Patents

Literature

67results about How to "Continuous and stable combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

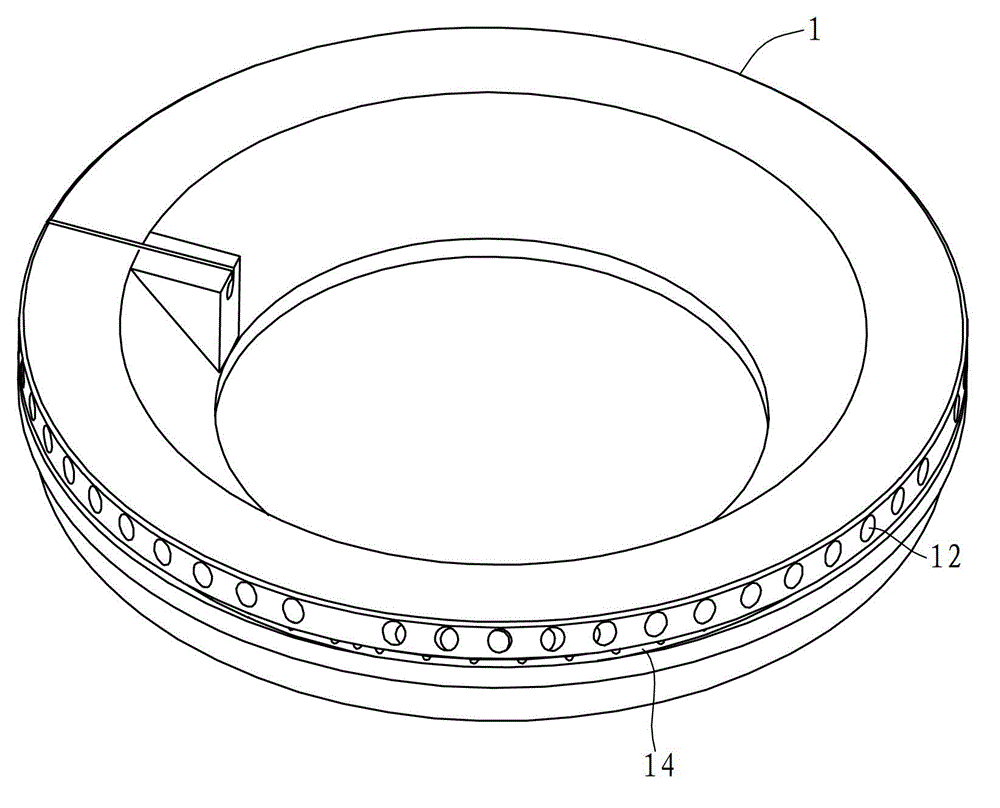

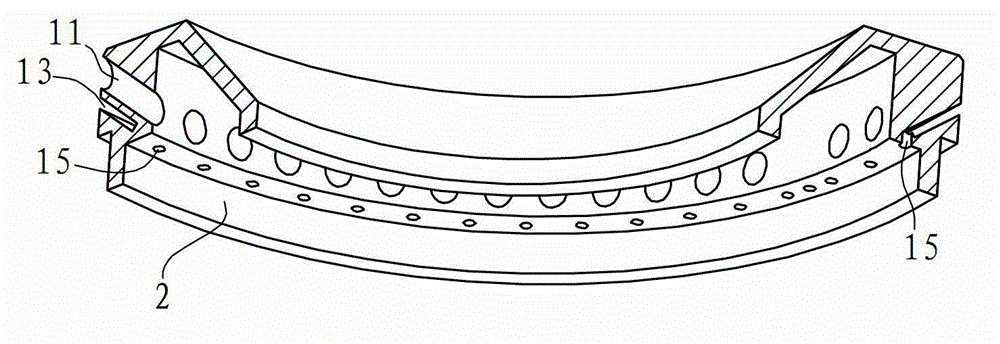

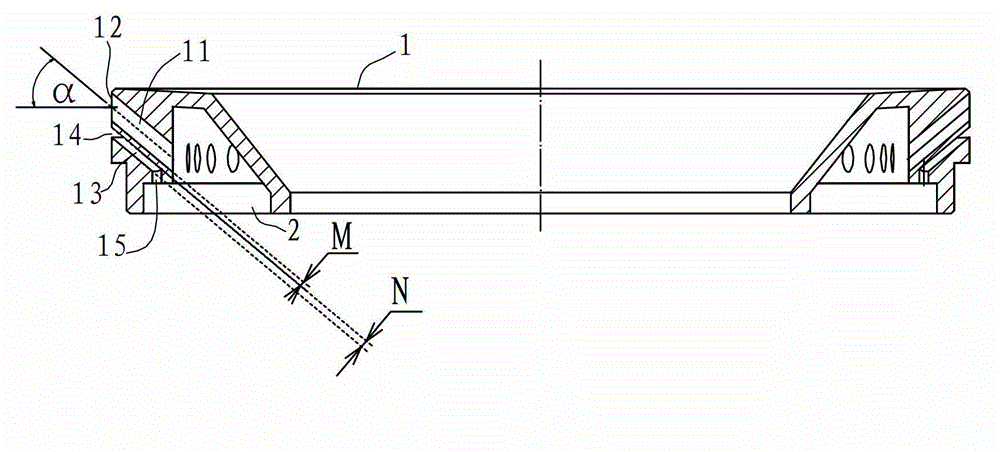

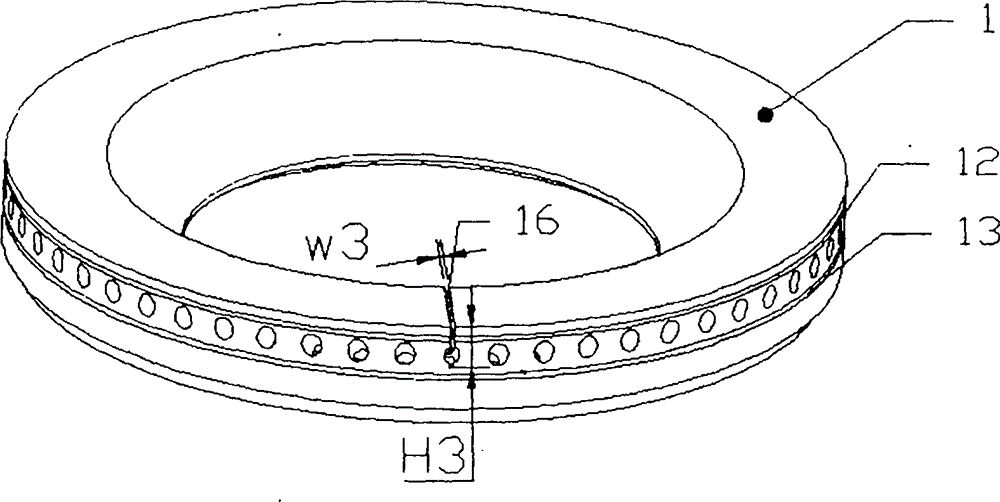

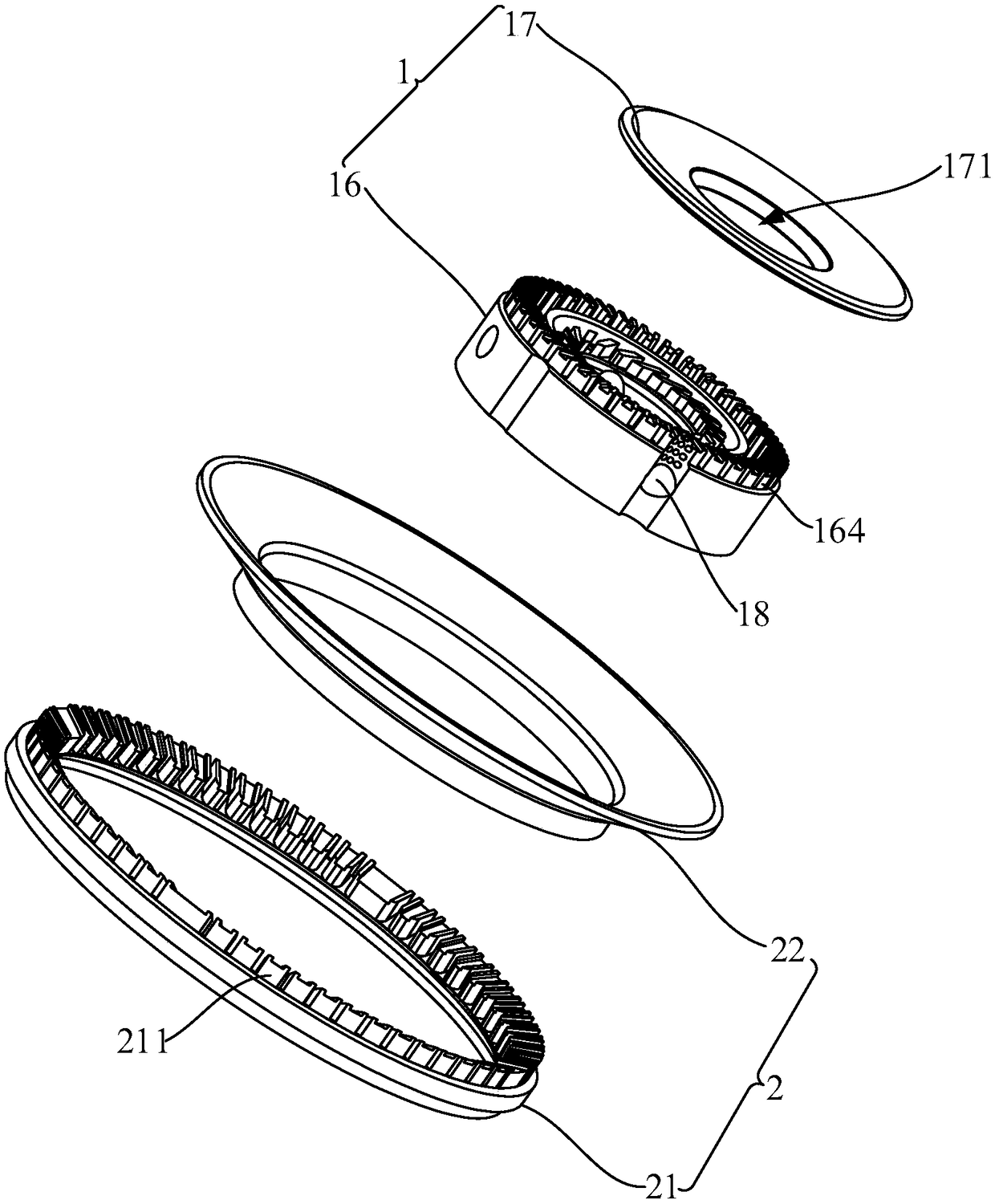

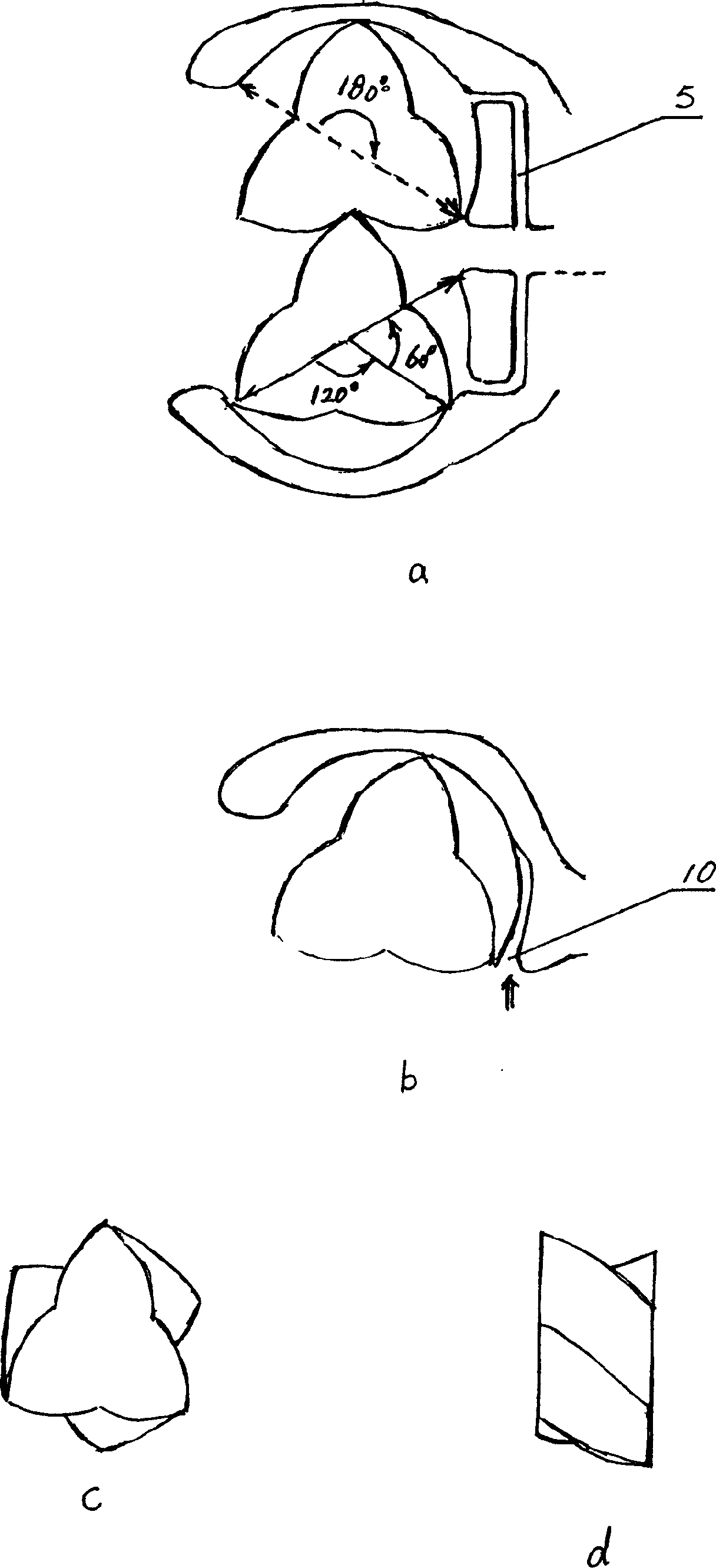

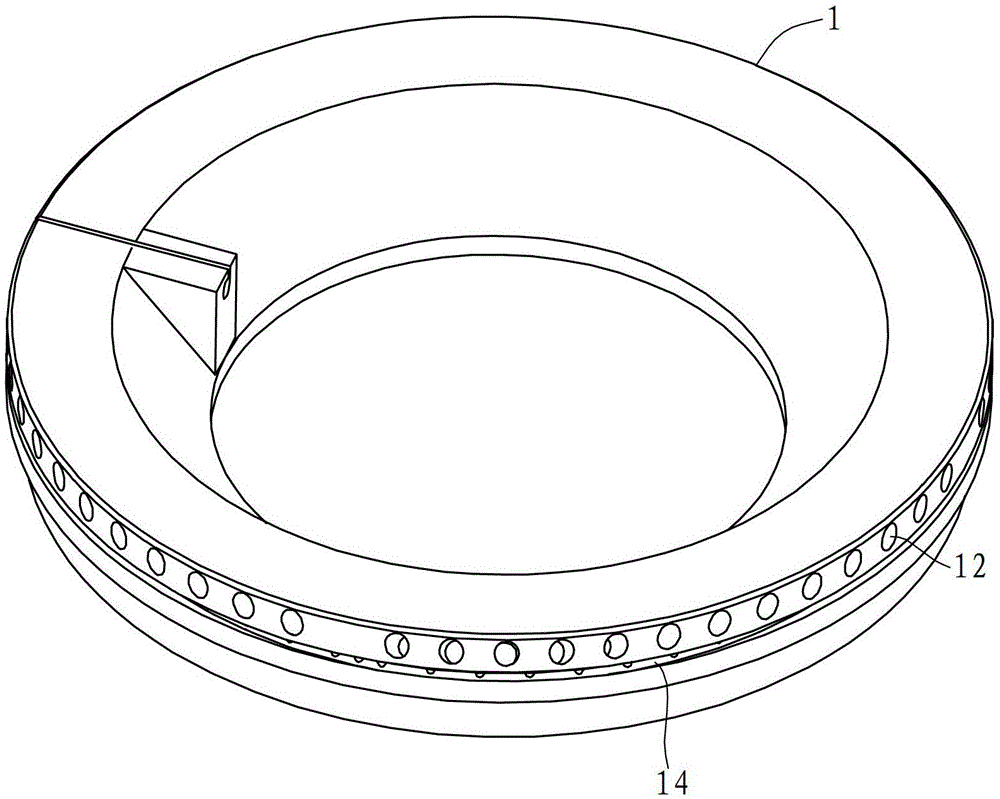

Outer burner cap of burner

ActiveCN102913911A"Control" effect is perfect"Control" effect caused byGaseous fuel burnerCombustorEngineering

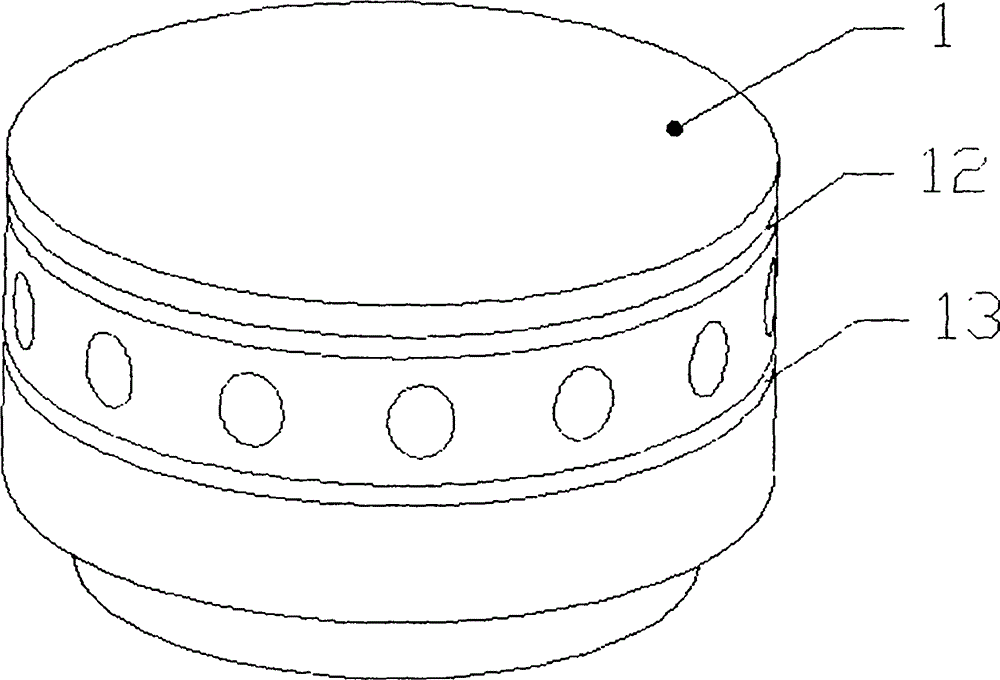

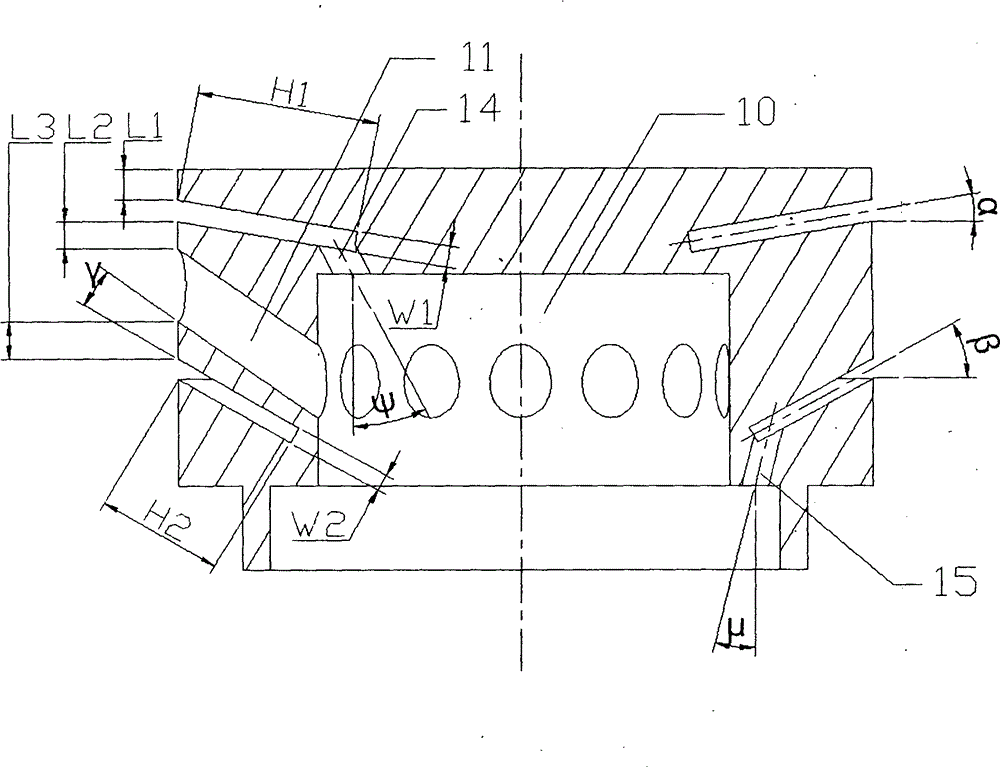

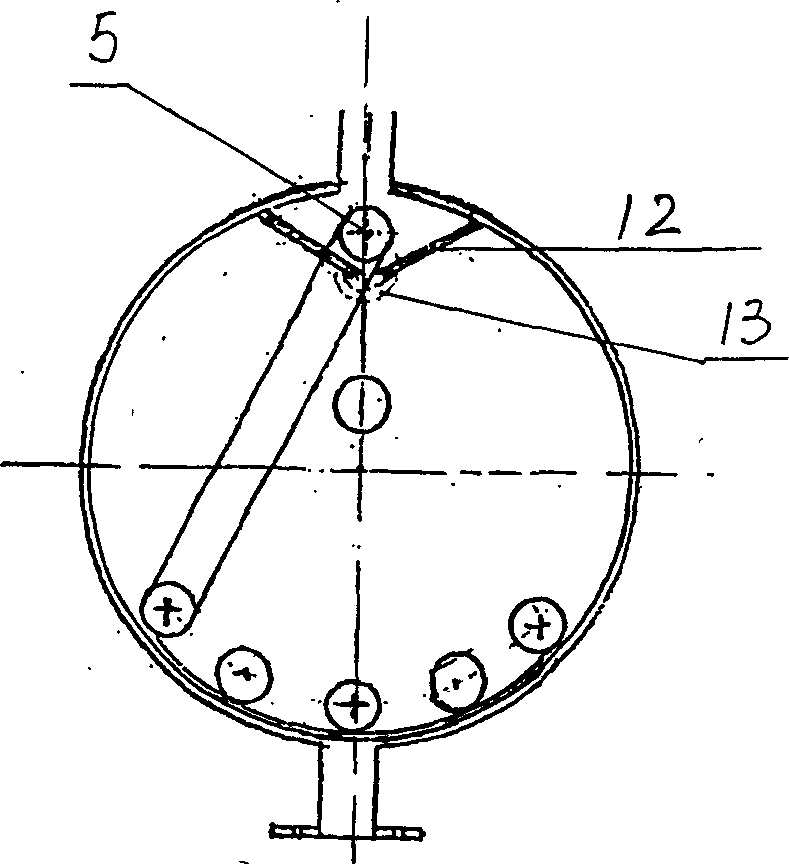

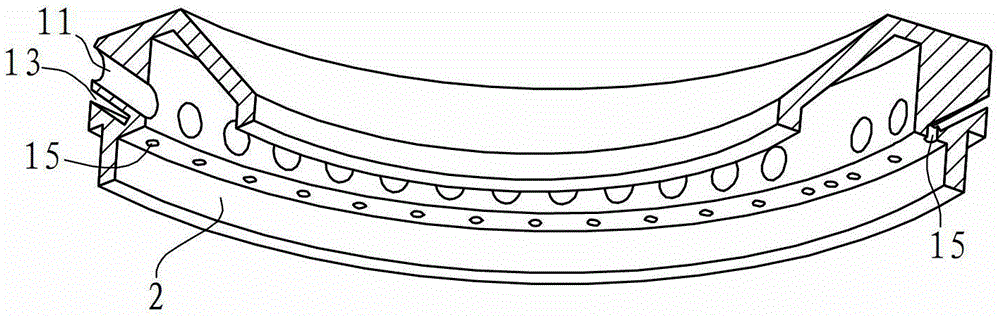

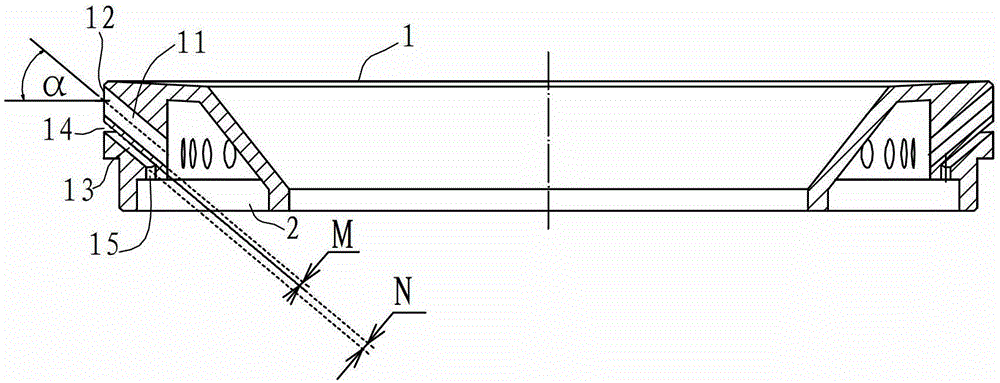

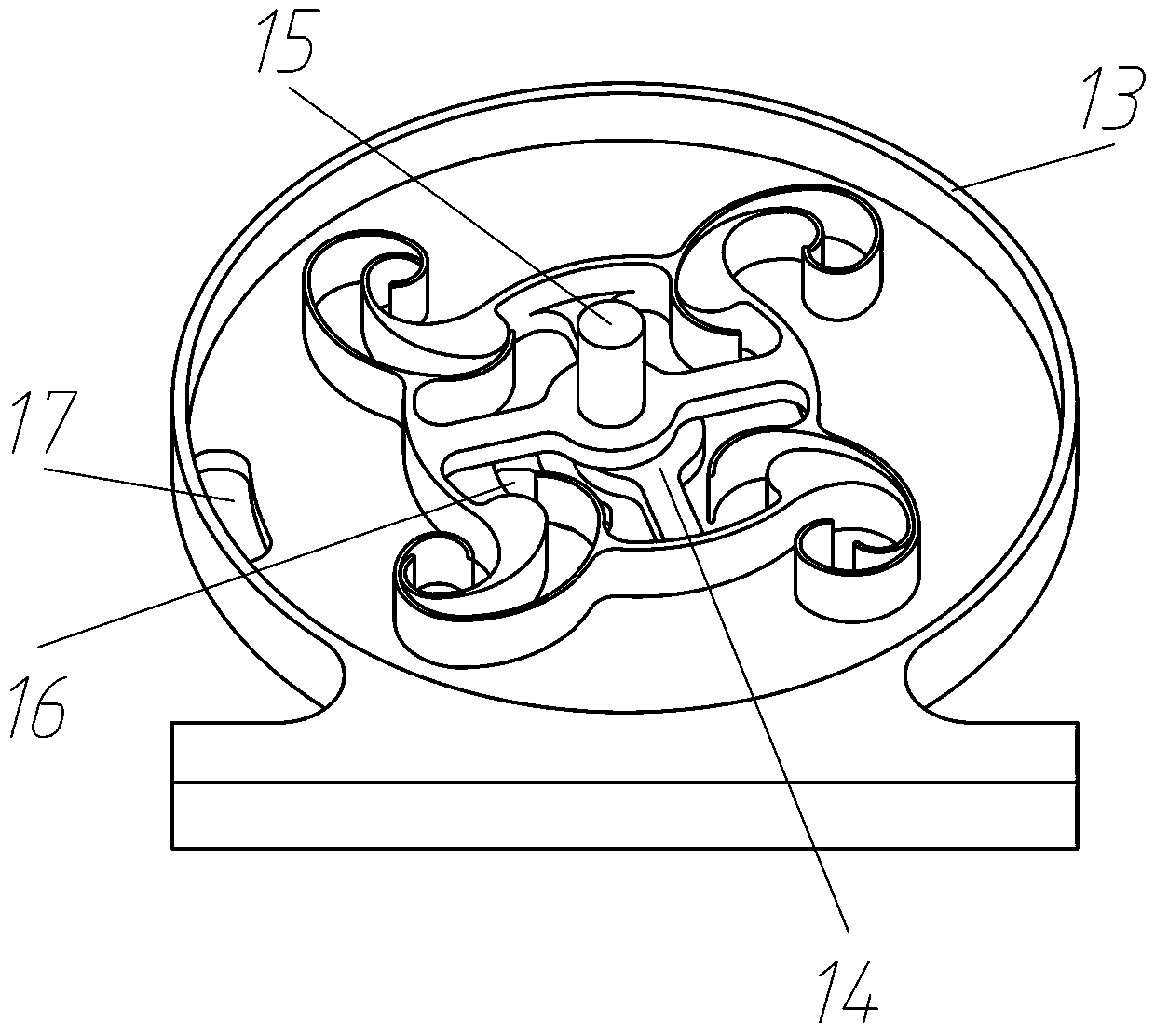

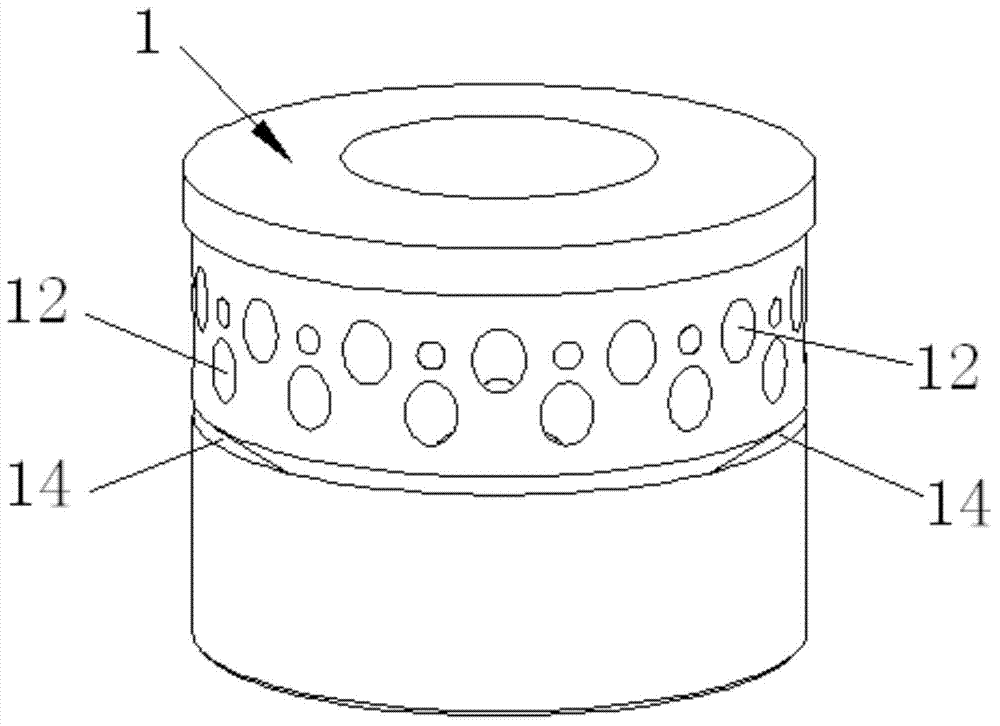

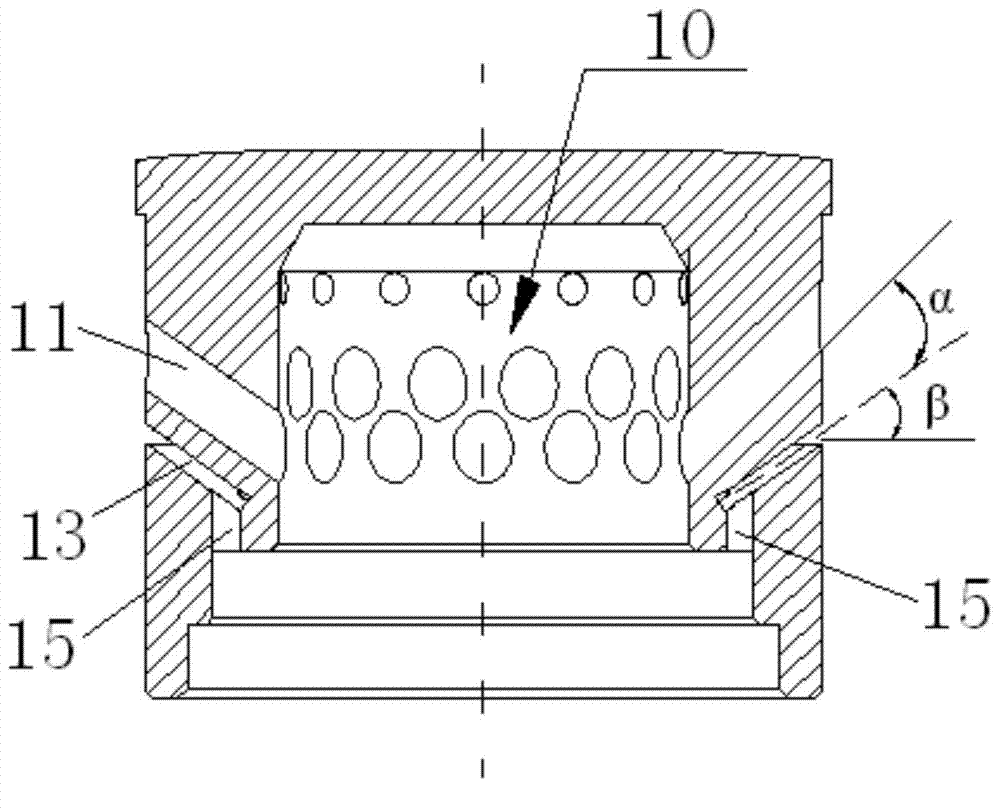

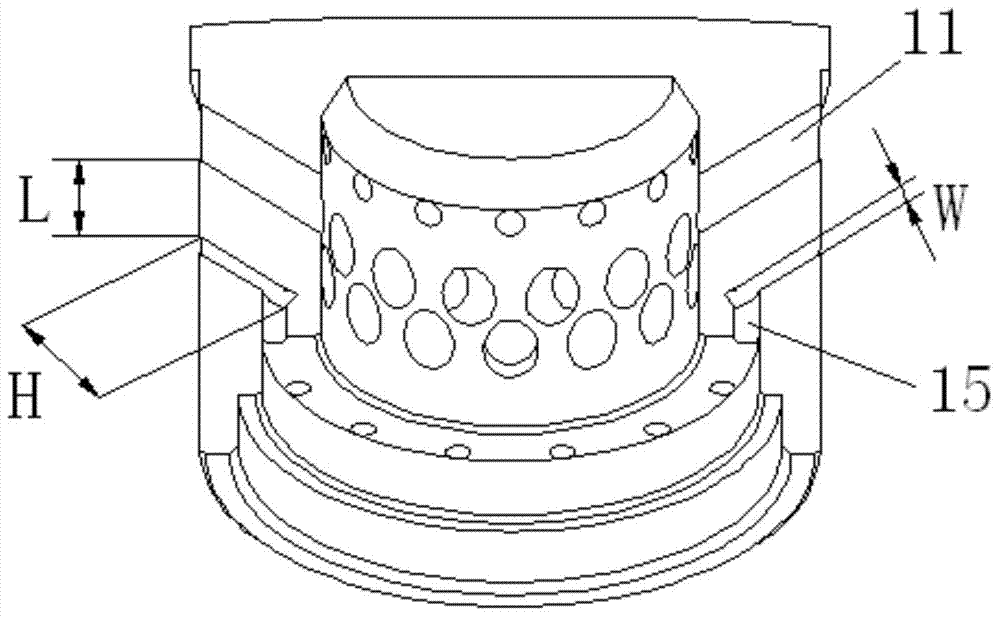

An outer burner cap of a burner comprises an outer burner cap body with a plurality of main flame channels. The lower end of the outer burner cap is provided with a gas mixing chamber communicated with the main flame channels. The main flame channels are provided with main flame holes on at least one of the inner side and the outer side of the outer turner cap body. The outer burner cap is characterized in that the outer flame cap body above or below the main flame channels peripherally forms a circular flame-stabilizing channel, and the outer end of the flame-stabilizing channel forms a flame stabilizer ring on the outer side or inner side of the outer burner cap body. The inner end of the flame-stabilizing channel is communicated with the gas mixing chamber. Compared with the prior art, the outer burner cap has the advantage that the flame-stabilizing channel at the lower edges of the main flame holes can well 'stabilize' flame from the main flame holes during burning so as to stabilize burning.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Outer fire cover of burner

InactiveCN105299646AImprove efficiencyImprove stabilityGaseous fuel burnerHeating efficiencyEngineering

The invention discloses an outer fire cover of a burner. The outer fire cover comprises a cylindrical fire cover body. A plurality of main fire holes are formed in the fire cover body at intervals in the circumferential direction. One ends of the multiple main fire holes are communicated with a gas mixing cavity. Two annular flame stabilizing grooves are formed above and below the main fire holes in the outer fire cover body in the circumferential direction of the outer fire cover body. One side of each flame stabilizing groove is formed in the vertical surface of the outer side of the fire cover body so that a circle of stable flames can be formed, and the other side of each flame stabilizing groove is communicated with the gas mixing cavity. A fire transferring groove is formed in the upper surface of the outer fire cover body. One end of the fire transferring groove is divided above the upper flame stabilizing groove and the main fire holes so that the upper flame stabilizing groove and the gas mixing cavity can be communicated. Main flames of the outer fire cover are controlled by flame stabilizing flames in the upper flame stabilizing groove and flame stabilizing flames in the lower flame stabilizing groove at the same time so that the optimal state can be achieved; in addition, the main flames can be pulled by the flame stabilizing flames sufficiently during combustion, continuous and stable combustion of the main flames is achieved, the stability and reliability of fire transferring are improved, and the heat efficiency is improved.

Owner:ZHEJIANG MONY COOKING UTENSILS

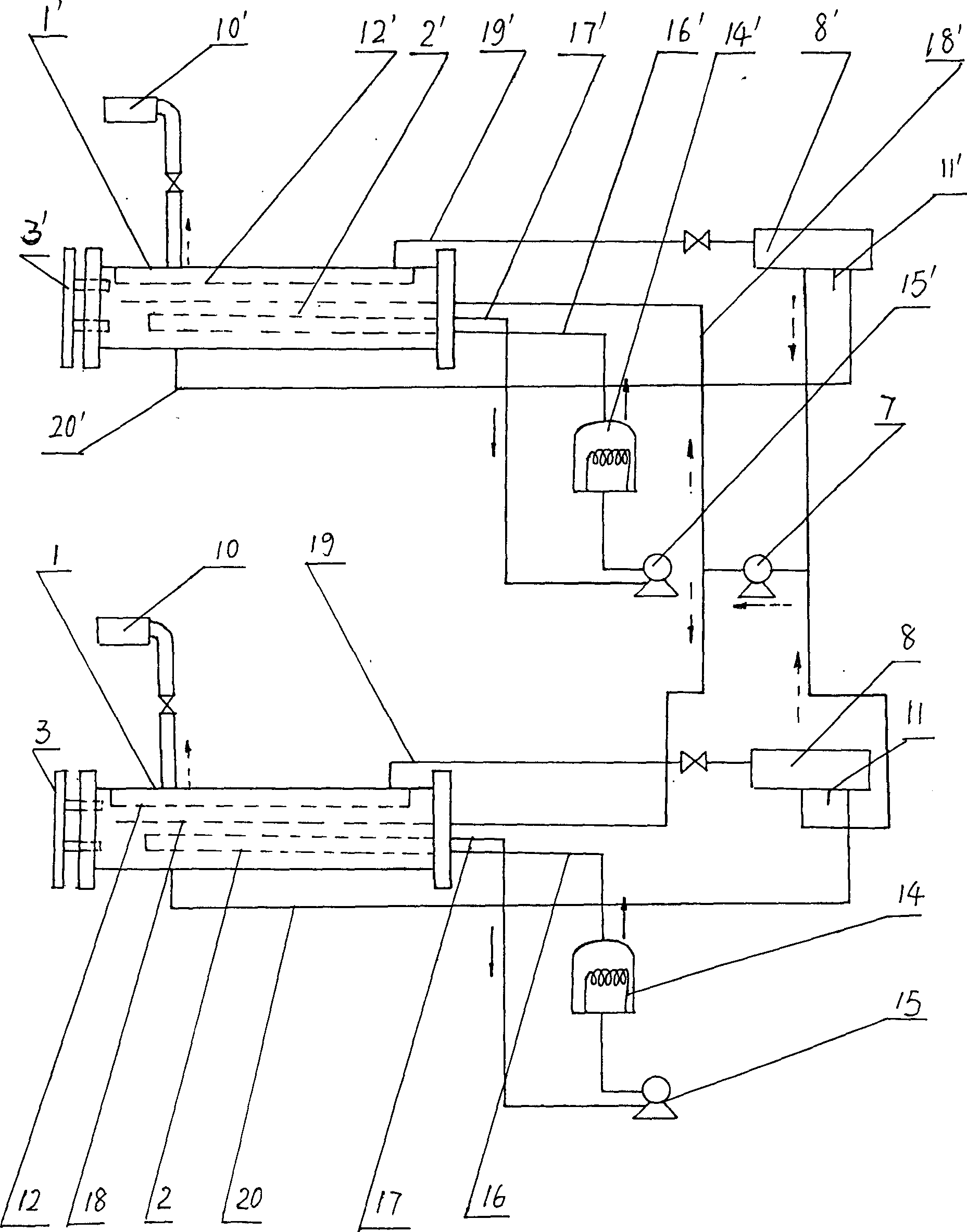

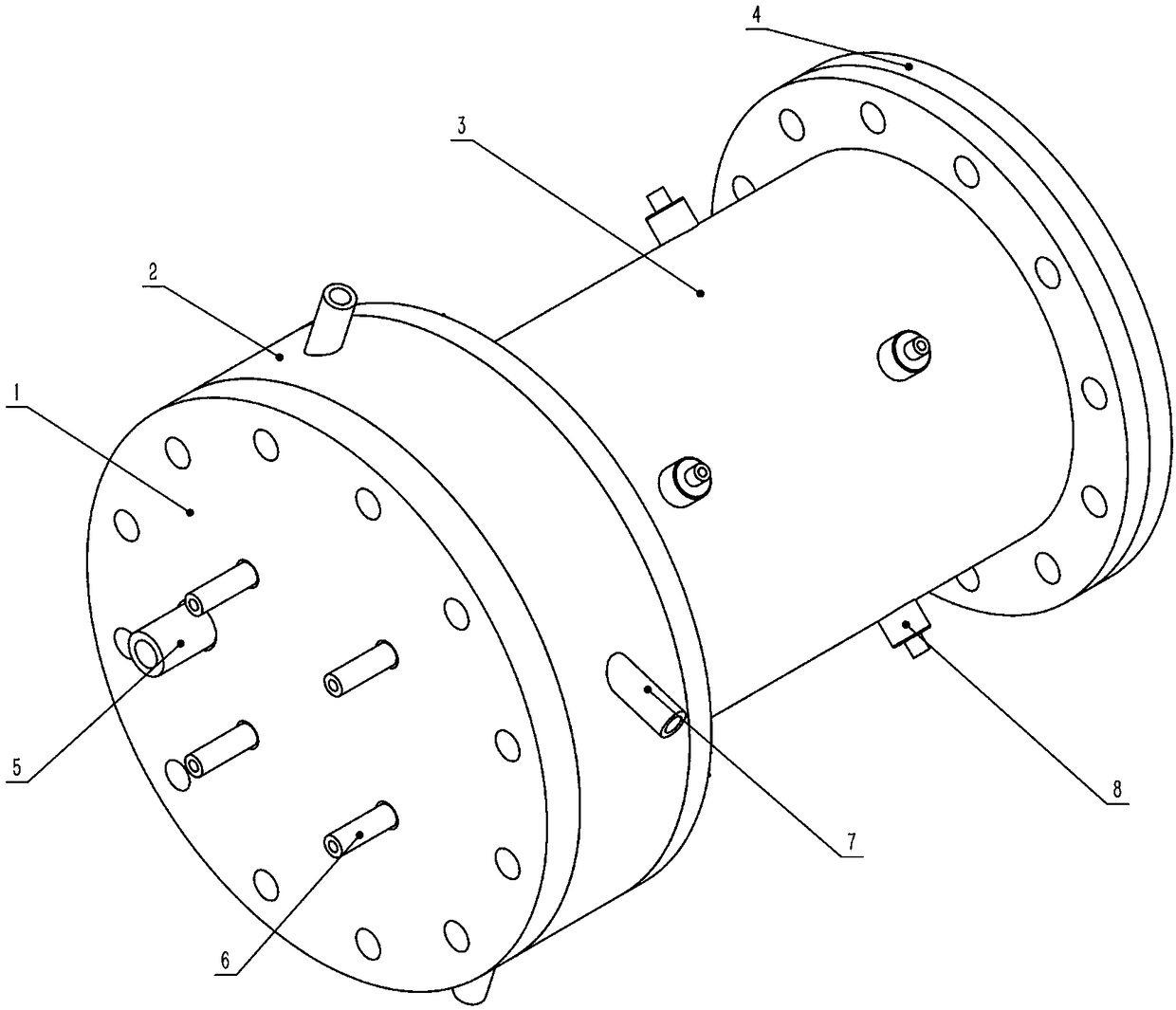

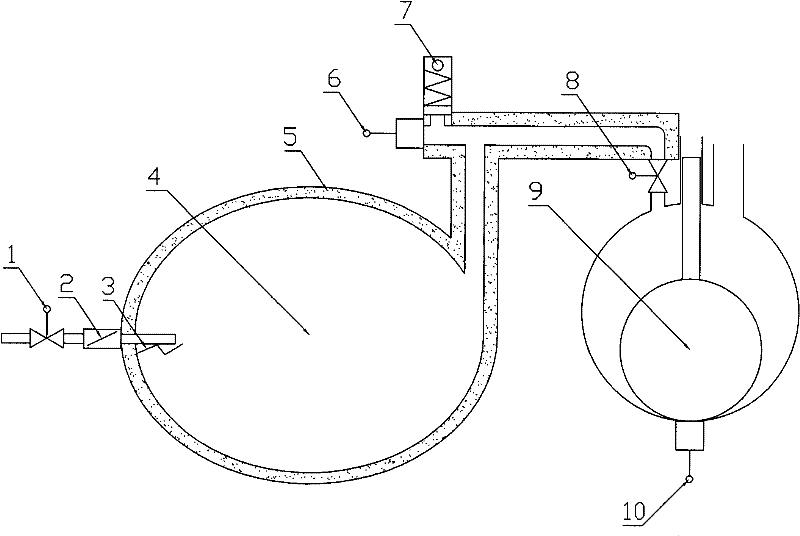

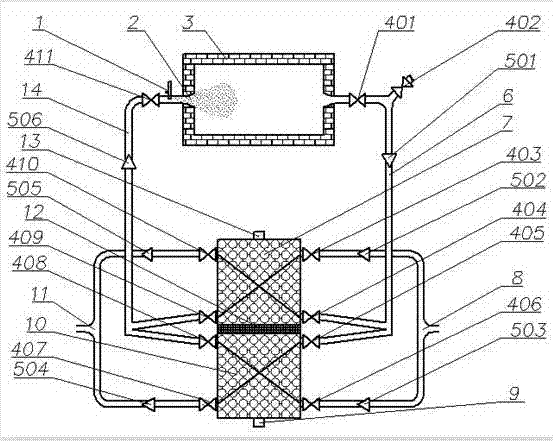

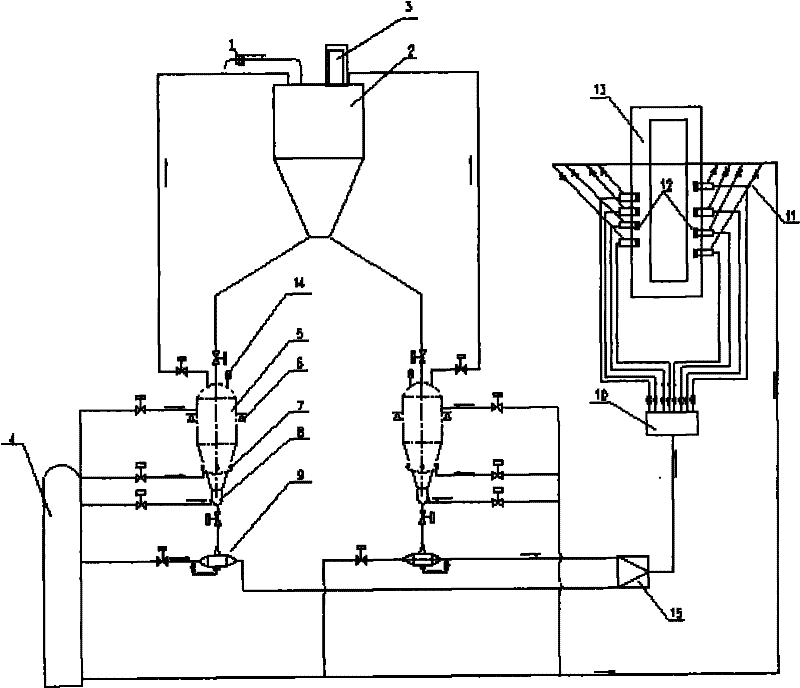

Biological oil combustion device

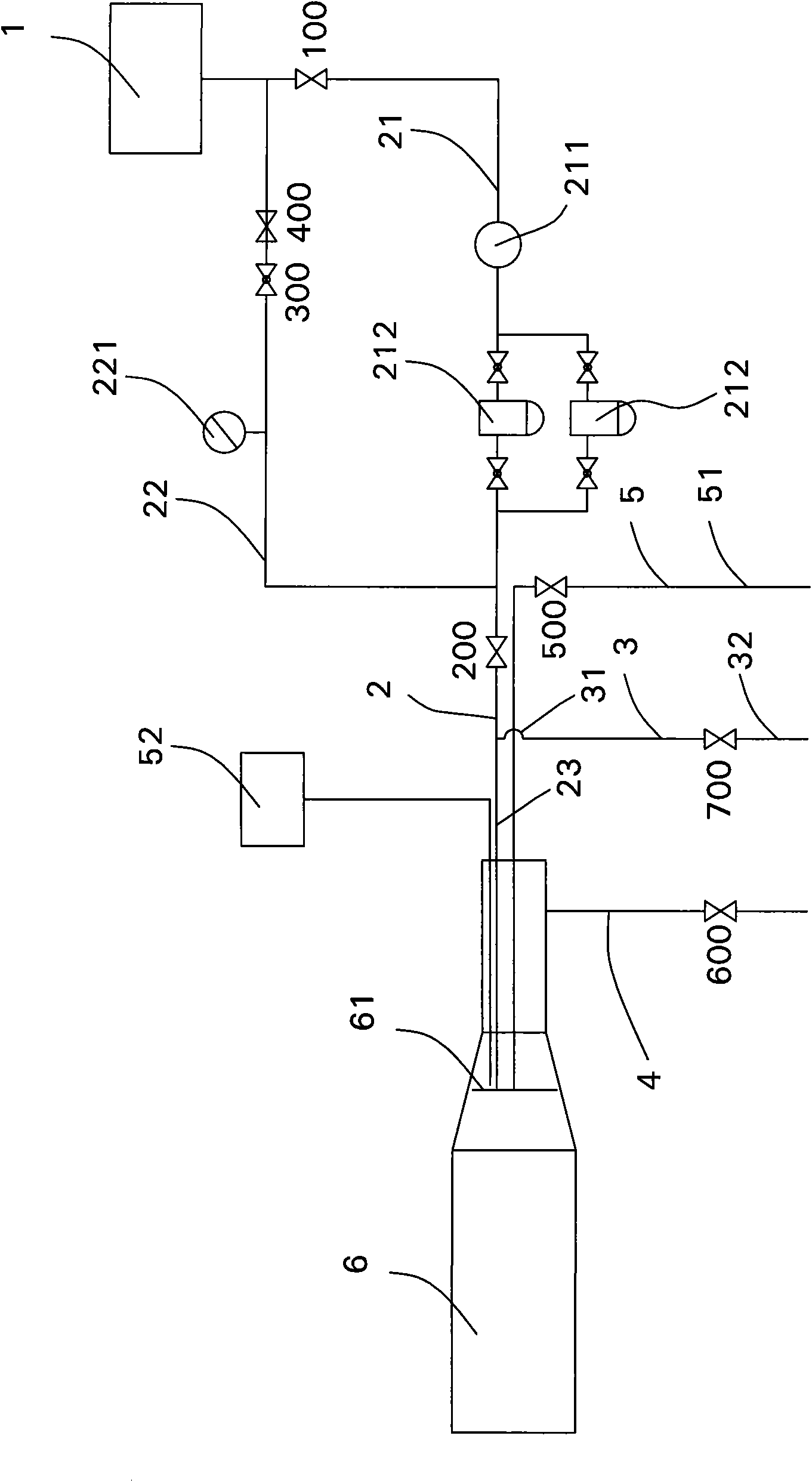

ActiveCN101539290ASolve difficult problems that are not easy to igniteOvercome the difficult problem of atomizationCombustion using gaseous and pulverulent fuelBurnersCombustion chamberCombustible gas

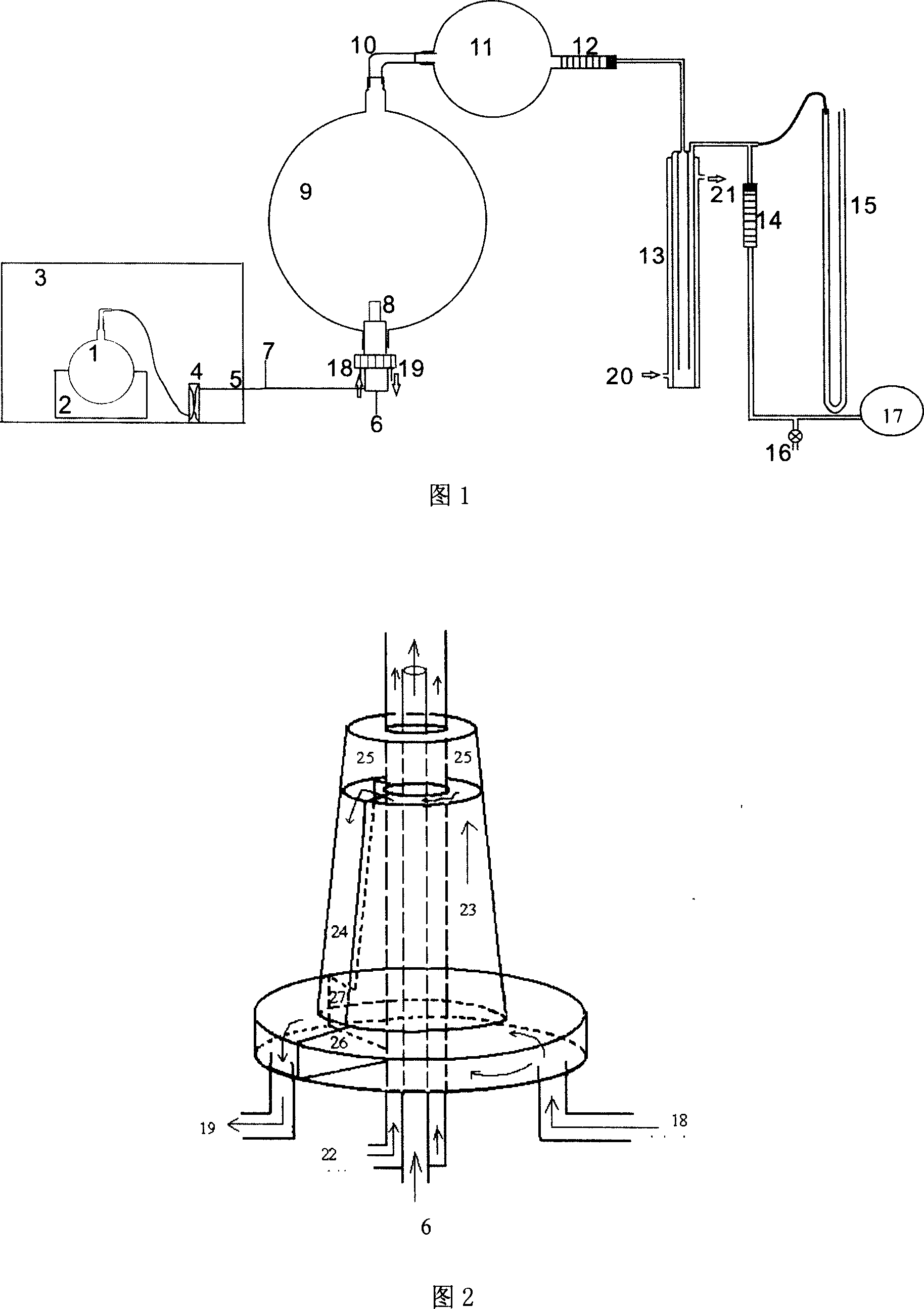

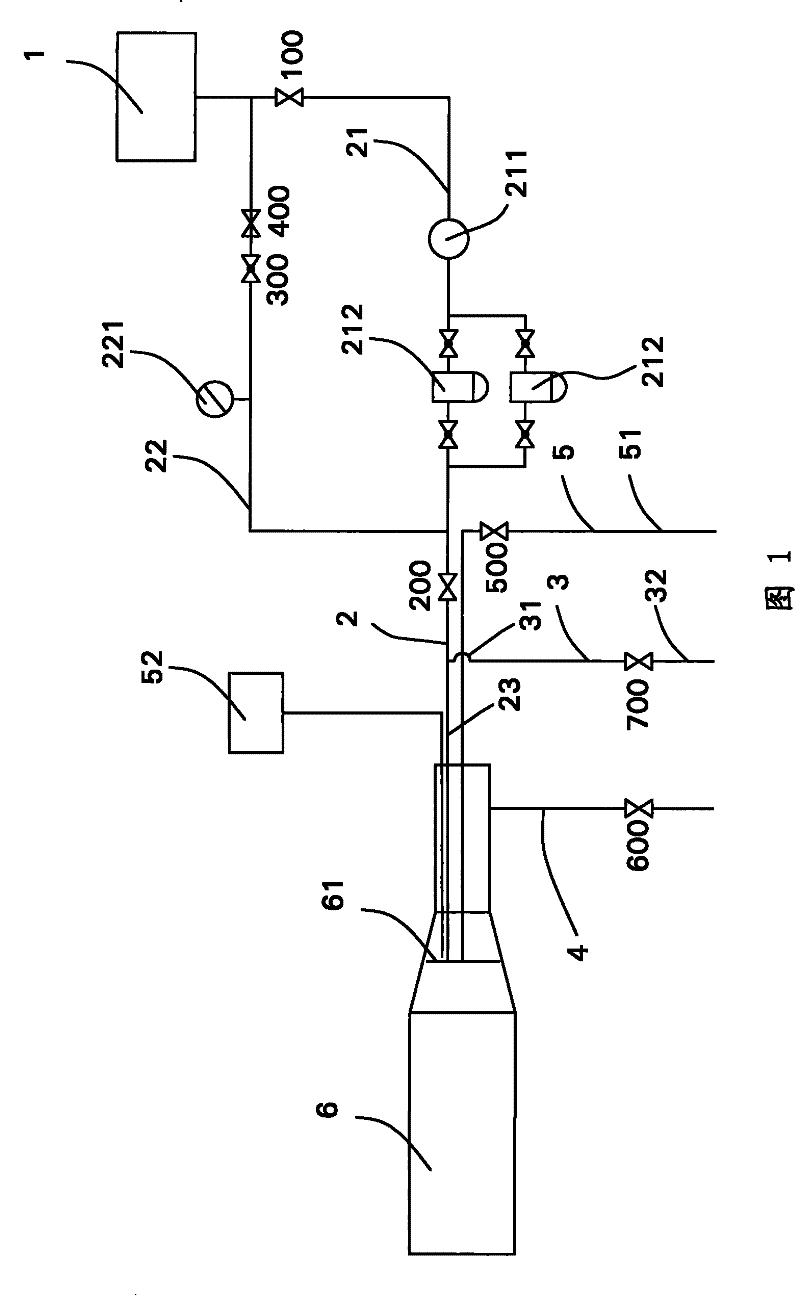

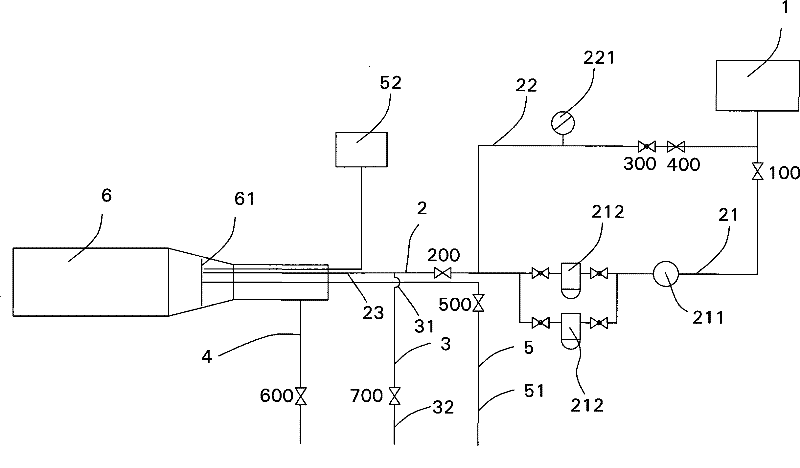

The invention discloses a biological oil combustion device, which comprises an oil storage tank, an atomization system, a steady combustion chamber, an auxiliary ignition system, a combustion air-distribution system used for providing combustion air for the combustion of biological oil, and a conveying system conveying the biological oil into the steady combustion chamber from the oil storage tank, wherein the conveying system comprises a first oil conveying passage and an oil return passage which are connected between the oil storage tank and the atomization system and are mutually and parallelly arranged, and a second oil conveying passage which is connected between the atomization system and the steady combustion chamber; the first oil conveying passage comprises at least one filter; the oil return passage is provided with a pressure transmitter; the auxiliary ignition system comprises a combustible gas conveying pipeline and a high-pressure igniter which extend into the steady combustion chamber; the combustion air-distribution system is communicated with the steady combustion chamber; and a spinning disk which can guide the rotating convection of the biological oil is arranged in front of the atomization system of the biological oil and the auxiliary ignition system in the steady combustion chamber. The device can realize the sustainable and steady combustion of the biological oil, can fully release the energy of the biological oil, and has convenient maintenance and long service life.

Owner:GUANGZHOU DEVOTION THERMAL TECH

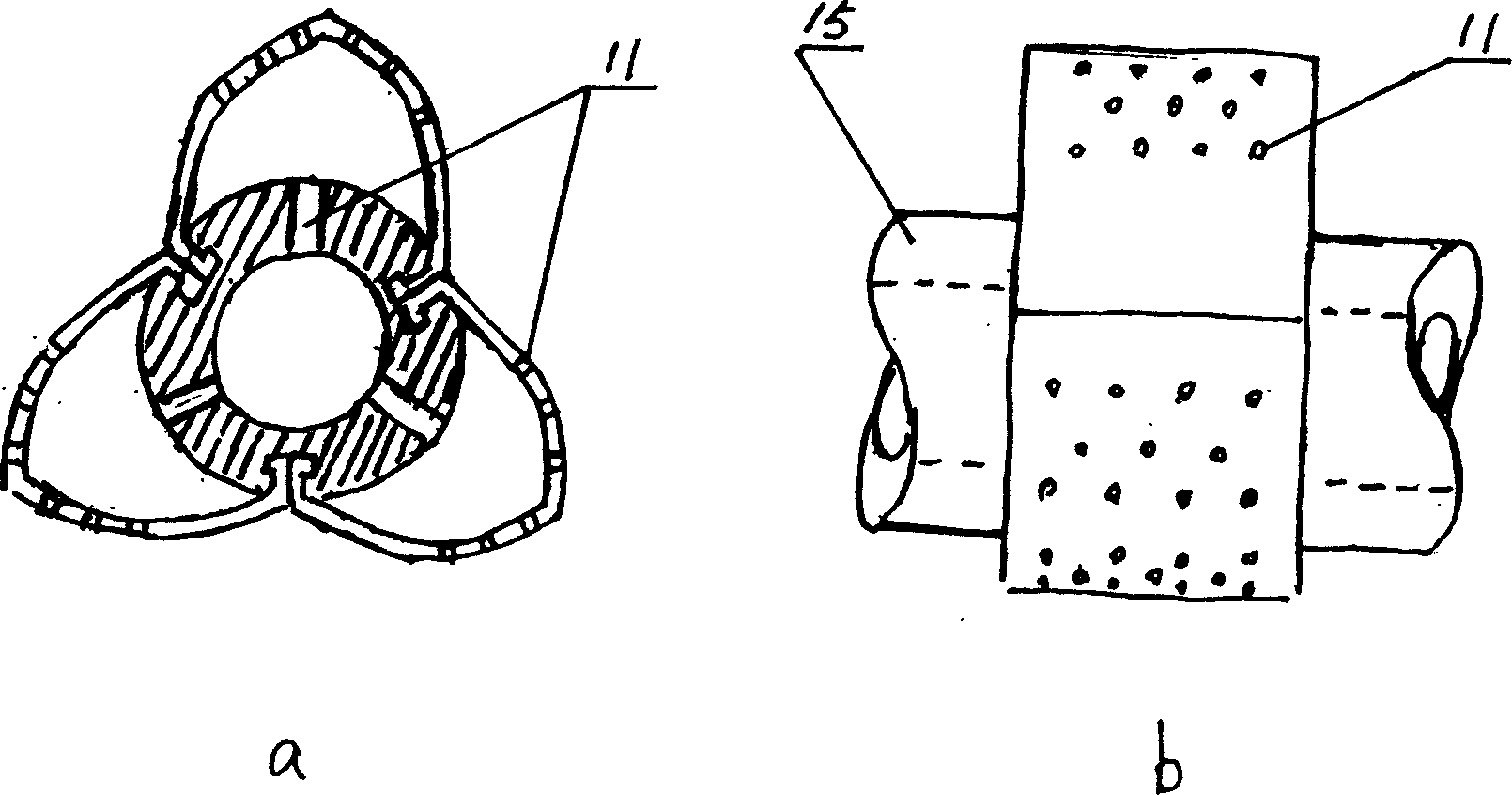

Inner ring fire cover of burner

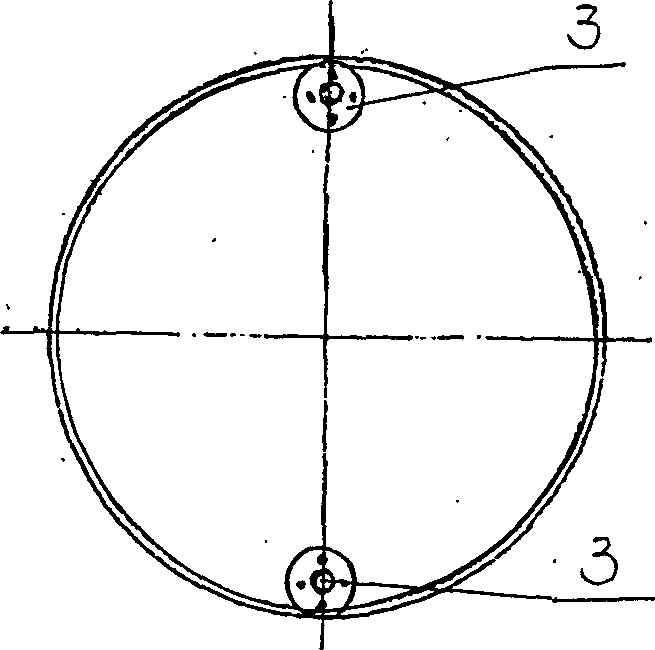

InactiveCN105276585AContinuous and stable combustionHigh thermal efficiencyGaseous fuel burnerCombustorEngineering

The invention discloses an inner ring fire cover of a burner. The inner ring fire cover comprises a cylindrical fire cover body. The fire cover body is provided with a plurality of main fire holes in the circumferential direction in a spaced mode. One ends of the main fire holes are communicated with a gas mixing cavity. The other ends of the main fire holes are all opened in the outer side vertical surface of the fire cover body and form at least one circle of the main fire holes in the axial direction of the fire cover body in the spaced mode. In addition, two circles of annular flame stabilizing grooves are formed in the positions above and below the main fire holes in the inner ring fire cover body around the peripheral direction. One sides of the flame stabilizing grooves are opened in the outer side vertical surface of the fire cover body to form a circle of stable flames. The other sides of the flame stabilizing grooves are communicated with the gas mixing cavity. A main flame of the inner ring fire cover is controlled by flame-stabilizing flames in the two circles of the flame stabilizing grooves above and below the main fire holes simultaneously to reach the best state. In addition, in the burning process, the main flame can be fully pulled by the flame-stabilizing flames, thereby burning continuously and stably, and the thermal efficiency is improved.

Owner:ZHEJIANG MONY COOKING UTENSILS

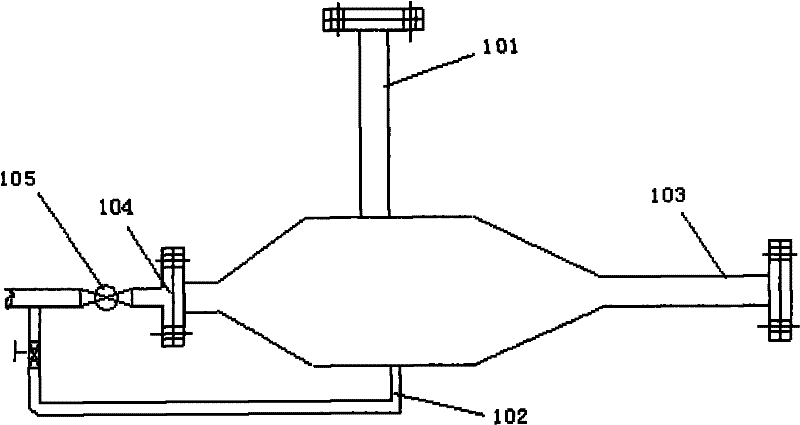

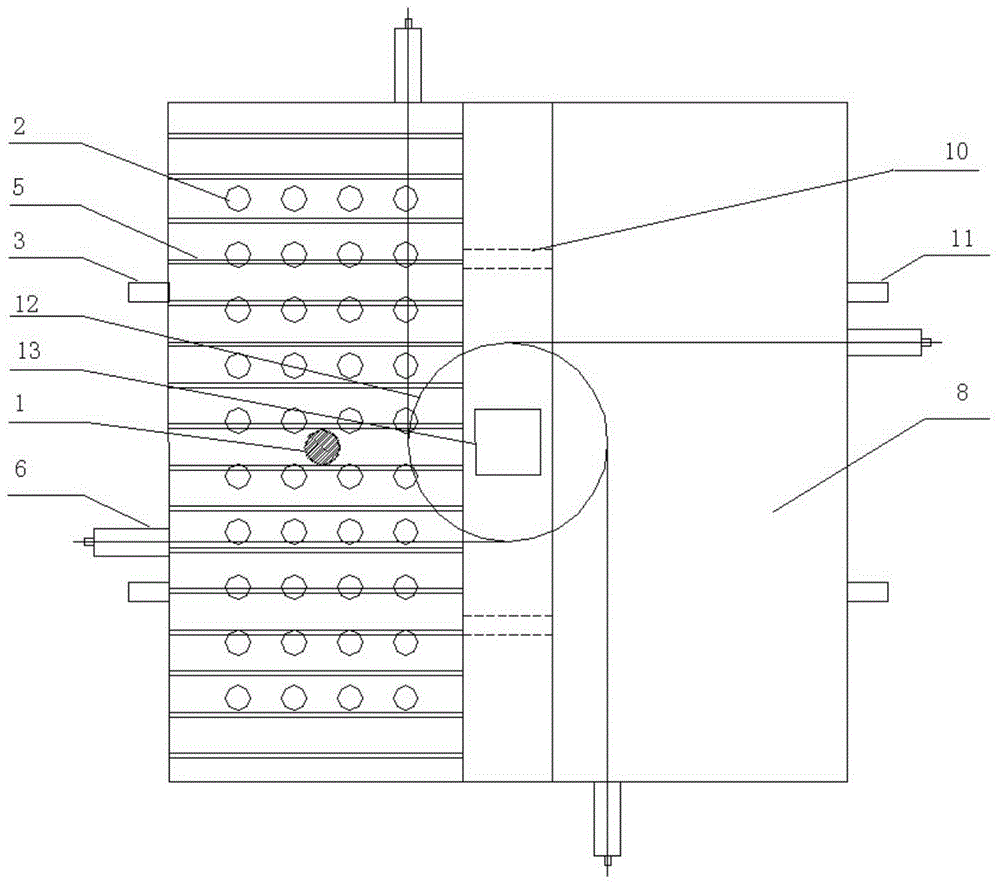

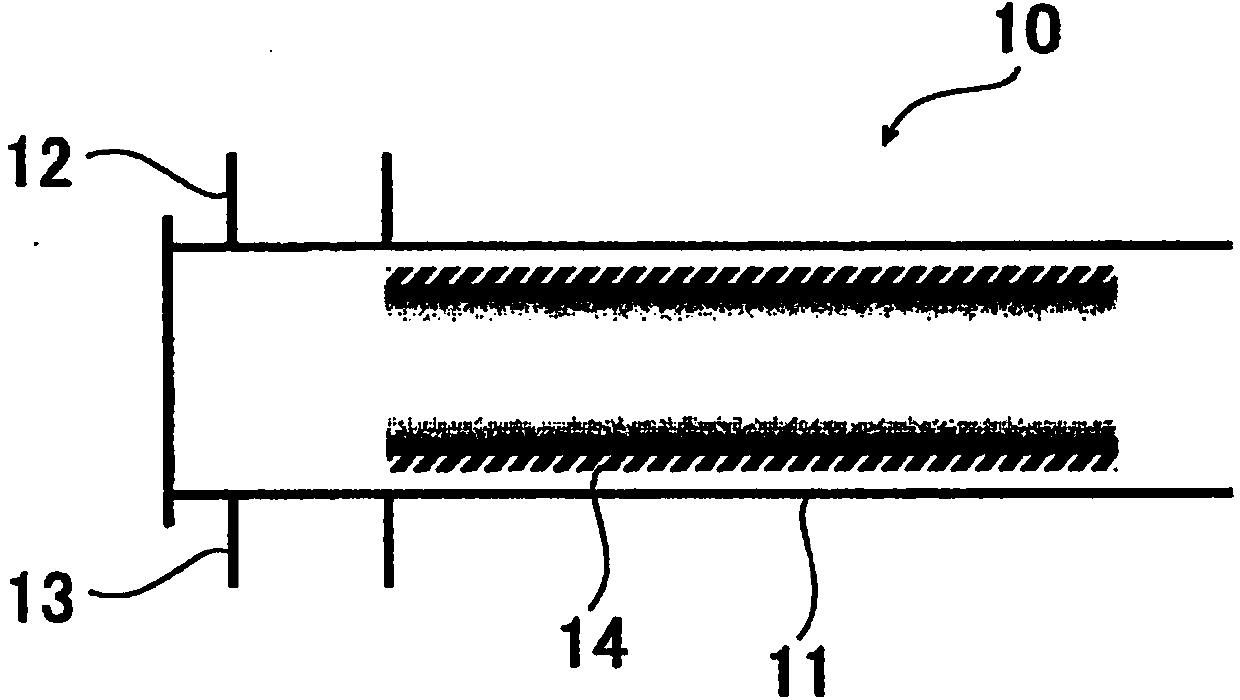

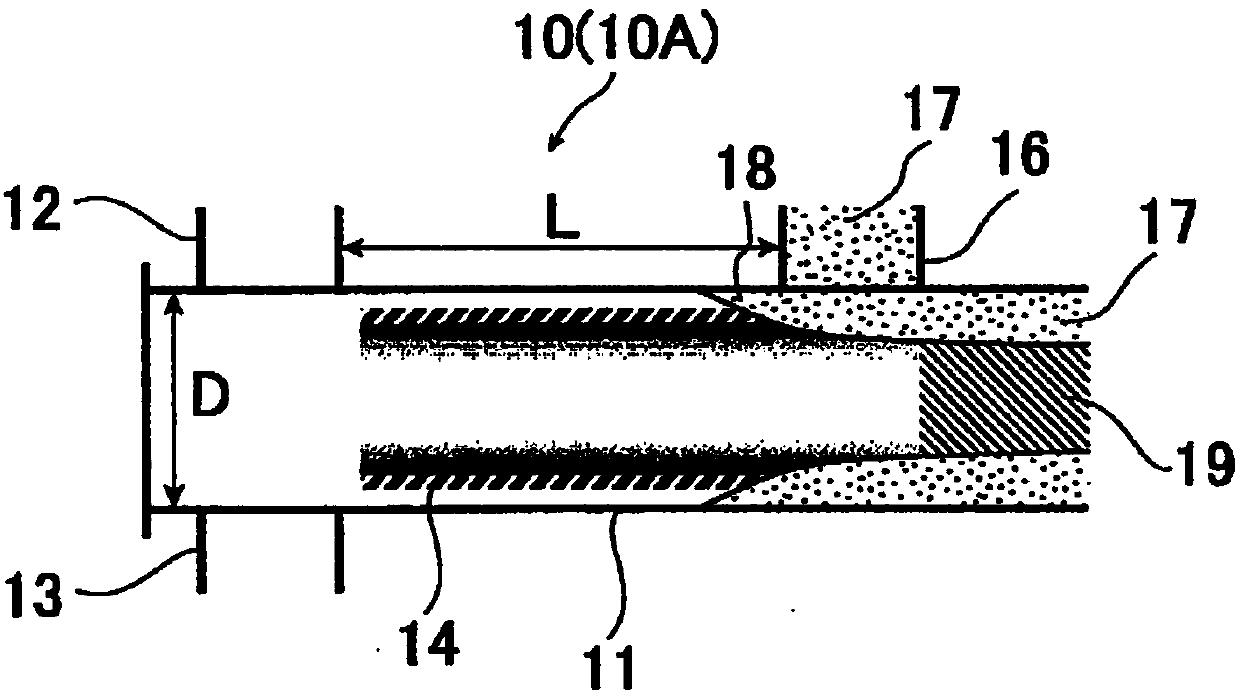

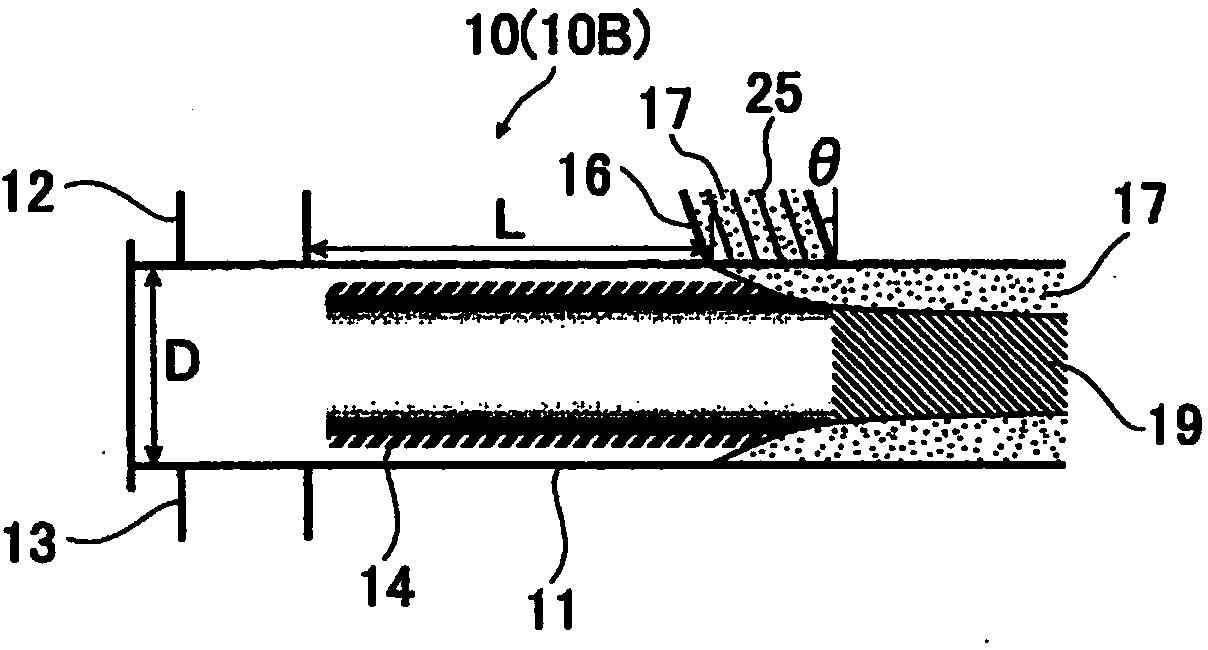

Fluid mixing device

InactiveUS7410288B1Increase probabilityWell mixedFlow mixersFuel supply apparatusBiomedical engineeringFlow divider

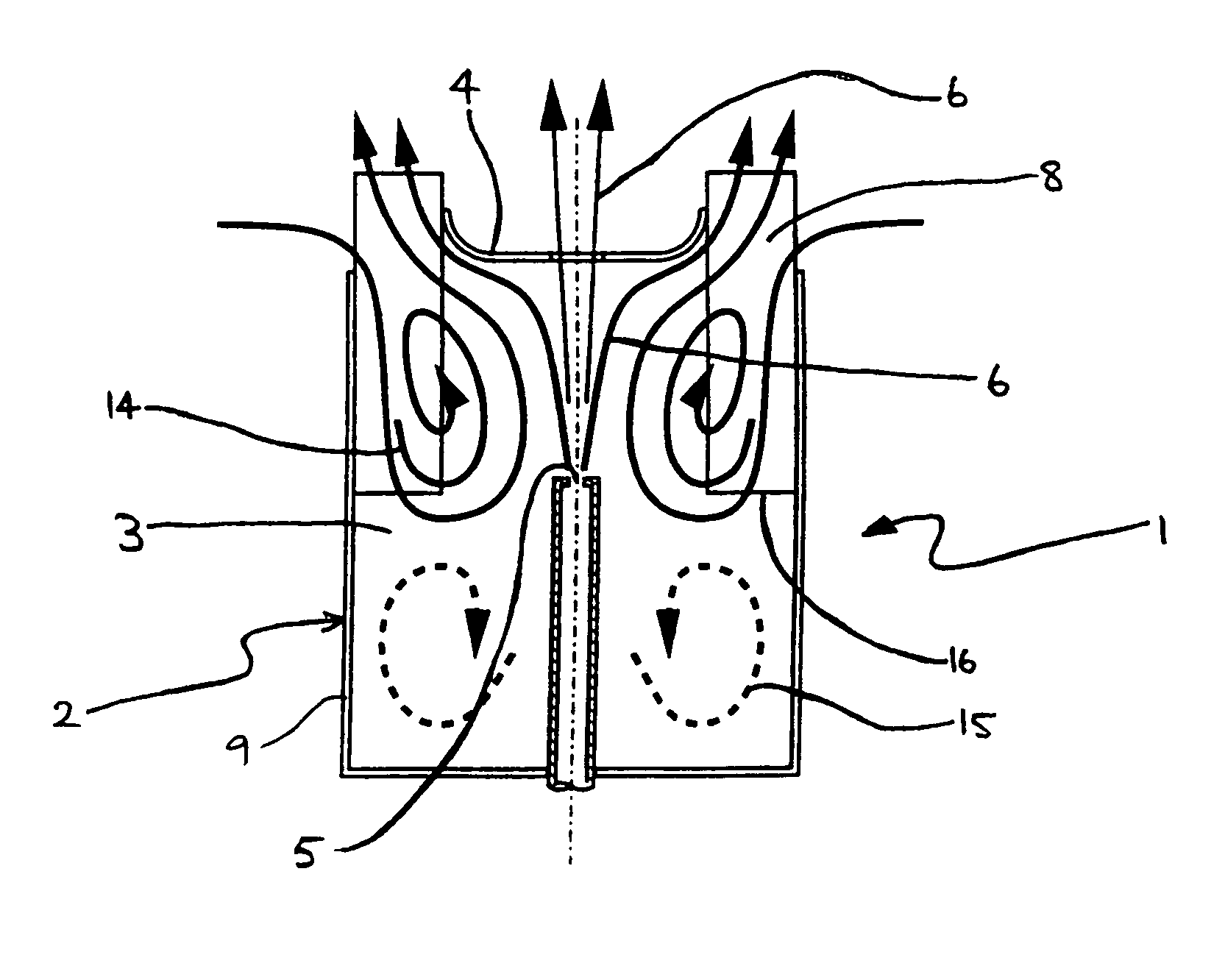

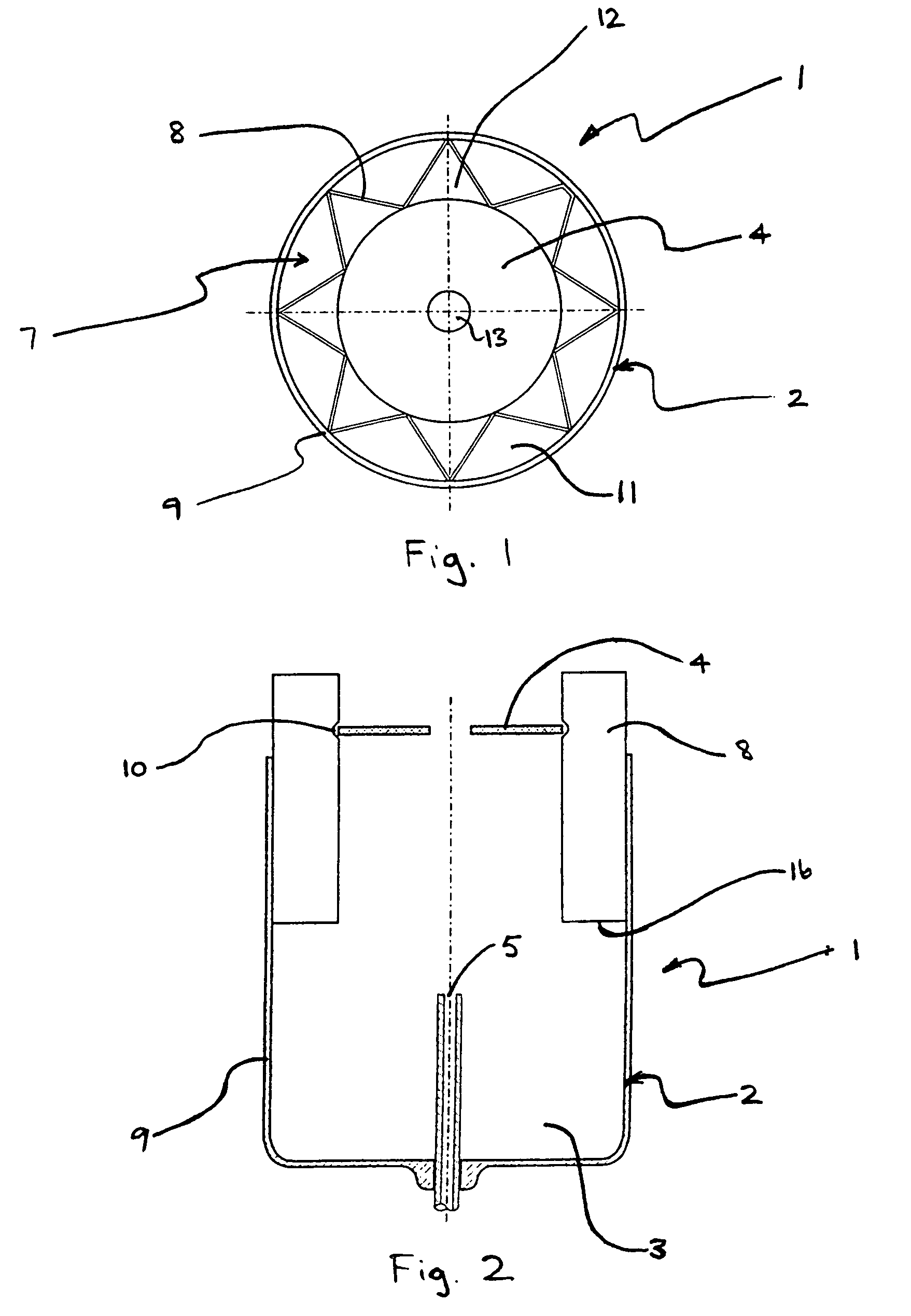

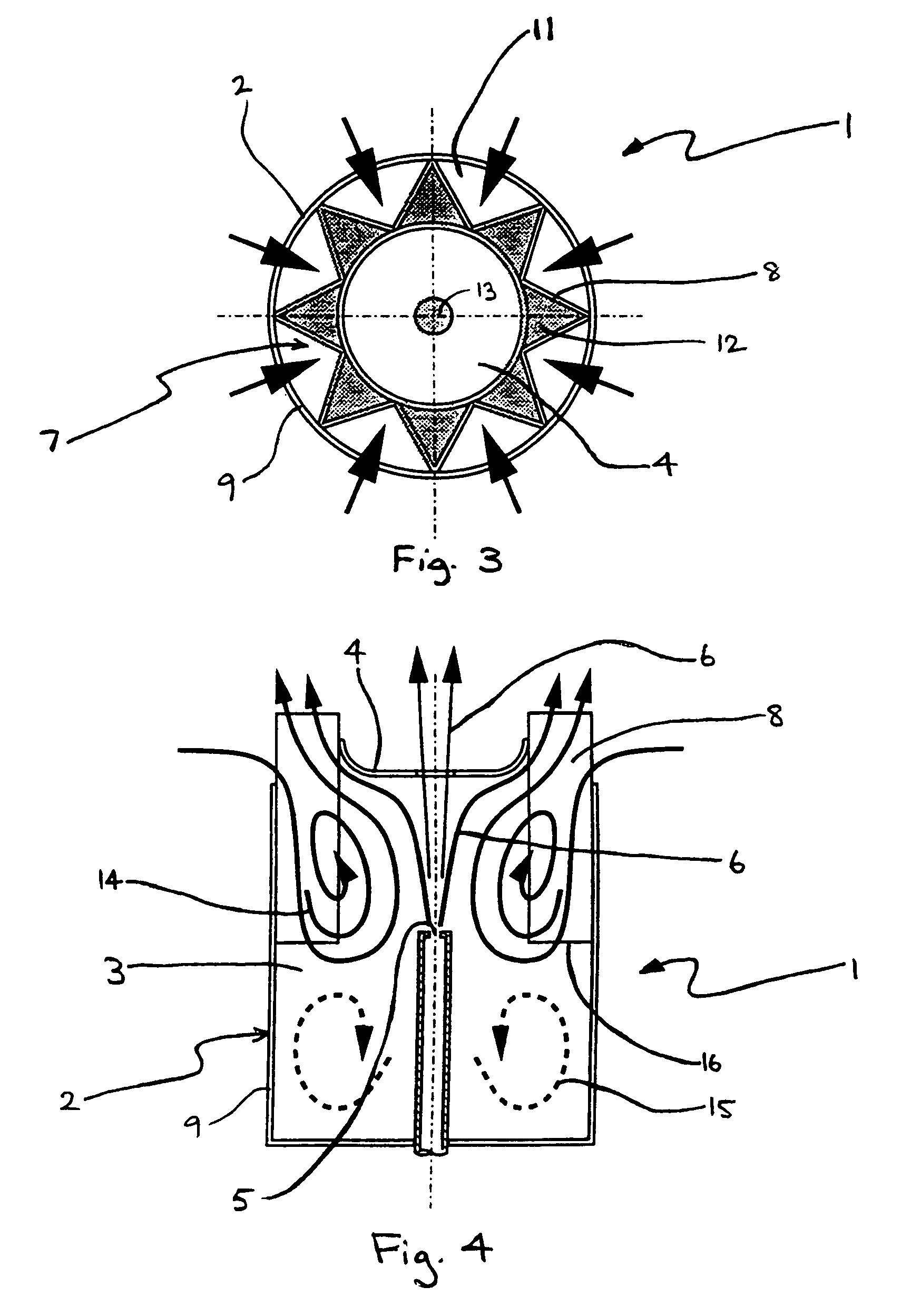

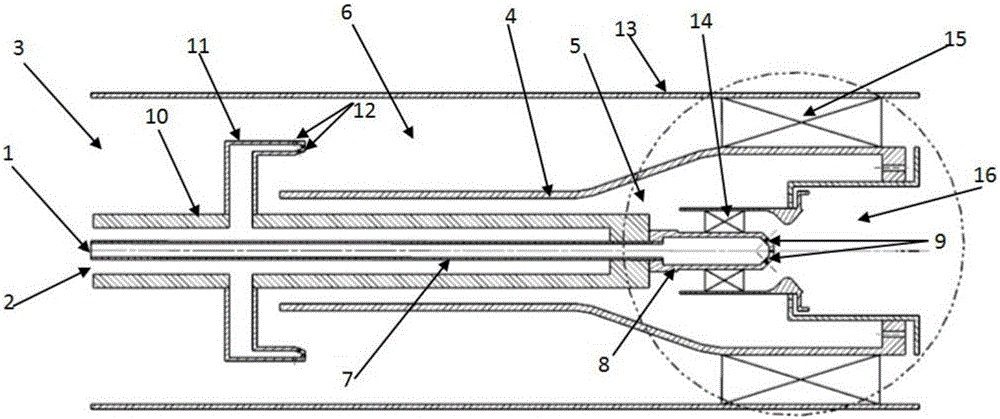

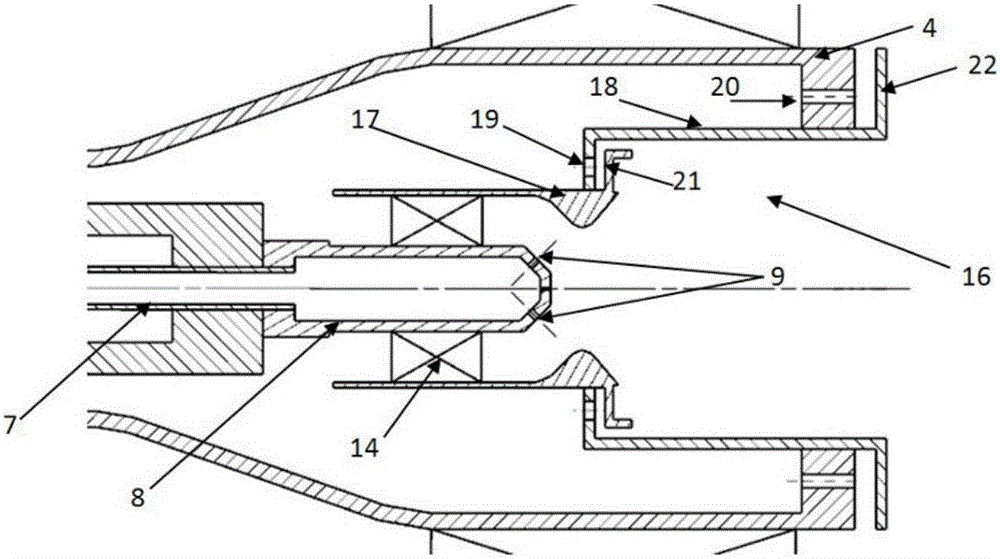

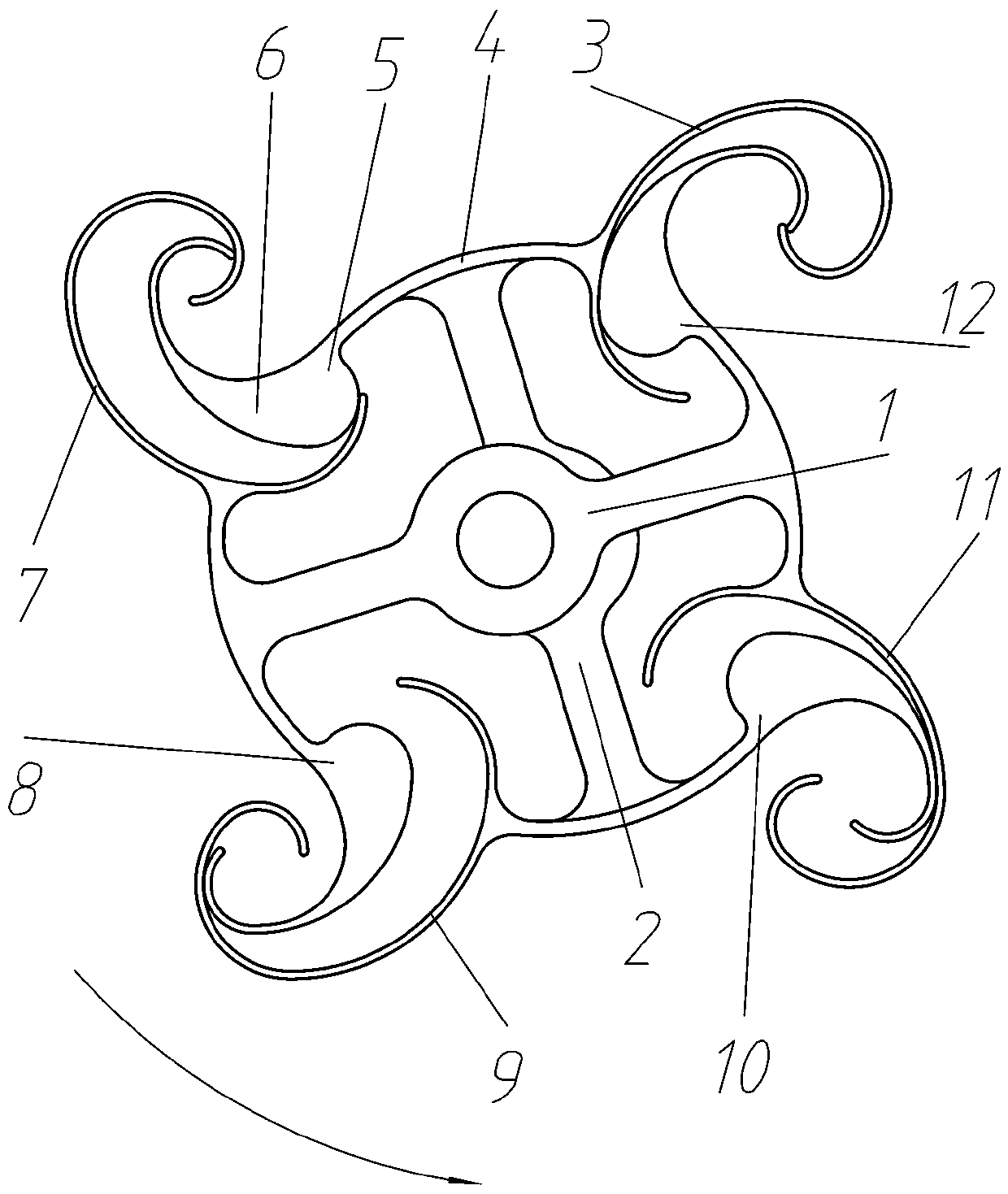

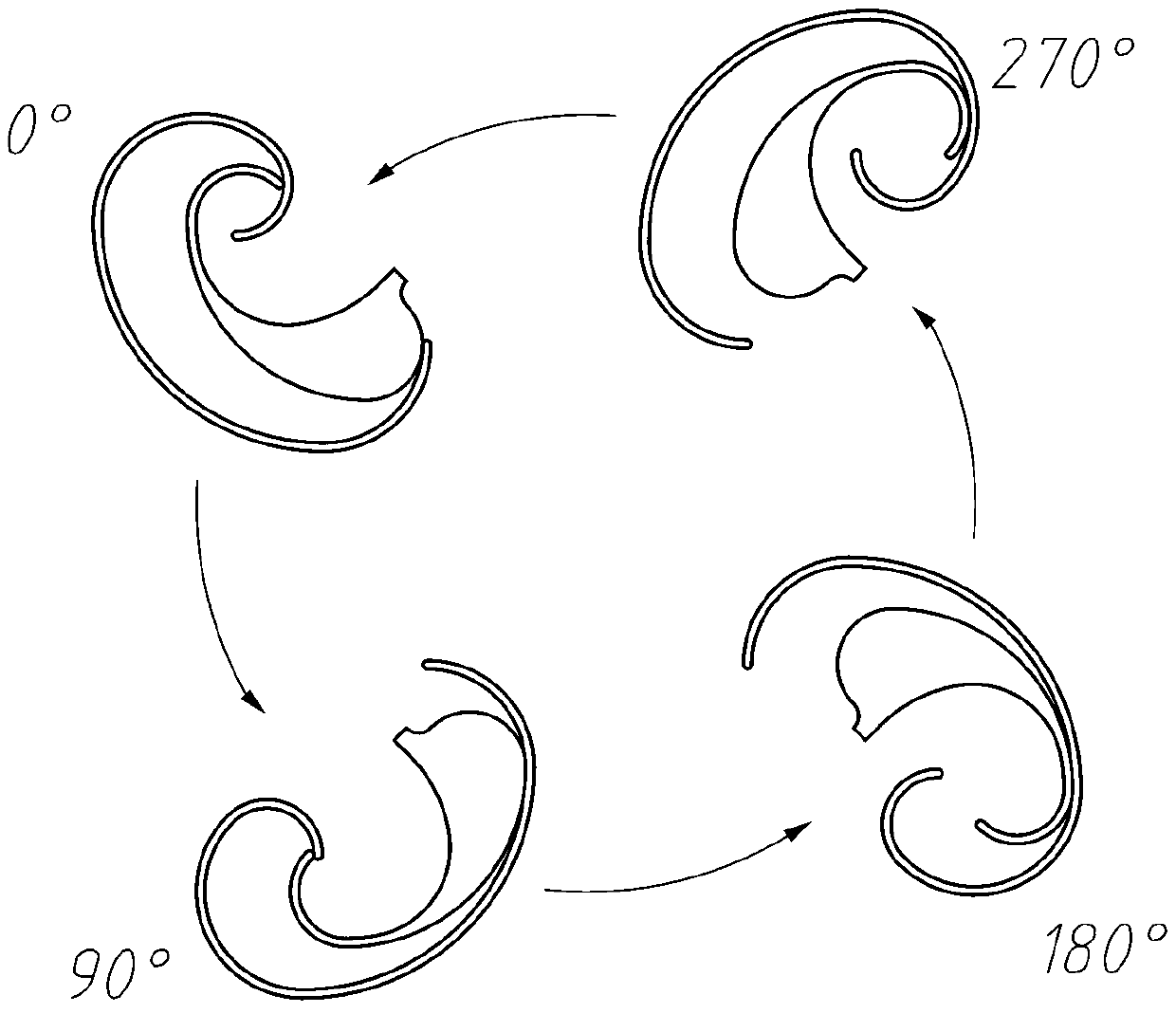

A fluid mixing device (1) includes a chamber (3) and a bluff body (4) defining one end of the chamber (3). A first fluid inlet (5) is located toward an opposite end of the chamber (3) from the bluff body (4) and arranged to direct fluid toward the bluff body (4). A region substantially surrounding the bluff body (4) has a flow divider (8) defining second fluid inlet(s) (11) to the chamber (3) and mixed fluid outlets (12) from the chamber (3). A fluid flow from the first fluid inlet (5) and / or from the second fluid inlet (11) establishes a recirculating vortex system (14) within the chamber and results in a mixture of fluids from the first fluid inlet (5) and the second fluid inlet(s) (11) being directed through the mixed fluid outlets (12).

Owner:LUMINIS PTY LTD

Combustion and synthesis device for carbon cluster

The invention discloses a combusting synthesized device of carbon cluster, which comprises the following parts: sealed case, combusting gas providing mechanism, combusting head, combusting cavity, carbon ash collecting cavity, vacuum pump, two filters, water cool system, pneumatic testing and displaying device and vent valve, wherein the combusting head connects flow meter and oxygen providing pipe; the lower end of combusting cavity connects combusting head; the carbon ash collecting cavity interconnects combusting cavity; the vacuum pump connects sealed case; one filter connects carbon ash collecting cavity and the other filter connects vacuum pump; the water cool mechanism of combusting head of water cool system is set on the exterior of combusting head, which is between filter and vacuum pump; the pneumatic testing and displaying device is set between sealed case and vacuum pump; two ends of vent valve connect vacuum pump inlet and sealed case through pipe; the other end of vent valve interconnects atmosphere.

Owner:XIAMEN UNIV

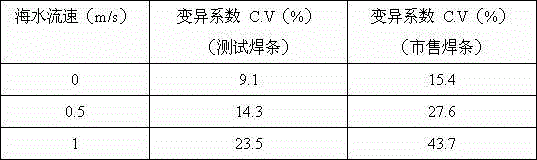

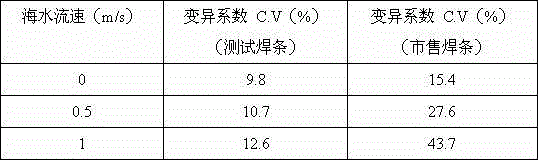

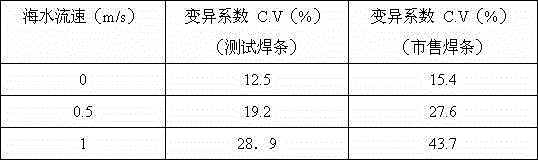

High-stability coating for underwater wet welding rod

InactiveCN104874939ASmooth startStable arc burningWelding/cutting media/materialsSoldering mediaSolid componentCoating

The invention discloses a high-stability coating for an underwater wet welding rod. The coating is prepared by mixing a solid component and a liquid component, wherein the mass of the added liquid component is 15%-20% of that of the solid component; the solid component is prepared from raw materials in percentage by mass as follows: 45%-55% of rutile, 10%-16% of fluorite, 5%-8% of marble, 4%-8% of ferromanganese, 8%-15% of nickel powder, 8%-10% of cryolite and 0%-2% of cesium nitrate; the liquid component adopts potassium-sodium water glass with the potassium-sodium ratio being 3:1 at the temperature of 20 DEG C. According to the high-stability coating for the underwater wet welding rod, arc strike can be performed smoothly under the conditions that the water depth doesn't exceed 20 meters and the water velocity is not higher than 1.2 m / s, continuous stable combustion is realized, an electric arc extinguishing phenomenon is avoided, the strength is higher than or equal to 400 MPa, and the welding requirements of a non-structural member are basically met.

Owner:青岛哈工海洋工程技术有限公司

Tube type vaporization device for liquefied gas for industrial use

InactiveCN1789816ABurn fullyContinuous and stable combustionLiquid fuel feeder/distributionCombustion typesCombustorAutomatic control

This invention relates to one industry oiling tube evaporation device, which comprises Evaporation part, heating part, automatic control part, burst part and liquid supply part, wherein, the evaporation tube is one hollow tube with its inside located with heating medium recycling tube; the said evaporation tube two ends are sealed with one end located with liquid level meter connected to the evaporation tube and with the other end located with heating medium entrance, exhaust mouth and gas liquid entrance; the heating medium entrance and exhaust mouth are separately connected to the heating medium recycling tube entrance and exhaust mouth.

Owner:肖杰

Fire cover, combustor and gas stove

PendingCN108443883AWide fire adjustment rangeMeet the SimmerGaseous fuel burnerEngineeringGas stoves

The invention discloses a fire cover, a combustor and a gas stove. The fire cover comprises an inner fire cover and an outer ring fire cover, wherein an inner ring gas cavity and a middle ring gas cavity are formed in the inner fire cover; the inner fire cover is provided with a central cavity with an upward opening, the inner ring gas cavity is located at the periphery of the central cavity, inner ring fire holes communicating with the inner ring gas cavity are formed in the inner circumferential wall of the center cavity, and middle ring fire holes communicating with the middle ring gas cavity are further formed in the inner fire cover. The fire cover can meet the requirement that the combustor has a wide firepower adjusting range, and meanwhile continuous and stable combustion of quitesmall fire of an inner ring can be realized.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

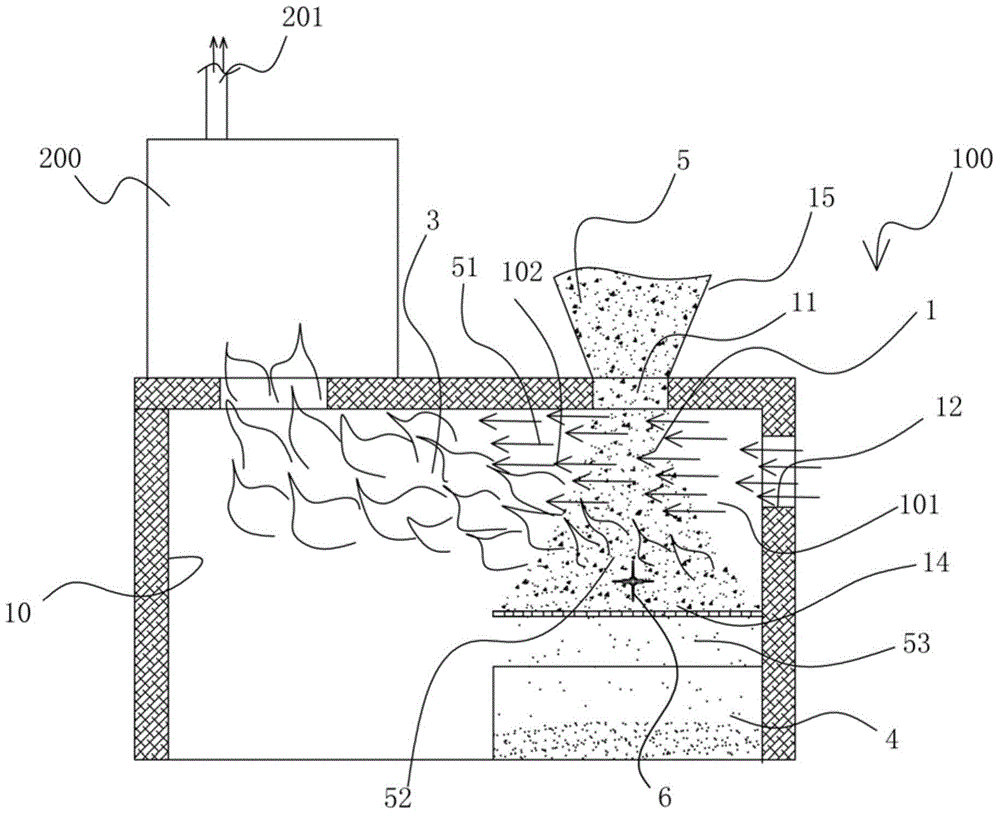

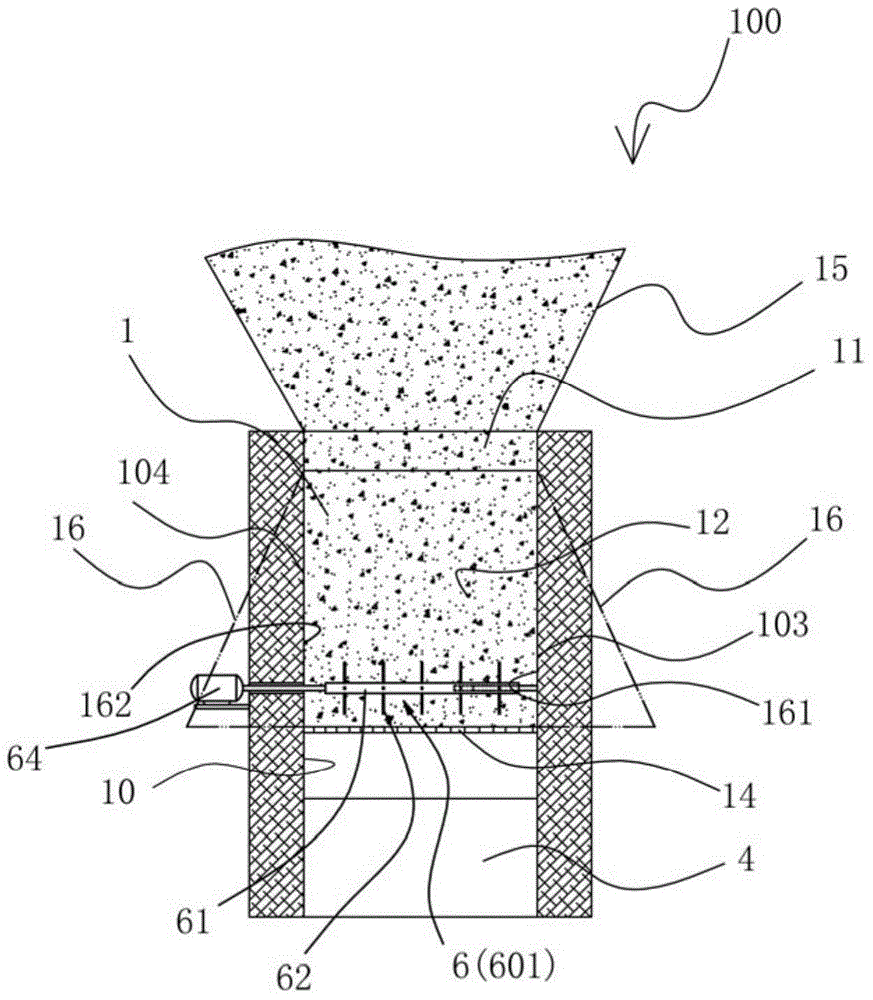

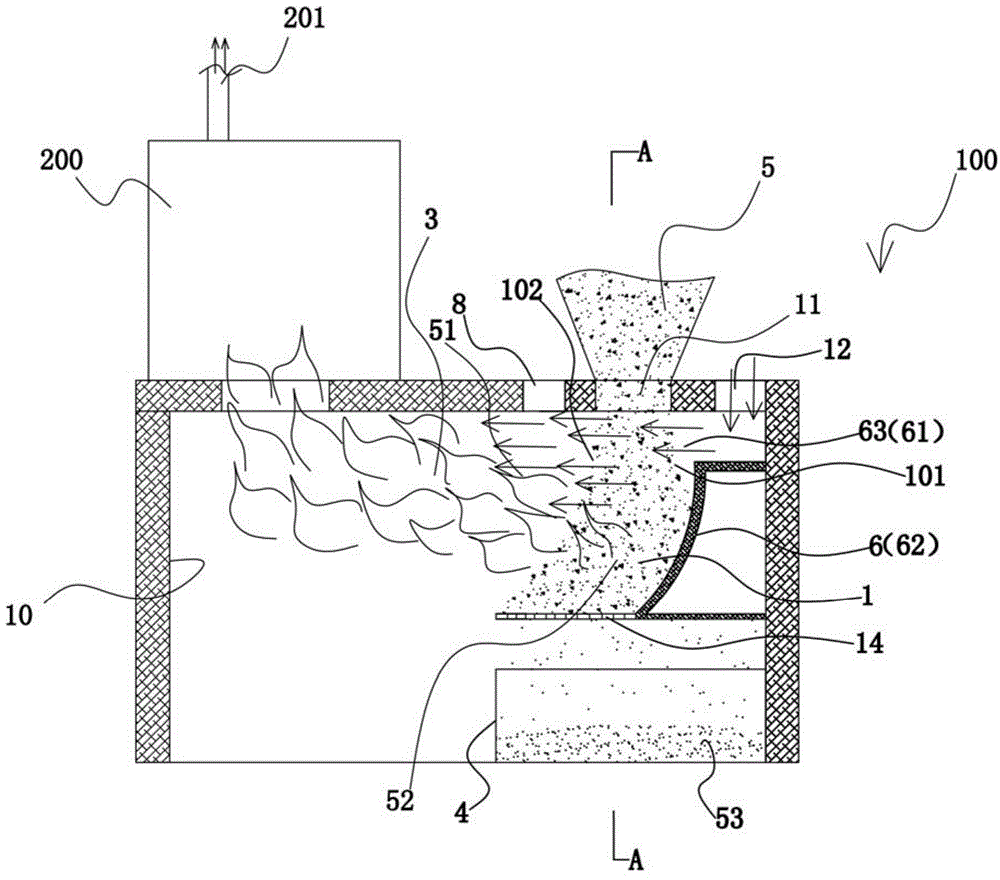

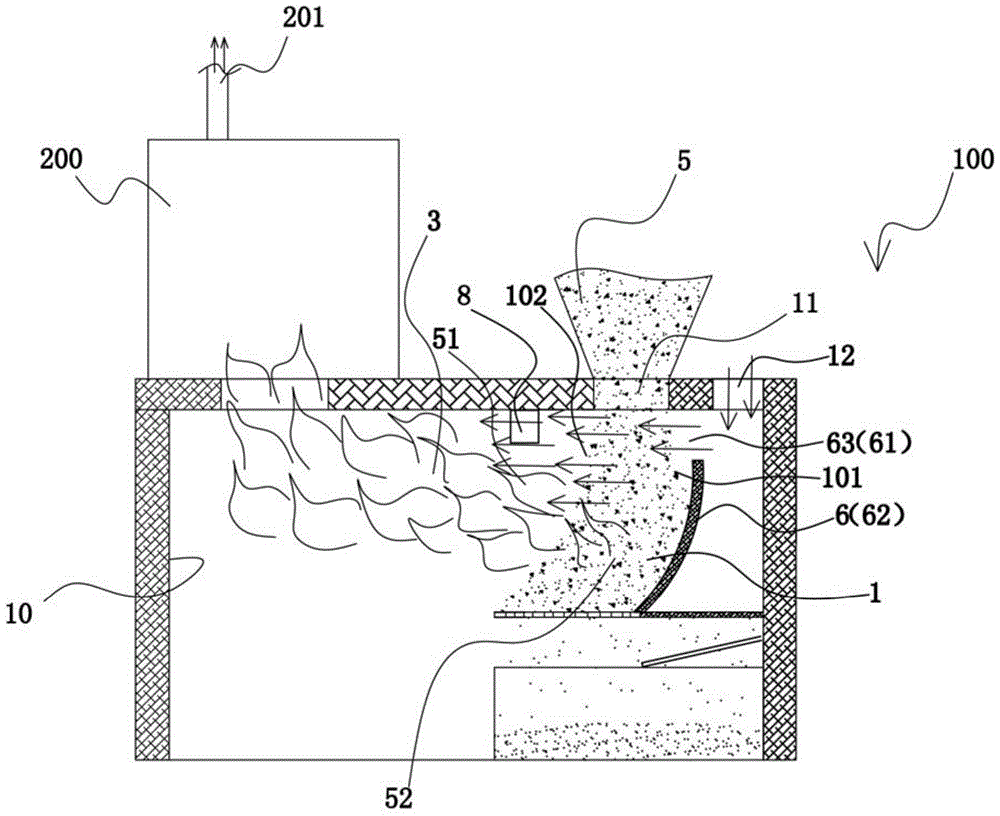

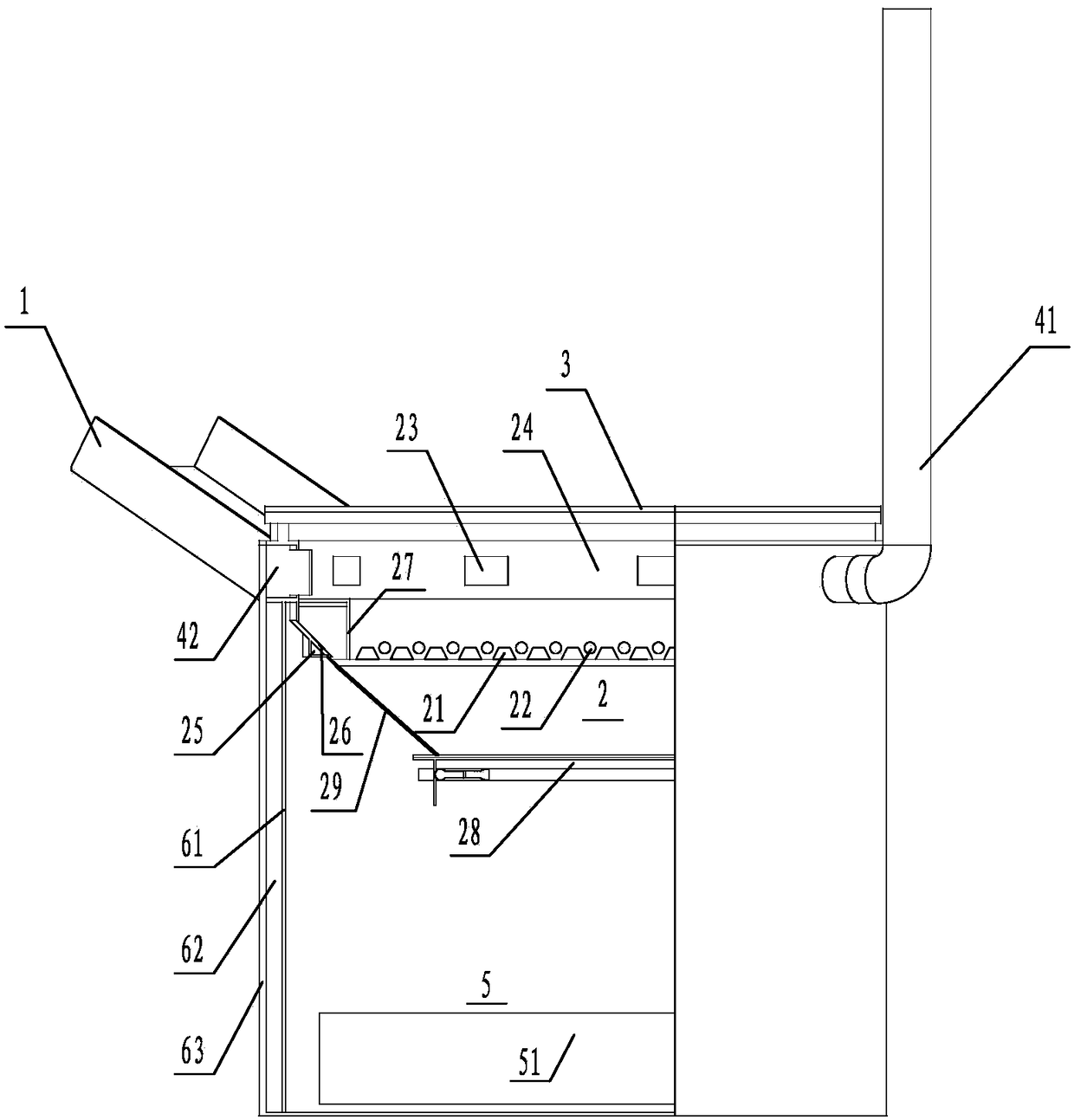

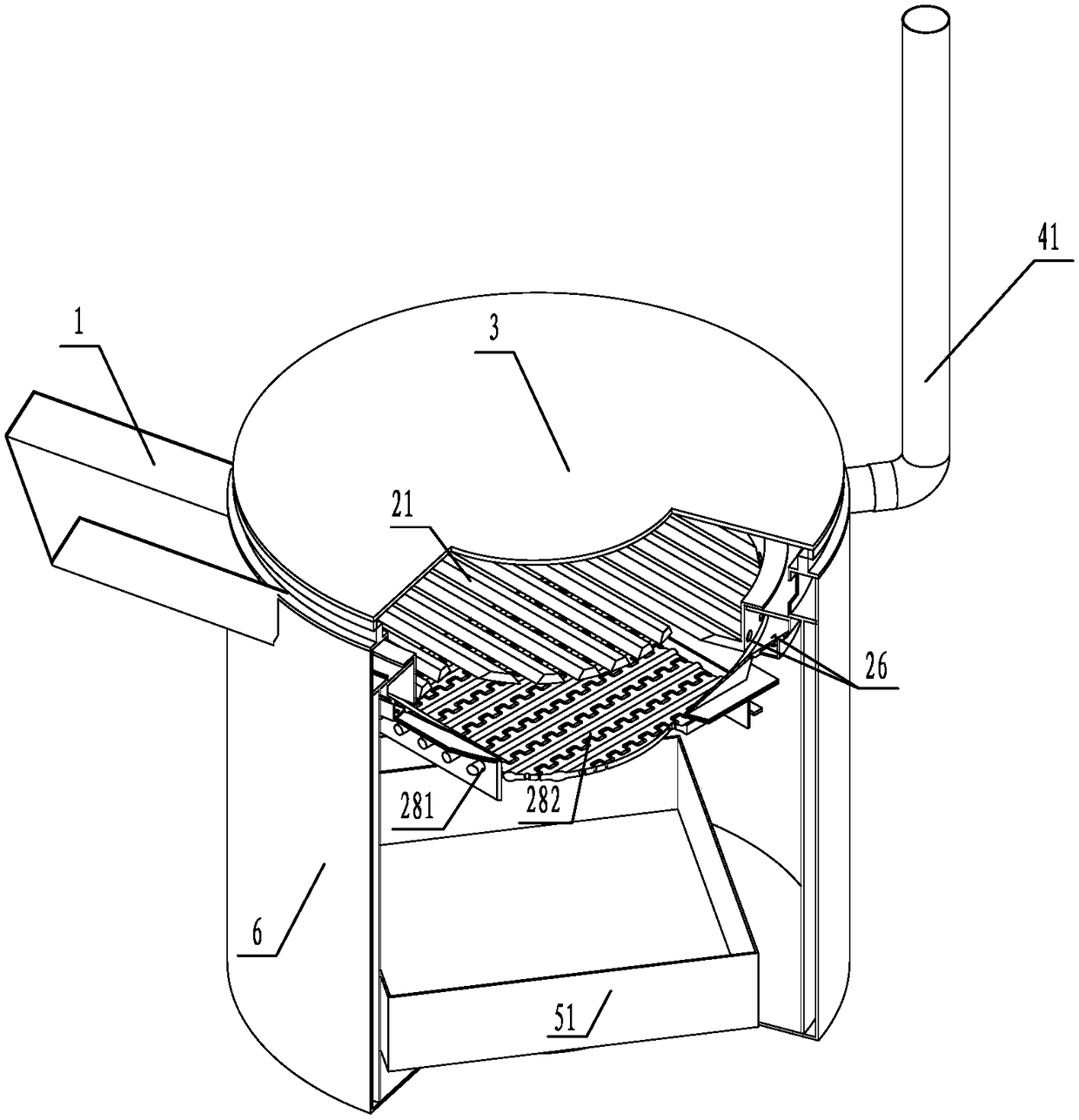

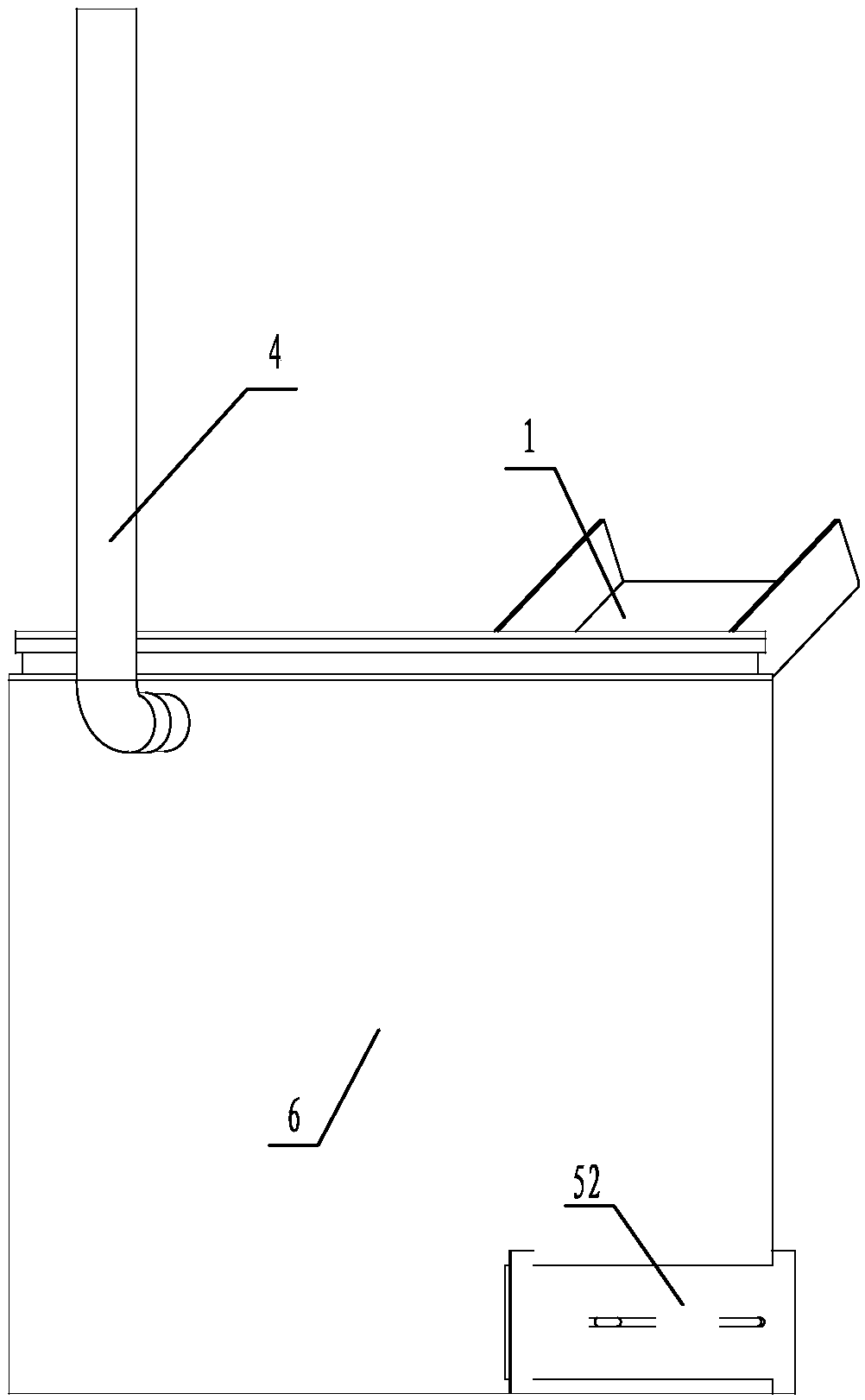

Solid fuel combustion apparatus

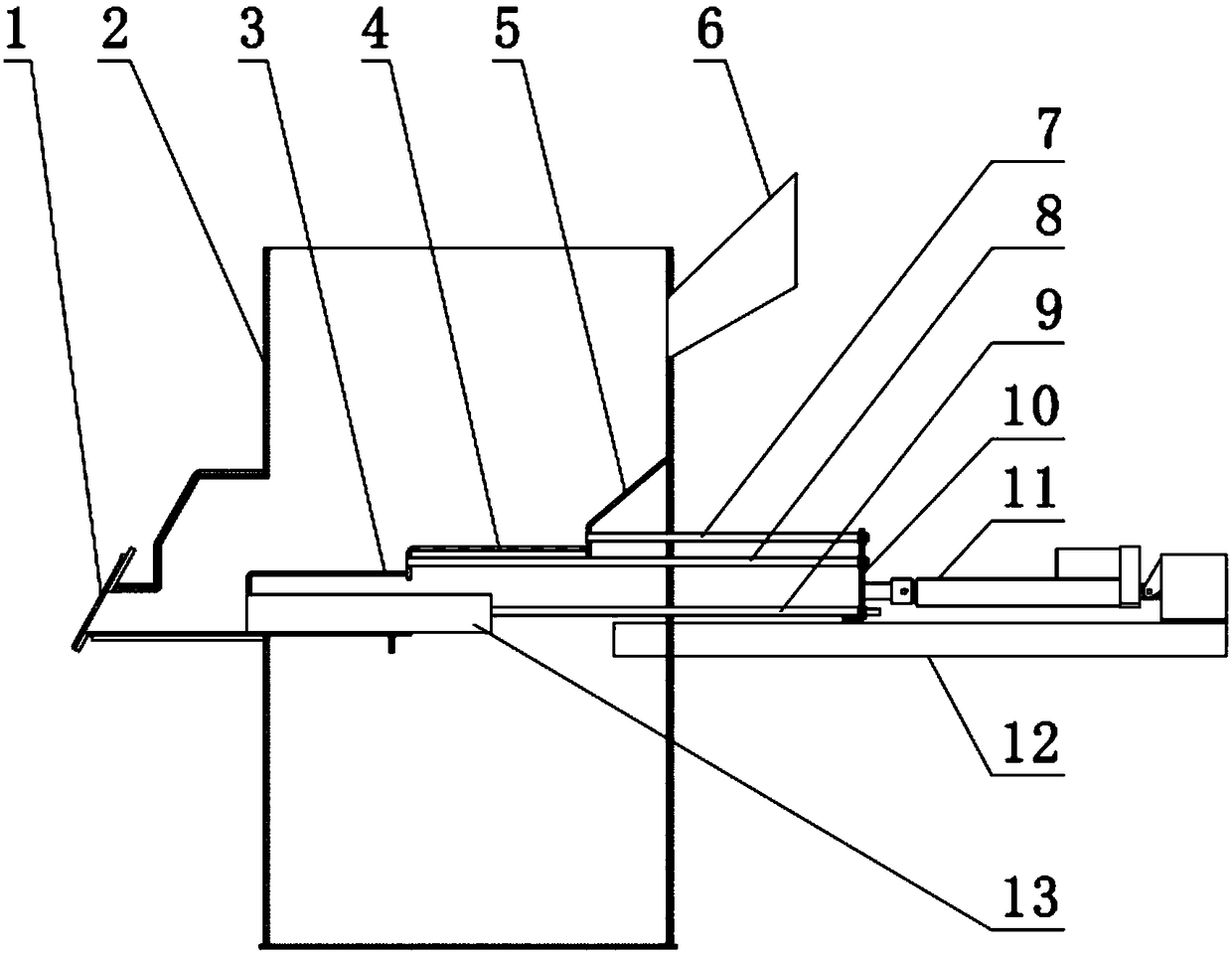

InactiveCN104976613ASave human effortImprove combustion efficiencySolid fuel combustionCombustion apparatusExhaust gasAutomotive engineering

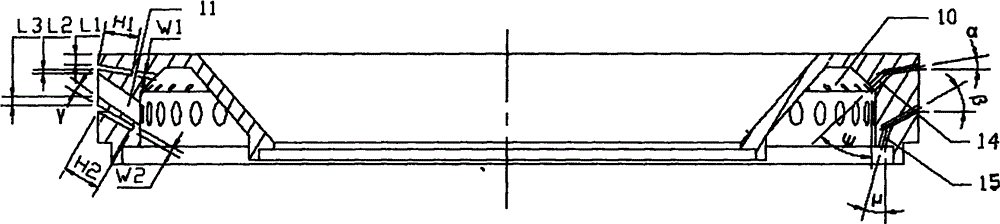

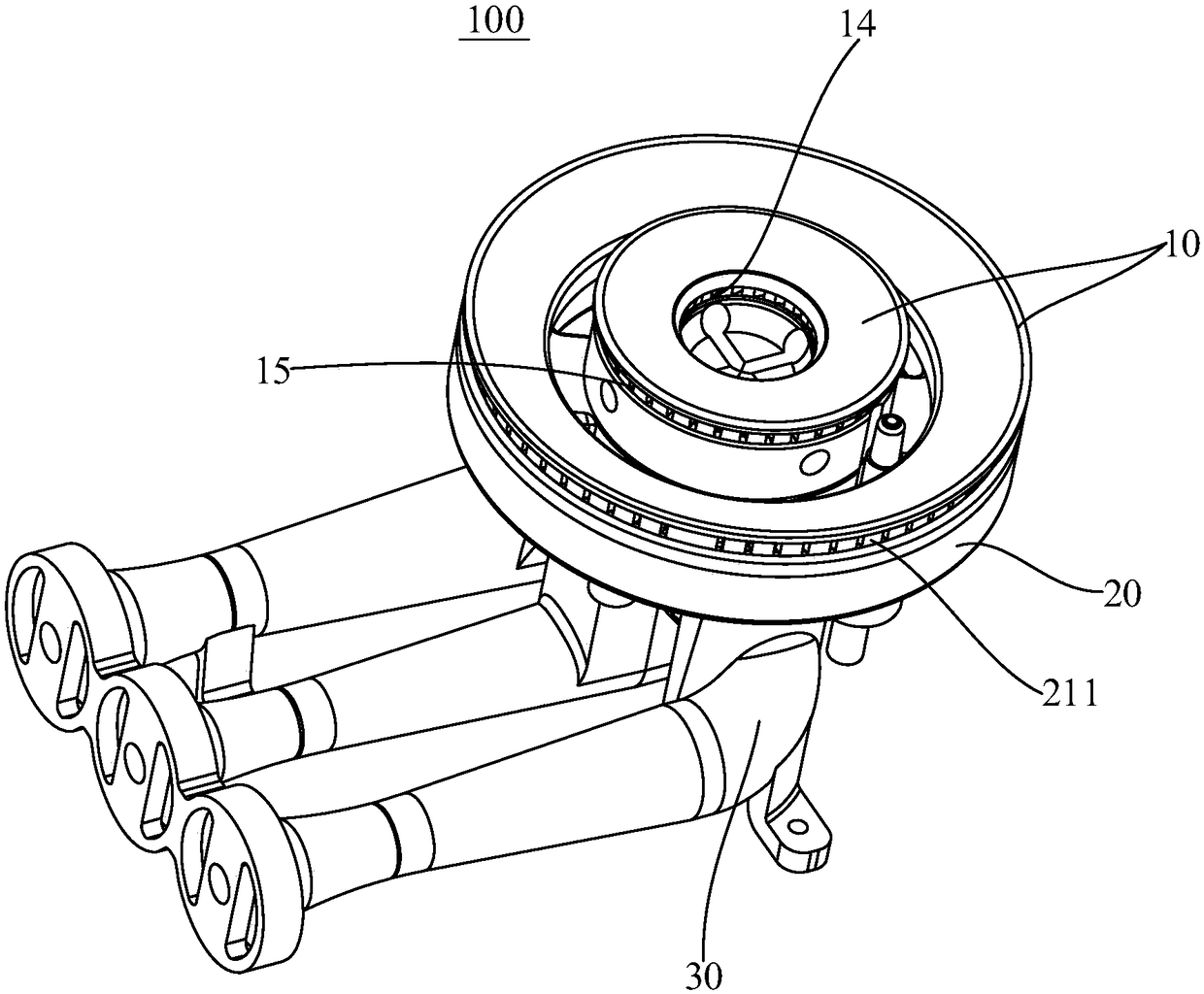

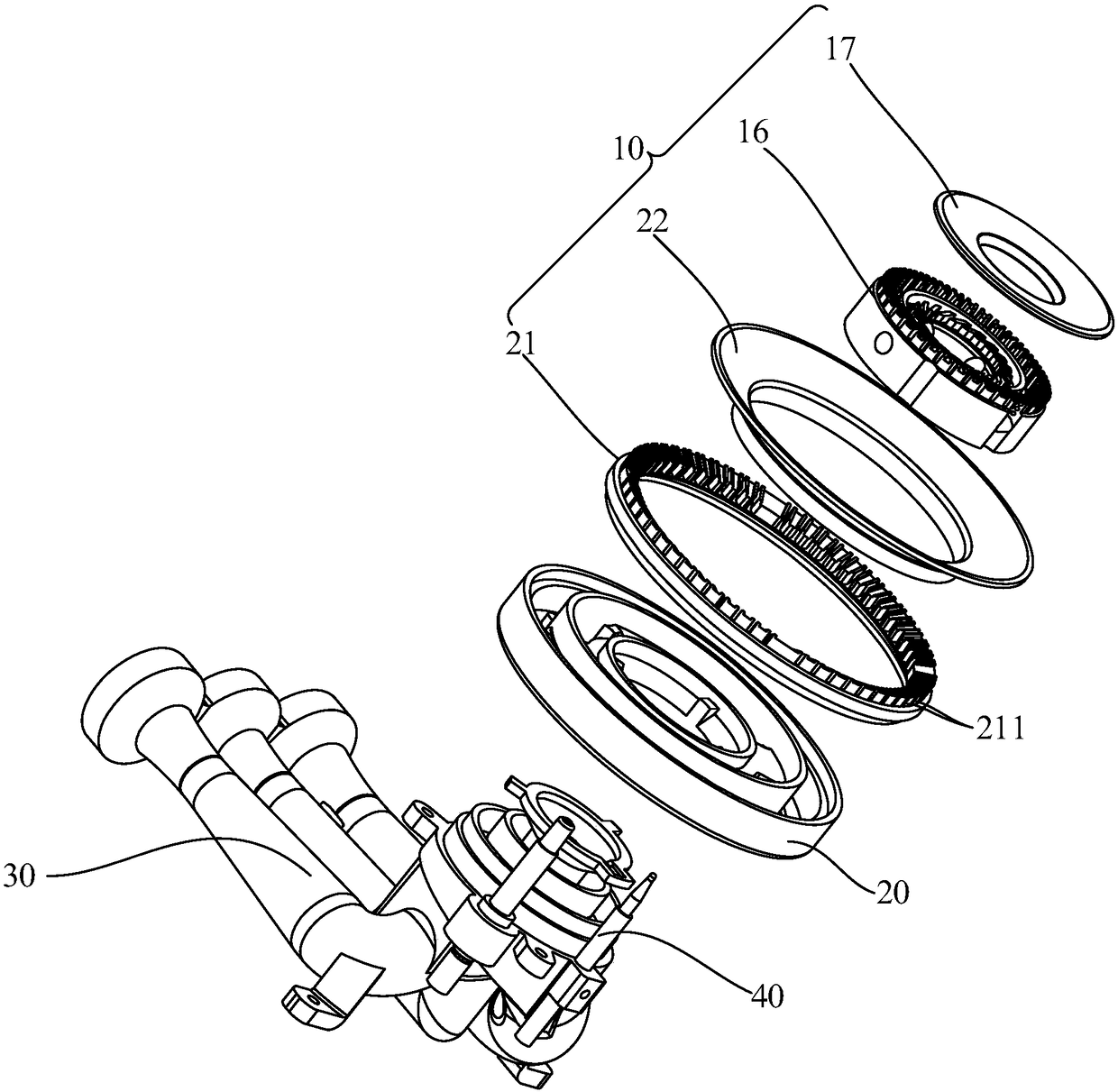

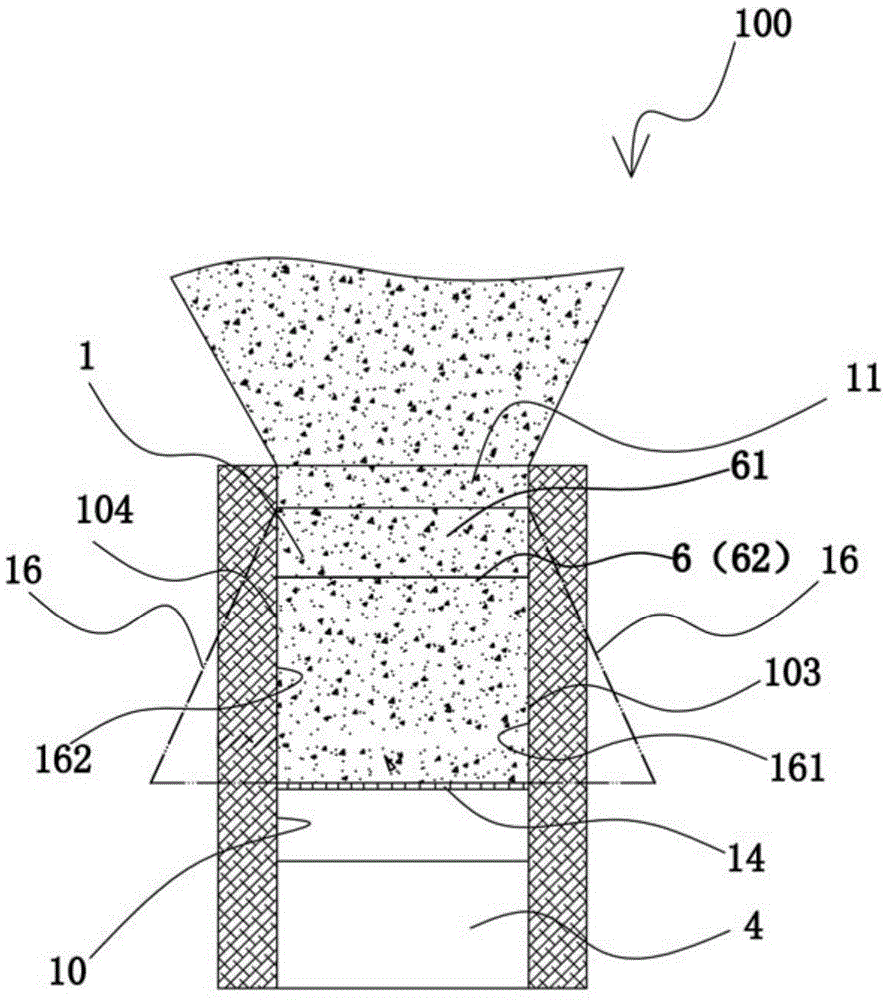

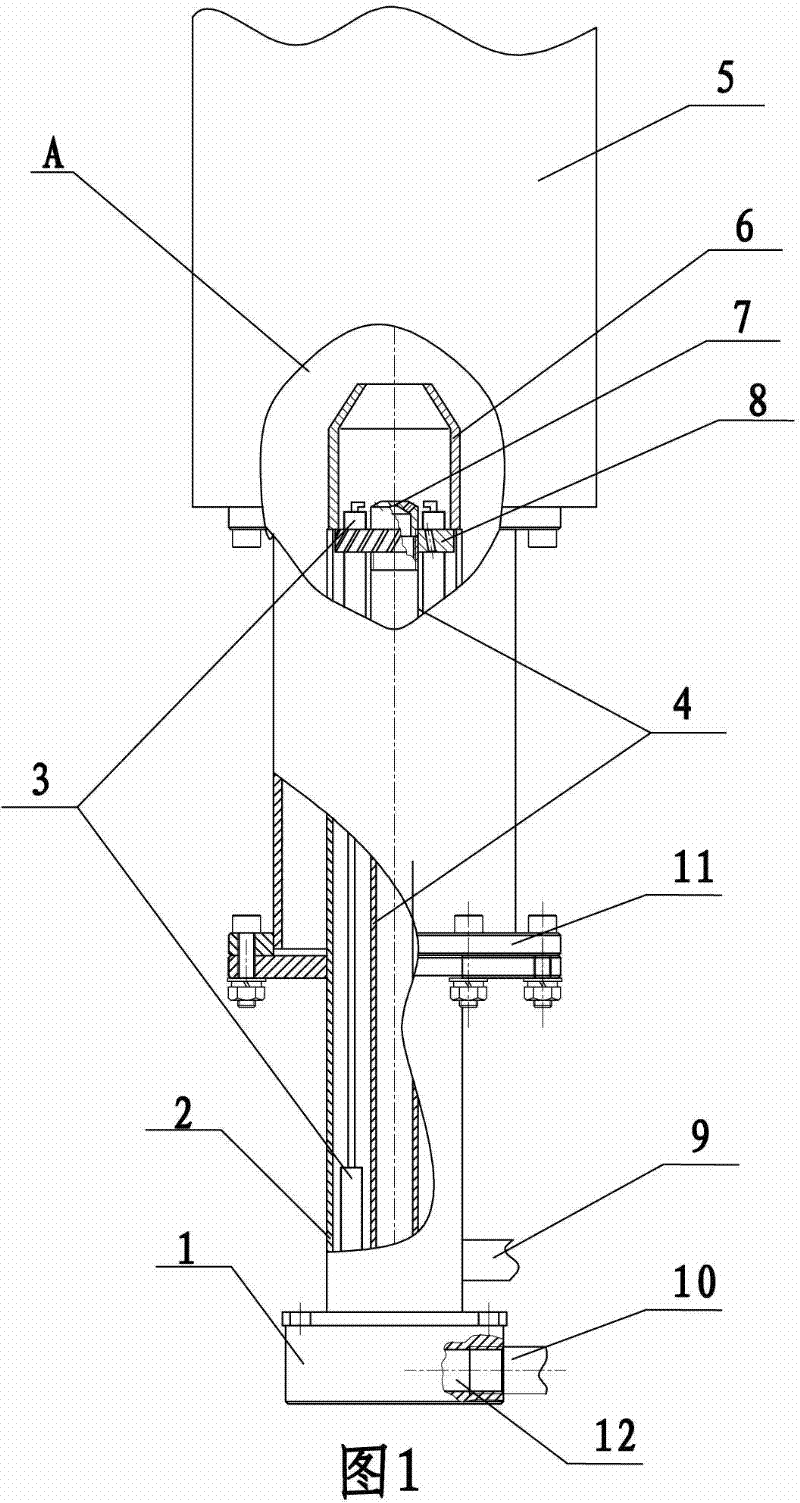

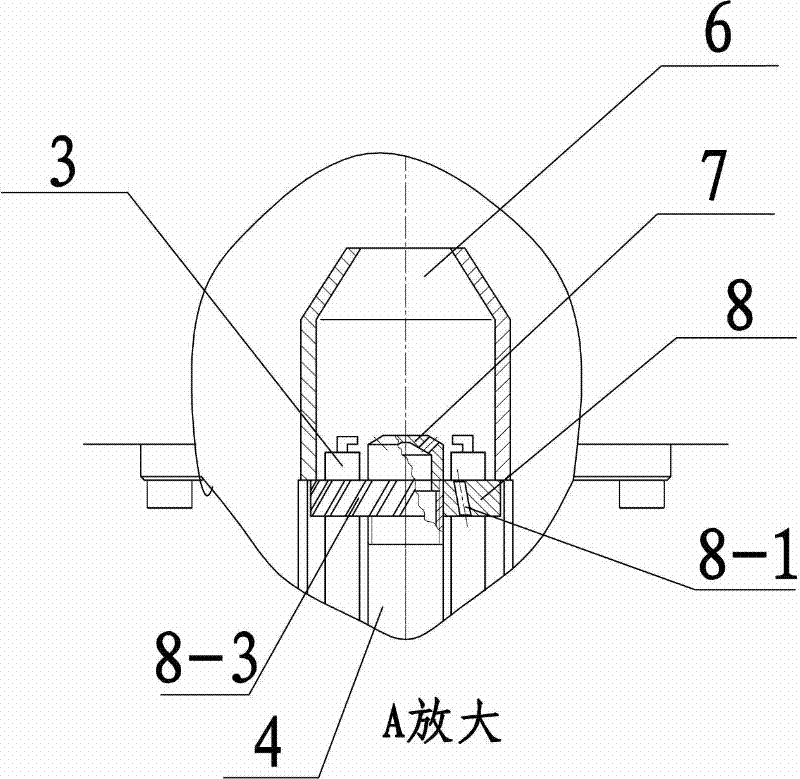

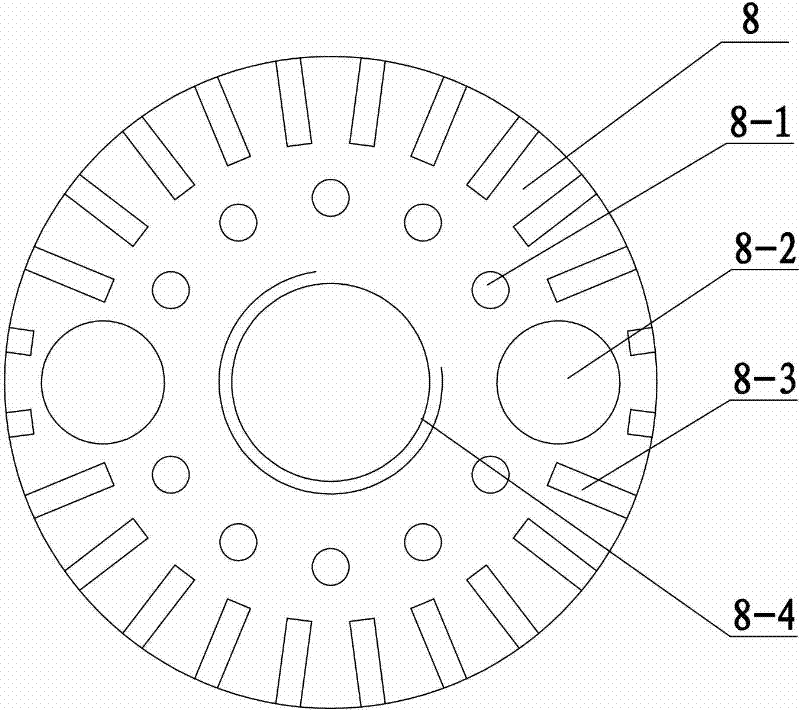

Disclosed is a combustion device (100) for solid fuels. An air inlet side (101) is formed above a furnace grate (14) in a furnace (10) and on one side of a fuel stocking layer (1) of the combustion device (100), a combustion side (102) is formed in the furnace (10) on the other side opposite to the fuel stocking layer (1); a shuffle mechanism (6) is arranged in the fuel stocking layer (1) above the furnace grate (14) for receiving the solid fuels, and the fuels in a combustion state can be shuffled by controlling the movement of the shuffle mechanism (6), which is beneficial for discharging ash.

Owner:车战斌

Opposed firing boiler with thermal power flexibility regulating function and regulating method thereof

InactiveCN106287672AImprove the ability of deep peak shavingThe improvement of deep peak shaving ability is outstandingCombustion using gaseous and pulverulent fuelFuel supply regulationCombustorEngineering

The invention relates to a boiler with a thermal power flexibility regulating function and a regulating method thereof, in particular to the field of opposed firing boilers. The boiler is characterized in that upper burners are burners located on the first layer and the second layer from the top of the boiler; in the upper burners, the front wall and the back wall which are located on the same layer are both provided with the burners, and the burners located on the uppermost layer are set to be peak regulating burners; lower burners are burners located on the first layer from the bottom of the boiler; in the lower burners, any burners on the front wall and / or the back wall are peak regulating burners; the peak regulating burners are internal burning type burners, coal powder can be ignited in the peak regulating burners, and stable burning can be achieved; and the other burners are ordinary burners which are internal burning type burners or external burning type burners. The boiler with the thermal power flexibility regulating function has the beneficial effects that the thermal power operation flexibility and the fuel flexibility of the boiler can be improved, the deep peak regulating capacity of the boiler is remarkably improved, the rapid climbing capacity is achieved, and the boiler can be rapidly started or stopped.

Owner:CHONGQING FURAN TECH

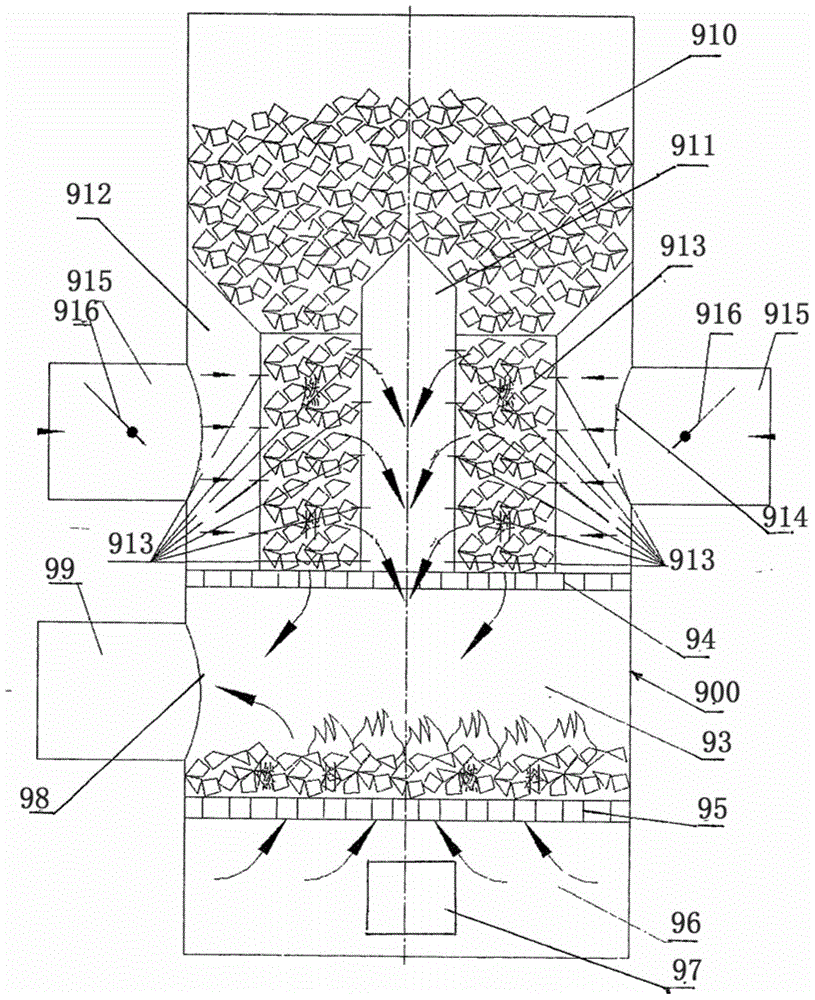

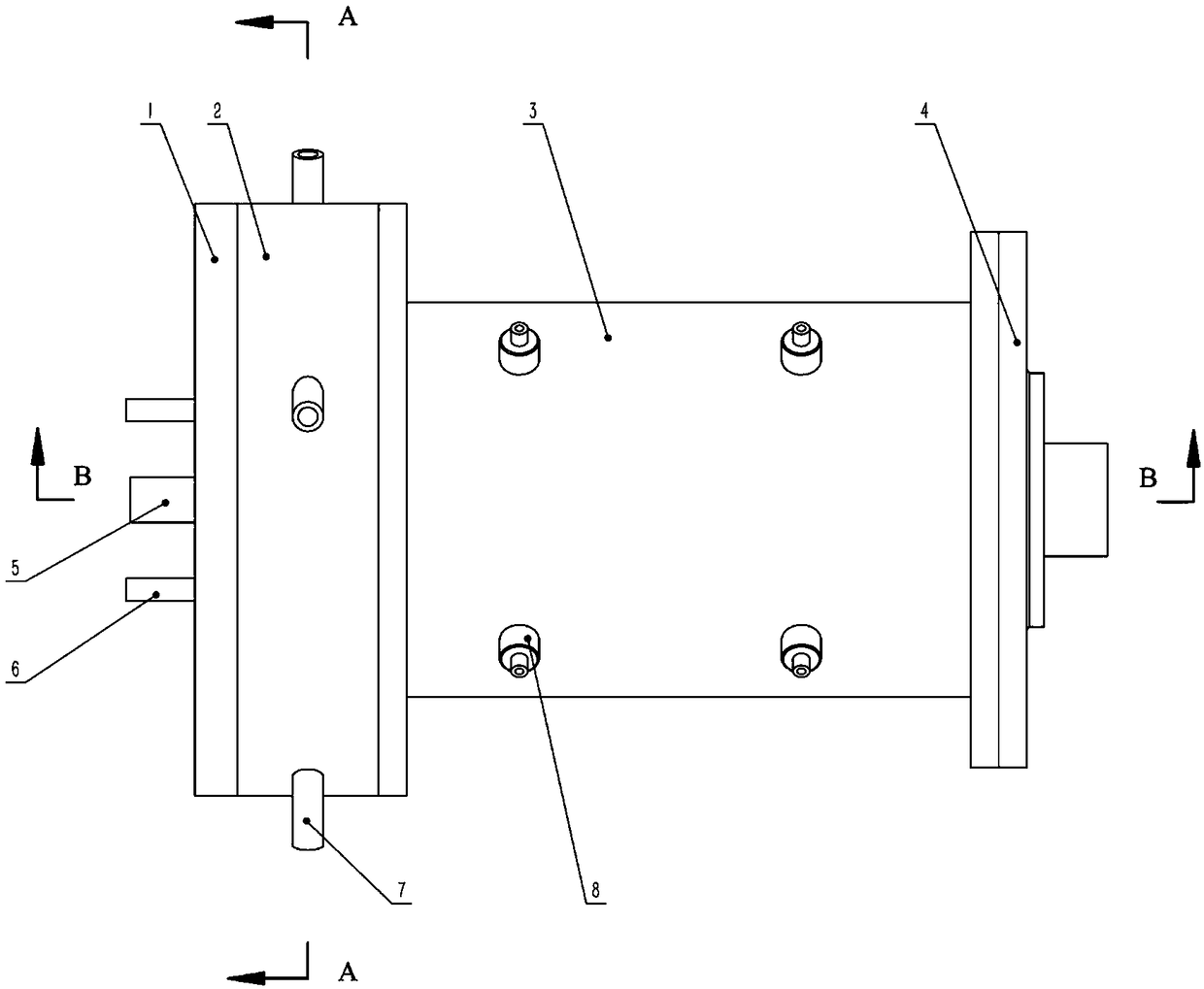

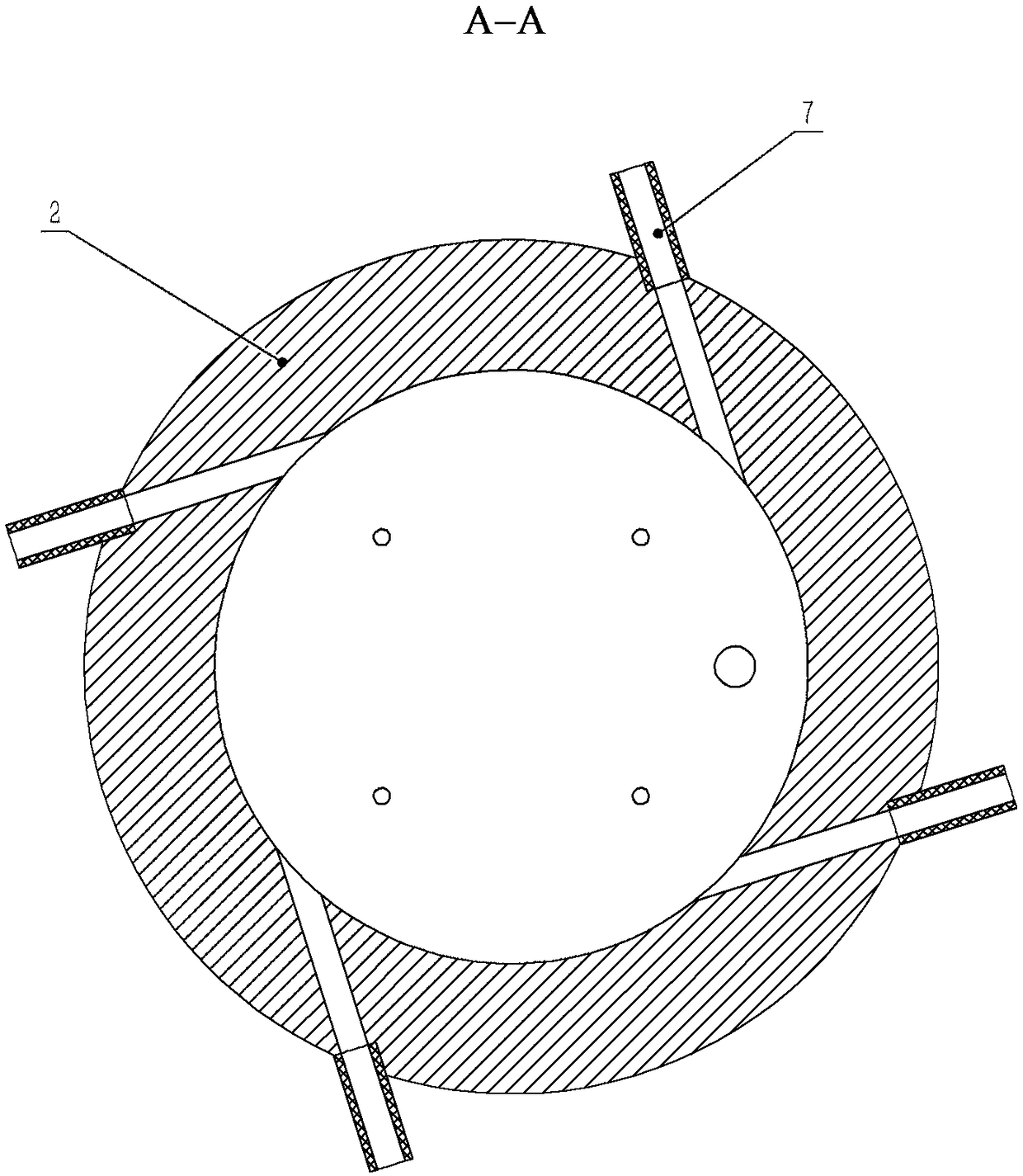

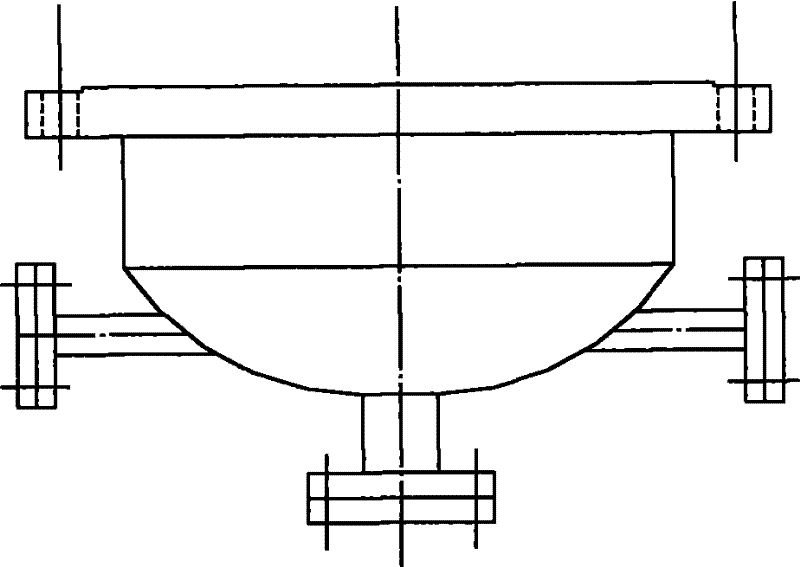

Double combustion chamber device for burning aluminum particles and water

InactiveCN109058977AContinuous and stable combustionImprove combustion efficiencySolid fuel combustionNon-combustible gases/liquids supplyCombustion chamberLiquid water

The invention relates to a double combustion chamber device for burning aluminum particles and water. The double combustion chamber device comprises a pre-combustion chamber and an afterburning chamber, wherein the pre-combustion chamber comprises four aluminum particle inlets which are uniformly distributed in the circumferential direction, one ignition starting inlet and four water vapor inletswhich are uniformly distributed in the circumferential direction; the steam tangentially enters the pre-combustion chamber to form a vortex flow, the aluminum particles enter the pre-combustion chamber along the axial direction and also form the vortex flow under the driving of the steam, and a steady-state high-temperature region is formed in the pre-combustion chamber to promote the subsequent aluminum particles to be successfully ignited after the initial ignition of the aluminum particles is successful; the afterburning chamber is provided with a plurality of water nozzles which are uniformly distributed in the circumference, the aluminum particles which are incompletely combusted enter the afterburning chamber and are subjected to supplementary combustion with liquid water injected into the water nozzle, and meanwhile, a large amount of water is added to the rear part of the afterburning chamber to increase the gas flow in the afterburning chamber and reduce the afterburning roomtemperature, and therefore the needed high-temperature and high-pressure mixed fuel gas is obtained for doing work. According to the double combustion chamber device for burning aluminum particles andwater, continuous and stable combustion of aluminum particles can be realized, the structure is simple, low in cost, high in aluminum particle burning efficiency and the like.

Owner:NAT UNIV OF DEFENSE TECH

Solid fuel combustion method and combustion device

InactiveCN105090935ASolve the melting ash problemContinuous and stable combustionSolid fuel combustionCombustion apparatusSolid fuelExhaust gas

A solid fuel combustion method and combustion device (100). The combustion device (100) comprises a furnace (10). The side of a fuel stack layer (1) close to a combustion cavity (3) forms a combustion side (102), and the other side opposite the combustion side (102) forms an air inlet side (101). The air inlet side (101) is provided with a side wall (6) that provides air only to the upper portion of the fuel stack layer (1).

Owner:车战斌

Burner for gas calorific value instrument

InactiveCN102519039AIncrease contact surfaceBlock the trend of burningGaseous fuel burnerSpray nozzleCombustible gas

The invention belongs to the technical field of a gas calorific value instrument, and particularly relates to a burner for the gas calorific value instrument, which comprises a gas inlet, a gas pipe, a high-pressure ignition electrode, the burner, an air pipe body and an air inlet, wherein the gas inlet is connected with a burner base provided with a gas channel; the gas pipe, the high-pressure ignition electrode and the bottom end of the air pipe body are connected with the burner base; the high-pressure ignition electrode and the gas pipe are arranged in the air pipe boy; the gas inlet is communicated with the gas pipe by the gas channel; a nozzle head is communicated with the gas pipe; a circular air mixing board is provided with a thread through hole, symmetrical through holes, a group of circular combustion-supporting air through holes and a group of long-strip combustion-supporting air through holes; and the burner consists of the circular air mixing board, the nozzle head and an injection pipe. The burner for the gas calorific value instrument is simple in structure, capable of guaranteeing the combustible gas to be rapidly mixed and gas with low calorific value to be easily ignited, and safe and stable in the combustion process.

Owner:赵桐斌

Radial two-stage rotational flow spray nozzle of combustion chamber

InactiveCN106678871AImplement combustion modeReliable ignitionContinuous combustion chamberCombustion chamberSpray nozzle

The invention discloses a low-pollution radial two-stage rotational flow spray nozzle of a combustion chamber. The radial two-stage rotational flow spray nozzle comprises a central fuel channel, a peripheral fuel channel and an annular air channel which are coaxially arranged in the radial direction, and the annular air channel is separated into a central air channel body and a peripheral air channel body by a splitter plate; the central air channel body and the peripheral air channel body are internally provided with a central rotational flow device and a peripheral rotational flow device respectively; and an outlet of the central fuel channel is provided with a premixing cavity. By means of the spray nozzle structure, combustion stability and good discharging performance are guaranteed, gas or liquid fuel, such as natural gas which is cleaner, can be utilized, and the radial two-stage rotational flow spray nozzle has the advantage that the work state is easy to adjust.

Owner:林宇震

Biological oil combustion device

ActiveCN101539290BSolve difficult problems that are not easy to igniteOvercome the difficult problem of atomizationCombustion using gaseous and pulverulent fuelBurnersCombustion chamberCombustible gas

The invention discloses a biological oil combustion device, which comprises an oil storage tank, an atomization system, a steady combustion chamber, an auxiliary ignition system, a combustion air-distribution system used for providing combustion air for the combustion of biological oil, and a conveying system conveying the biological oil into the steady combustion chamber from the oil storage tank, wherein the conveying system comprises a first oil conveying passage and an oil return passage which are connected between the oil storage tank and the atomization system and are mutually and parallelly arranged, and a second oil conveying passage which is connected between the atomization system and the steady combustion chamber; the first oil conveying passage comprises at least one filter; the oil return passage is provided with a pressure transmitter; the auxiliary ignition system comprises a combustible gas conveying pipeline and a high-pressure igniter which extend into the steady combustion chamber; the combustion air-distribution system is communicated with the steady combustion chamber; and a spinning disk which can guide the rotating convection of the biological oil is arranged in front of the atomization system of the biological oil and the auxiliary ignition system in the steady combustion chamber. The device can realize the sustainable and steady combustion of the biological oil, can fully release the energy of the biological oil, and has convenient maintenance and long service life.

Owner:GUANGZHOU DEVOTION THERMAL TECH

Mixed combustion type engine

InactiveCN102192013AContinuous and stable combustionImprove utilization efficiencyGas turbine plantsTurbine/propulsion fuel controlInsulation layerExternal combustion engine

The invention discloses a mixed combustion type engine, which is a novel energy-saving and emission-reducing engine. The mixed combustion type engine consists of an oil-gas input device, a one-way valve, an ignition device, a combustion chamber, a heat insulation layer, a pressure sensor, a safety valve, a flow adjusting device, an engine and an angle sensor. The combustion chamber and the engine are separately designed in the mixed combustion type engine, fuel and air are adjusted by the oil-gas input device and then sprayed to the combustion chamber in a multi-point mode, the ignition device carries out ignition, the fuel is continuously combusted and gasified in the combustion chamber, the temperature is raised, the air is expanded with heat, the fuel and the air generate high pressure in the combustion chamber together, and the high pressure is controlled by the flow adjusting device and propels the engine to rotate. The mixed combustion type engine has the advantages of an internal-combustion engine and an external-combustion engine, the fuel is continuously and stably combusted, the heat is fully utilized, the utilization efficiency of the fuel is high, little exhaust is discharged, the engine only has working and exhaust strokes, the working efficiency is high, the idle working condition is good, the working temperature is low, the cooling requirement is low, the process requirements of the combustion chamber and the engine are low, and an efficient device can be conveniently designed and manufactured.

Owner:周永胜

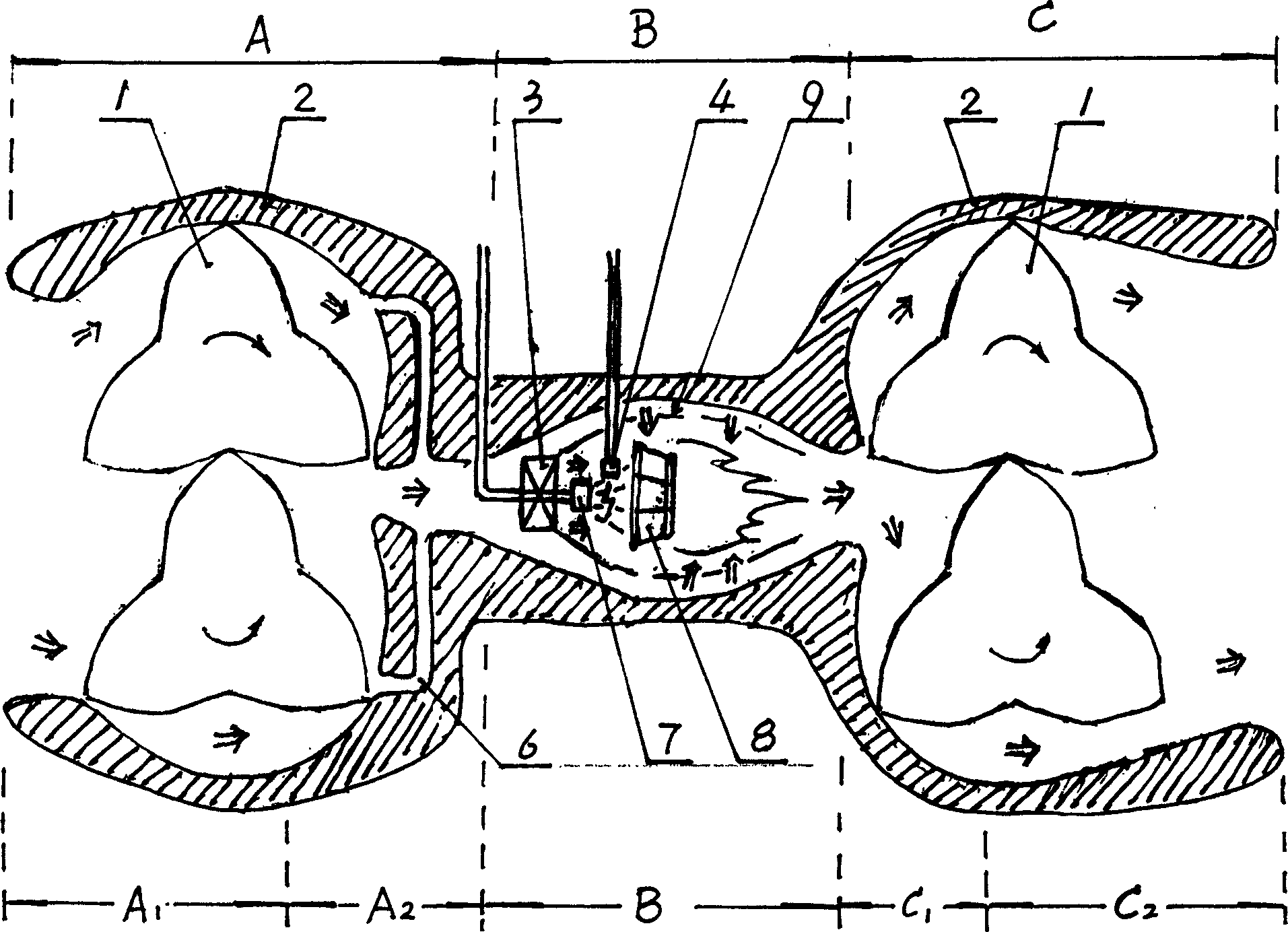

Internal combustion engine of disrotatory rotor

InactiveCN1661216ABottle diameter to overcome output powerGuaranteed continuous outputInternal combustion piston enginesEngine of intermeshing engagement typeInternal combustion engineTurbine

An explosive motor with disrotatory rotor is composed of pressurizer, burner, expander and driving device. It is featured as setting a pair of disrotatory rotor in each of pressurizer and expander, making section of columnar rotor be form of three petals distributed uniformly in 360 degree, setting petal top curvature radius to be less than that of expander and pressurizer, setting pressurizer air inlet to be greater than air outlet with pressure buffer device and making expander air exhaust volume be greater than its air suction volume.

Owner:刘军

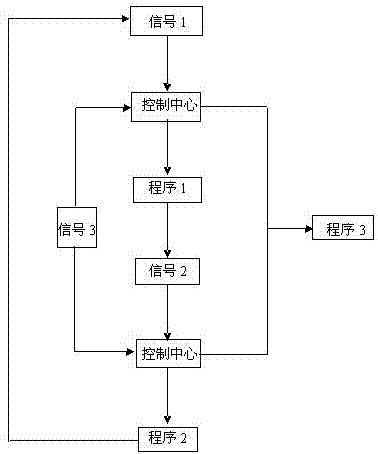

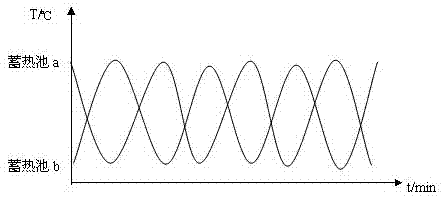

Economical heat storage combustion device and control method thereof

InactiveCN103759285AContinuous and stable combustionRealize automatic controlIndirect carbon-dioxide mitigationCombustion regulationCombustionInsulation layer

The invention discloses an economical heat storage combustion device and a control method thereof. The economical heat storage combustion device comprises a fuel oil switch, a combustion nozzle, a combustion furnace, two heat storage ponds, two thermal infrared imagers, a control center, and corresponding pipelines and valves, wherein a heat insulation layer is clamped between the two heat storage ponds, the two thermal infrared imagers are respectively connected with the control center, and the control center directly controls the corresponding valves. The economical heat storage combustion device and the control method thereof are simple and useful, safe and reliable, and continuous and stable in combustion, and can achieve full automatic control.

Owner:HENAN SHENGSHI ENERGY SAVING ENVIRONMENTAL PROTECTION ENG

Burner outer fire cover

ActiveCN102913911B"Control" effect is perfect"Control" effect caused byGaseous fuel burnerCombustorEngineering

An outer burner cap of a burner comprises an outer burner cap body with a plurality of main flame channels. The lower end of the outer burner cap is provided with a gas mixing chamber communicated with the main flame channels. The main flame channels are provided with main flame holes on at least one of the inner side and the outer side of the outer turner cap body. The outer burner cap is characterized in that the outer flame cap body above or below the main flame channels peripherally forms a circular flame-stabilizing channel, and the outer end of the flame-stabilizing channel forms a flame stabilizer ring on the outer side or inner side of the outer burner cap body. The inner end of the flame-stabilizing channel is communicated with the gas mixing chamber. Compared with the prior art, the outer burner cap has the advantage that the flame-stabilizing channel at the lower edges of the main flame holes can well 'stabilize' flame from the main flame holes during burning so as to stabilize burning.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Synchronous inner-meshing double-rotor structure as well as rotor compressor and rotor engine based on synchronous inner-meshing double-rotor structure

PendingCN110080979ASimple structureIncrease the compression ratioInternal combustion piston enginesRotary piston pumpsEngineeringInspired gas

Owner:张满云

Inner ring fire cover of combustor

InactiveCN104515132AImprove thermal efficiency and ignition success rateSimple structureBurner safety arrangementsGaseous fuel burnerEngineeringHeating efficiency

The invention discloses an inner ring fire cover of a combustor. The inner ring fire cover of the combustor comprises a cylindrical fire cover body; a through hole is formed in the middle part of the fire cover body to form an air mixing chamber; the lower end surface of the air mixing chamber communicates with an air supply slot in a furnace head seat; a plurality of main fire channels are circumferentially formed at intervals in the fire cover body; one end of each main fire channel communicates with the air mixing chamber, and while the other end of each main fire channel is opened in the vertical surface of the outer side of the fire cover body to form at least one circle of main flame holes which are axially formed at intervals in the fire cover body; a circle of annular flame stabilizing channel is circumferentially formed in the fire cover body; one side of each flame stabilizing channel is opened in the vertical surface of the outer side of the fire cover body to form a circle of flame stabilizing rings, and while the other side of each flame stabilizing channel communicates with the air mixing chamber. The inner ring fire cover of the combustor has the advantages that the main flame of the inner ring fire cover is controlled by the flame stabilizing flame in the flame stabilizing rings to achieve the optimal state, so that the continuous and stable combustion can be achieved, the heat efficiency and the ignition success rate can be increased, and the effect of soft fire without extinguishing can be achieved.

Owner:SAKURA BATH & KITCHEN PRODS CHINA

Multi-stage deslagging furnace

The invention discloses a multi-stage deslagging furnace. The multi-stage deslagging furnace comprises a furnace body with a cavity. The upper portion of one side of the furnace body is provided witha feed port, and the lower portion of the other side of the furnace body is provided with a slag outlet. The furnace body is at least internally provided with a first-stage inclined fire grate close to the feed port and a second-stage horizontal fire grate connected with the bottom of the first-stage inclined fire grate. A slag discharge box is further arranged on the slag discharge face of the bottom of the furnace body. A first-stage step and a slag discharge box step are arranged between the bottom of the first-stage inclined fire grate and the second-stage horizontal fire grate and betweenthe second-stage horizontal fire grate and the slag discharge box correspondingly. The multi-stage deslagging furnace further comprises a first-stage slag push rod set and a slag discharge box connecting rod used for pushing the slag discharge box out of the furnace body. The first-stage slag push rod set and the slag discharge box connecting rod can move simultaneously. According to the multi-stage deslagging furnace provided by the invention, the multi-stage fire grates are arranged in the furnace body so that granular fuel can move on the different fire grates, the granular fuel with the high ash content can be burned continuously and stably, and furnace slag can be automatically discharged from the furnace body.

Owner:HUNAN NONGYOU MACHINERY GRP

Burning method for pulverized solid fuels transferred by dilute phase pneumatic in tunnel kiln and dilute phase pneumatic transferring system

ActiveCN101761934BContinuous and stable combustionGuaranteed mixLump/pulverulent fuel feeder/distributionTunnel kilnPositive pressure

Owner:武汉欣永昌节能技术有限公司

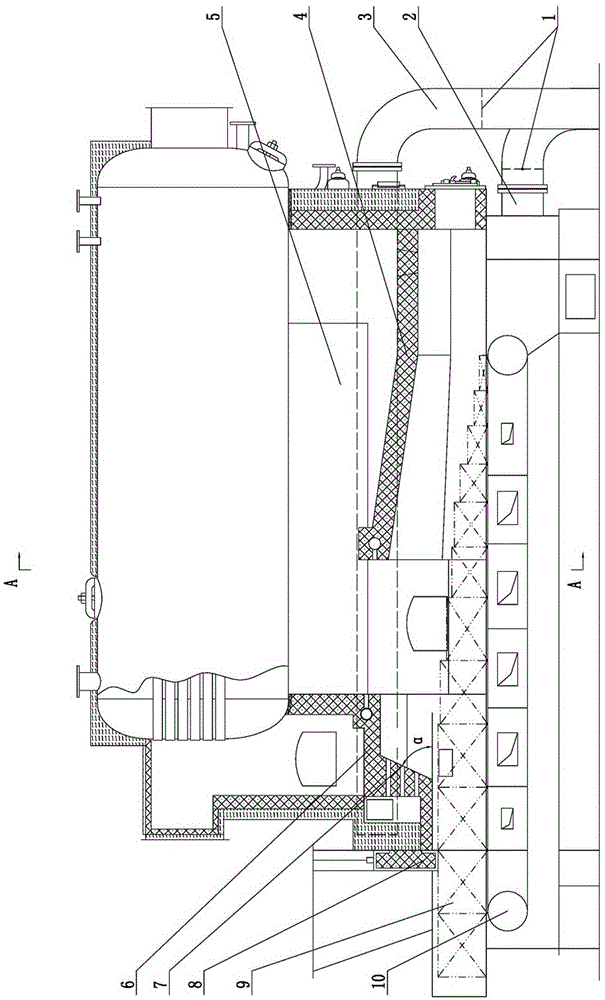

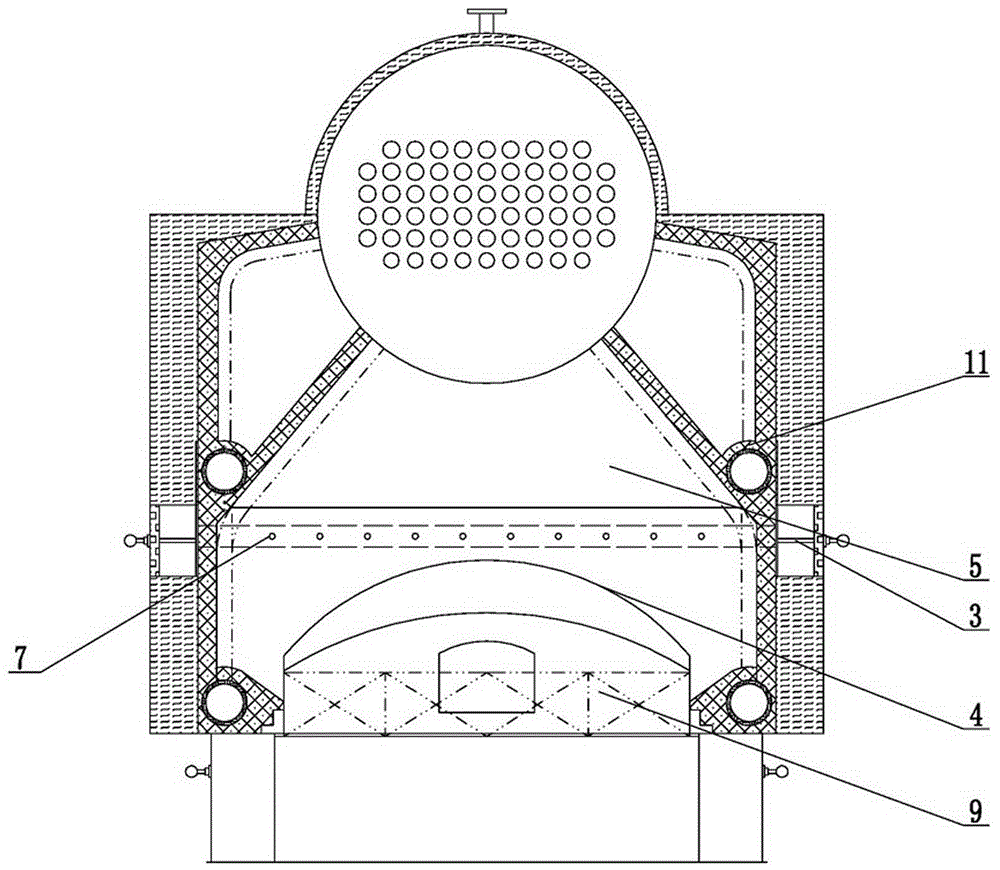

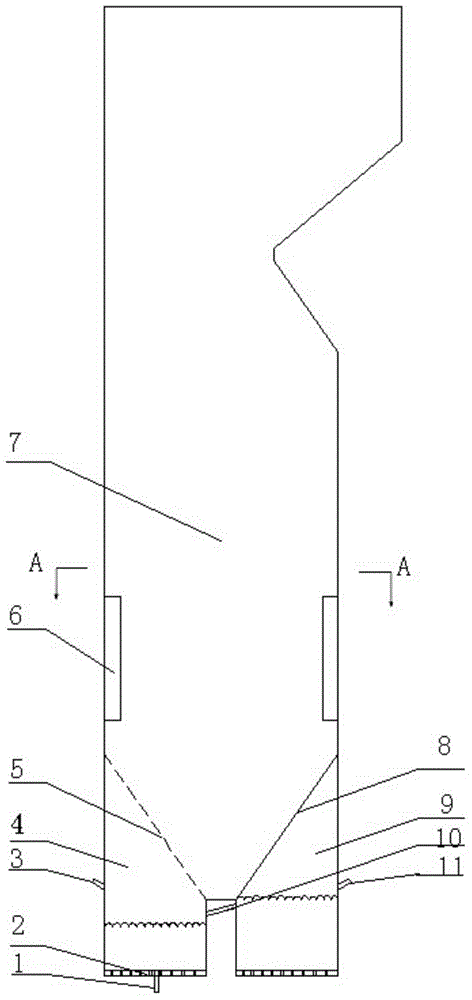

Bundling direct-burning type straw boiler

InactiveCN105276567ARun smoothlyContinuous and stable combustionSolid fuel combustionCasings/liningsEngineeringHearth

The invention discloses a bundling direct-burning type straw boiler, and relates to an improvement of a boiler structure. By means of the bundling direct-burning type straw boiler, straw is directly bundled through special equipment in the field and conveyed to a boiler room, and then the straw can be directly burnt, and the burning cost is reduced. The bundling direct-burning type straw boiler comprises a boiler body with a primary air tube and a secondary air tube, a fuel inlet is formed in the front end of the boiler body, a conveying belt type fire grate is arranged in the boiler body, and the front end of the fire grate extends out from the fuel inlet and is arranged outside the boiler body; and a front arch and a rear arch are arranged at the positions, corresponding to the fire grate, in the boiler body, and an outlet of the secondary air tube of the boiler body is arranged in the front arch and the rear arch. The bundling direct-burning type straw boiler is structurally characterized in that an inlet of the secondary air tube of the boiler body is formed in the back end of the boiler body, and the secondary air tube of the boiler body is arranged in a boiler wall passing through a hearth; and an included angle formed between the front arch and the horizontal plane is larger than or equal to 55 degrees and smaller than or equal to 70 degrees.

Owner:李征

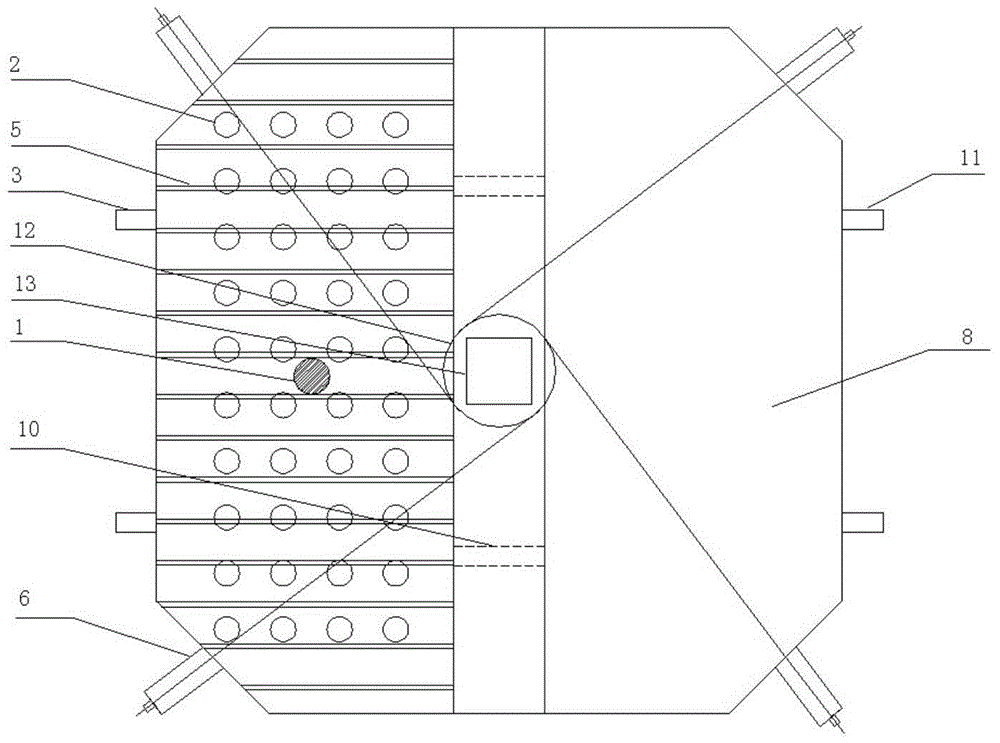

Combined Coal Gasification and Combustion Fluidized Bed-Powdered Coal Furnace in Series

ActiveCN103727528BContinuous and stable combustionBurn fullyFluidized bed combustionApparatus for fluidised bed combustionCombustion chamberProcess engineering

The invention discloses series-connected compounded gas gasification and combustion fluidized bed-pulverized coal furnace, relates to a fluidized bed-pulverized coal furnace, and aims to solve the problem that two fuels cannot be combusted at the same time, the low-load stable combustion is difficult, a specific pulverized furnace has poor adaptability to coal types and the power consumption of a coal mill is high when the fuel particles and the combustion activities of the conventional pulverized coal furnace are different. The series-connected compounded gas gasification and combustion fluidized bed-pulverized coal furnace comprises a pulverized coal suspension combustion chamber, a water cooling wall, a combustion fluidized bed, a gasification fluidized bed and an overflow pipe, wherein the combustion fluidized bed and the gasification fluidized bed are positioned on the lower side of an ash cooling hopper in the pulverized coal suspension combustion chamber; the gasification fluidized bed is completely separated from a furnace hearth through the water cooling wall; the gasification fluidized bed is communicated with the combustion fluidized bed through the overflow pipe; the combustion fluidized bed is separated from the furnace hearth by staggered pipe bundles, so that the gasification fluidized bed, the combustion fluidized bed and the pulverized coal suspension combustion chamber are connected in series. The series-connected compounded gas gasification and combustion fluidized bed-pulverized coal furnace is used for high-efficiency combustion of a coal-fired boiler.

Owner:HARBIN INST OF TECH

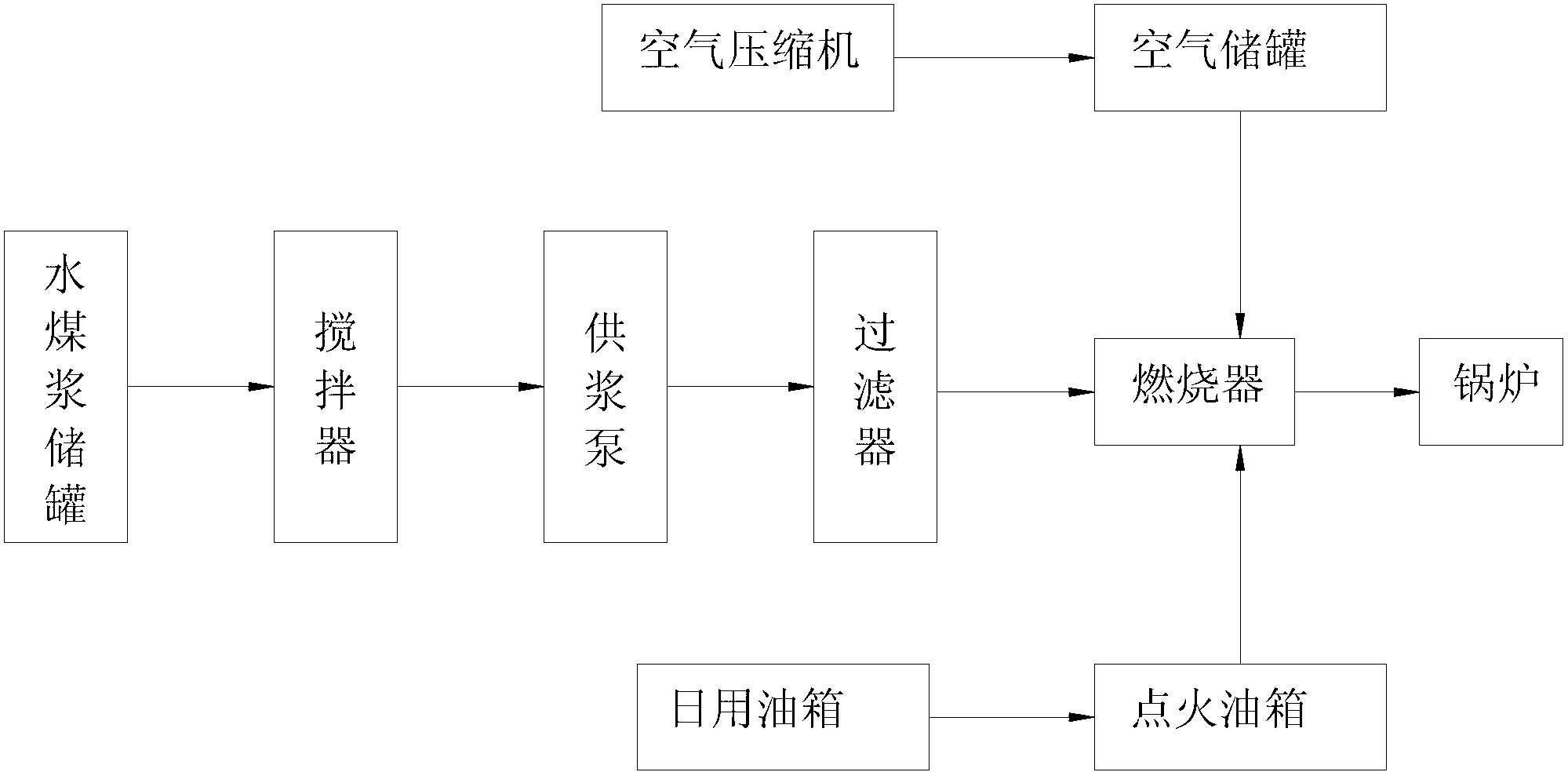

Combustion system with coal water slurry fired boiler

InactiveCN102997228AAvoid heavy polluting processes with insufficient combustion at low temperaturesThe furnace heats up rapidlyCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustion systemFuel tank

The invention relates to a combustion system with a coal water slurry fired boiler. The combustion system comprises a coal water slurry storage tank, a stirrer, a slurry supply pump, a filter, a combustor and the boiler which are sequentially connected with one another, wherein the combustor is respectively provided with an air-blast system and an ignition oil way which are used for atomizing coal water slurry, the air-blast system comprises an air storage tank and an air compressor acting on the air storage tank, the air storage tank is connected with the combustor, and the ignition oil way comprises a daily oil tank and an ignition oil tank which are sequentially connected with the combustor. The combustion system totally adopts flow conveying and atomization of pipelines, can implement automatic ignition of oil in a short time, is simple and convenient to operate and high in safety, and requires labor intensity which is much less than that required by a coal-fired boiler.

Owner:CHANGZHOU OLYMSPAN THERMAL ENERGY EQUIP

Small-flame low-strength double-layer burning device for biomass forming fuel and burning method

PendingCN108343947AGuaranteed uptimeEvenly heatedOil/fat bakingSolid fuel combustionCombustorEngineering

The invention discloses a small-flame low-strength double-layer burning device for biomass forming fuel and a burning method. The small-flame low-strength double-layer burning device structurally comprises six parts of a double-layer burner, a feeding device, an ash collecting device, a smoke discharging device, a pot body and a furnace body, and the furnace body is arranged on the lower side of the pot body; the furnace body is internally provided with the double-layer burner and the ash collecting device, the ash collecting device is provided with a furnace door, the side face of the furnacebody is provided with the feeding device, and the upper portion of the feeding device is provided with the smoke discharging device. The small-flame low-strength double-layer burning device belongs to a cooking pancake furnace, the burning method can form a small-flame, low-strength, continuous, stable and efficient burning state, and the demand of the low-temperature heating surface of the burning device is met.

Owner:SHANDONG YINGCAI UNIV

Antiviral antibacterial incense and preparation method thereof

InactiveCN108379638AReduce dosageGood combustion effectAntibacterial agentsBiocidePeppermintsChemistry

The invention belongs to the field of fine chemicals and particularly relates to antiviral antibacterial incense and a preparation method thereof. Decoction is prepared first via water extraction; active medicinal effective ingredients are stored and protected via the porous inorganic material bentonite having good water-absorbing capacity, so that chances for the effective ingredients to be oxidized and inactive during high-temperature combustion are greatly slimmed; the antiviral antibacterial incense is prepared through the compatibility with wood flour, a binder and other auxiliary materials. The antiviral antibacterial incense can be ignited to produce smoke that has slight, sweet, slightly spicy, and fresh peppermint smell, which soothes and relax a smeller; the antiviral antibacterial incense can also kill harmful viruses and bacteria in the air and can inhibit common viruses and bacteria to 90% and above, such as Escherichia coli and Staphylococcus aureus. The smoke contains various effective Chinese herbal ingredients that can resist viruses and bacteria; the smell passes through olfactory cells of the orifices and enter the body via the skin so as to assist in clearing harmful viruses and bacteria in the body, thereby benefiting people's physical health.

Owner:MINNAN NORMAL UNIV

Tubular flame burner

ActiveCN103857961AContinuous and stable combustionPulverulent fuel combustion burnersNon-combustible gases/liquids supplyExhaust gasCombustion chamber

This tubular flame burner has a tubular combustion chamber having one open end, and is provided at the closed end side of the combustion chamber with a nozzle that blows in a fuel gas and a nozzle that blows in an oxygen-containing gas facing in the direction of the tangent line of the inner wall surface thereof. The open end side of the combustion chamber is provided with a nozzle that blows in a gas for adjusting the temperature of the combustion exhaust gas, and is provided with a backflow prevention means for preventing the gas for adjusting temperature blown in from the nozzle for blowing in the gas for adjusting temperature from backflowing towards the nozzle for blowing in the fuel gas.

Owner:JFE STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com