Fuel oil atomizing device

A technology of fuel atomization and fuel oil, applied in the direction of combustion chamber, combustion method, combustion type, etc., can solve the problems of unable to meet the requirements of stable and efficient combustion of the combustion chamber, short range of oil mist, high axial jet velocity, etc., to achieve increased The effect of centrifugal atomization, increasing the average area, and ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

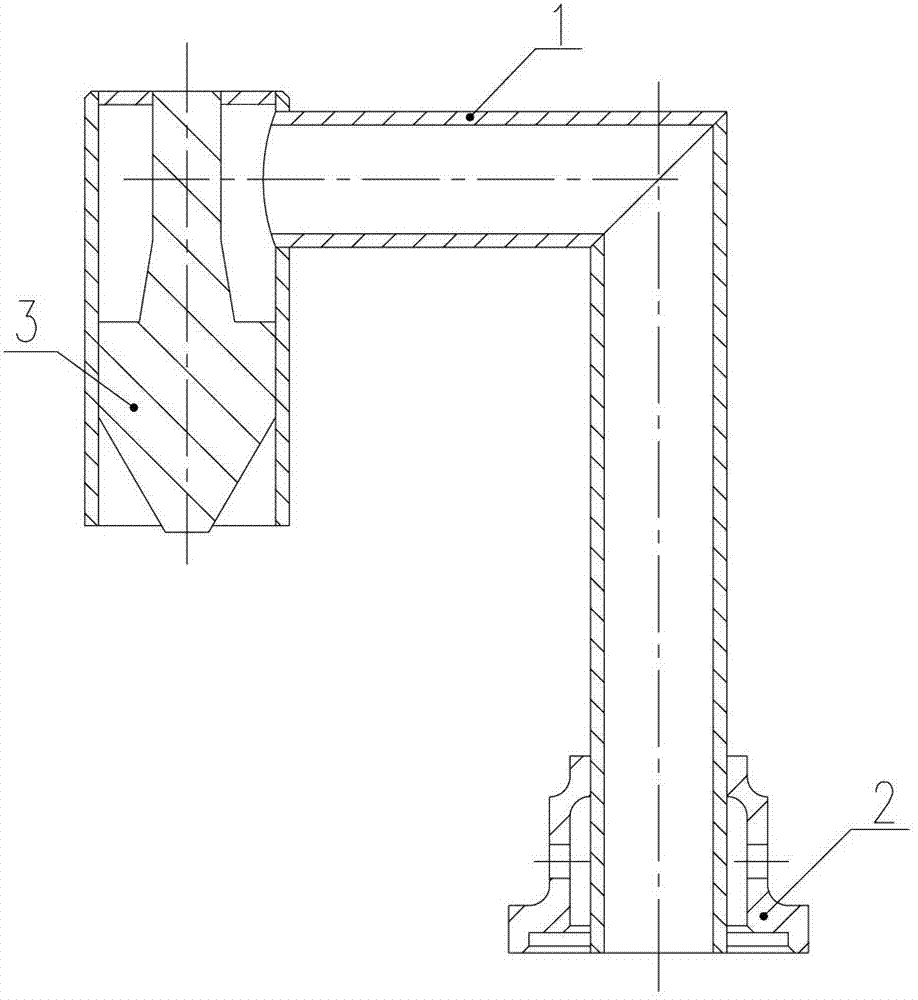

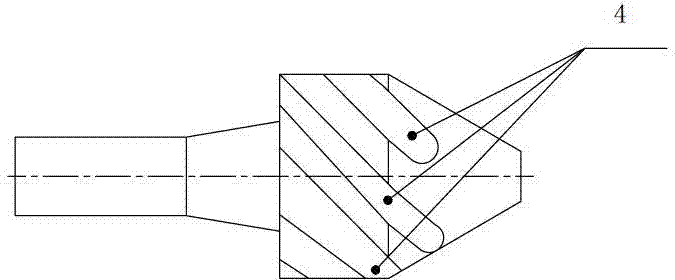

[0009] As shown in the figure, the fuel atomization device includes an evaporating tube 1, an air cup 2 and an oil swirler 3. The evaporating tube 1 is a Γ-shaped three-section tube at 90° to each other. At the fuel outlet of the evaporating tube 1 An oil spinner 3 is provided inside the oil spinner 3, and the outer surface of the oil spinner 3 is provided with 4 to 6 spiral grooves 4, and an air cup 2 is installed outside the evaporation pipe 1 at the fuel inlet, and the air cup 2 The mouth of the cup is flush with the fuel inlet of the evaporating tube 1, and an air outlet is provided on the side wall of the air cup 2. The number of air outlets provided on the side wall of the air cup is 6, and the number of the spiral grooves is preferably 5. The installation method of the air cup and the evaporation tube is welding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com