Heat storage type liquefied natural gas gasifier

A technology of liquefied natural gas and gasification equipment, which is applied to heat storage heaters, fluid heaters, lighting and heating equipment, etc., can solve problems such as dependence on electricity, limited working hours, and inability to use natural gas, so as to prevent environmental pollution and overcome Effects that cost more

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

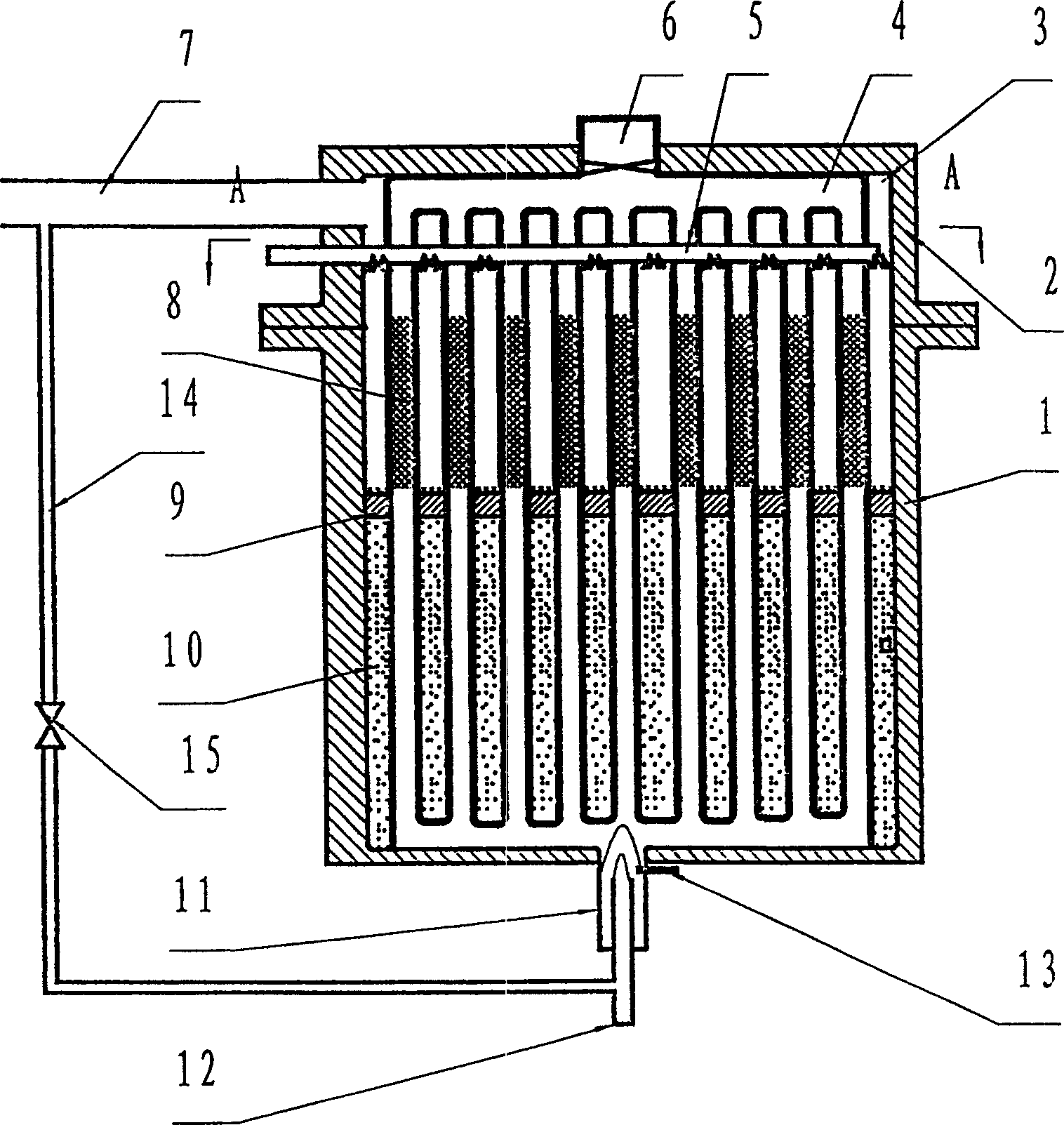

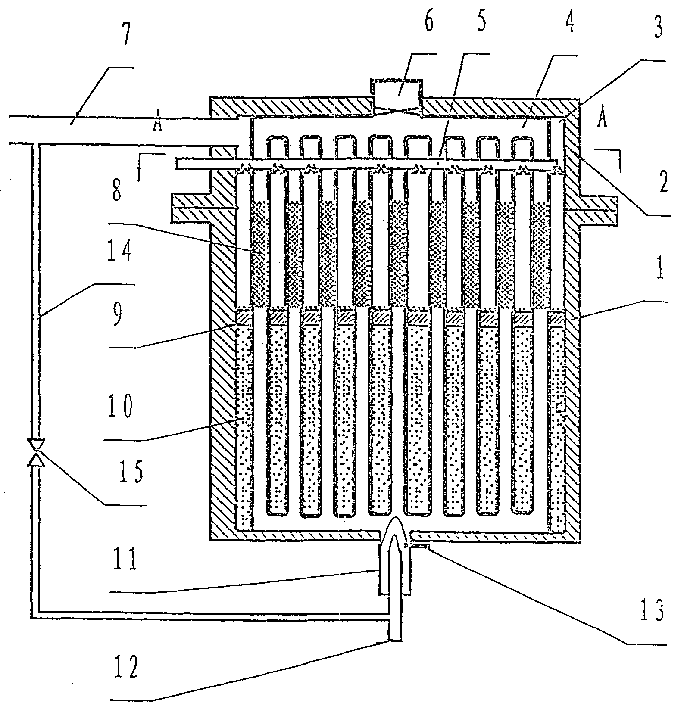

[0017] A thermal storage type liquefied natural gas gasification device is manufactured. Such as figure 1 As shown, the device includes: a heat exchanger 4; it is characterized in that it also includes a heat insulating shell 1, a heat insulating top cover 2, a heat conducting partition 9, a spray pipe 5, a natural gas collecting pipe 7, a heat storage medium 10, a heat exchange Device 4, natural gas steam inlet pipe 12, electronic igniter 13, bypass pipe 14, bypass valve 15; wherein, the heat conduction partition 9 and the heat insulation shell 1 are fixedly connected, and the heat exchanger 4 is fixed in the heat conduction partition 9, The upper shell side of the heat exchanger 4 is the liquefied natural gas gasification chamber, the lower shell side of the heat exchanger 4 is filled with heat storage medium, the natural gas steam inlet pipe 12 is coaxially fixed inside the inlet pipe 11 of the heat exchanger, and the electronic igniter 13 It is fixed in the inlet pipe 11 ...

Embodiment 2

[0022] Utilize the heat storage type liquefied natural gas gasification device gasification natural gas of embodiment 1, concrete steps are as follows:

[0023] (1) The natural gas produced by the evaporation of the liquefied natural gas storage tank is passed into the heat exchanger through the inlet pipe 11 of the heat exchanger, and the electronic igniter 13 is ignited and burned, and the heat of combustion is transferred to the shell side through the lower part of the heat exchanger with excellent thermal conductivity The heat storage medium paraffin carries out phase change heat storage, and the exhaust gas after combustion is discharged through the outlet pipe 6 of the heat exchanger;

[0024] (2) The liquefied natural gas is sprayed onto the surface of the heat exchanger 4 through the spray pipe 5, and the cold energy is transferred to the wall surface of the heat exchanger 4;

[0025] (3) The heat exchanger 4 continuously transfers the heat of the paraffin 10 to the na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com