Opposed firing boiler with thermal power flexibility regulating function and regulating method thereof

A technology of hedging combustion and adjustment method, which is applied in the direction of combustion method, adjustment of fuel supply, combustion of block fuel and liquid fuel, etc. It can solve the problems of sacrificing boiler efficiency, furnace fire extinguishing and blasting, easy flameout, etc., and achieves the improvement of adjustment Peak flexibility, rapid load response, and the effect of increasing furnace temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

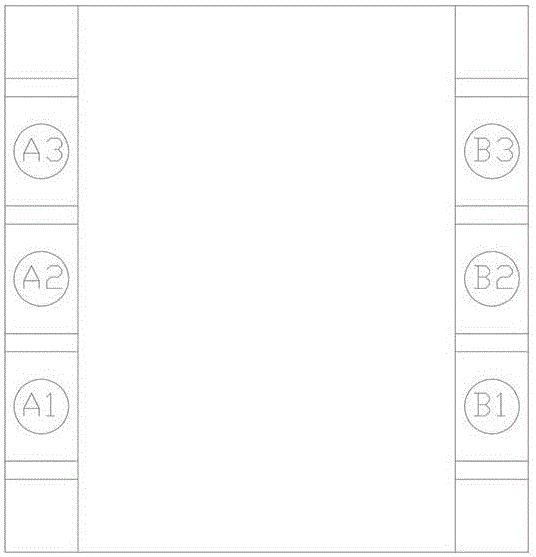

[0060] Embodiment one, combine figure 1 It can be seen that for a counter-fired boiler with a thermal power flexible adjustment function, the burner is divided into an upper burner and a lower burner according to the horizontal elevation of the installation position. It is characterized in that: the upper burner is from the top of the boiler to The burners on the first and second floors are counted from the bottom. In the upper burners, the burners that have burners on the front wall and the back wall of the same layer and are located on the uppermost floor are set as peak-shaving burners; The burner is the burner on the first floor counting from the bottom of the boiler. Any front wall and / or rear wall of the lower burner is a peak-shaving burner, and the peak-shaving burner is an internal combustion burner. The pulverized coal is ignited and burns stably. The other burners are ordinary burners, and the ordinary burners are internal combustion burners or external combustion b...

Embodiment 2

[0087] Embodiment two, such as figure 1As shown, the second embodiment is basically the same as the first embodiment, except that the burners on the lower front wall and the rear wall are all peak-shaving burners. That is, in this embodiment, burners A3, B3, A1, and B1 are peak-shaving burners, and A2, B2 are ordinary burners.

[0088] Use the fault combustion method to carry out deep peak regulation of the boiler, increase the load of the boiler and start and stop the boiler:

[0089] The fault combustion method refers to all the peak-shaving burners A3 and B3 on the front wall and back wall of the upper first floor of the boiler and all the peak-shaving burners A1 and B1 on the front wall and back wall of the lower first floor of the boiler. Common burners A2 and B2 on the front wall and rear wall of the second floor above the boiler are put into operation.

[0090] The specific steps for boiler deep peak regulation through fault combustion are as follows:

[0091] (1) Wh...

Embodiment 3

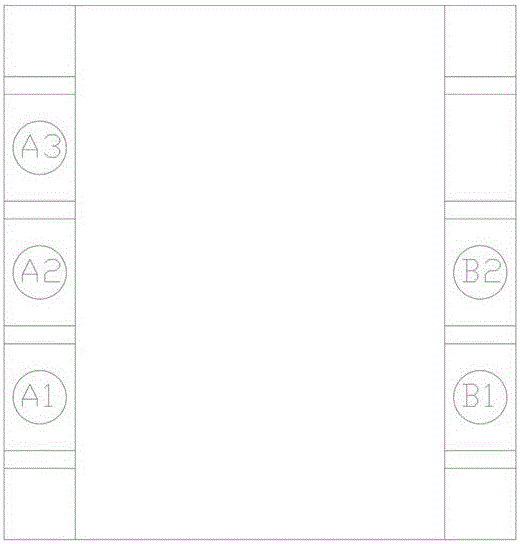

[0104] Embodiment three, combining Figure 4 It can be seen that for a counter-fired boiler with a thermal power flexible adjustment function, the burner is divided into an upper burner and a lower burner according to the horizontal elevation of the installation position. It is characterized in that: the upper burner is from the top of the boiler to The burners on the first and second floors are counted from the bottom, burner A3 is installed on the front wall of the upper first floor, burner A2 is installed on the front wall of the upper second floor, and burner B2 is installed on the rear wall, so A2 and B2 shall be equipped with peak-shaving burners, and A3 shall be an ordinary burner. Any front wall and / or rear wall of the lower burner is a peak-shaving burner, and the peak-shaving burner is an internal combustion burner, which can ignite pulverized coal inside and burn stably, and the other burners are ordinary combustion The common burner is an internal combustion burne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com