Method for determining open cup flash point of oil product

A technology for open flash point and oil products, which is applied in the field of determination of open flash point of oil products, can solve the problems of poor precision of measurement results, harmfulness to human body, strict environmental requirements, etc., and achieves small deviation, good correlation and good precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

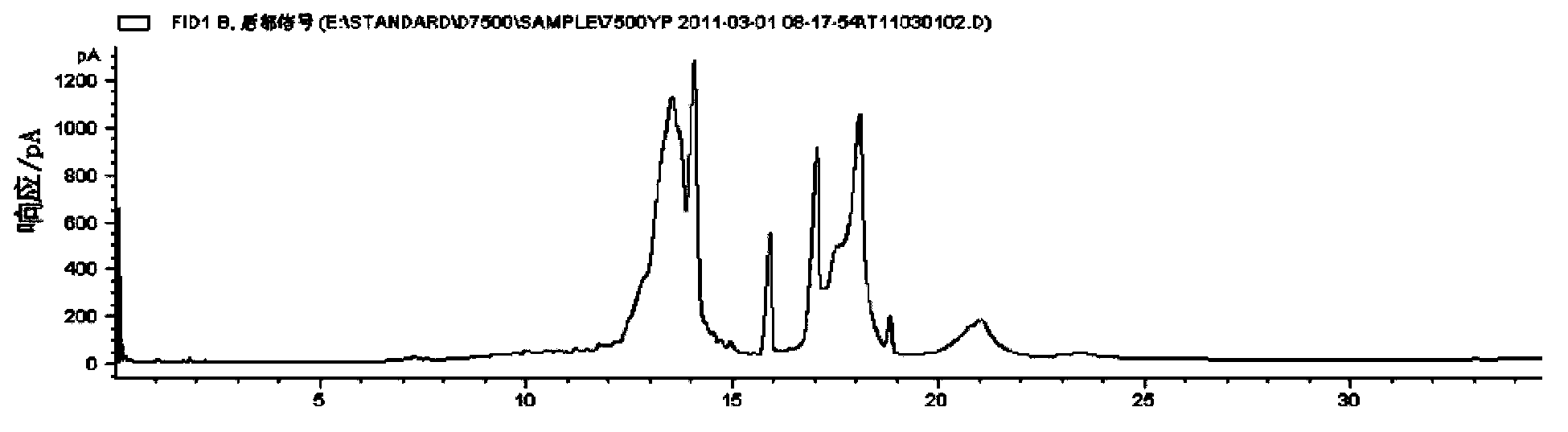

[0033] This embodiment is used to illustrate the method for measuring the open flash point of oil products of the present invention.

[0034] According to the method of NB / SH / T0829-2010 "Determination of Boiling Range Distribution of Petroleum Fractions with Boiling Range 174℃~700℃ (Gas Chromatography)", the boiling range distribution of internal combustion engine oils of the same brand but with different base oil compositions was measured. its T 10% , and substitute the test results into the correlation formula (1) for calculation to obtain its open flash point; and calculate the open flash point (measured value) measured according to the method of GB / T3536-2008 The difference of the open flash point (calculated value), the results are shown in Table 1 below.

[0035] Table 1

[0036]

Embodiment 2

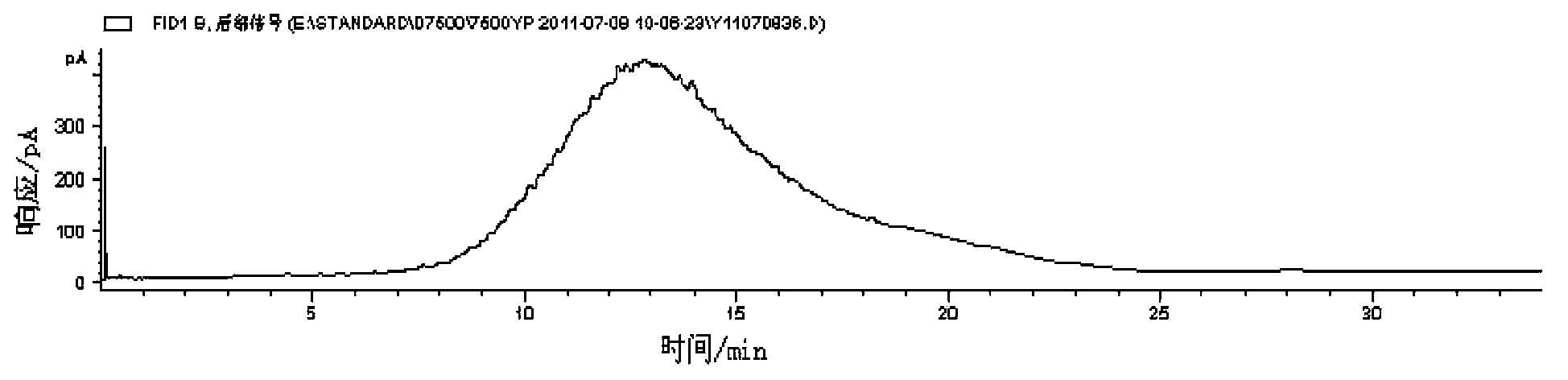

[0038] This embodiment is used to illustrate the method for measuring the open flash point of oil products of the present invention.

[0039] According to the method of NB / SH / T 0829-2010 "Determination of Boiling Range Distribution of Petroleum Fractions with a Boiling Range of 174°C to 700°C (Gas Chromatography)", the boiling range distribution of internal combustion engine oils of the same brand but with different base oil compositions was measured. Get it 3% and T 10% , and substitute the test results into the correlation formula (2) for calculation to obtain its open flash point; at the same time, according to the method of GB / T 3536-2008, the open flash point of each internal combustion engine oil sample was tested respectively, and calculated according to GB / T 3536 The difference between the open flash point (measured value) measured by the method of -2008 and the open flash point (calculated value) calculated by formula (1), the results are shown in Table 2 below.

[...

Embodiment 3

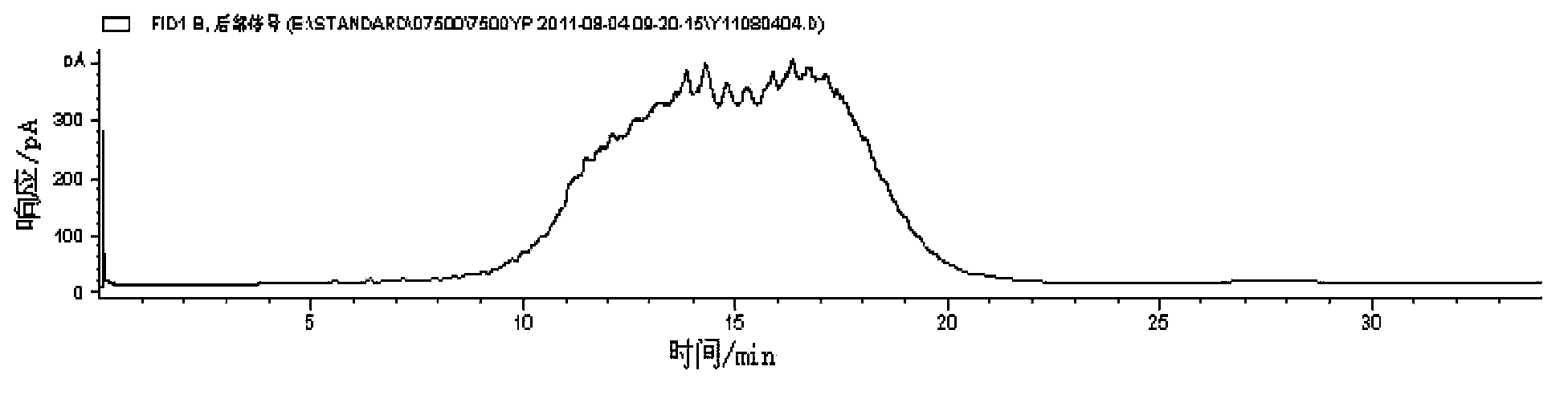

[0043] This embodiment is used to illustrate the method for measuring the open flash point of oil products of the present invention.

[0044] According to the method of NB / SH / T 0829-2010 "Determination of Boiling Range Distribution of Petroleum Fractions with Boiling Range 174℃~700℃ (Gas Chromatography)", the boiling range distribution of different brands of internal combustion engine oil was measured, and the T 3% and T 10% , and substituting the test results into the correlation formulas (1) and (2) for calculation to obtain the open flash point; and calculate the open flash point (measured value) and The difference between the open flash point (calculated value 1) calculated according to the correlation formula (1) and the open flash point (calculated value 2) calculated according to the correlation formula (2), the results are shown in Table 3 below.

[0045] table 3

[0046]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com