A treatment system for oily sludge

A technology for treating system and sludge, which is applied in pyrolysis treatment of sludge, petroleum industry, vaporization of by-products, etc. Solution efficiency, improve the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

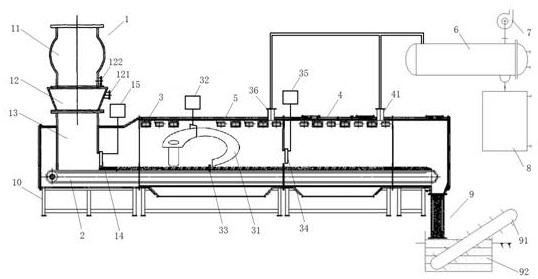

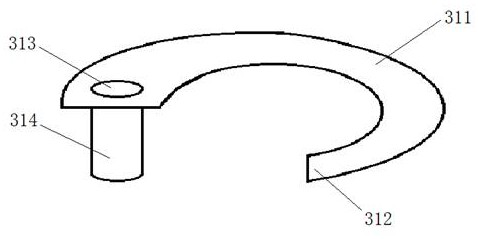

[0044] This embodiment provides a treatment system for oily sludge, which is mainly used in the harmless and resourceful treatment of oily sludge produced in oil exploration, refining and petrochemical industries, such as figure 1As shown, the processing system includes: a feeding device 1, an upper feed bin 11, a feed deoxygenation bin 12, an air inlet 121, an air outlet 122, a feed bin 13, a feed bin door 14, a first pushing device 15, Horizontal conveying device 2, main microwave pyrolysis furnace 3, screw conveying device 31, second pushing device 32, temperature detection device 33, main furnace door 34, third pushing device 35, first exhaust port 36, auxiliary microwave pyrolysis Furnace 4, second exhaust port 41, microwave outlet 5, condensation device 6, air extraction device 7, oil-water separation device 8, discharge device 9, slag discharger 91, pool 92, frame 10. The feed bin door 14 , the horizontal conveying device 2 , the main microwave pyrolysis furnace 3 , the...

Embodiment 2

[0060] This embodiment provides a treatment method for oily sludge, which can be applied to the treatment system for oily sludge in Example 1. The treatment method includes the following steps:

[0061] S1. Control the first pushing device 15 to close the feed bin door 14;

[0062] S2. After the material is fed and deoxidized, the first pushing device 15 is controlled to open the feed bin door 14, and the deoxidized material is transported to the main microwave pyrolysis furnace 3 through the material conveyor belt;

[0063] S3, controlling the third pusher 35 to close the main furnace door 34 of the main microwave pyrolysis furnace 3;

[0064] S4. Carry out temperature-controlled cycle pyrolysis treatment in the main microwave pyrolysis furnace 3, after the temperature-controlled cycle pyrolysis treatment, the material is transported to the auxiliary microwave pyrolysis furnace 4 through the material conveyor belt;

[0065] S5. Perform secondary pyrolysis treatment in the au...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com