Mixed combustion type engine

An engine and co-combustion technology, which is applied in the direction of engine components, machines/engines, gas turbine devices, etc., can solve the problems of low fuel utilization efficiency of internal combustion engines, difficulty in designing and manufacturing engines, and high work and exhaust temperatures, so as to facilitate design and manufacture, The effect of low cooling requirements and high work frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

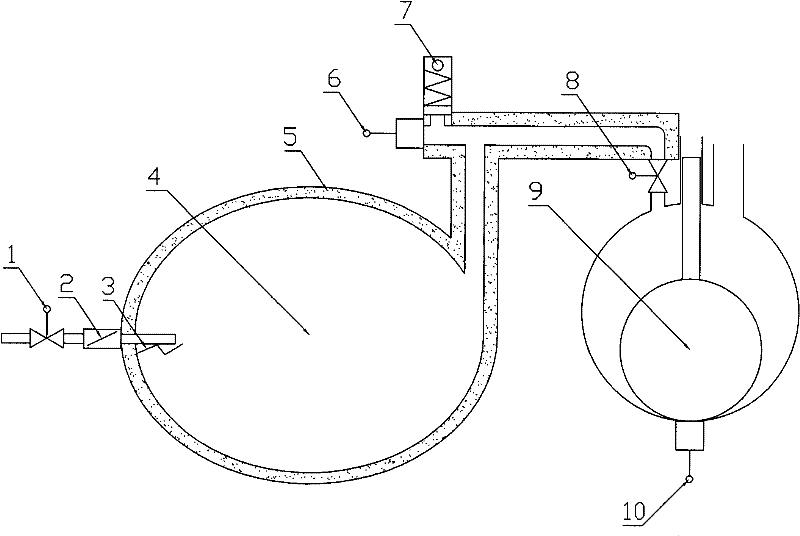

[0007] As shown in the drawings, the co-combustion engine consists of oil and gas input device 1, check valve 2, ignition device 3, combustion chamber 4, insulation layer 5, pressure sensor 6, safety valve 7, flow regulating device 8, engine 9, angle Sensor 10 etc. are made up.

[0008] The working principle of the co-combustion engine is: according to the pressure sensor and load conditions, the fuel and air are regulated by the oil and gas input device and then injected into the combustion chamber at multiple points. Thermal expansion, together with fuel gas, forms high-pressure gas and is stored in the combustion chamber. At the same time, fuel and air are continuously injected into the combustion chamber through the oil and gas input device for combustion, and the gas pressure in the combustion chamber continues to rise. When the pressure exceeds the limit value, the oil and gas input device is closed, and the combustion stops. Working again, the fuel starts to burn again...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com