High-stability coating for underwater wet welding rod

A high-stability, wet-process technology, used in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problem of lack of stable combustion underwater wet welding electrodes, etc., and achieve good underwater welding process performance, The effect of good re-strike performance and beautiful weld formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1, the solid component is made of the following raw materials in mass percentage: 55% rutile, 12% fluorite, 6% marble, 5% ferromanganese, 10% nickel powder, 10% cryolite, 2% cesium nitrate ;

[0020] The effect is as follows:

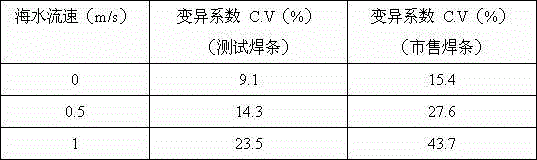

[0021]

Embodiment 2

[0022] Example 2, the solid component is made of the following raw materials in mass percentage: 53% rutile, 11% fluorite, 8% marble, 5% ferromanganese, 10% nickel powder, 11% cryolite, 2% cesium nitrate ;

[0023] The effect is as follows:

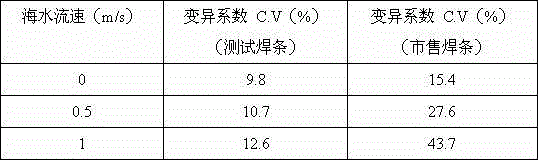

[0024]

Embodiment 3

[0025] Example 3, the solid component is made of the following raw materials in mass percentage: 52% rutile, 15% fluorite, 5% marble, 4% ferromanganese, 13% nickel powder, 10% cryolite, 1% cesium nitrate ;

[0026] The effect is as follows:

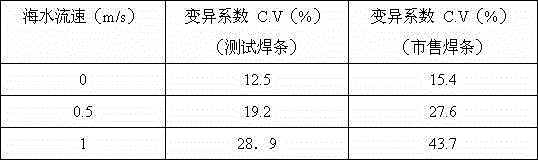

[0027]

[0028] The main effect of each component in the drug skin of the present invention is as follows:

[0029] Rutile: The main function is to make slag, which can adjust the melting point, viscosity, surface tension and fluidity of slag, improve weld formation and slag removal, and reduce spatter. Titanium element is an element with low ionization potential. The presence of a large amount of titanium element helps to reduce the arc voltage and improve arc stability. When the artificial rutile content is too high, a large number of fine and many splashes will appear, and the slag will become too active, which will easily lead to poor slag coverage; when the rutile content is too low, the fluidity of the slag will also become po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com