Inner ring fire cover of combustor

An inner ring fire and burner technology, which is applied in the direction of burner, burner, gas fuel burner, etc., can solve the problems of inner ring fire cover flying, flameout, and large difference in gas pressure, so as to improve thermal efficiency and ignition The effect of success rate, favorable for wide application, and increased manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

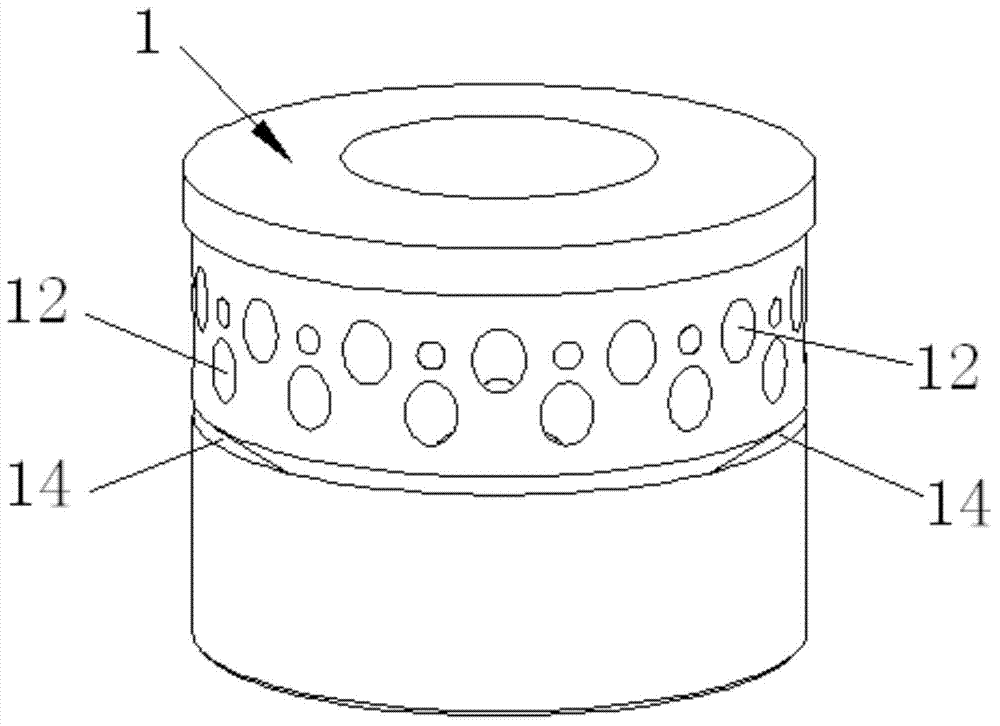

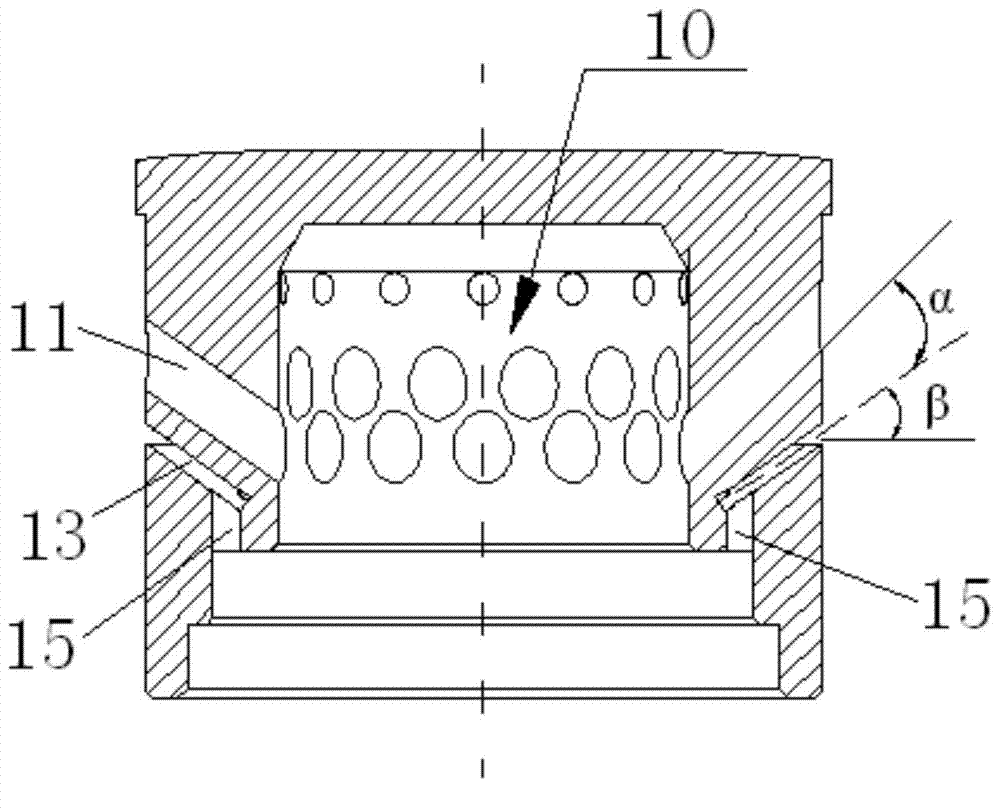

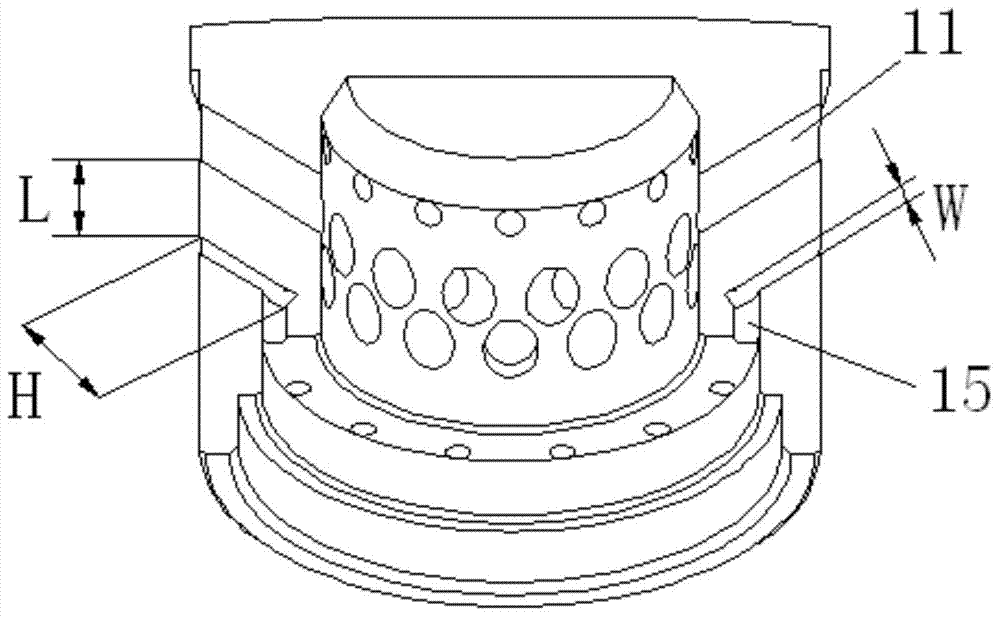

[0021] The present invention relates to a burner inner ring fire cover, the inner ring fire cover is detachably positioned on the upper end of the burner base, the inner ring fire cover includes a cylindrical fire cover body 1, the fire cover The middle part of the body 1 is provided with a through hole to form a gas mixing chamber 10, and the lower end surface of the gas mixing chamber 10 communicates with the gas supply groove on the burner seat; Several main fire passages 11 are opened, and one end of the several main fire passages 11 is connected to the air-mixing chamber 10, and the other ends of the several main fire passages 11 are all opened in the fire cover body 1. On the outer vertical surface, at least one circle of main flame holes 12 spaced apart from each other along the axial direction of the fire cover body is formed; in addition, on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Section width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com