Liquid fuel vaporization combustion device

A combustion device and technology of liquid fuel, applied in the directions of liquid heating fuel, combustion method, heating fuel, etc., can solve the problems of reduced combustion efficiency, incomplete vaporization, increased air pressure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings.

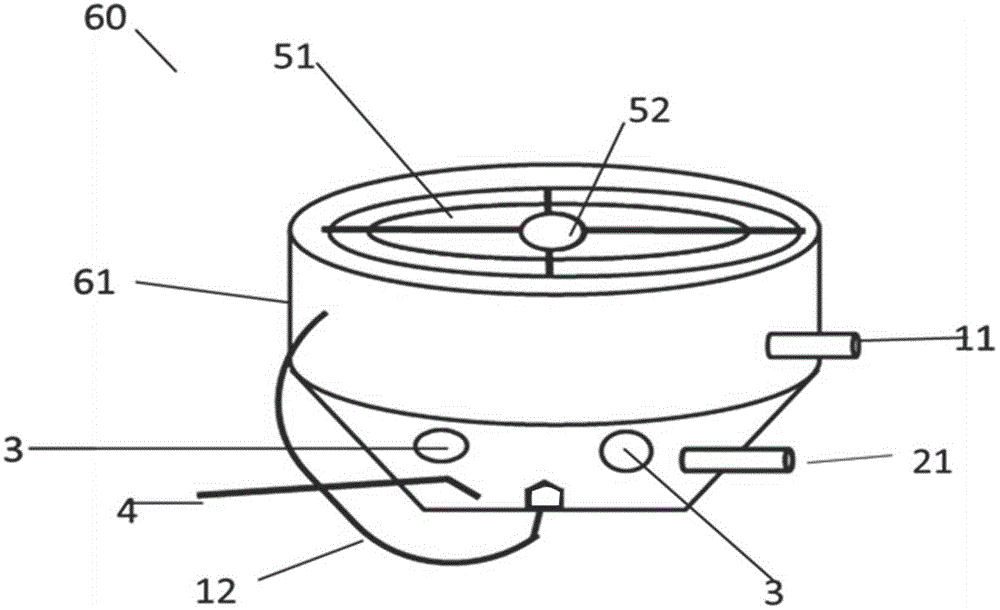

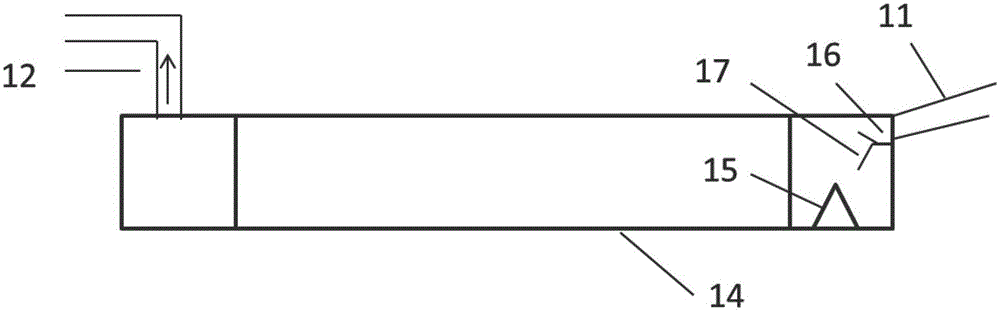

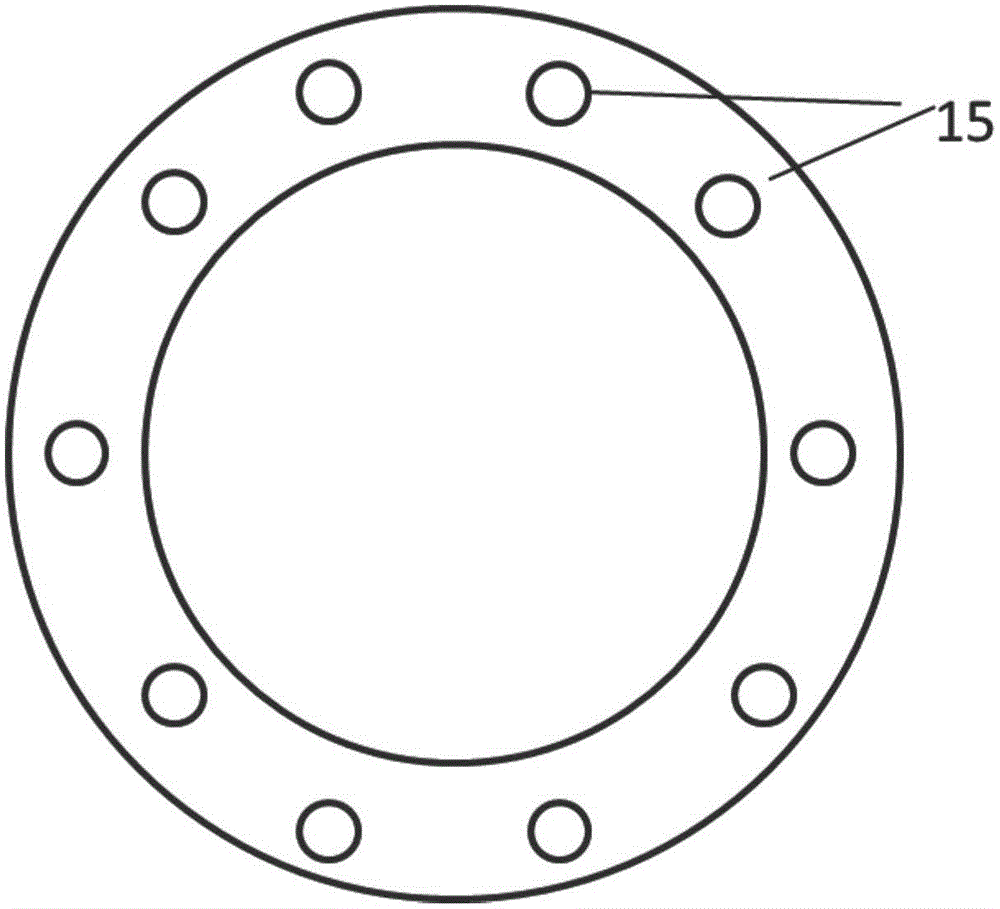

[0020] Such as figure 1 , figure 2 , image 3 , Figure 4 as well as Figure 5 As shown, the burner 60 includes a burner housing 61, a vaporization device 1, a vaporization device inlet pipe 11 connected to the vaporization device 1 and a vaporization device outlet pipe 12; a preheating device 2 and a preheating device 2 Connected preheating device inlet pipe 21; multiple air inlet holes 3, connecting the inner cavity of the burning appliance 60 with the atmosphere; one ignition device 4, the ignition point 41 is facing the liquid outlet of the preheating device inlet pipe 21; one vaporization The nozzle 13 is connected to the gas outlet pipe 12 and is located inside the burner 60; the gasification device 1 is ring-shaped, and its bottom wall 14 is concaved to form 2-18 conical or frustum-shaped bottom wall protrusions 15; the upper half of the side wall of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com