Burner outer fire cover

A technology for an outer fire cover and a burner is applied in the field of the outer fire cover, which can solve the problems of unstable combustion area and easy flame jumping, and achieve the effect of avoiding waste and accidents and improving thermal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

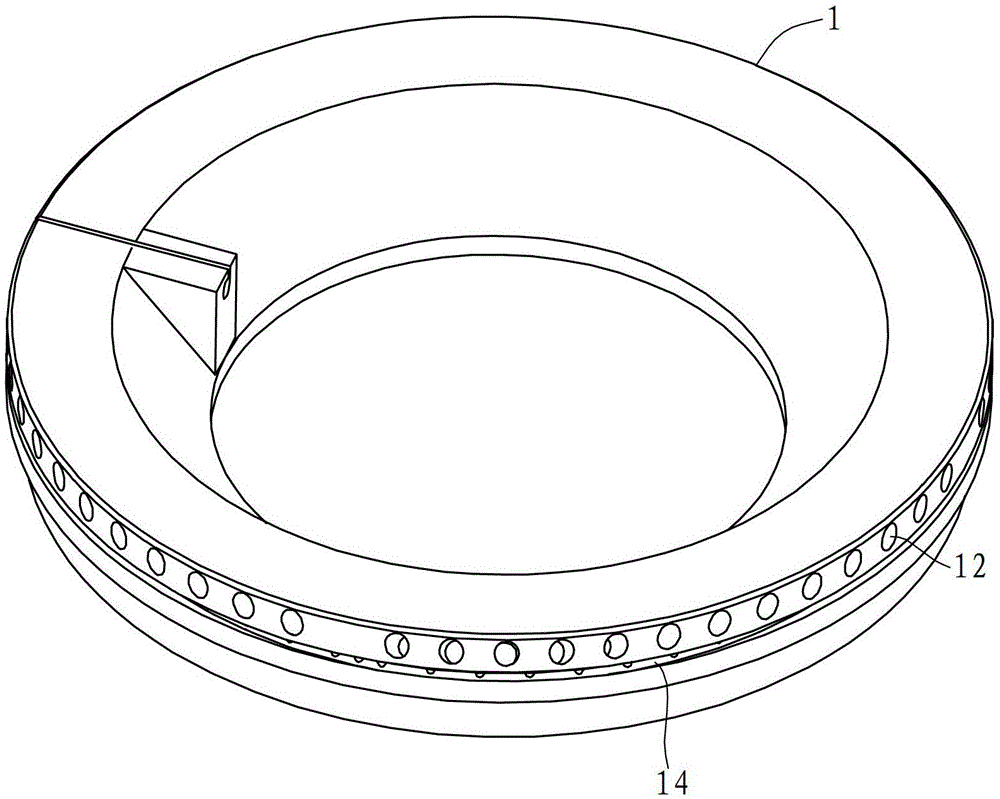

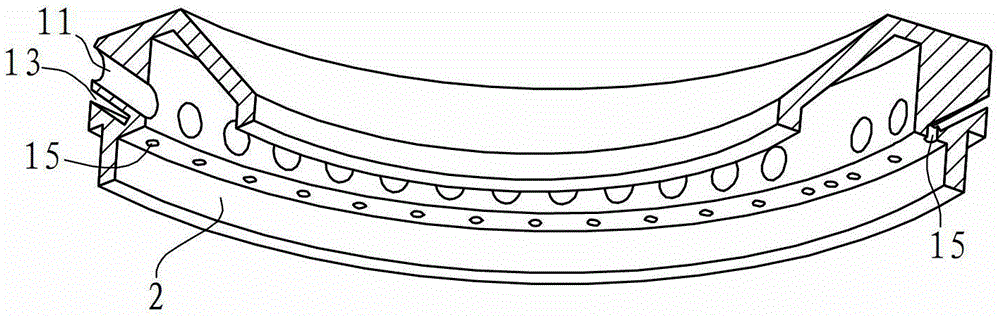

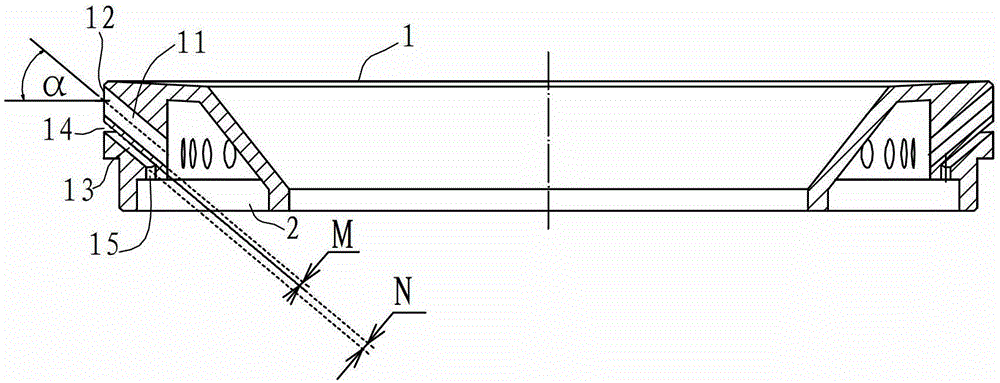

[0018] Example 1, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the burner outer fire cover includes an outer fire cover body 1 with a plurality of main fire passages 11, and the lower end surface of the outer fire cover body 1 has an air mixing chamber 2, which communicates with the main fire passages 11, and the main fire passage 11 is connected to the main fire passage 11. The fire channel 11 forms a main fire hole 12 on the outer end surface of the outer fire cover body. The outer fire cover body 1 is located below the main fire channel 11 and forms an annular flame-stabilizing channel 13 around the circumferential direction. The outer end of the flame-stabilizing channel 1 is outside the outer fire cover body. A flame-stabilizing ring 14 is formed on the side, and the inner end communicates with the gas mixing chamber 2 . Further, the inner end of the flame-stabilizing channel 13 is connected with a plurality of independent air intake channels 15 vert...

Embodiment 2

[0022] Example 2, such as Figure 5 As shown, the outer fire cover body 1 is located above the main fire passage 11 and forms an annular flame-stabilizing passage 13 around the circumferential direction, and the length direction of the section of the main fire passage 11 and the flame-stabilizing passage 13 forms an acute angle β, and β is 30° . Refer to Example 1 for other structures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com