Energetic material flash point test method and equipment thereof

A test method and flash point technology, applied in the direction of material flash point, etc., can solve the problems of personnel and equipment danger, achieve a wide range of trials, ensure life safety, and improve the effect of intrinsic safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

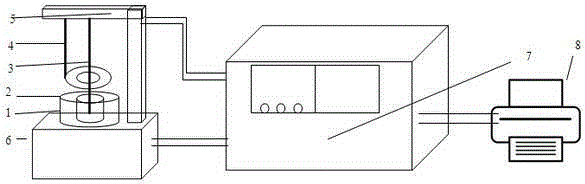

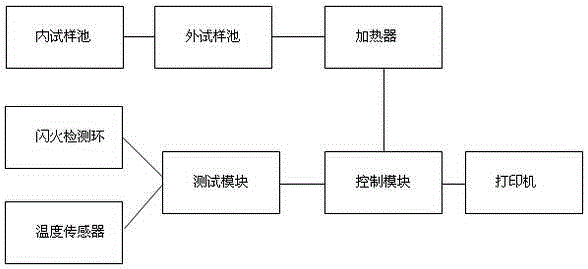

Method used

Image

Examples

Embodiment 1

[0042] Accurately weigh 10ml of nitromethane, the energetic material to be tested, and place it in the inner sample cell (small volume measuring cup 1 # ); put the inner sample cell into the outer sample cell (large-volume measuring cup No. 0), the rest of the steps are as above, and the test results are as follows:

[0043]

Embodiment 2

[0045] Accurately weigh 5ml of nitroethane, the energetic material to be tested, and place it in the inner sample cell (small volume measuring cup 2 # ), put the inner sample cell into the outer sample cell (large-volume measuring cup No. 0), the rest of the steps are as above, and the test results are as follows:

[0046]

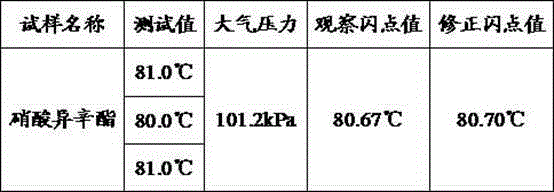

Embodiment 3

[0048] Accurately weigh 2ml of isooctyl nitrate, the energetic material to be tested, and place it in the inner sample cell (small volume measuring cup 3 # ), put the inner sample cell into the outer sample cell (large-volume measuring cup No. 0), the rest of the steps are as above, and the test results are as follows:

[0049]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com