Combined type refrigerant low-temperature flash point testing system

A test system and composite technology, applied in the direction of material flash point, etc., can solve problems such as unfavorable energy saving, frost or condensation, and inability to measure flash point, so as to save water and avoid frost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

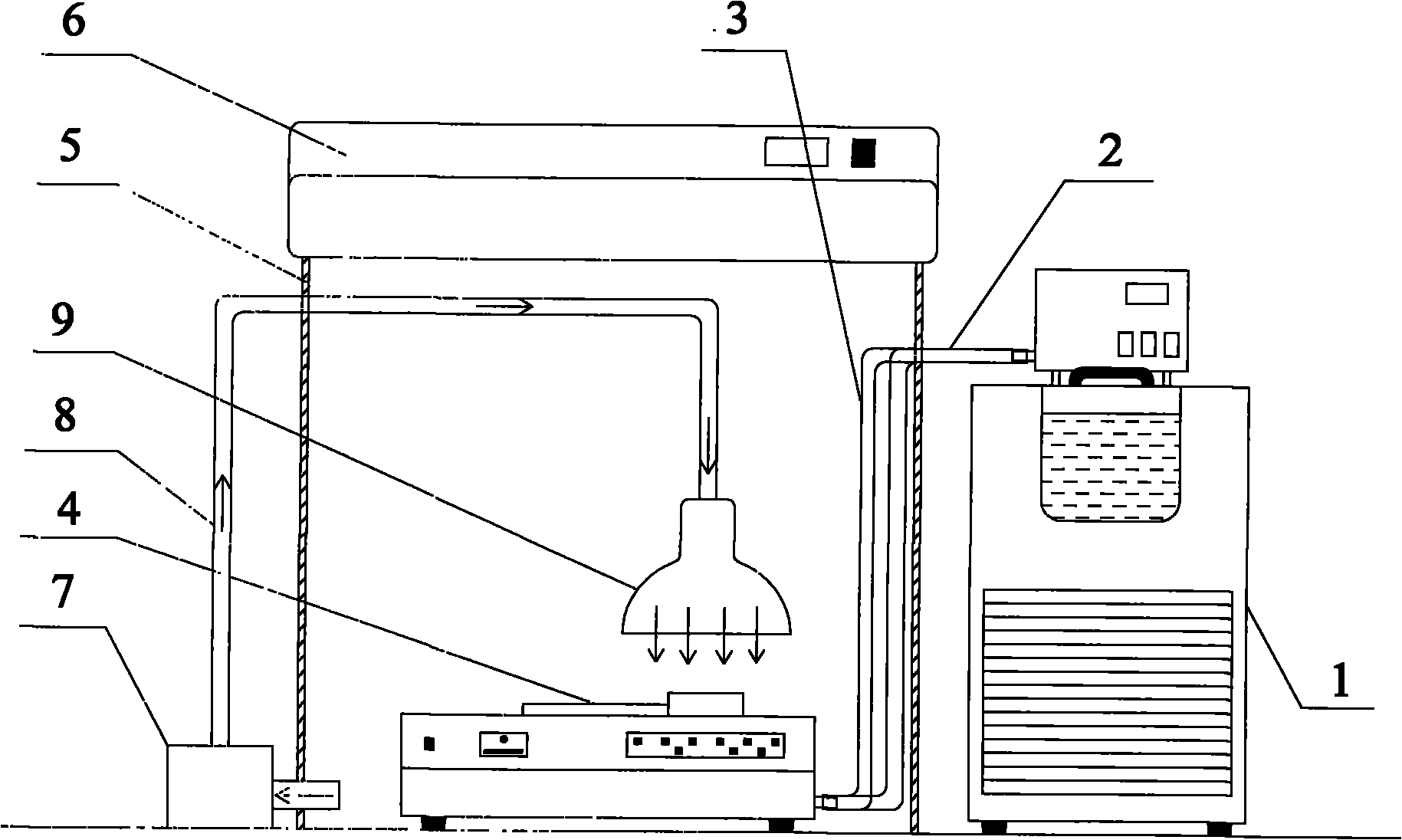

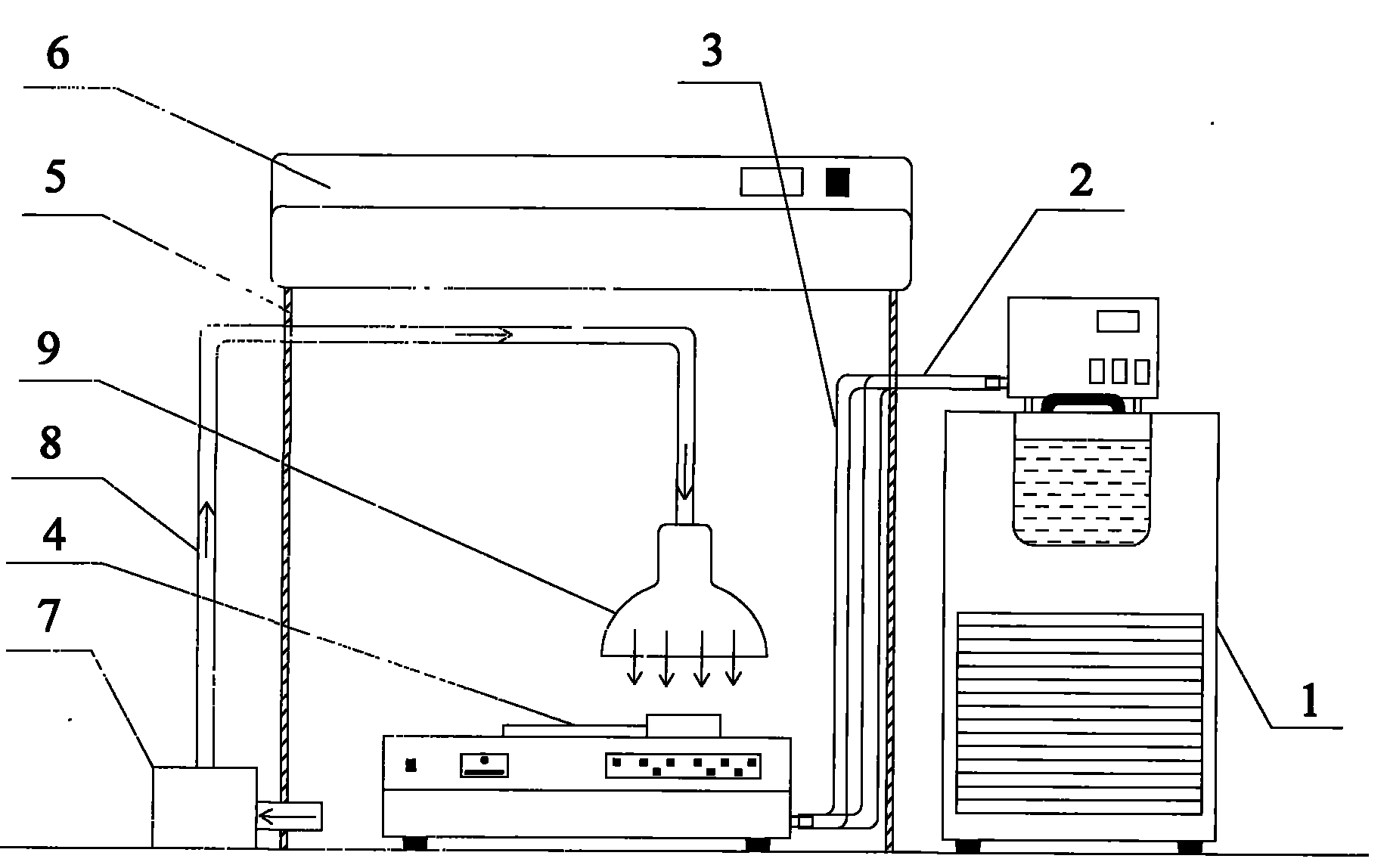

[0019] A kind of low-temperature flash point test system of compound refrigeration, its structure is as follows figure 1 As shown, the test system is composed of an external cooling device, a flash point test device, an isolation cover, an air filter device and an air drying device. connect. The isolation cover is set in the middle of the flash point test system, the flash point test device is set inside the isolation cover, the air filter is set on the top of the isolation cover, and the air drying device is set on the other side of the flash point test system.

[0020] The external cooling device includes a low-temperature constant temperature tank 1, a thermal insulation pipeline 2 and a thermal insulation pipeline 3. One end of the thermal insulation pipeline 2 is connected to the outlet of the low temperature constant temperature tank 1, and the other end passes through the side wall of the isolation cover 5 and is connected to the coolant inlet of the flash point test de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com