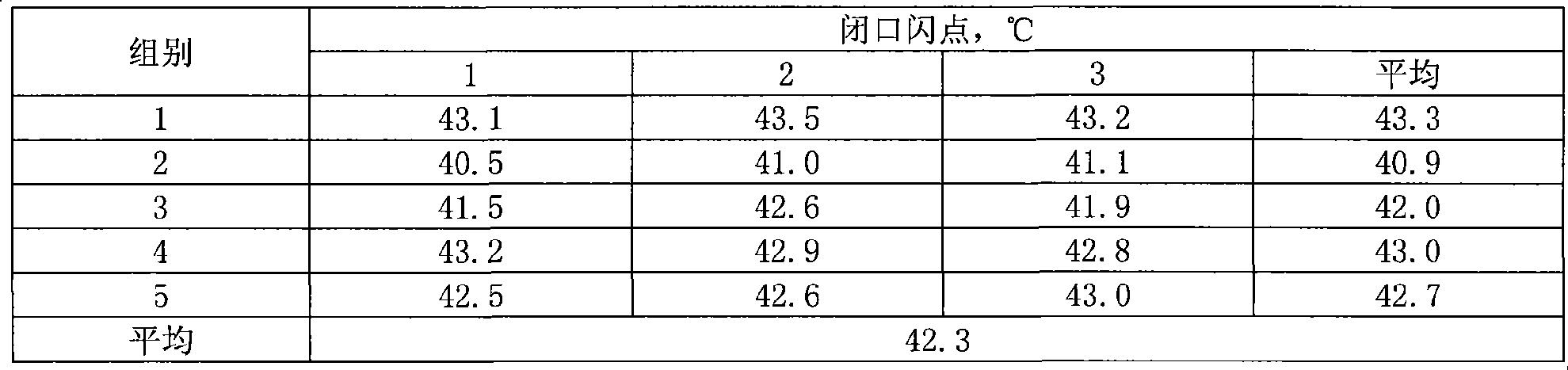

Experiment method for detecting light fuel oil component content in aerooil

ActiveCN101487808AImprove the accuracy of judgmentSimple and fast operationMaterial flash-pointAviationKerosene

The invention provides a test method for detecting the contents of light fuel components in aeroplane oil, which comprises the following steps: (1) a closed flash point tester is used for measuring the closed flash points of various batches of light fuel and aeroplane oil so as to find out the average flash temperature of the light fuel and the aeroplane oil; two tested flash point temperature values are taken as the starting point of a flash point-content trendency curve chart; (2) the light fuel and the aeroplane oil are prepared into mixing testing oils at different ratios; the closed flash temperature of the test oil is measured; (3) the trendency curve chart of the contents of the kerosene in the aeroplane oil is drawn according to the measured closed flash point temperature and the proportion of the contents of kerosene in the mixing testing oils; the content of the kerosene component mixed in the aeroplane oil is calculated by a repression equation. The test method decides the proportion of the kerosene contents in the aeroplane oil by using the content tendency chart of No. 3 jet fuel in 8B aeroplane oil and can accurately determine the amount of the contents of the kerosene in batch mode, has the high judgment accuracy and simple operation.

Owner:PLA NO 5719 FACTORY

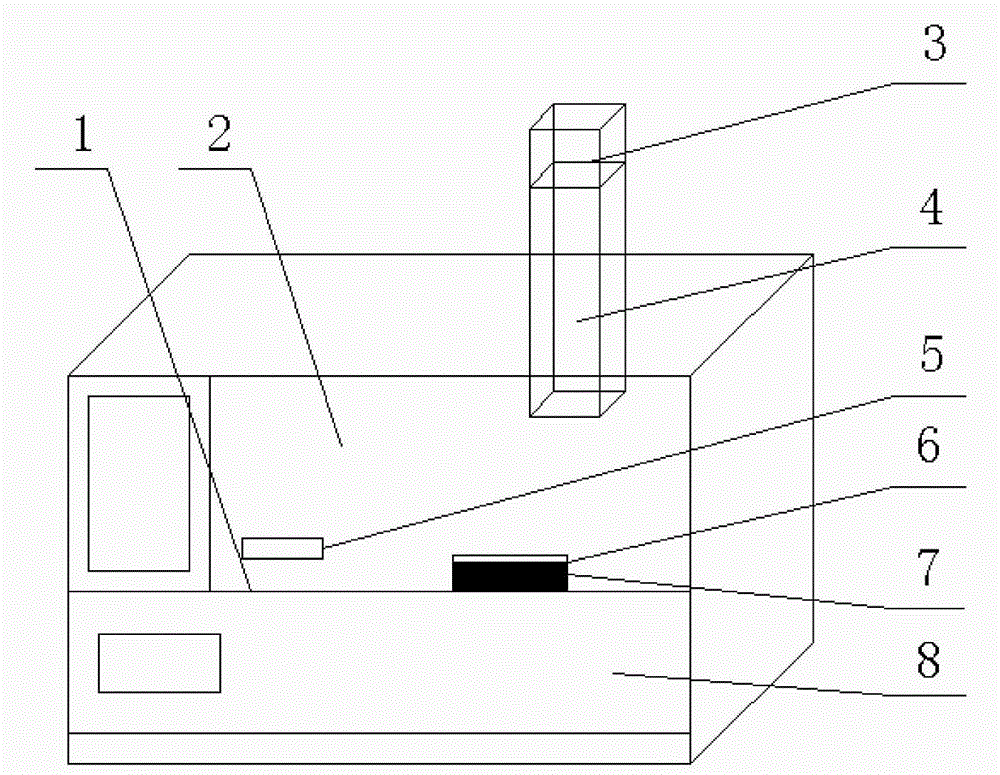

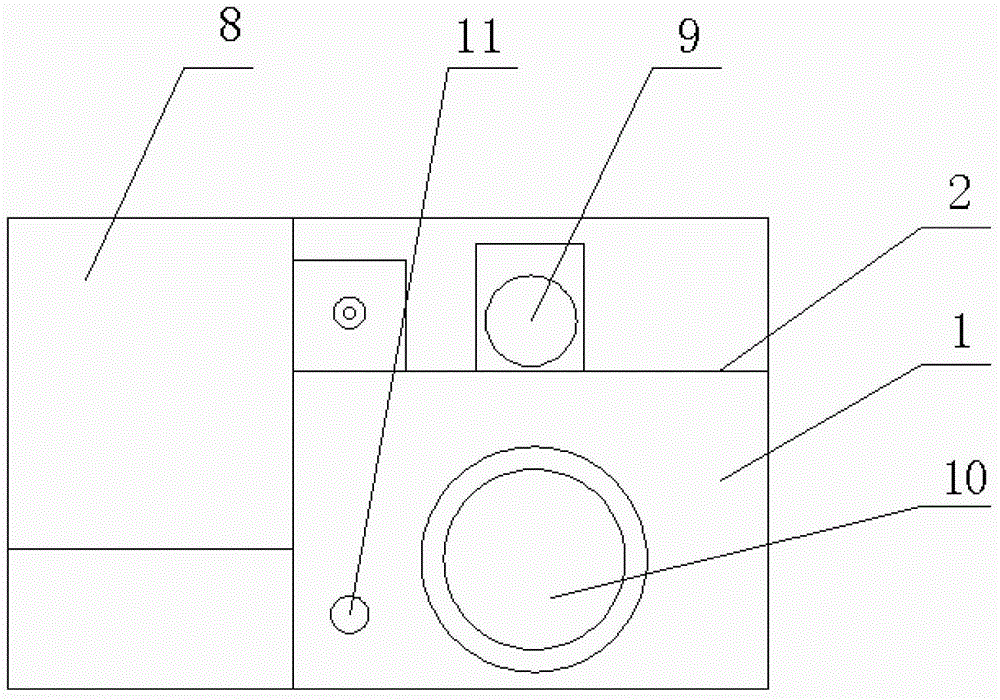

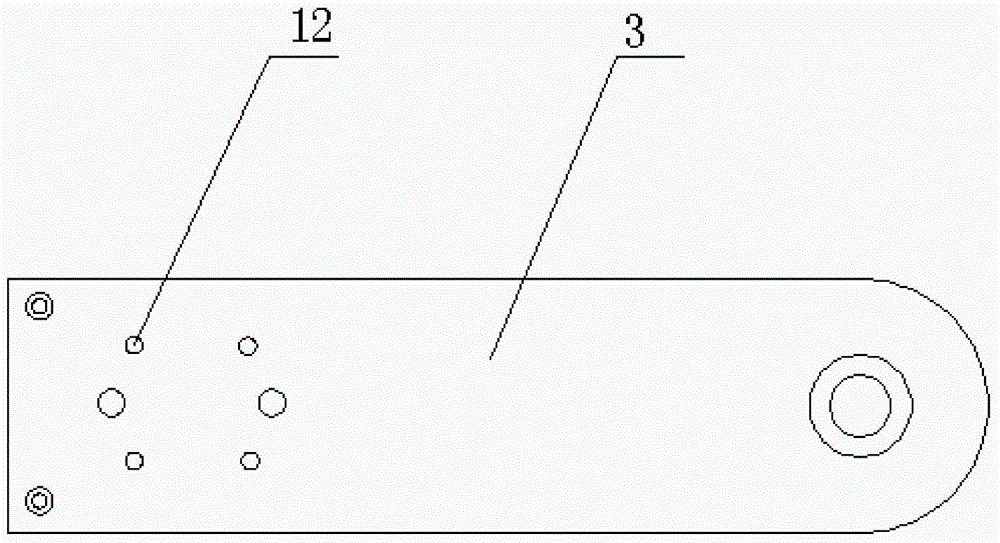

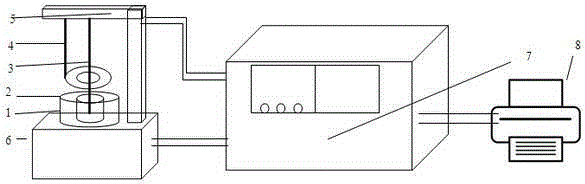

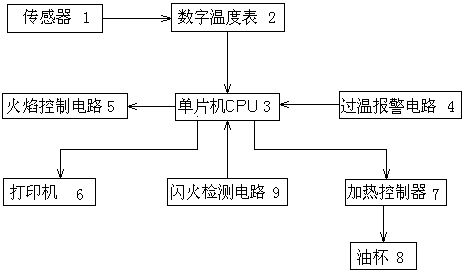

Intelligent open flash point tester

InactiveCN102980914AHigh sensitivityReliable detectionMaterial flash-pointMicrocontrollerDigital thermometers

The invention provides an intelligent open flash point tester, and relates to the field of testing apparatuses. The intelligent open flash point tester comprises a sensor (1), a digital thermometer (2), a singlechip central processing unit (CPU) (3), an over-temperature alarm circuit (4), a flame control circuit (5), a printer (6), a heating controller (7), an oil cup (8) and a flashing point detection circuit (9), wherein the sensor (1) is connected with the digital thermometer (2); the digital thermometer (2), the over-temperature alarm circuit (4) and the flashing point detection circuit (9) are all connected with the singlechip CPU (3); the singlechip CPU (3) is connected with the flame control circuit (5), the printer (6) and the heating controller (7) respectively; and the heating controller (7) is connected with the oil cup (8). The intelligent open flash point tester is totally controlled by a micro computer; a test process is performed automatically after an operator types in a pre-flashing point once; and if the operator presets the flash point improperly, the intelligent open flash point tester sends an alarm, and refuses to execute. The intelligent open flash point tester can judge a test result, and has the characteristics of high sensitivity, reliable detection and the like.

Owner:杨加珍

Asphalt flash point detection device

PendingCN110823957APrevent proliferationAvoid pollutionMaterial flash-pointDispersed particle separationActivated carbonProcess engineering

The invention provides an asphalt flash point detection device comprising a Cleveland opening cup, a heating device, an igniter, a temperature measuring device, a control system, a protective cover and an exhausting device. The Cleveland opening cup is arranged on the heating device; a temperature sensor is arranged in the Cleveland opening cup; a base is arranged at the bottom of the heating device; and a gas tank box is arranged on one side of the base. According to the invention, a situation that asphalt splashes out in the detection process and operators are injured is avoided and harmfulgas is prevented from diffusing around, so that the harmful gas is effectively absorbed through the arranged exhausting device, the harmful gas is prevented from being dissipated to the environment topollute the environment, and the body health of operators is guaranteed. Moreover, an activated carbon adsorption net is arranged at the end opening of an exhaust pipe to effectively absorb the harmful gas, so that the exhausted gas cannot pollute the environment.

Owner:阜阳市路兴公路工程检测有限公司 +1

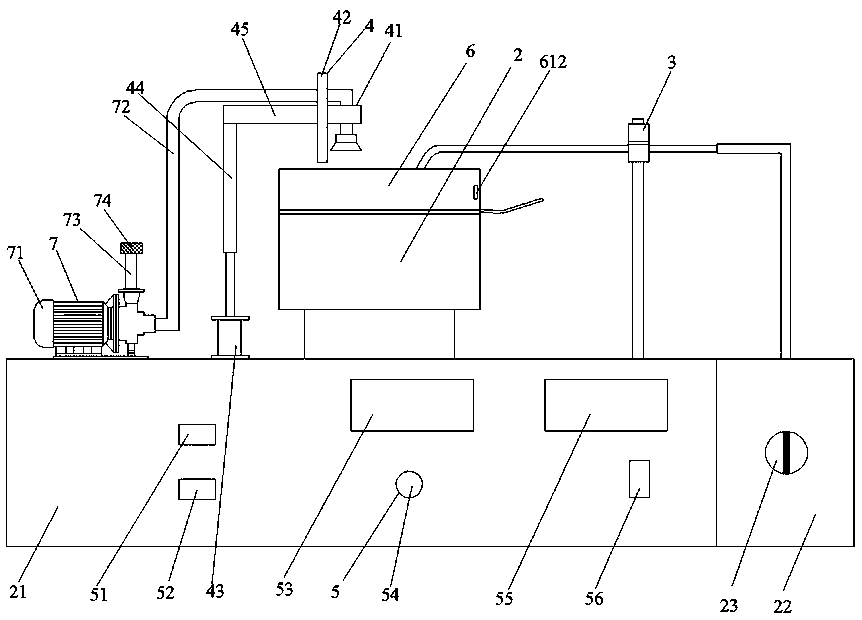

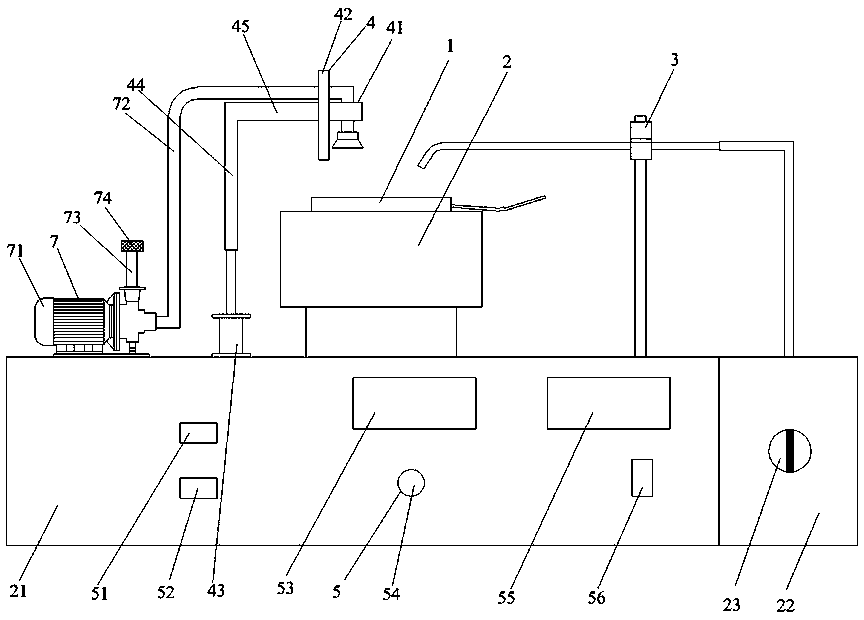

Automatic opening type mineral oil flash point testing device

InactiveCN104990957APrecise temperature controlEasy to operateMaterial flash-pointOperabilityFlash point

The invention discloses an automatic opening type mineral oil flash point testing device. The testing device comprises a heating device, an automatic ignition device and an automatic programmable temperature recorder, wherein an open oil cup is arranged on the heating device, the automatic ignition device is located above the oil cup, and the automatic programmable temperature recorder is connected with both the heating device and the oil cup. According to the testing device, temperature is accurately controlled and timely recorded, automatic ignition and sweep-burning time is controllable, and flash point missing is avoided. Furthermore, the flash point testing device is easy to operate, high in operability, convenient to use, simple and reliable.

Owner:TAICANG LONGFANG OIL CO LTD

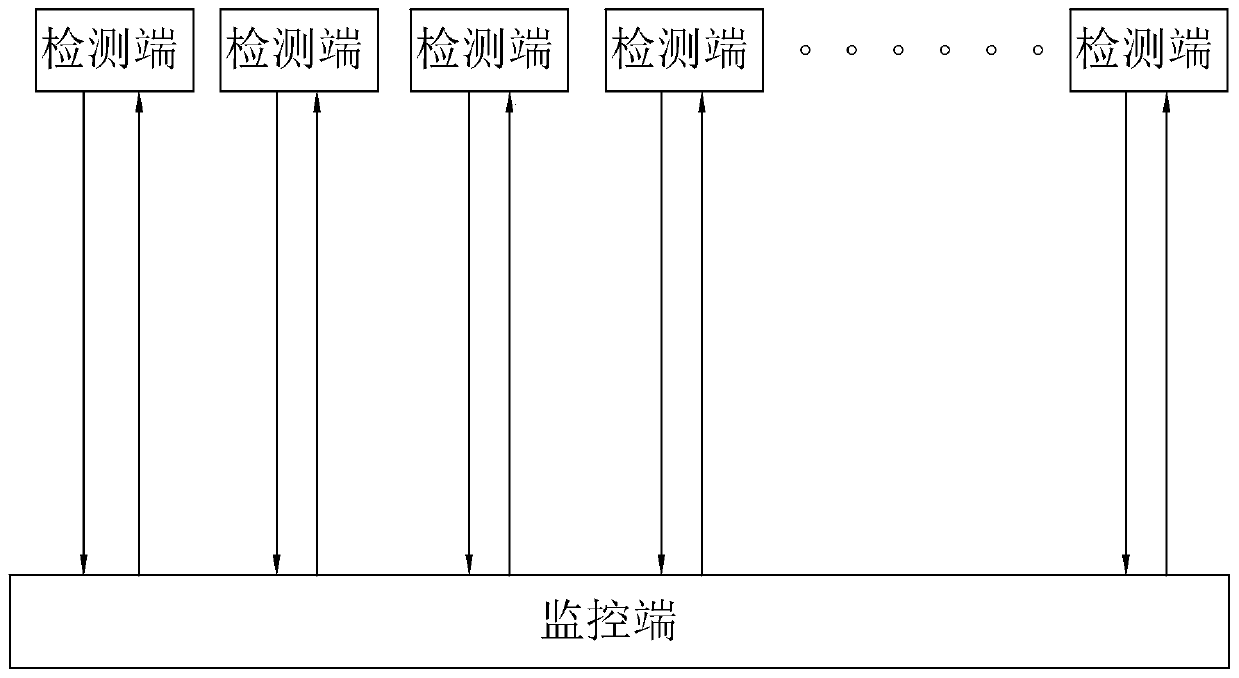

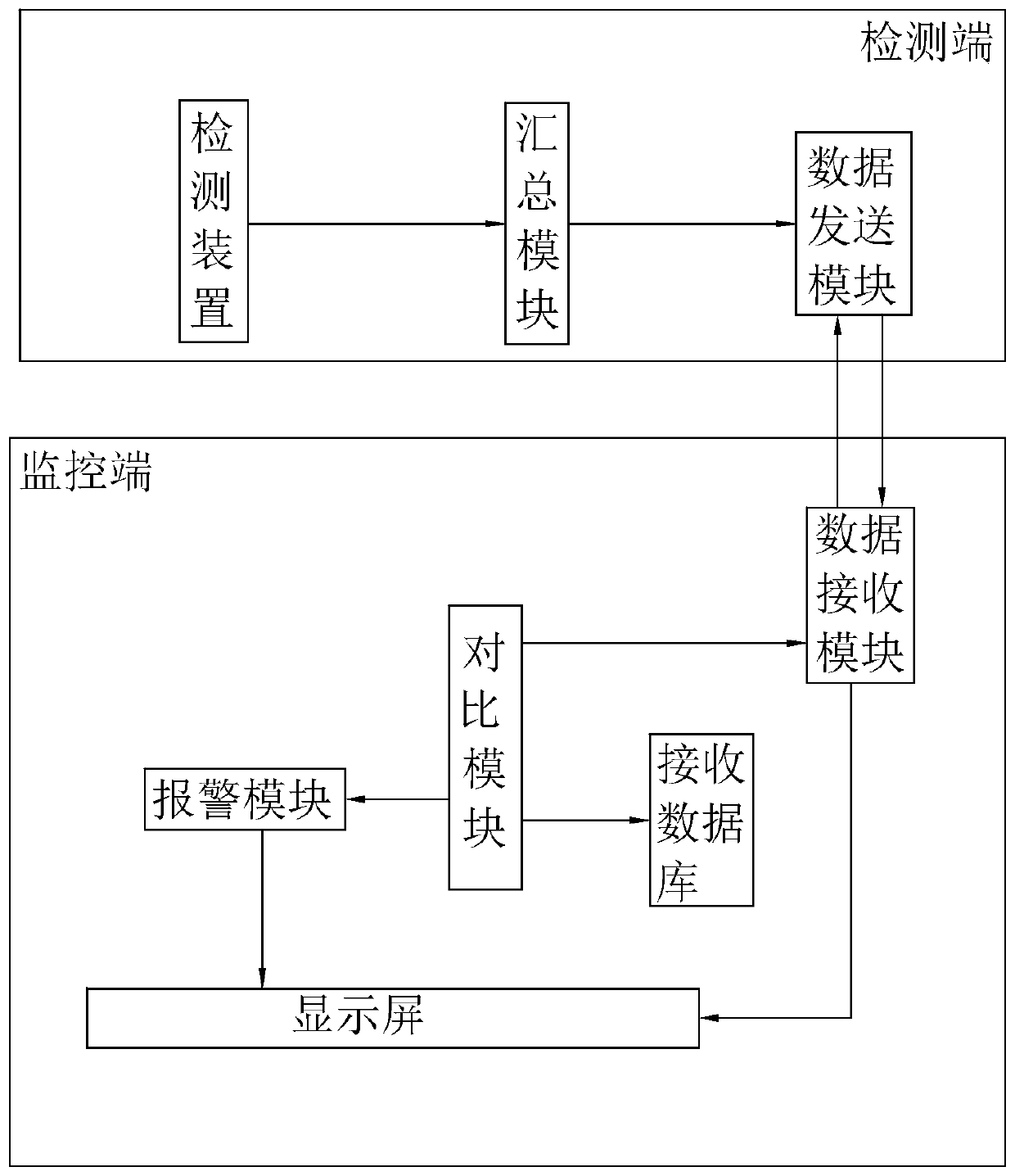

Oil remote monitoring system of transformer for power grid operation

PendingCN111366712AReduce surveySave manpower and material resourcesTesting dielectric strengthComponent separationMaster stationPower grid

The invention discloses an oil remote monitoring system of a transformer for power grid operation, and relates to the technical field of monitoring systems. The key points of the technical scheme areas follows: the system comprises a plurality of detection terminals and a monitoring terminal, the detection terminal is provided with a detection device which is used for detecting transformer oil indexes to obtain detection data and sending out detection signals and a data sending module which is in signal connection with the detection device and used for receiving the detection signals and thenremotely sending the detection signals to the monitoring terminal, the monitoring terminal is provided with a data receiving module which is matched with the data sending module and is used for receiving the detection data, and the monitoring terminal is provided with a display screen which is used for displaying the detection data. The system solves the technical problem that the workload is large when a large amount of data is sent to a master station to be gathered, and has the advantage of reducing the workload.

Owner:深圳市资通科技有限公司

Cleaning agent for oil-based drilling fluid as well as preparation method and evaluation method thereof

ActiveCN106634913AAbundant resourcesThe evaluation method is simpleFlow propertiesMaterial flash-point2-ImidazolineCleansing Agents

The invention discloses a cleaning agent for an oil-based drilling fluid as well as a preparation method and evaluation method thereof. The cleaning agent is prepared from the following components in percentage by weight: 50-60% of tetraethylenepentamine, 20-25% of fatty acid alkanol amide, 10-15% of 2-methyl-2-imidazoline and 5-10% of dimethylacetamide. The preparation method of the cleaning agent comprises the steps of: adding the tetraethylenepentamine into a reactor according to the percentage by weight, starting stirring, dripping fatty acid alkanol amide and dimethylacetamide, then adding 2-methyl-2-imidazoline, after continuing stirring for 5min, heating the mixture to 45-50 DEG C, stirring for 30-60min at constant temperature, and cooling the mixture to room temperature to obtain the cleaning agent. The evaluation method of the cleaning agent comprises determination of drainage time: (1) preparation of a standard test fluid; (2) preparation of a pulp sample; and (3) determination of the drainage time. The cleaning agent prepared by the preparation method is excellent in temperature resistance, and has an excellent cleaning effect for the residual oil-based drilling fluid which has complex components, a stable rubber matrix structure and high adhesion strength.

Owner:广汉市福客科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com