Phase-change energy storage and heating device as well as energy storage and heating method

A phase change heat storage and phase change energy storage technology, applied in central heating, can solve the problems of decreased utilization rate of waste heat, low efficiency of waste heat recovery and utilization system, and high requirements for waste heat capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0137] According to a first embodiment of the present invention, a variable energy storage device is provided;

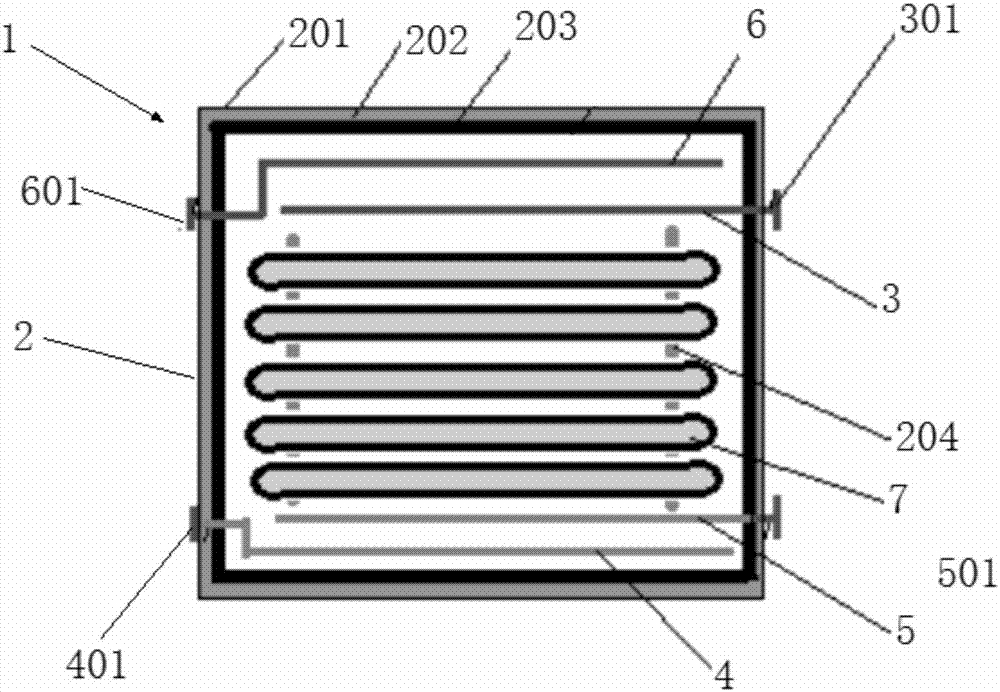

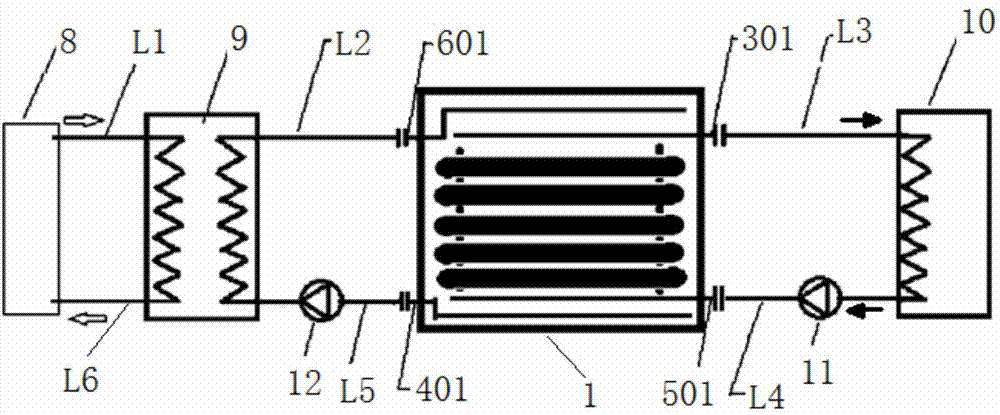

[0138] A phase change energy storage device 1, the device comprising:

[0139] 1) Energy storage device box body 2,

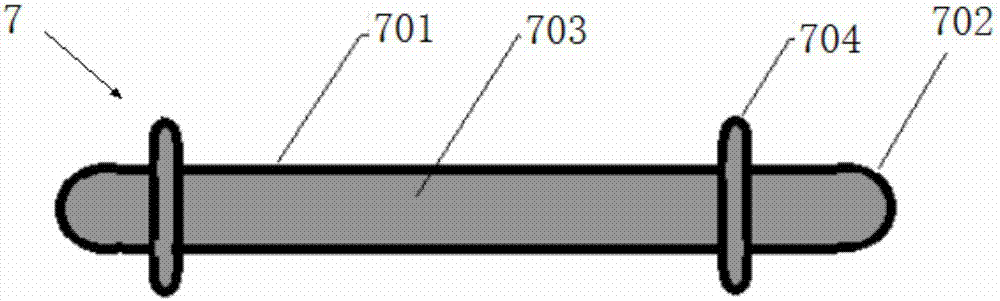

[0140] 2) Central heat storage component, which includes: heat supply outlet water distributor 3, heat storage return water distributor 4, heat supply return water distributor 5, heat storage outlet water distributor 6, phase change heat storage element 7 The heat supply and return water distributor 3 and the heat storage and return water distributor 4 are arranged on the upper part of the box body 2, and the heat supply and return water distributor 5 and the heat storage and outlet water distributor 6 are arranged on the lower part of the box body 2. The change heat storage element 7 is arranged in the middle of the box body 2, and a plurality of phase change heat storage elements 7 are arranged in an array or a laminated body,

[0141] Wherein, t...

Embodiment 1

[0219] Phase change heat storage materials include the following components:

[0220]

[0221]

[0222] Preparation process: heat and melt the component a), continue to heat up to 90°C, then add other components, stir and mix to form a phase-change heat storage material in the form of a mixture. The density (ρ) of the mixture is 2520kg / m 3 . Phase transition temperature range: 82-95°C. Latent heat of phase change (L) = 322-333kJ / kg. Specific heat capacity (Cp) = 5.52 kJ / kg·°C. The mixture was heated from 50°C to 90°C with a volume expansion rate of 0.05%.

[0223] Filling: Let the mixture cool to about 40°C, fill it into the tube-shaped or rod-shaped heat storage element (7), and weld the sealed port.

Embodiment 2

[0229] A phase change energy storage device 1, the device comprising:

[0230] 1) Energy storage device box body 2,

[0231] 2) Central heat storage component, which includes: heat supply outlet water distributor 3, heat storage return water distributor 4, heat supply return water distributor 5, heat storage outlet water distributor 6, phase change heat storage element 7 The heat supply and return water distributor 3 and the heat storage and return water distributor 4 are arranged on the upper part of the box body 2, and the heat supply and return water distributor 5 and the heat storage and outlet water distributor 6 are arranged on the lower part of the box body 2. The change heat storage element 7 is arranged in the middle of the box body 2, and 20 phase change heat storage elements 7 are arranged in an array or a laminated body,

[0232] Wherein, the outlet 301 of the heat supply outlet water distributor 3 is located at the upper part of the outer side of the energy stora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com