Synchronous inner-meshing double-rotor structure as well as rotor compressor and rotor engine based on synchronous inner-meshing double-rotor structure

A dual-rotor engine and rotor compressor technology, applied in the field of machinery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

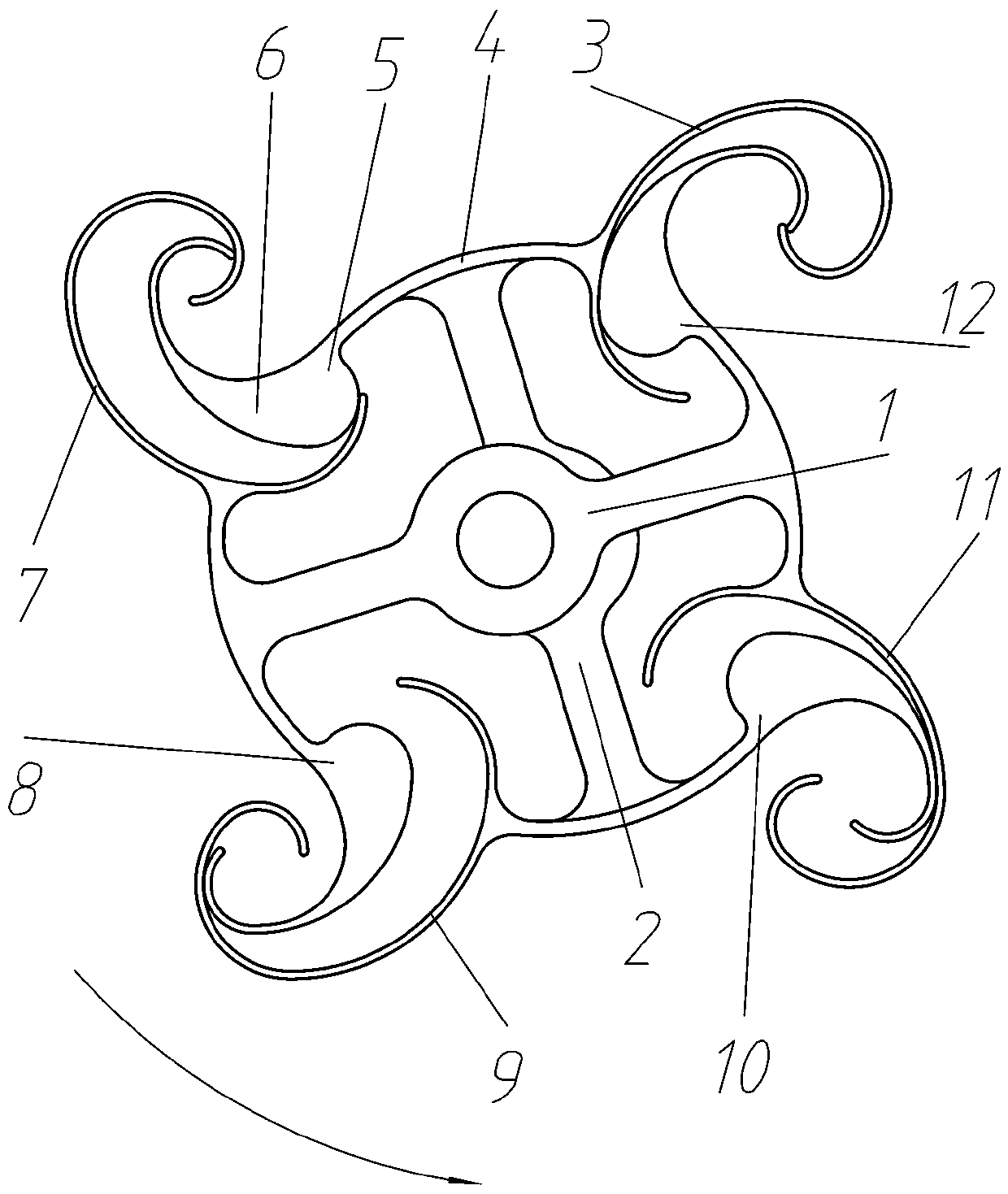

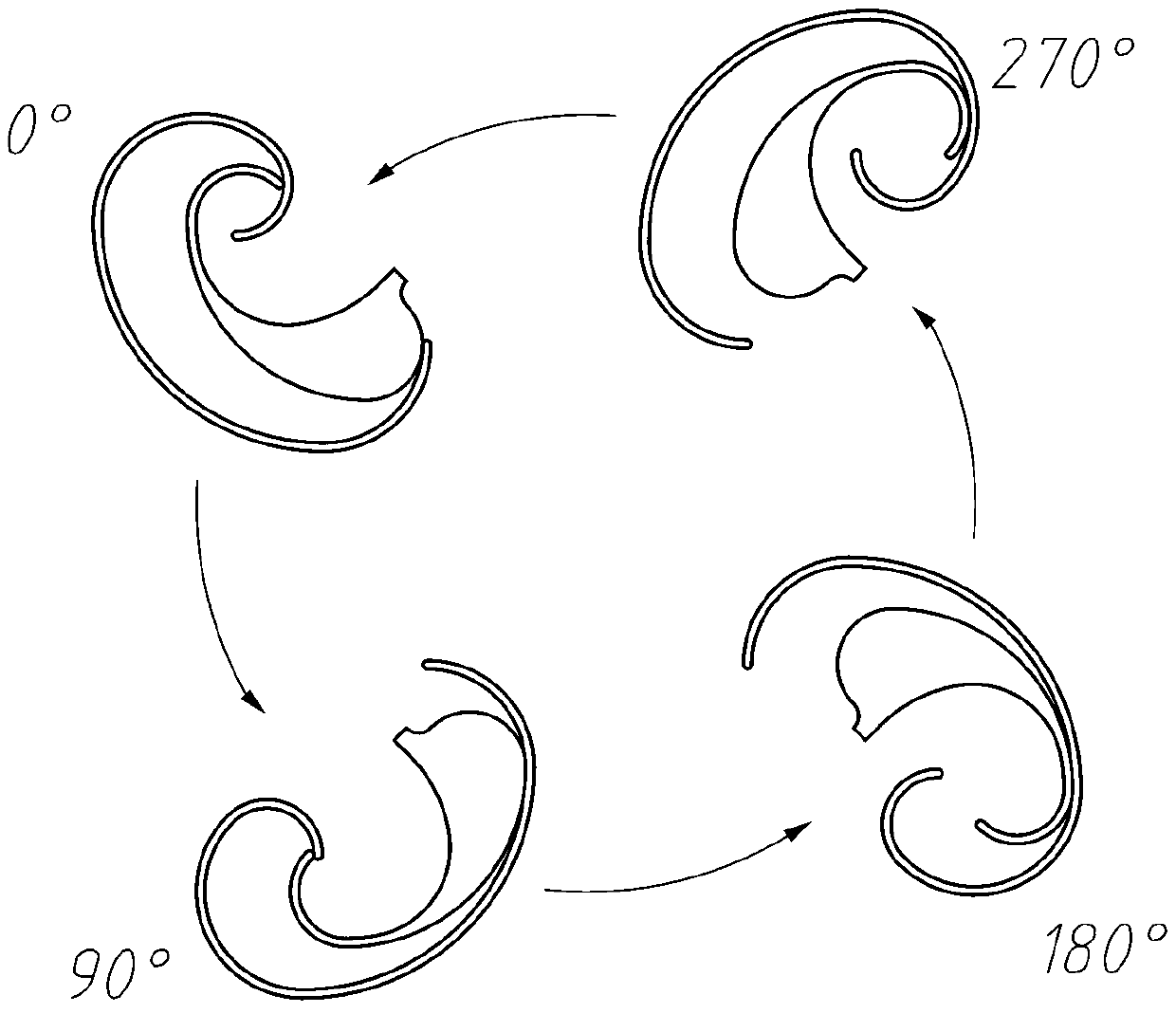

[0044] figure 1 It is a schematic diagram of the synchronous internal meshing double rotor structure of the preferred embodiment 1 of the present invention, as shown in figure 1 As shown, this embodiment provides a synchronous internal meshing double-rotor structure for a rotary compressor and a rotary engine. It includes an active rotor 1 and a passive rotor 2. The axes of the active rotor 1 and the passive rotor 2 are parallel and the axis distance d>0. The active rotor 1 and the passive rotor 2 rotate synchronously counterclockwise around their respective rotor axes.

[0045] figure 1 The synchronous internal meshing double rotor shown has a curved C-shaped plate 3, a T-shaped plate 5 composed of a separator 4 connected to a core plate 6 at one end, and the other end of the separator 4 of the T-shaped plate 5 is connected to a C-shaped On the outer wall of the plate 3, the T-shaped plate 5 and the C-shaped plate 3 form a basic structural unit, hereinafter referred to as a...

Embodiment 2

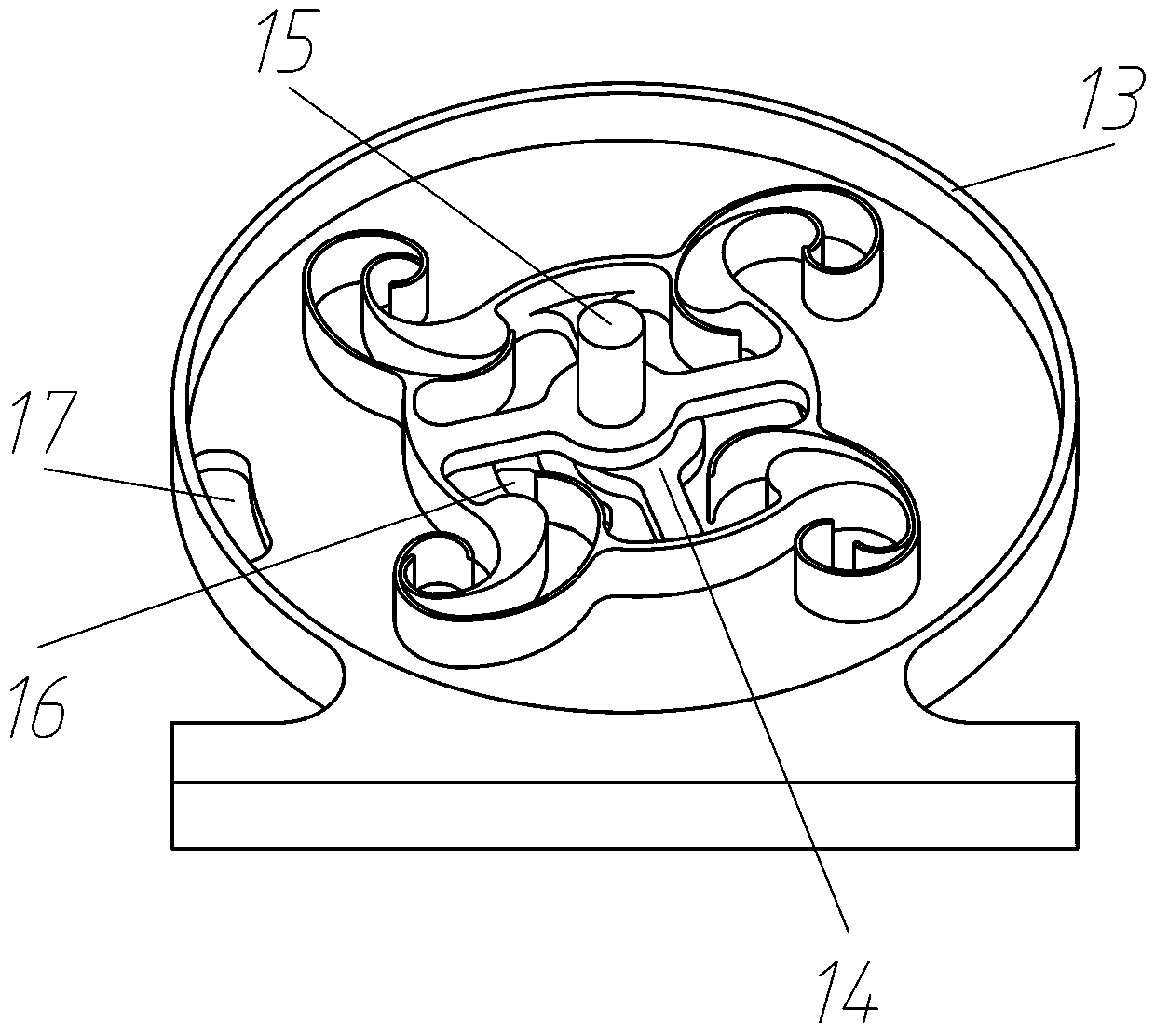

[0053] image 3 It is a schematic diagram of the internal structure of the rotary compressor of the second preferred embodiment of the present invention, such as image 3 As shown, this embodiment provides a rotor compressor based on a synchronous internal meshing double rotor structure, including a cylindrical casing 13 and a synchronous meshing double rotor. In the rotary compressor, the driven rotor is mounted on the casing through a bearing On the fixed shaft 14 on the inner and lower bottom surface, the active rotor shaft 15 is installed on the upper bottom surface of the casing through bearings and protrudes outside the casing. The cylindrical casing is in the center and the periphery of the TC unit surrounding the group separation A gas inlet 16 and a gas outlet 17 are respectively provided.

[0054] image 3 In the rotor compressor shown, rotating the driving rotor shaft 15 counterclockwise can suck gas from the inlet 16 and discharge the compressed gas from the outl...

Embodiment 3

[0056] Figure 4 It is a schematic diagram of the internal structure of the eccentric rotor compressor of the third preferred embodiment of the present invention, as Figure 4 As shown, this embodiment provides an improved eccentric rotor pump based on a synchronous meshing double rotor structure, including a cylindrical casing 18, a stator 19 and an eccentric rotor 20, and the stator 19 is equivalent to the synchronous meshing double rotor structure The TC unit of the active rotor is fixed between the two bottom surfaces in the casing, the axis of the active rotor is the axis of the stator, and the eccentric rotor 20 is equivalent to installing the passive rotor of the synchronous internal meshing double rotor on the eccentric shaft 21 through bearings, The eccentric distance of the eccentric shaft 21 is equal to the synchronous inner meshing double rotor wheelbase d, the axis of the rotation axis 22 of the eccentric rotor 20 is in line with the axis of the stator 19, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com