Automatic measuring device and method for flash point of insulating oil special for electric power

A technology for measuring device and insulating oil, applied in the direction of material flash point, etc., can solve the problems of fire danger, pollution of workers, physical injury, etc., and achieve the effect of avoiding environmental pollution problems, high degree of automation, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The implementation of the present invention will be described in further detail below. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

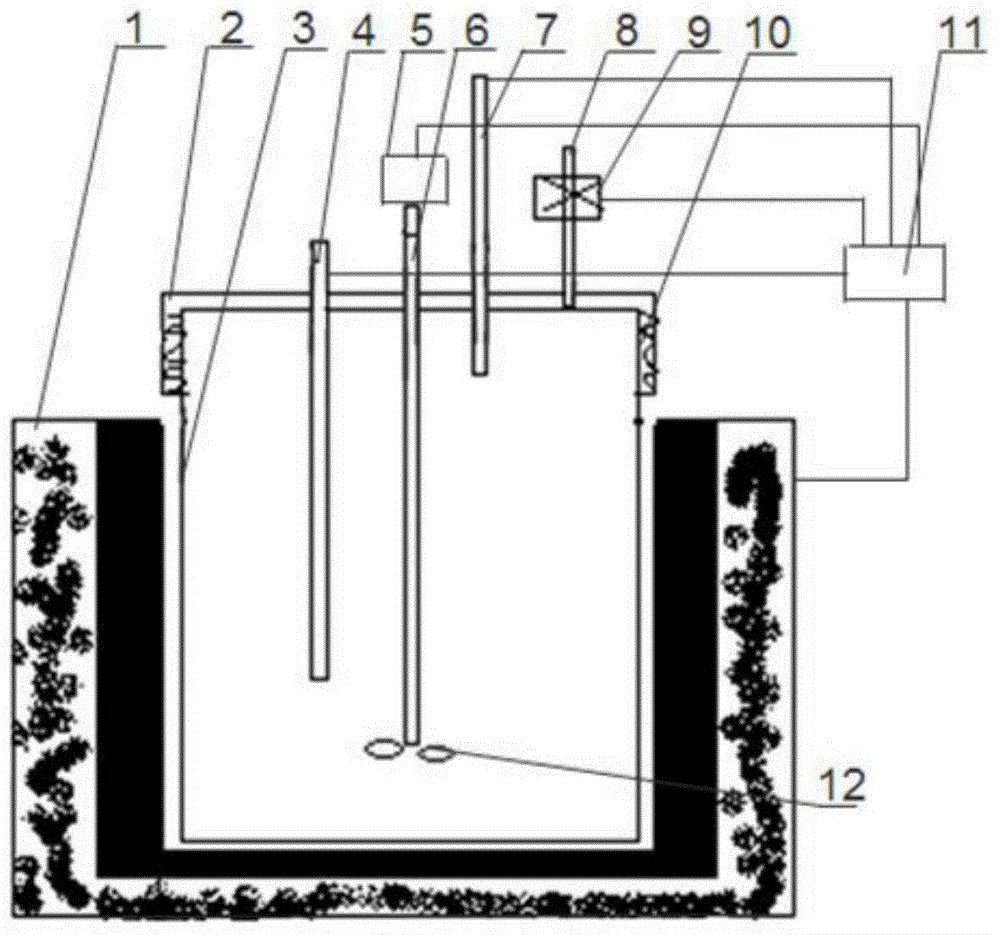

[0021] An automatic measuring device for the flash point of insulating oil specially used for electric power, such as figure 1 As shown, it includes a concave heating groove 1 connected to the control host 11, a test sealing oil cup 3 is placed in the concave heating groove, and an oil cup cover 2 is screwed on the upper opening of the testing sealing oil cup through a screw thread 10. A platinum resistance thermometer 4 connected to the control host, a stirring rod 6 with a motor 5 installed on the top, a pressure sensor 7 connected to the control host, and a combustion exhaust pipe 8 are respectively inserted through holes on the oil cup cover. It is connected with the control host, the combustion exhaust pipe is equipped with a solenoid valve 9 connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com