Pentagonal forming die barrel

A corner forming and mold barrel technology, which is applied in the direction of material forming presses, presses, manufacturing tools, etc., can solve the problems of uneven pyrolysis of raw materials, uneven gaps, and poor air permeability of raw material stacks.

Inactive Publication Date: 2017-03-08

宁夏卓越安科技有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] In the past, most of the raw materials in the production and extraction of wood tar did not undergo special processing, but mixed raw materials of various shapes and sizes at will, and then simply stacked them in the extraction box. In this way, in the raw material pile, The gap between raw materials and raw materials is uneven, resulting in poor air permeability of the raw material pile. In the process of extracting and producing wood tar by dry distillation, there will be uneven pyrolysis of raw materials, resulting in dead ends, and insufficient dry distillation evaporation, resulting in production Great waste of raw materials and low production efficiency

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

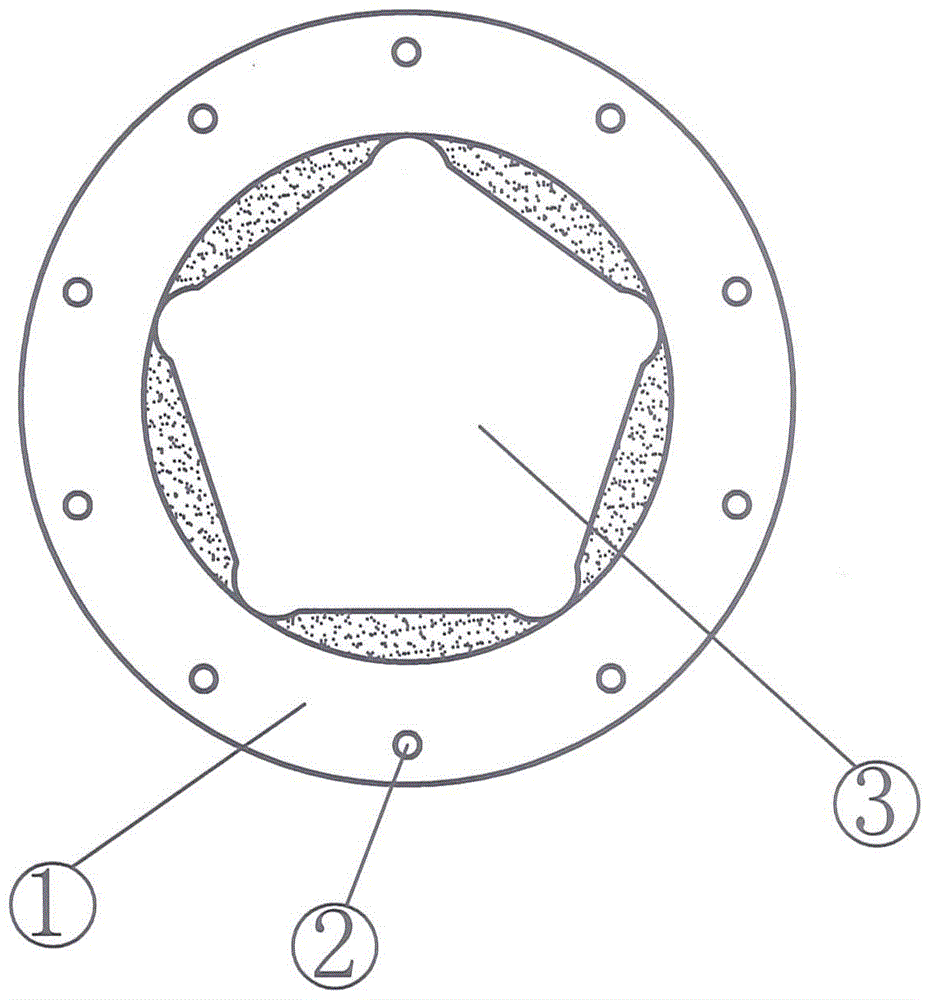

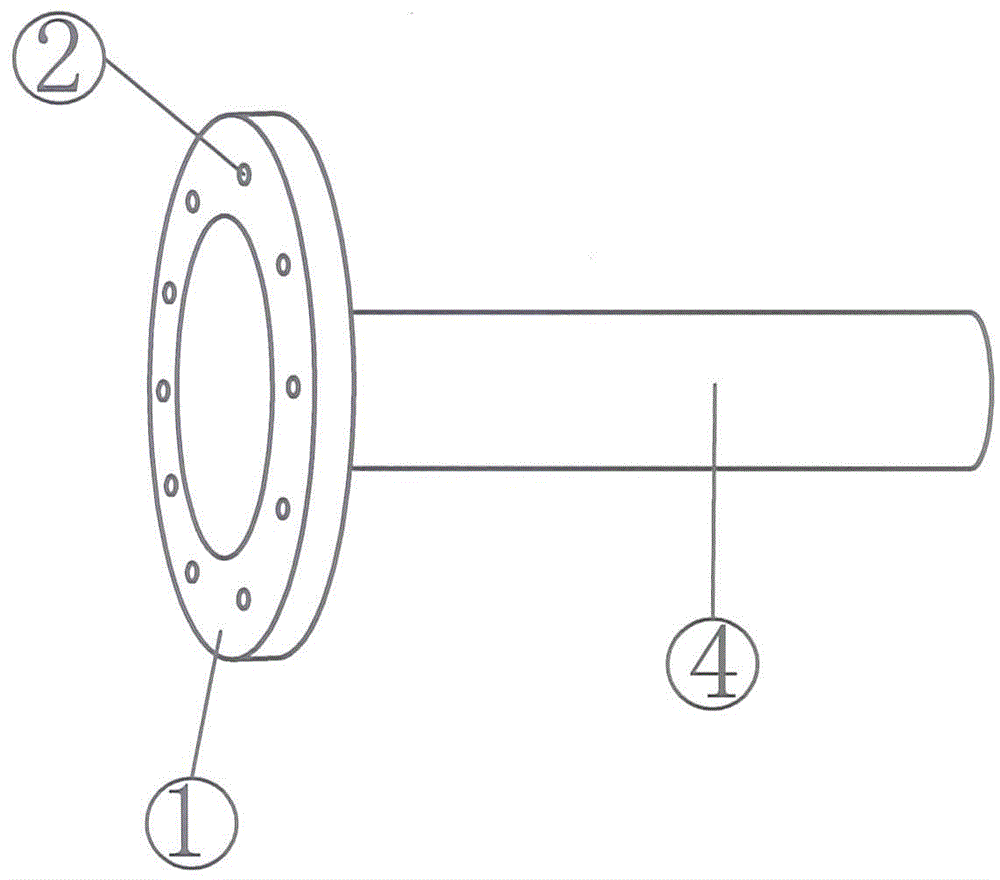

[0006] In the figure, there are multiple screw holes ② on the edge of the plane of the flange ①, and a pentagonal through hole ③ in the middle of the plane, which is vertically connected to the circular barrel body of the pentagonal molding barrel ④ in the middle of the plane of the flange ① , circular staving ④ and flange ① have the same through hole of a pentagonal shape, the formed pentagonal molding die barrel device.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a pentagonal forming die barrel. The pentagonal forming die barrel is used for extracting a main component as a prophase product of wood vinegar plant acid of an insecticidal plant pesticide from a plant, and processing and forming raw materials extracted from mother liquid wood tar production. The pentagonal forming die barrel is provided with a ring flange with the outer diameter of 0.2 meter and the thickness of 0.035 meter; a circular cylinder body with the length of 0.4 meter and the outer diameter of 0.12 meter is vertically linked to the middle of a plane of the pentagonal forming die barrel; identical pentagonal through holes are separately formed in the middle of the ring flange and the middle of the circular cylinder body; the depth of each through hole is 0.435 meter, and the inner diameter of each through hole is 0.055 to 0.065 meter; according to the formed pentagonal forming die barrel device, rod bodies with identical and regular shapes can be formed by a raw material body formed by the pentagonal forming die barrel; and after rod body raw materials are loaded into an extraction tank, identical gaps can be formed in all the rod bodies.

Description

technical field [0001] The invention is a pentagonal mold barrel used for extracting the main components of plant insecticides and pesticides from plants, the early product of wood vinegar plant acid, and the raw materials in the production and extraction of mother liquor wood tar. Background technique [0002] In the past, most of the raw materials in the production and extraction of wood tar did not undergo special processing, but mixed raw materials of various shapes and sizes at will, and then simply stacked them in the extraction box. In this way, in the raw material pile, The gap between raw materials and raw materials is uneven, resulting in poor air permeability of the raw material pile. In the process of extracting and producing wood tar by dry distillation, there will be uneven pyrolysis of raw materials, resulting in dead ends, and insufficient dry distillation evaporation, resulting in production Great waste of raw materials, and low production efficiency. Cont...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B30B11/22

CPCB30B11/22

Inventor 莫连云

Owner 宁夏卓越安科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com