Thermal Power Unit Working Fluid Split Cycle Peak Shaving System

A technology of thermal power units and working medium, applied in mechanical equipment, steam engine devices, engine components, etc., can solve problems such as low operating efficiency and difficulty in reducing emissions to meet standards, and achieve deep peak-shaving capabilities, huge economic and social benefits, The effect of improving peak shaving ability and operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

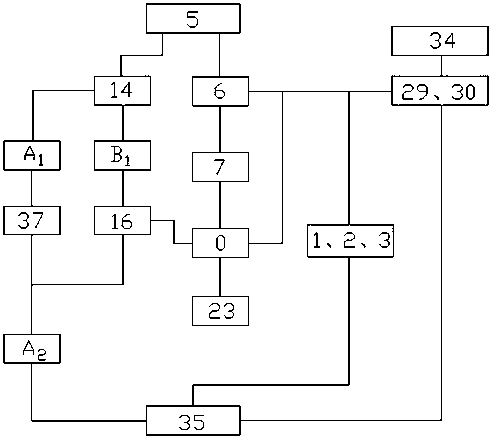

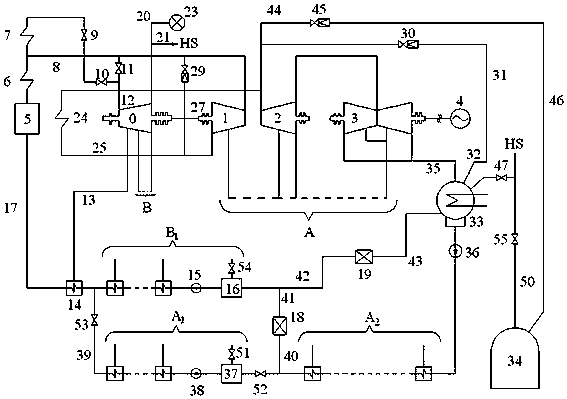

[0020] Such as figure 1 The structural diagram of the thermal power unit’s working fluid split cycle peak regulation system is shown. The system includes the thermal power unit’s heat source boiler 5 and its superheaters 6 and 7, No. 0 steam turbine 0 (or called No. 0 cylinder) and its conventional steam turbines 1, 2 and 3 (or high-pressure cylinder 1, medium-pressure cylinder 2, low-pressure cylinder 3), unit cold source condenser 35, high-pressure heater group A1 and B1, low-pressure heater group A2, No. 0 deaerator 16, No. 0 high-pressure heating device 14, deaerator 37, high pressure and low pressure bypass 29, 30, heat user 23, and heat storage device 34, etc.

[0021] The cold source working fluid from the cold source condenser 35 of the unit passes through the low-pressure heater group A2 and then diverts, and one way of working fluid passes through the deaerator 37, the high-pressure heater group A1, enters the No. 0 high-pressure heater 14, and is sequentially sent t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com