Biological oil combustion device

A combustion device and bio-oil technology, applied in burners, combustion ignition, combustion methods, etc., can solve the problems of inability to ensure the stability and sufficient combustion of bio-oil, change the properties of bio-oil, poor stability of bio-oil, etc., and improve operational safety. performance, accelerate evaporation, and ensure stable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

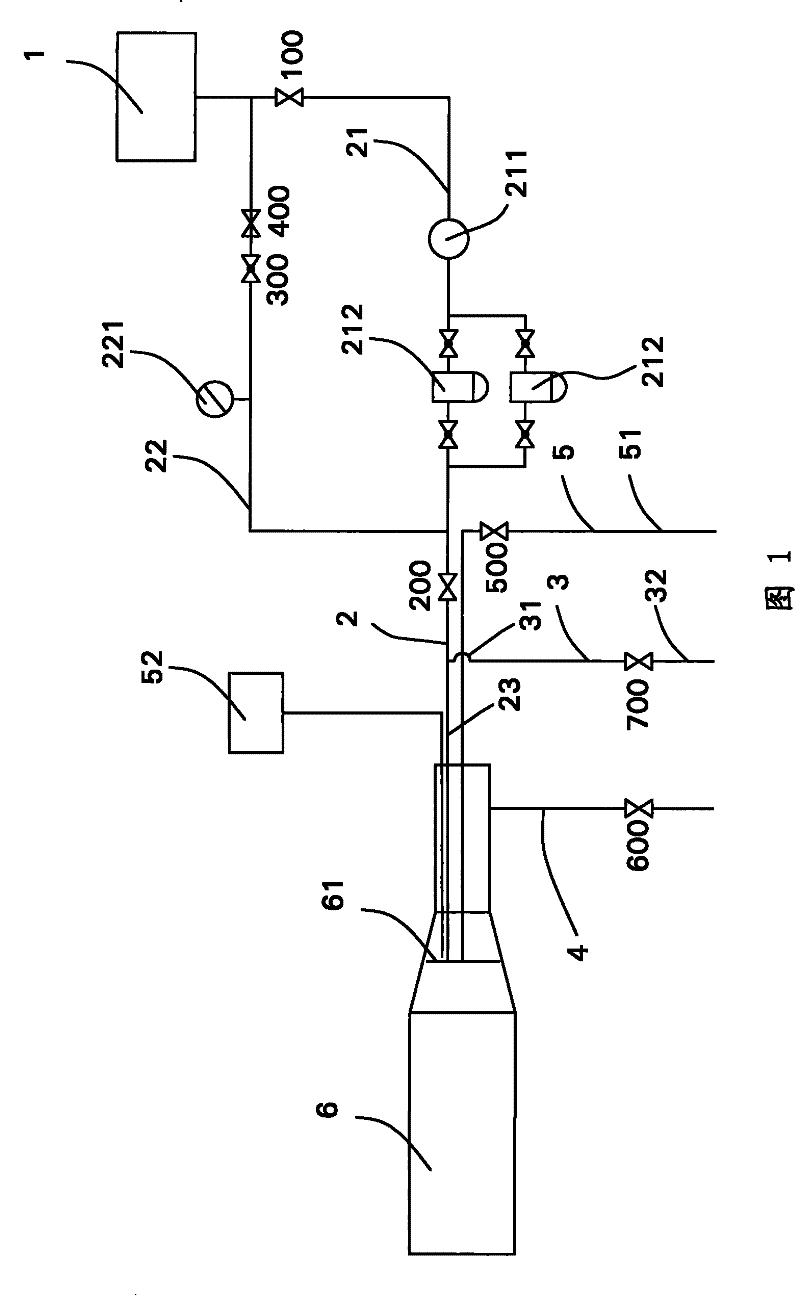

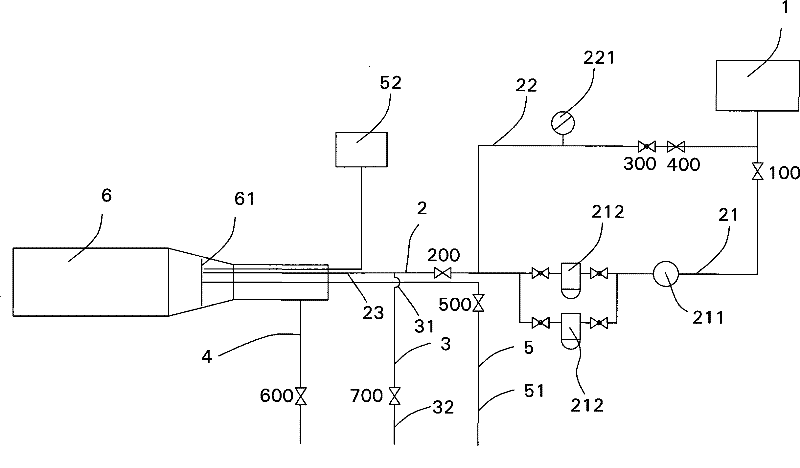

[0020] Please refer to figure 1 The bio-oil combustion device of the present invention includes an oil storage tank 1, an atomization system 3 for atomizing and decomposing bio-oil before combustion, a stable combustion chamber 6 for directly burning bio-oil, an auxiliary ignition system 5, and a combustion air distribution system 4 and the delivery system 2 that transports the bio-oil from the storage chamber to the stable combustion chamber 6.

[0021] The oil storage tank 1 is made of acid-resistant material, such as stainless steel. The delivery system 2 includes a first oil delivery passage 21 and an oil return passage 22 connected in parallel between the oil storage tank 1 and the atomization system 3 and a second oil passage connected between the atomization system 3 and the combustion chamber 6 The oil delivery passage 23, the end of the second oil delivery passage 23 extending into the combustion chamber 6 is connected with a nozzle (not shown). An oil pump 211 for ...

Embodiment 2

[0030] As another kind of scheme of the present invention, other parts are identical with embodiment 1, and difference is:

[0031] The oil pump 211 and the filter 212 on the first oil delivery channel 21 can exchange the front and rear positions according to the layout requirements of the device, and can also realize the function of delivering bio-oil.

[0032] The number of parallel-connected filters 212 on the first oil delivery passage 21 is two or more.

[0033] Other high combustion value gases can be selected instead of liquefied natural gas to be delivered to the stable combustion chamber 6 through the auxiliary ignition system 5, and the same ignition effect can be achieved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com