Burning method for pulverized solid fuels transferred by dilute phase pneumatic in tunnel kiln and dilute phase pneumatic transferring system

A technology of solid fuel and tunnel kiln, which is applied in the direction of combustion method, combustion equipment, fuel supply, etc., can solve the problem that there is no carbon-containing solid powder fuel directly injected into the tunnel kiln fuel and increase, so as to save fuel cost and enrich resources , the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below, the present invention will be further described in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

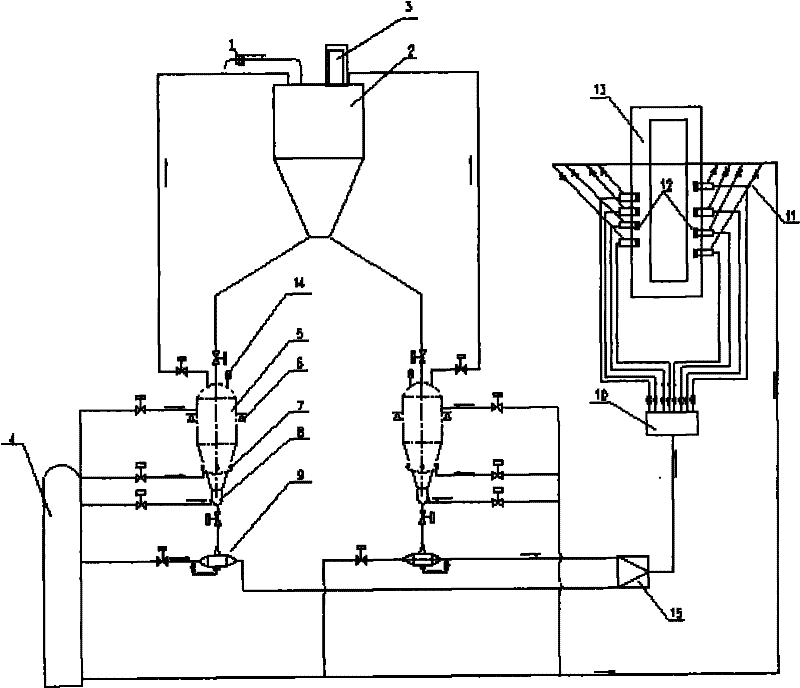

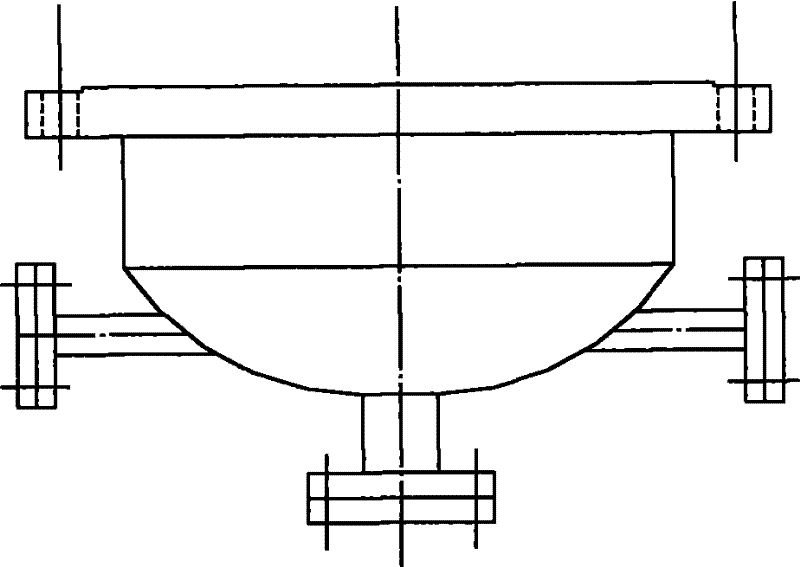

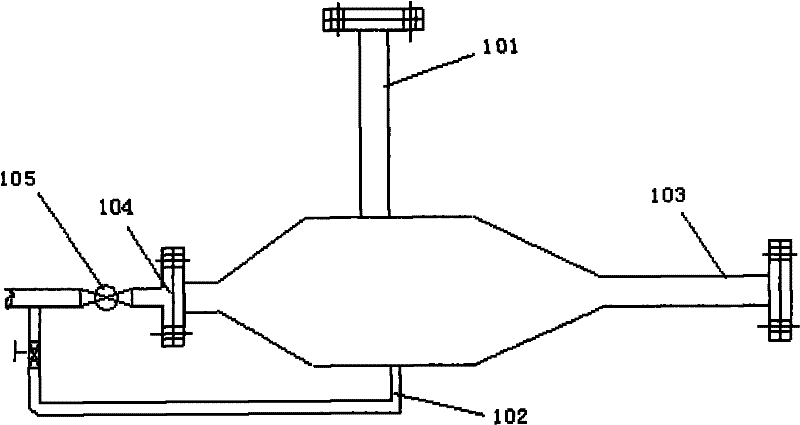

[0032] Such as Figure 1 to Figure 4 As shown, the carbon-containing solid powder fuel such as coal or petroleum coke powder is directly sprayed into the tunnel kiln firing refractory fuel supply system by using the dilute-phase pneumatic conveying method and the three-time fluidized homogeneous technology, and a 1-powder inlet filter is provided. , 2-fuel powder storage bin, 3-dust collector, 4-compressed gas storage tank, 5-powder injection tank, 6-weighing sensor, 7-primary fluidizer, 8-bottom discharge fluidization Conveyor, 9-mixer, 10-equal divider, 11-powder burner gas delivery branch, 12-solid powder burner, 14-pressure transmitter, 15-reversing valve.

[0033] The powder inlet filter 1 is connected to the top of the fuel powder storage bin 2 through the powder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com