Cooling chamber assembly for a gasifier

A technology for cooling chambers and gasifiers, which is applied in the field of gasifiers and can solve problems such as operational problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

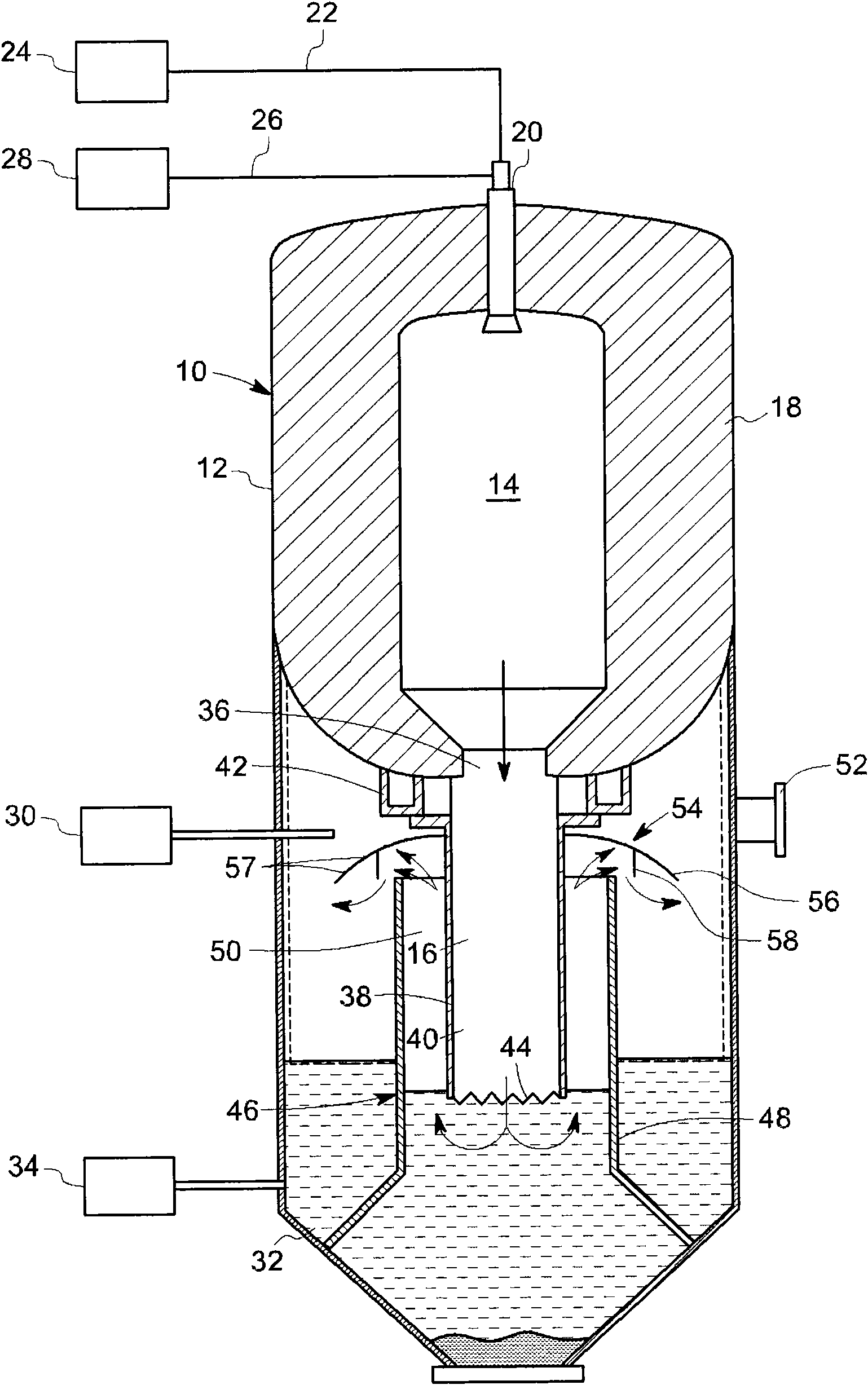

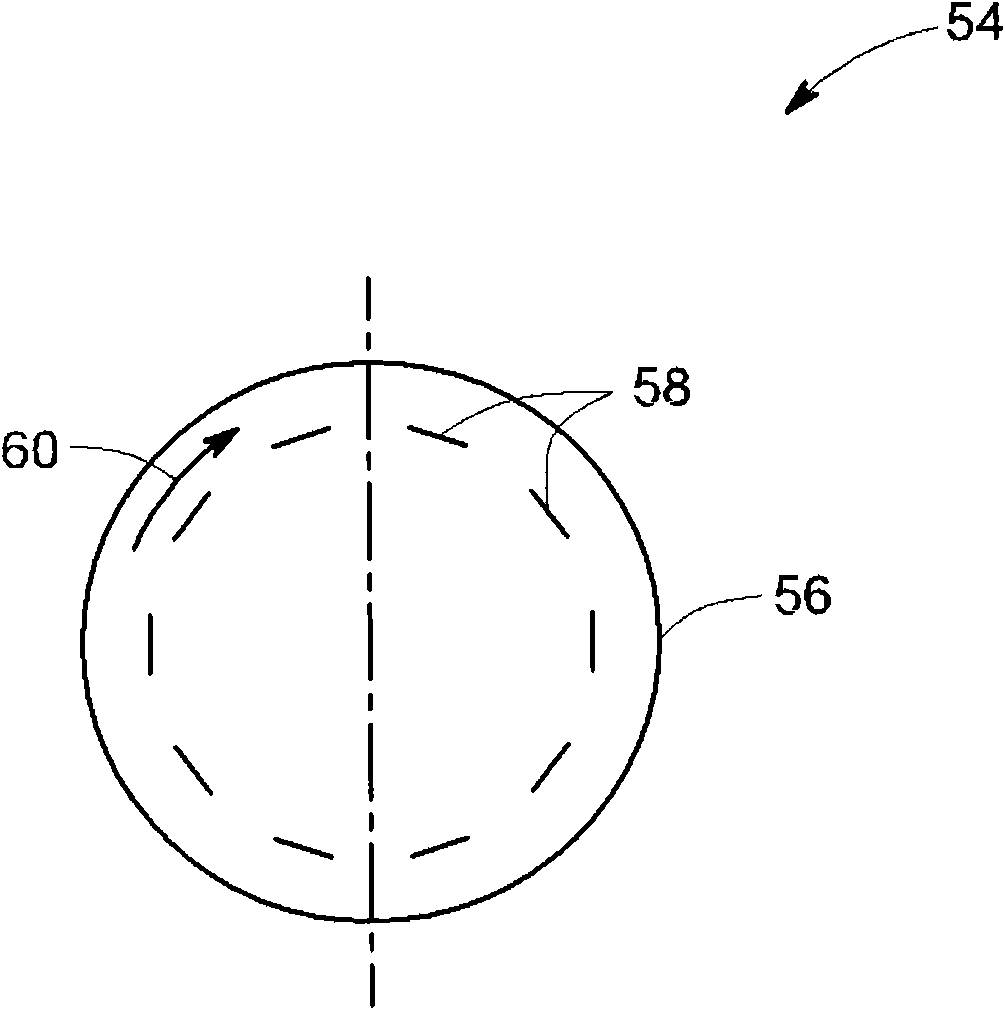

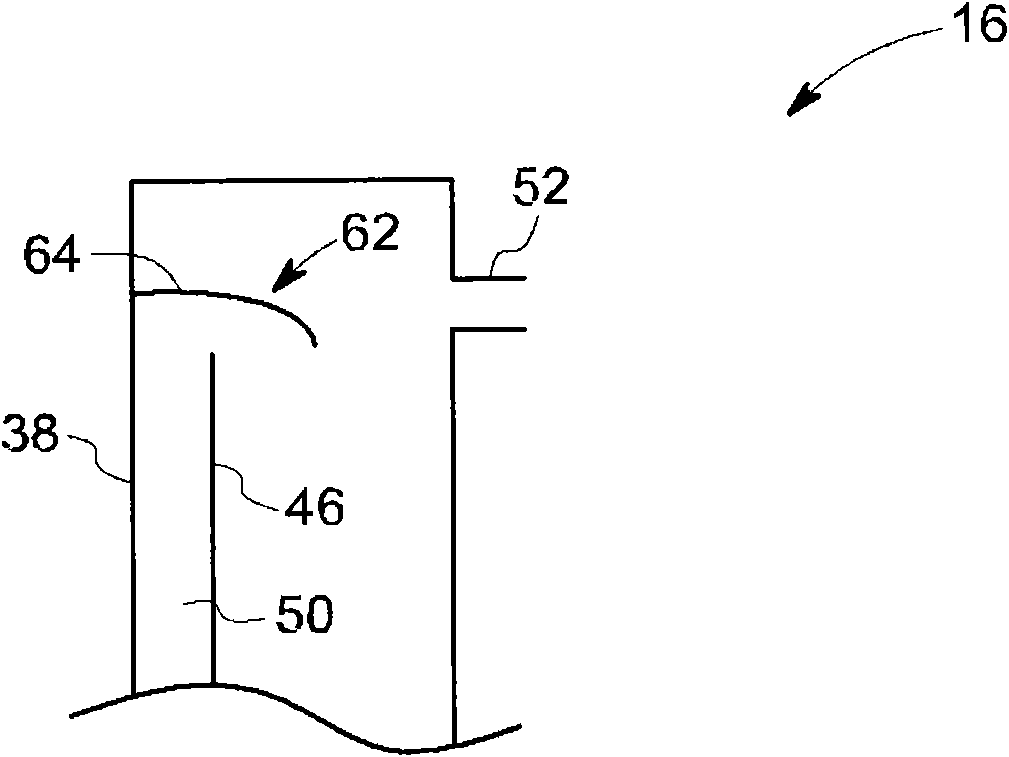

[0094] According to exemplary embodiments disclosed herein, a gasifier having a cooling chamber assembly configured to reduce the temperature of syngas downstream of a combustor is disclosed. The gasifier includes a cooling chamber containing a liquid coolant disposed downstream of the combustion chamber. Syngas produced from the combustor is directed through a dip tube to the cooling chamber to contact a liquid coolant and produce cooled syngas. The gasifier also includes a dip tube coupling the combustor to the cooling chamber and configured to direct syngas from the combustor to the cooling chamber to contact the liquid coolant and produce cooled syngas. The draft tube is arranged to surround the dip tube and define an annular passage therebetween. A liquid separator is disposed adjacent the outlet path of the cooling chamber and is configured to remove entrained liquid content from the cooled syngas channeled to the outlet path through the annular passage. In one embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com