Method for analyzing coal pyrolysis

An analysis method and coal pyrolysis technology, applied in the field of coal pyrolysis analysis, can solve problems such as insufficient thoroughness and detail in coal analysis, and inability to provide a more detailed data basis for coal processing, achieving accurate and reliable data, thorough analysis, The effect of uniform heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

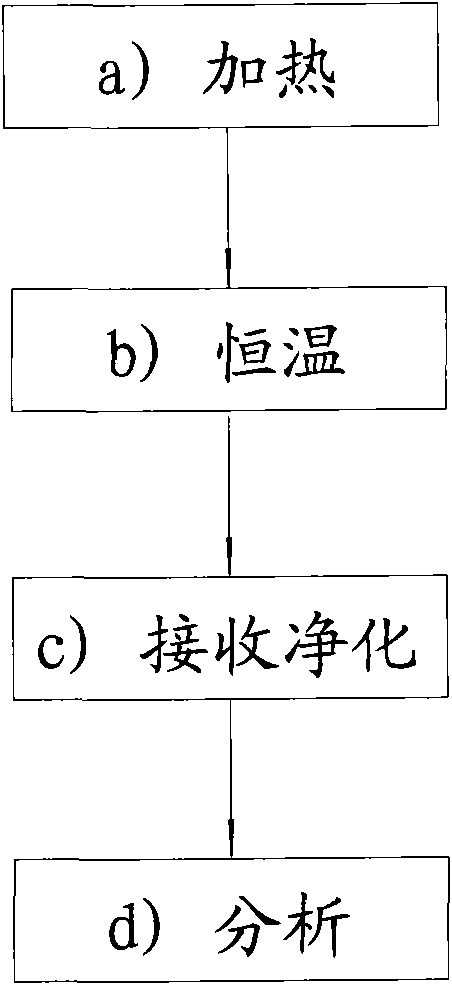

[0047] See figure 1 , figure 1 It is a process flow diagram of the coal pyrolysis analysis method provided in Example 1.

[0048] This embodiment mainly includes the following steps, which are respectively:

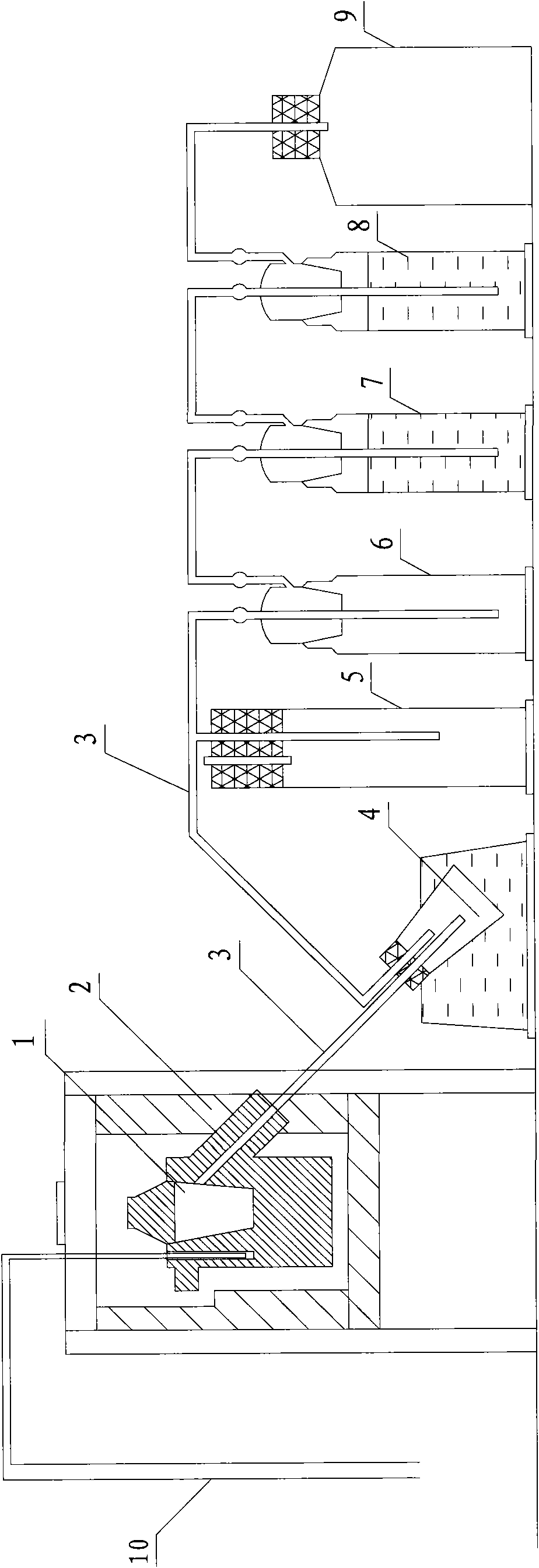

[0049] (1) Heat 2.704kg of low-quality A coal in the retort, the particle size of A coal is less than 6mm, stir while heating, heat to 300°C, and the heating rate is 5°C / min (Celsius / minute),

[0050] Keep the temperature constant for 10 minutes, and the products generated at this time pass through the oil-water receiving bottle and the absorption bottle set in turn; take the sample to analyze the collected products in the oil-water receiving bottle, and analyze the gas passing through the absorption bottle;

[0051] (2) Continue heating, stir while heating, heat to 500°C, and the heating rate is 5°C / min (Celsius / minute),

[0052] Keep the temperature constant for 10 minutes, and the products generated at this time pass through the oil-water receiving bottle and the ab...

Embodiment 2

[0059] The difference between this embodiment and embodiment 1 is that the heating rate is 4° C. / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com