Dual-output atomizer

A technology of atomizer and outlet end, which is applied in the field of dual output atomizers, and can solve the problems of not being able to provide energy supply and not being able to proceed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

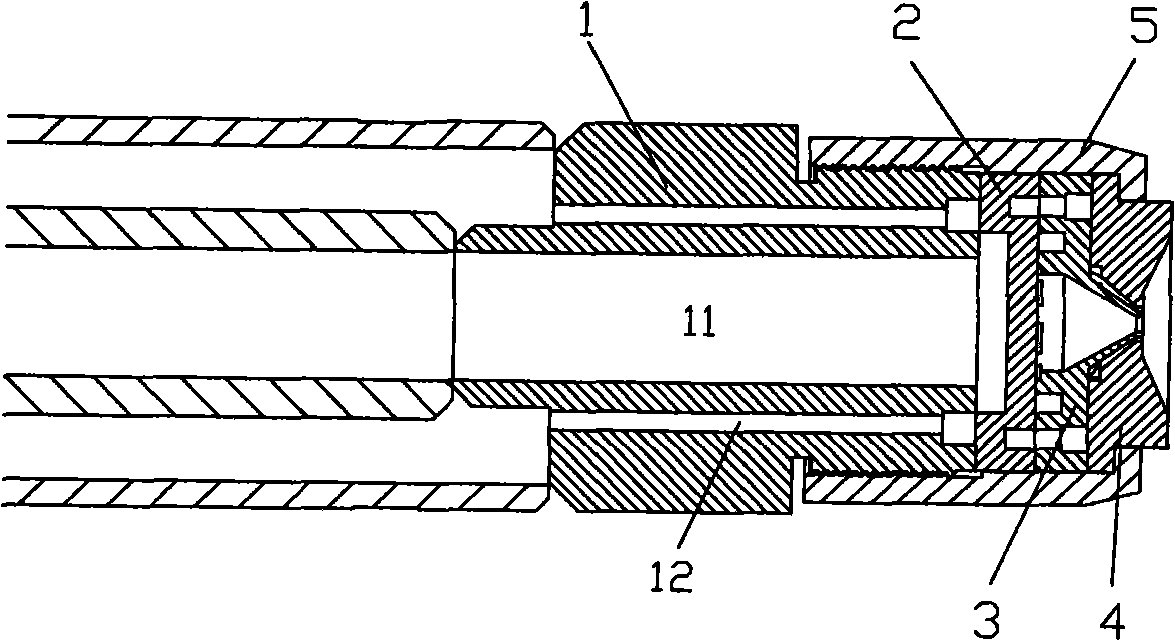

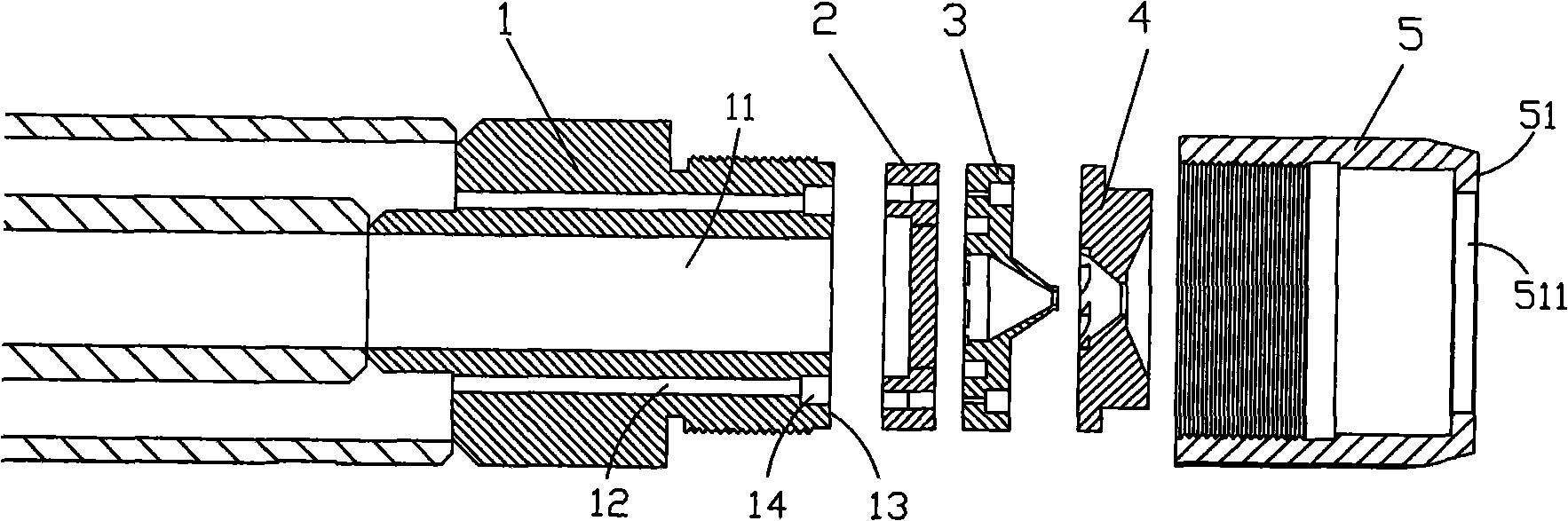

[0029] See Figure 1 ~ Figure 5c , The dual-output atomizer of the present invention includes a body 1, a shunt plate 2, an atomizer A3, an atomizer B4, and an end cover 5;

[0030] The body 1 is a cylinder with a channel A11 in the center and a channel B12 on the outside of the center channel A11; the end face 13 at the outlet end of the body channel B12 is provided with an annular groove 14 and the outlet end of the channel B12 is located in the ring Bottom of groove 14.

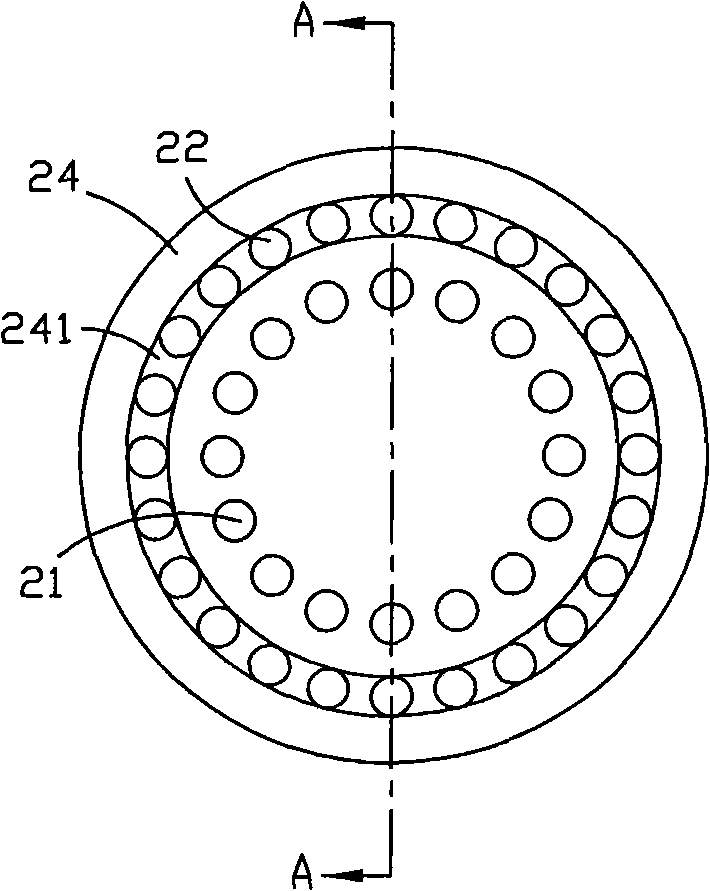

[0031] The splitter plate 2, one side of which is against the body 1, corresponds to the central channel A11 and the channel B12 of the body. The splitter plate 2 is provided with two inner and outer through holes along the circumference to form a first oil inlet 21 and a second oil inlet 22 ;

[0032] The atomizer A3 has one side against the flow divider 2, the side surface 31 is provided with an annular oil equalizing groove 311, the center of the annular oil equalizing groove 311 is provided with a swirling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com