Patents

Literature

38results about How to "Efficient atomization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

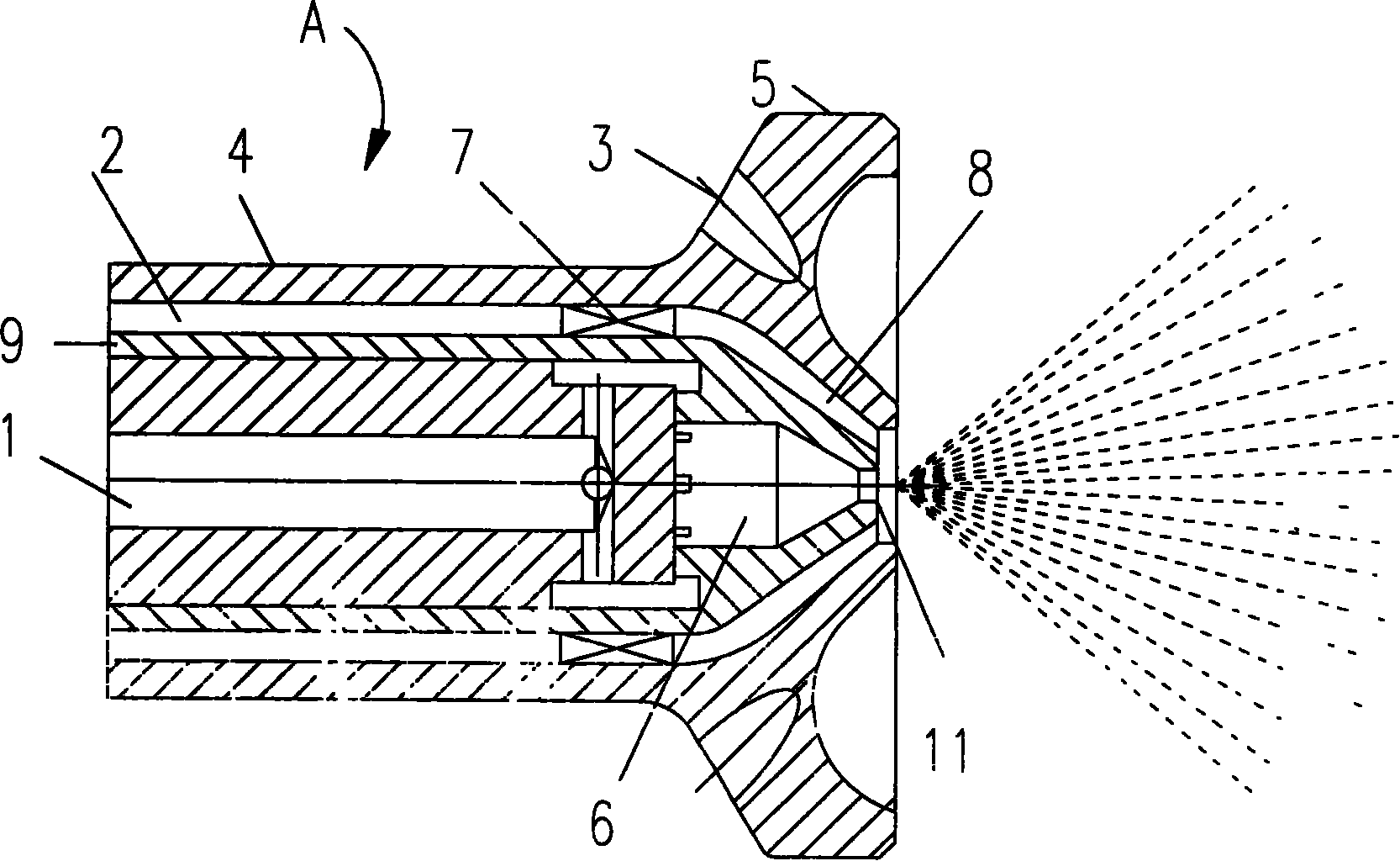

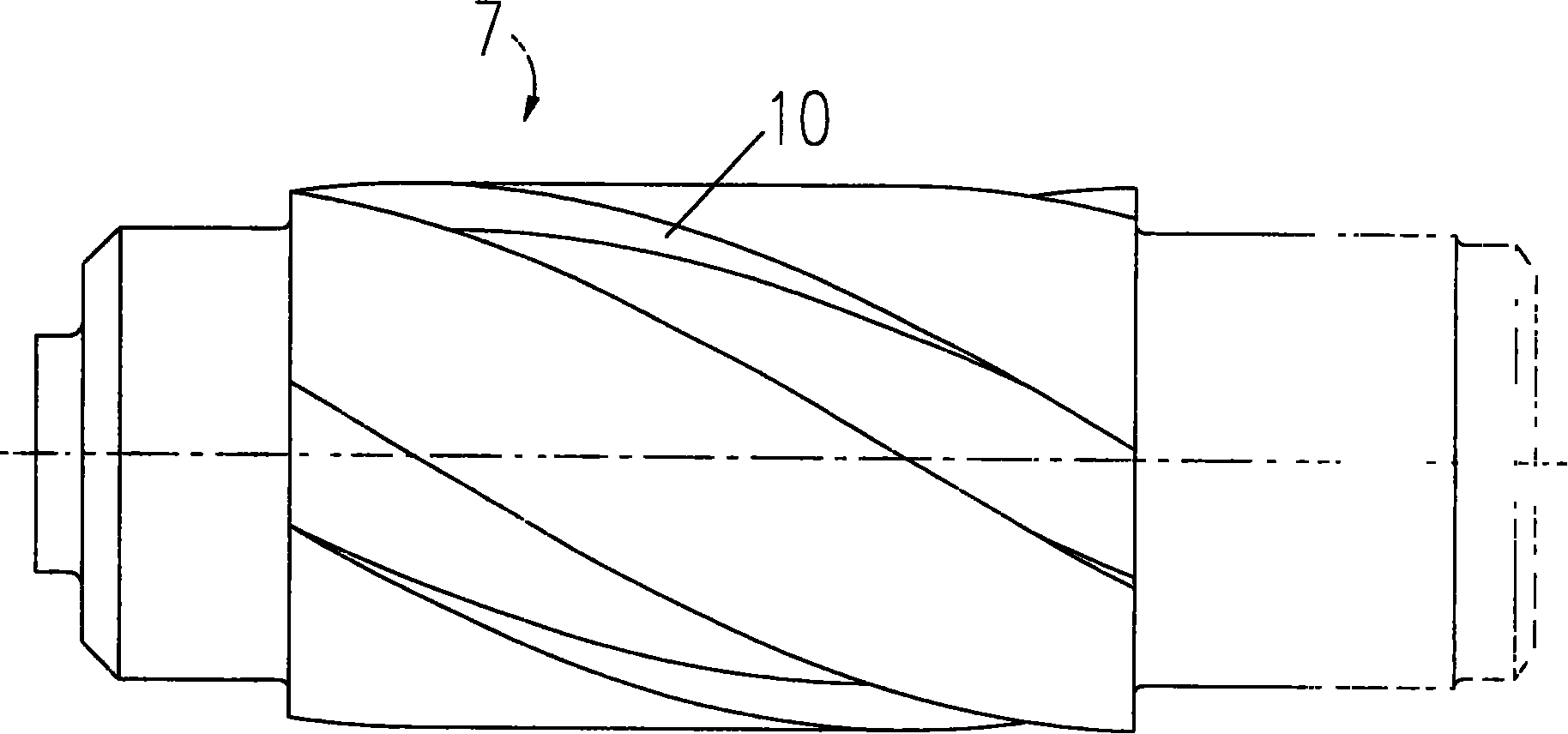

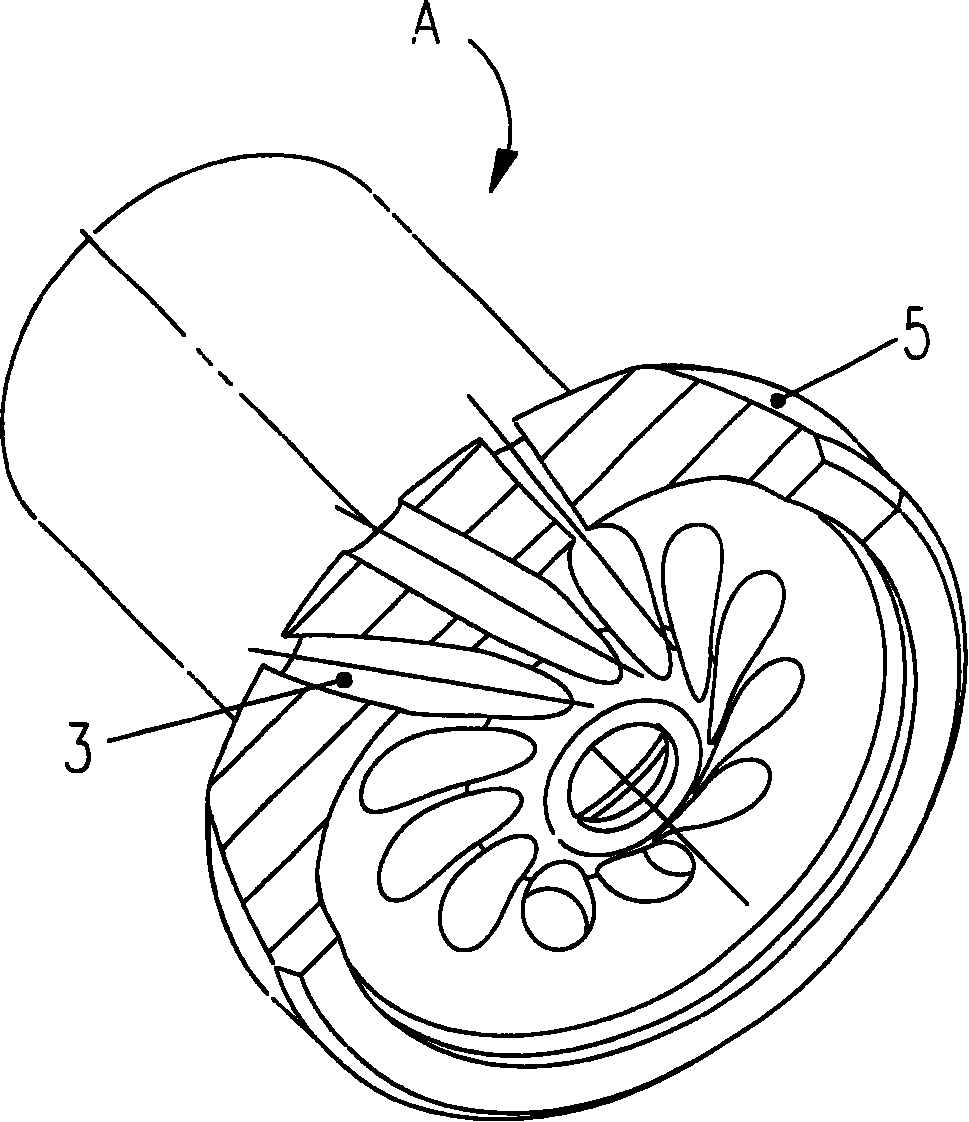

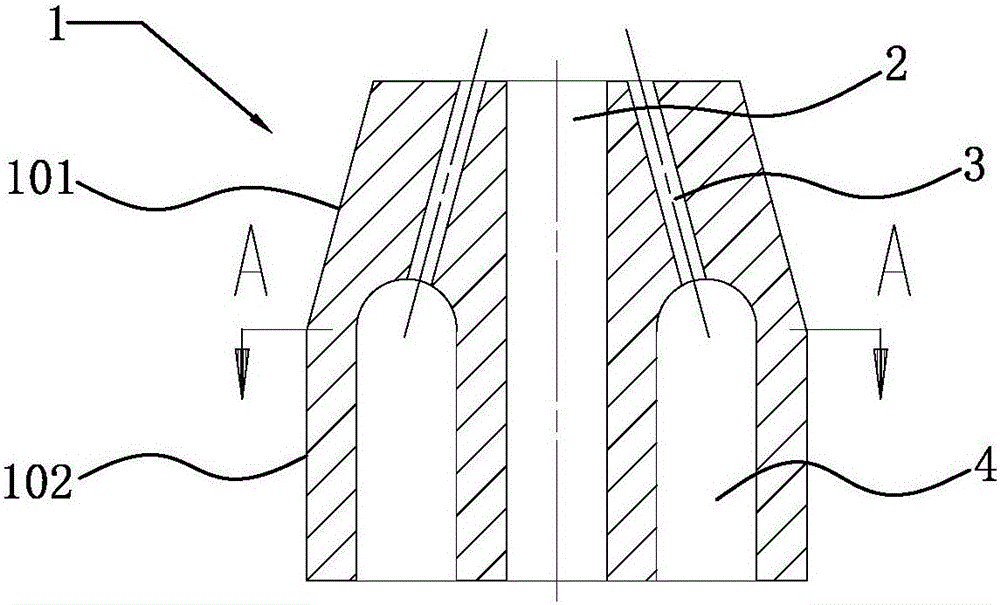

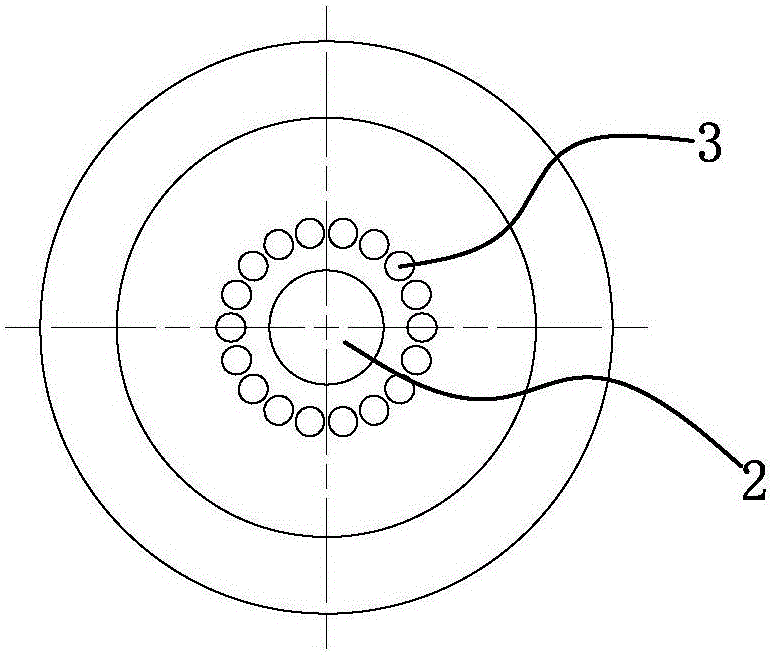

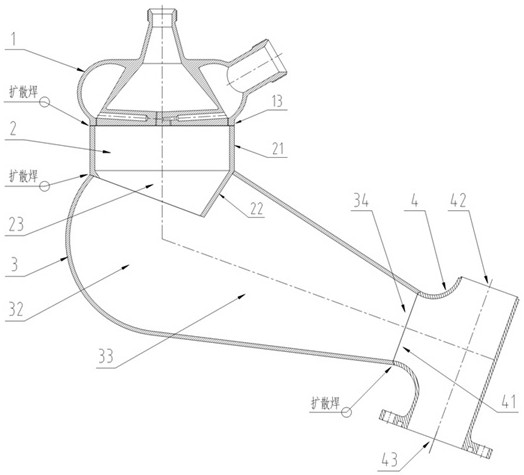

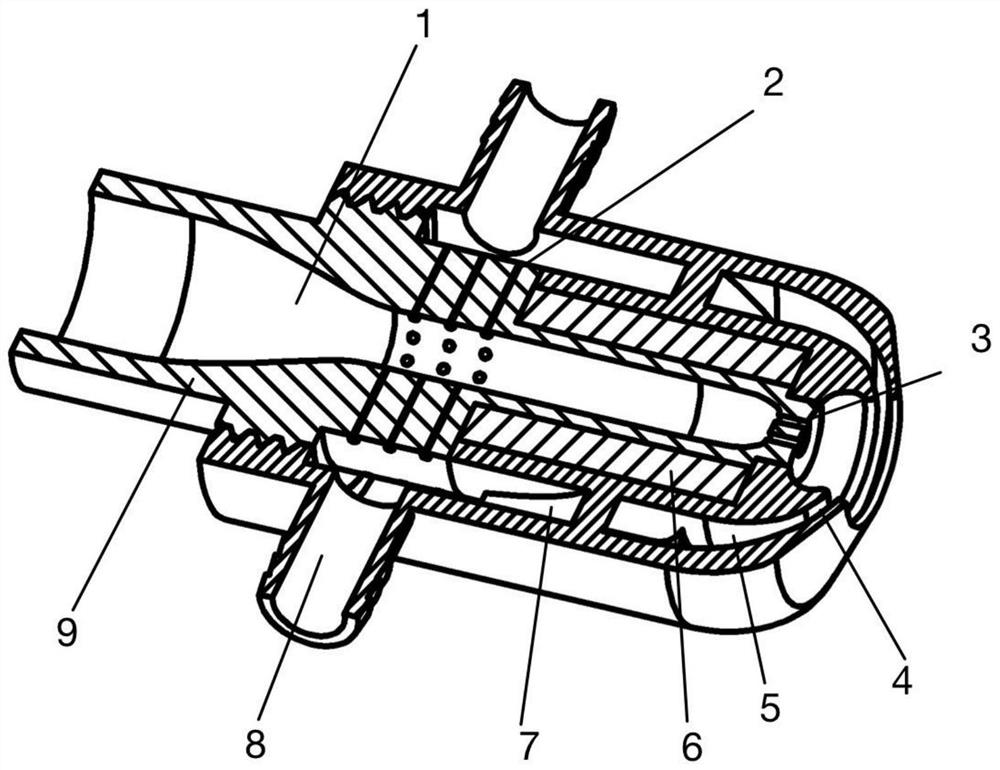

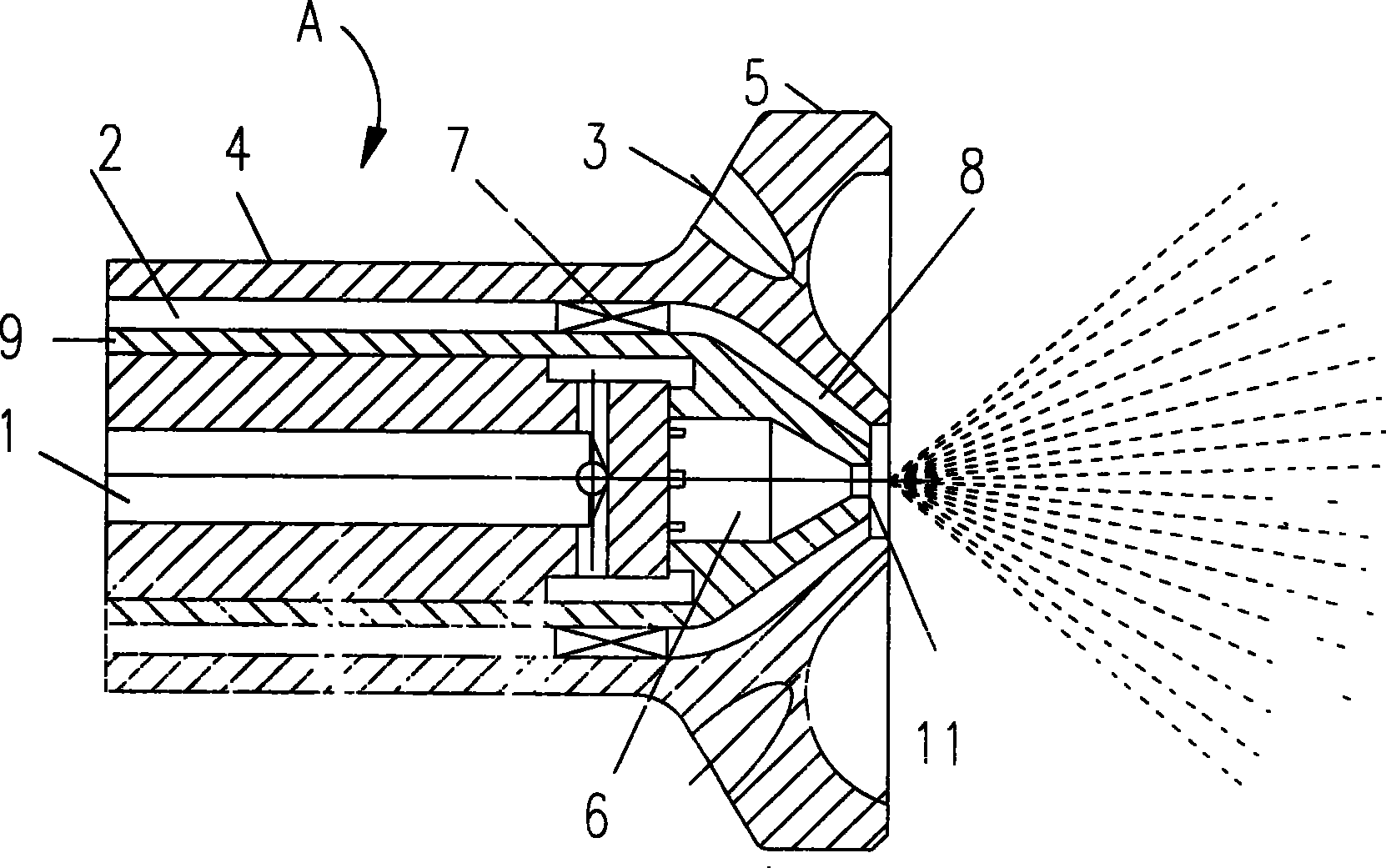

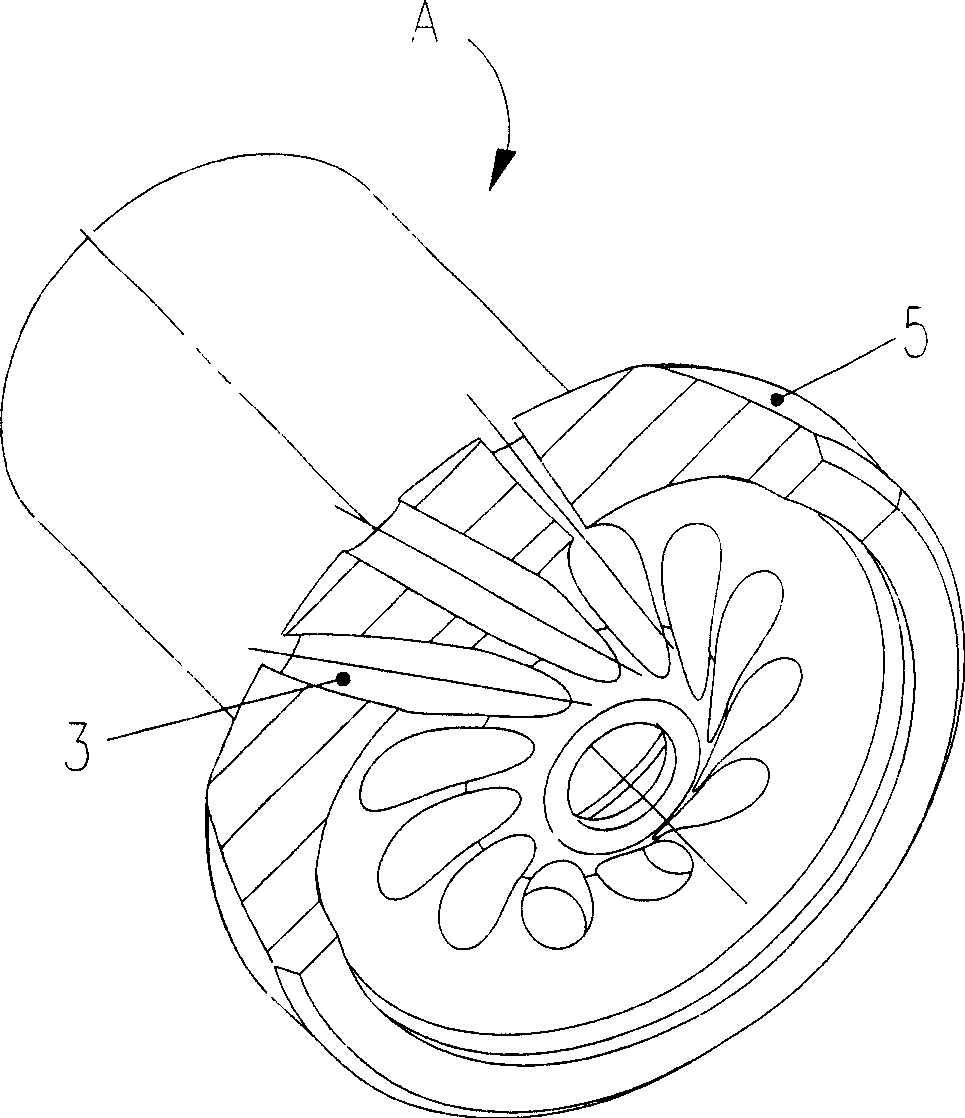

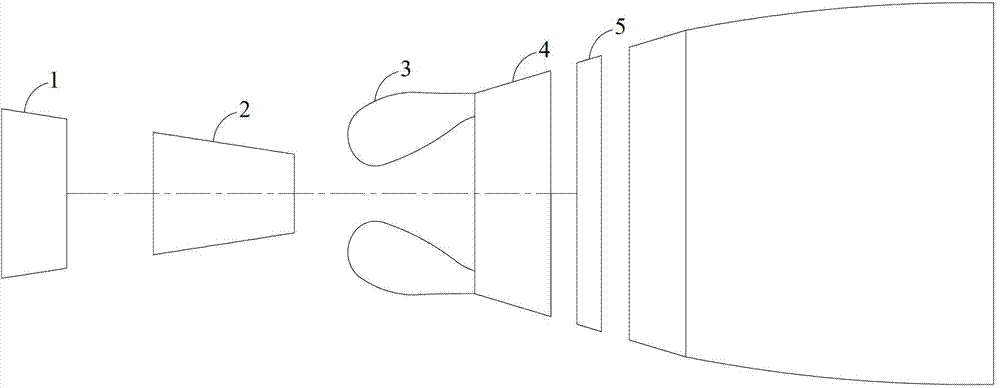

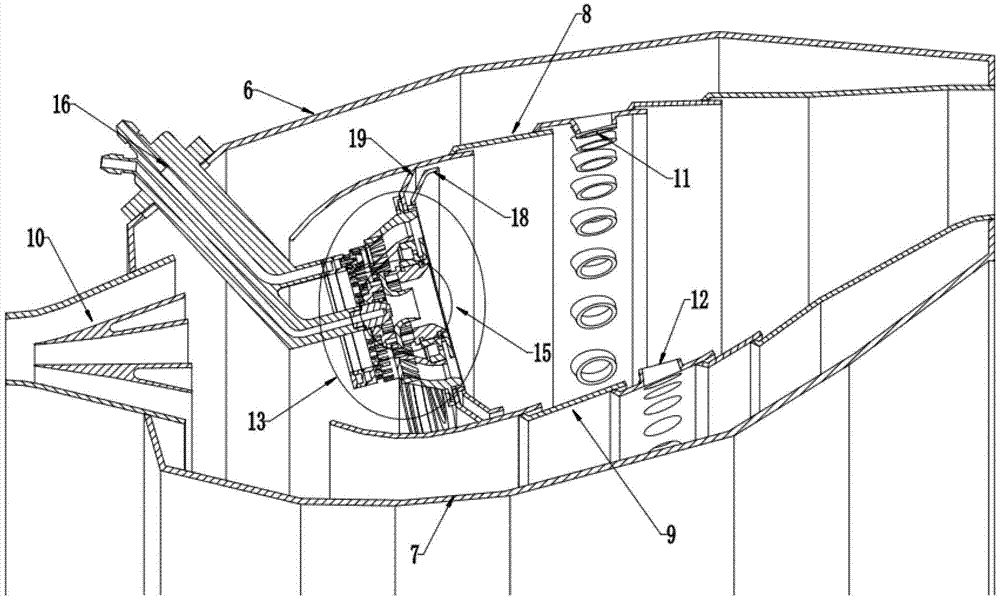

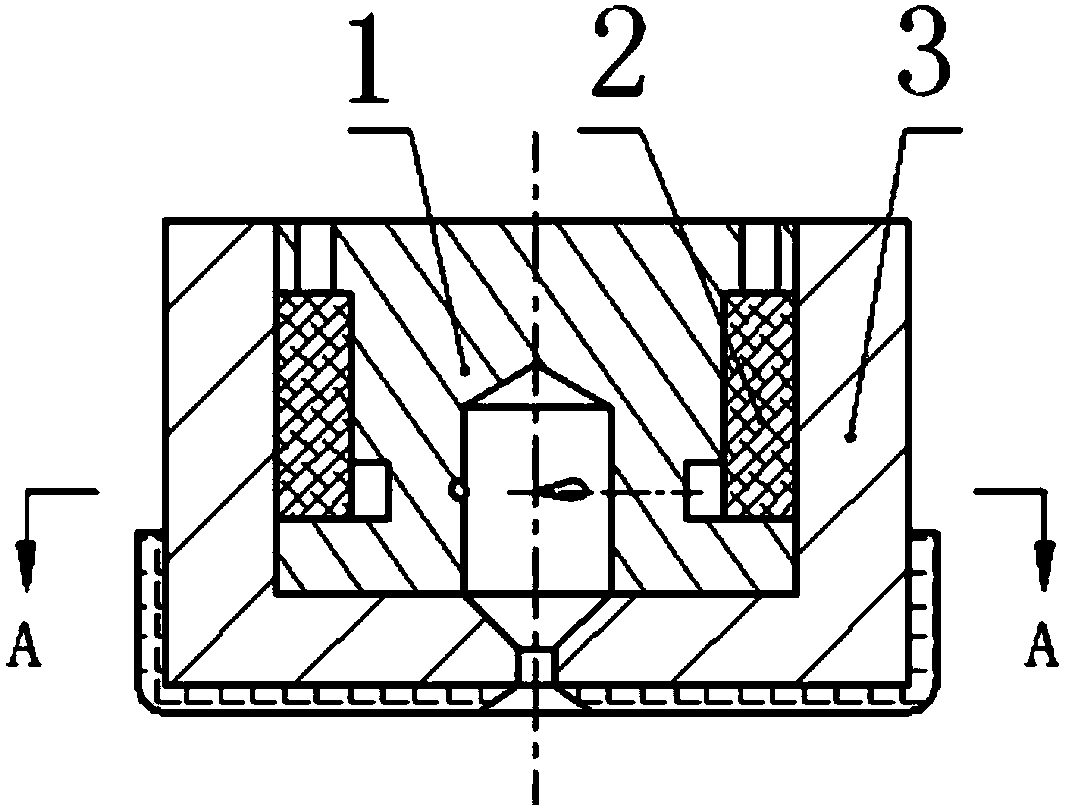

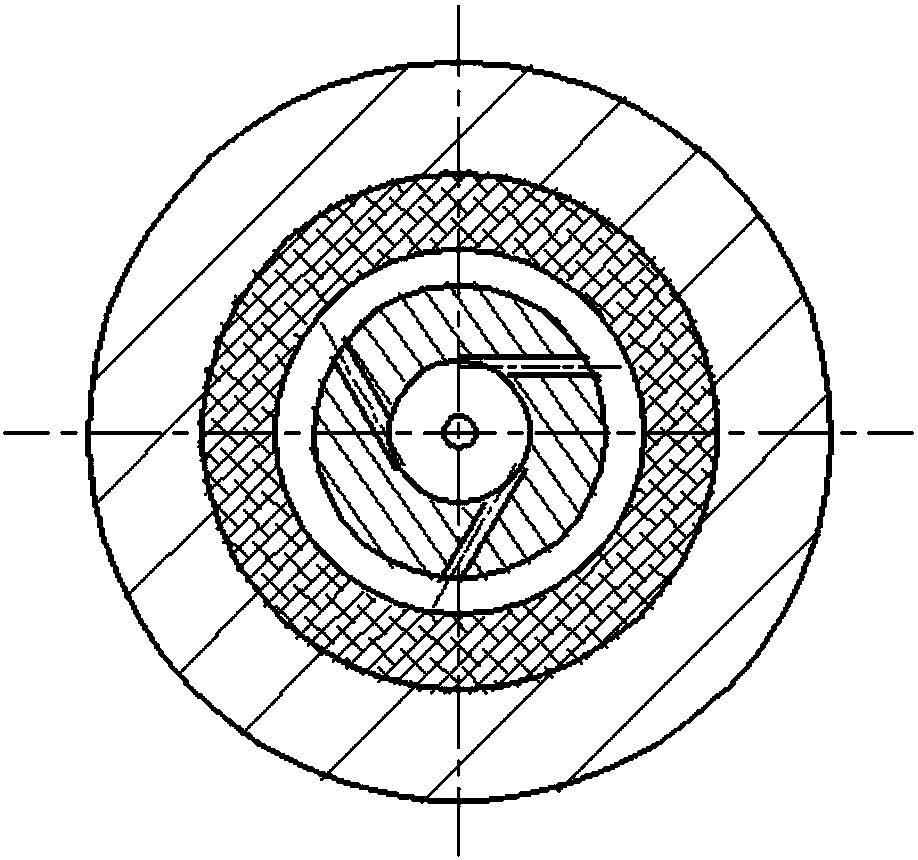

Nozzle for minisize gas-turbine combustor

ActiveCN101206029ACompact structureGood atomization qualityBurnersContinuous combustion chamberPollutantCombustion chamber

The invention discloses a nozzle of a combustion chamber of a miniature gas turbine, relates to the gas turbine technology, and in particular to a small size fluid fuel nozzle used in a combustion chamber of a 100 kW level miniature gas turbine. The nozzle consists of three parts which are a fuel oil passage, a fuel air passage and an air channel at the root of a burner, comprehensively utilizes the advantages of pneumatic nebulization and pressure atomization, and is a combined type high performance pneumatic atomizing nozzle. The nozzle of the invention has the characteristics that: the nozzle adopts a conventional processing method to realize excellent atomization of the fuel in small scale space, so as to meet the requirement for the quality of fuel atomization under a quite wide burden of the combustion chamber of the miniature gas turbine; the nozzle can avoid burnout and overcomes the defect of nozzle blockage caused by high temperature coking of the fuel; meanwhile, the nozzle can make the fuel in the combustion chamber to be combusted more fully and reduce discharge of pollutants such as smoke black and so on.

Owner:江苏中国科学院能源动力研究中心 +1

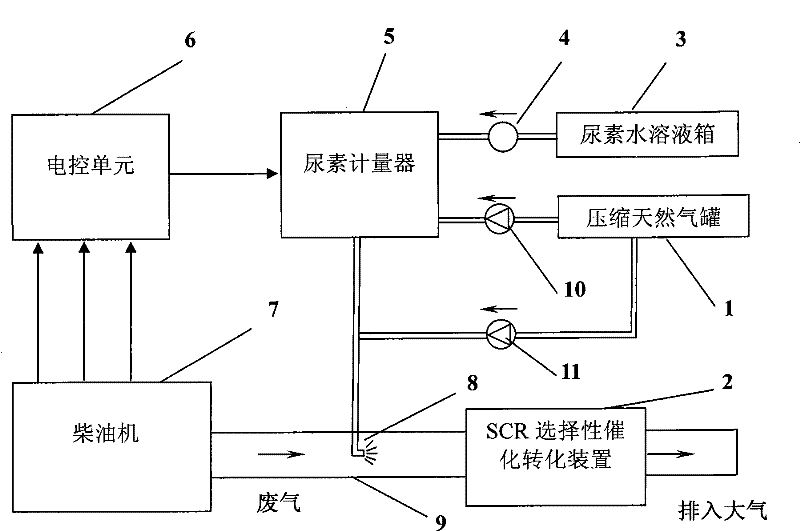

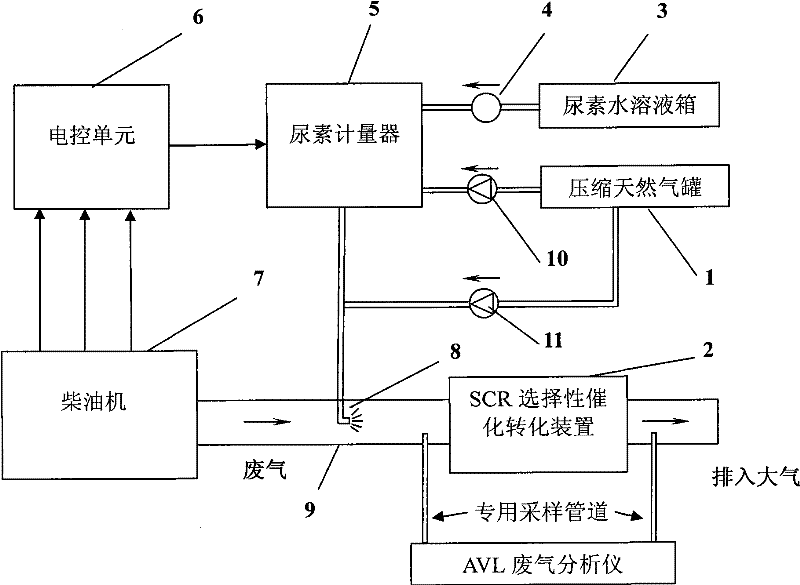

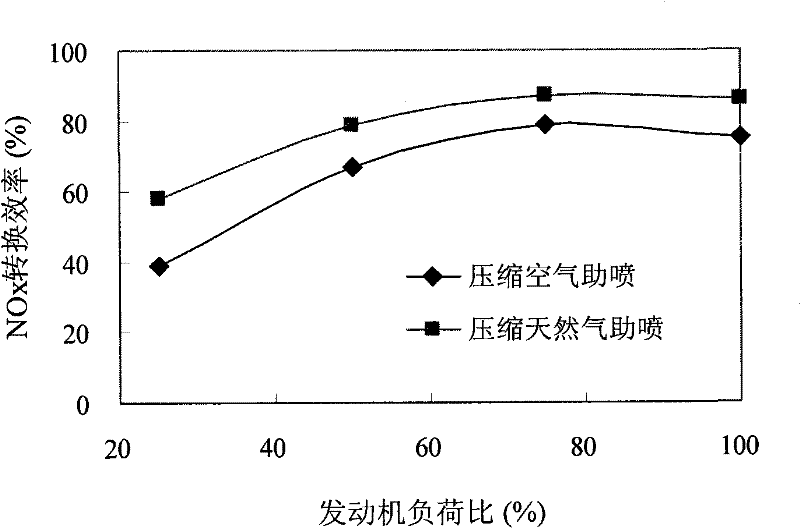

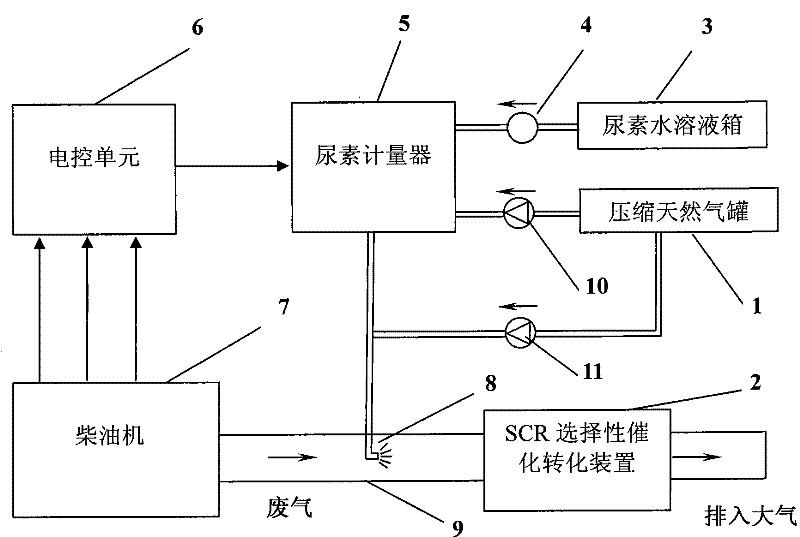

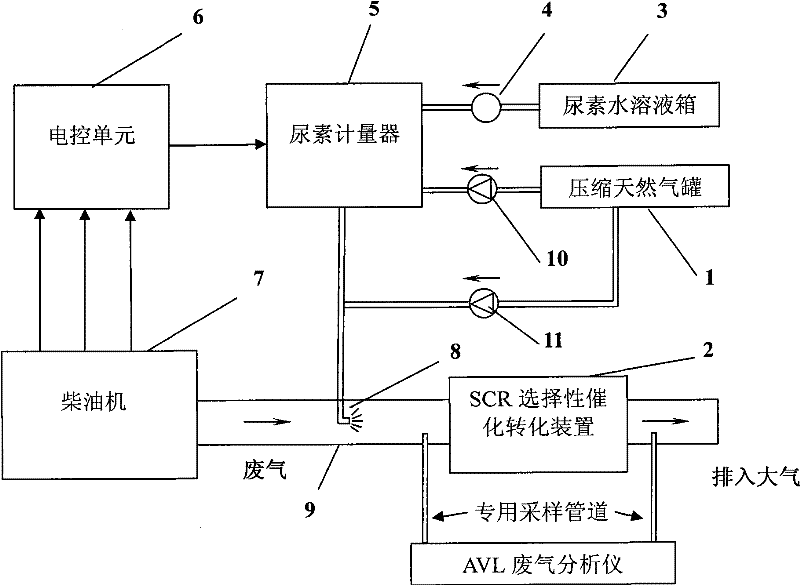

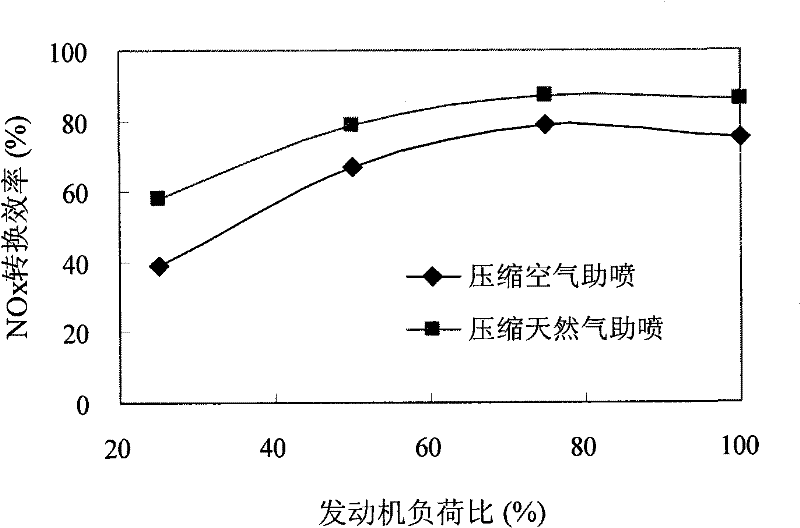

Ammonia selective catalytic reduction method for diesel injected by assistance of compressed natural gas

InactiveCN101749087AEmission reductionEfficient atomizationMethane captureInternal combustion piston enginesChemistryUrea

The invention belongs to the technical field of diesel tail gas aftertreatment, and in particular relates to an ammonia selective catalytic reduction method for a diesel injected by assistance of compressed natural gas. The method comprises the following steps: pumping urea out of a urea aqueous solution tank; filtering the urea, and delivering the urea to a urea gauger; introducing the compressed natural gas in a compressed natural gas tank into the urea gauger through a primary valve, mixing the compressed natural gas and urea solution, ensuring that the volume ratio of the compressed natural gas to the urea solution is 1:100-20 : 100, and primarily atomizing the urea solution; before the urea solution which is primarily atomized enters an exhaust pipe through a urea nozzle, mixing the compressed natural gas and urea solution which is primarily atomized, ensuing that the volumetric mixture ratio of the compressed natural gas to urea solution which is primarily atomized is 1:100-20:100 so as to improve the mixing uniformity and the atomization degree; decomposing the urea into NH3 and water at a high temperature in an exhaust pipe mixing zone, fully mixing the NH3 and the water and exhaust gas, introducing the mixture into an SCR selective catalytic reduction device; and in the SCR selective catalytic reduction device, reacting NH3 with NOx to generate ammonia gas and H2O, and then discharging the two into the atmosphere. The method realizes efficient atomization of the urea, also reduces the emission of the NOx by reduction through natural gas CH4, and improves the purifying effect on the diesel tail gas NOx.

Owner:TONGJI UNIV

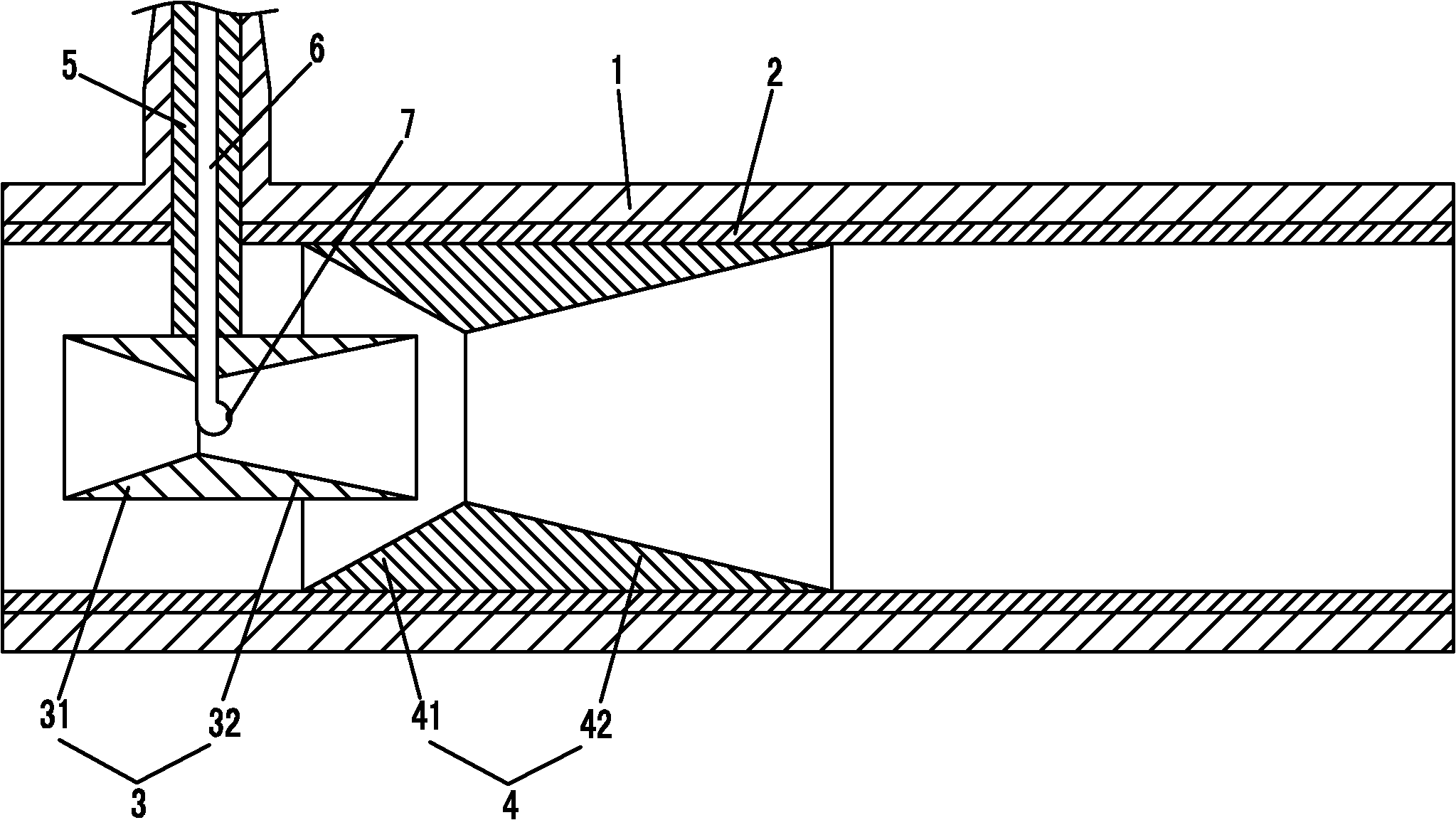

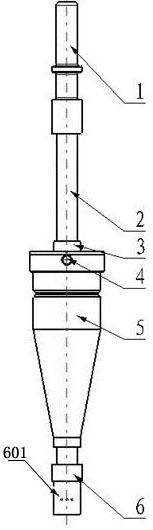

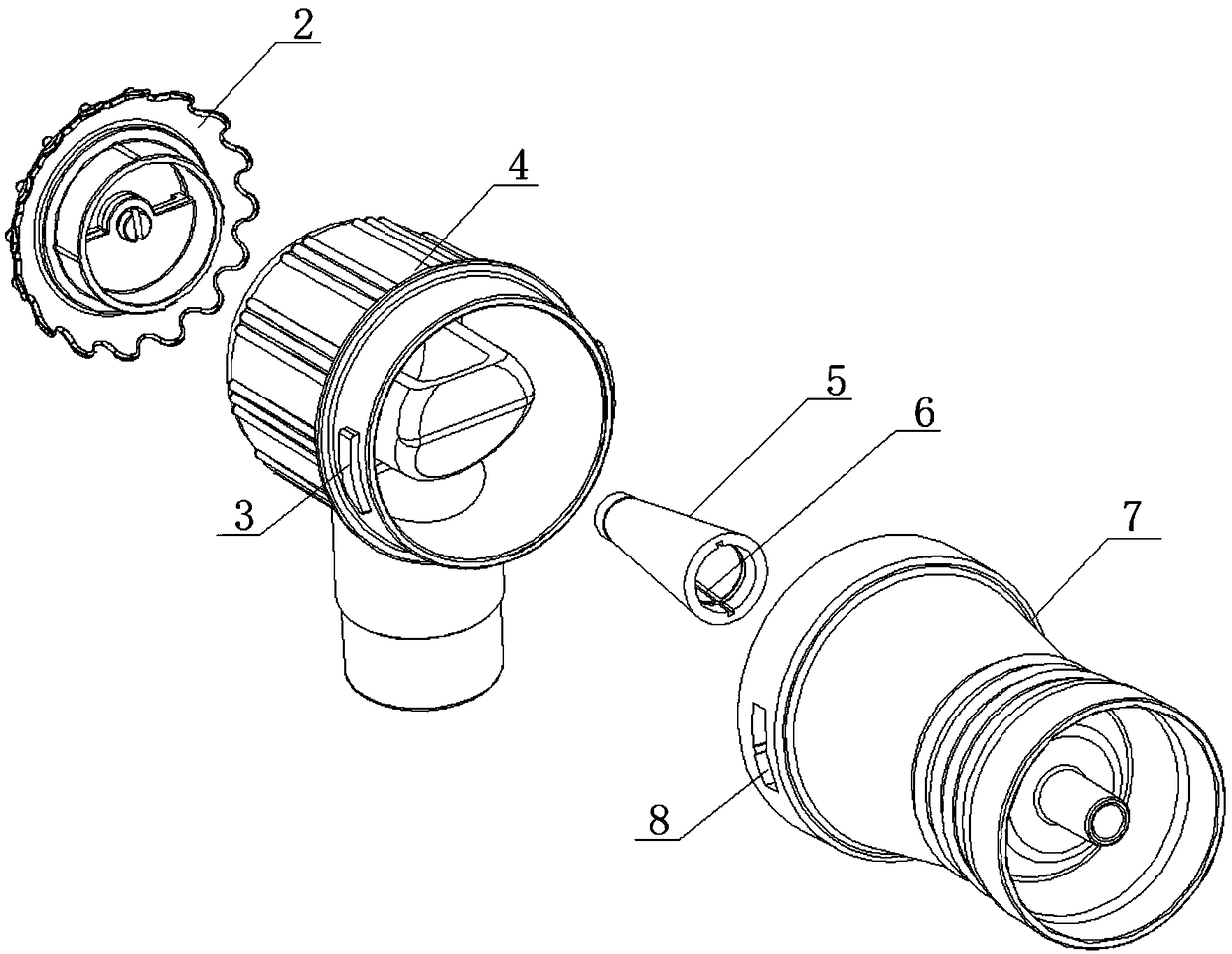

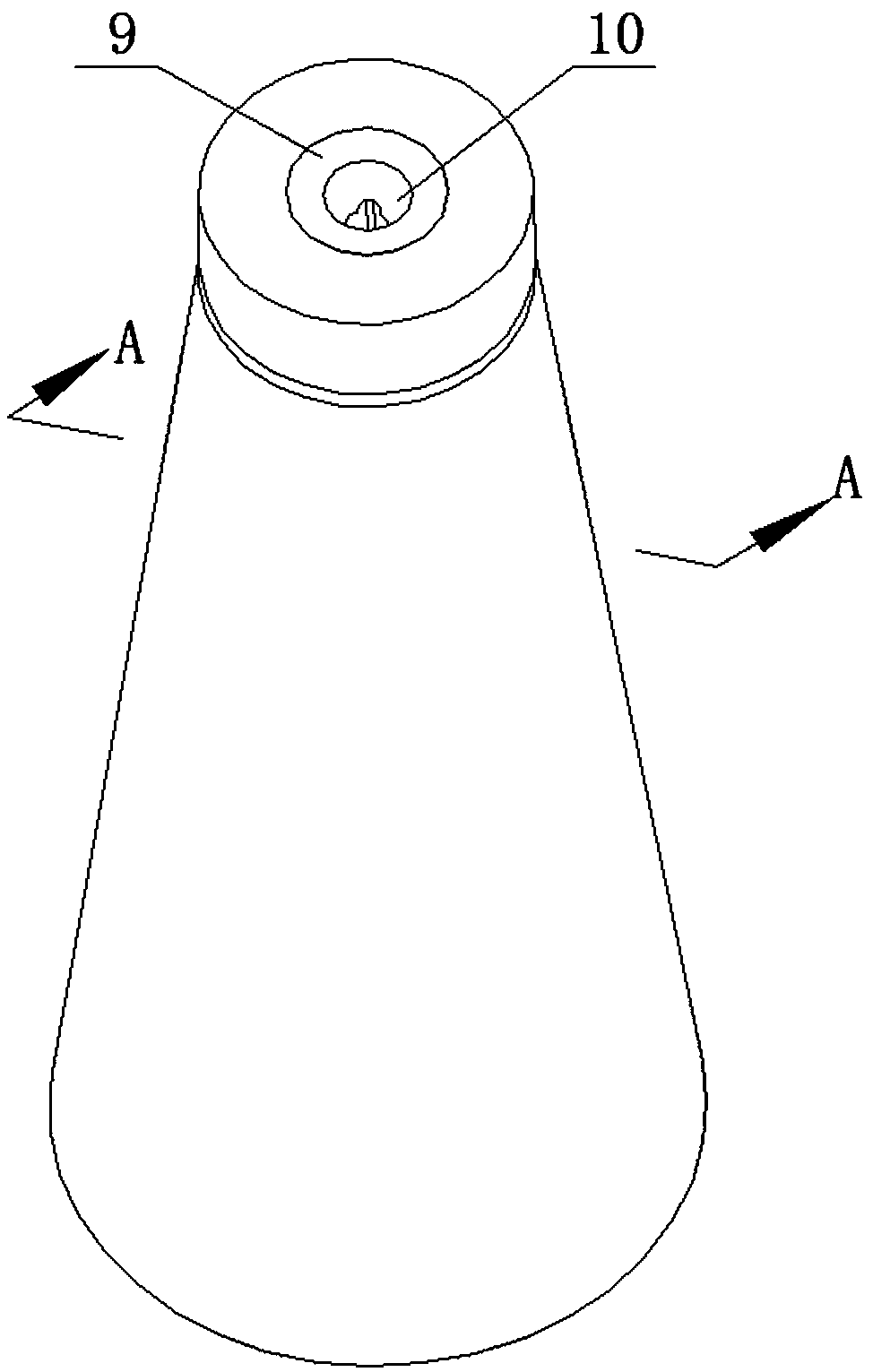

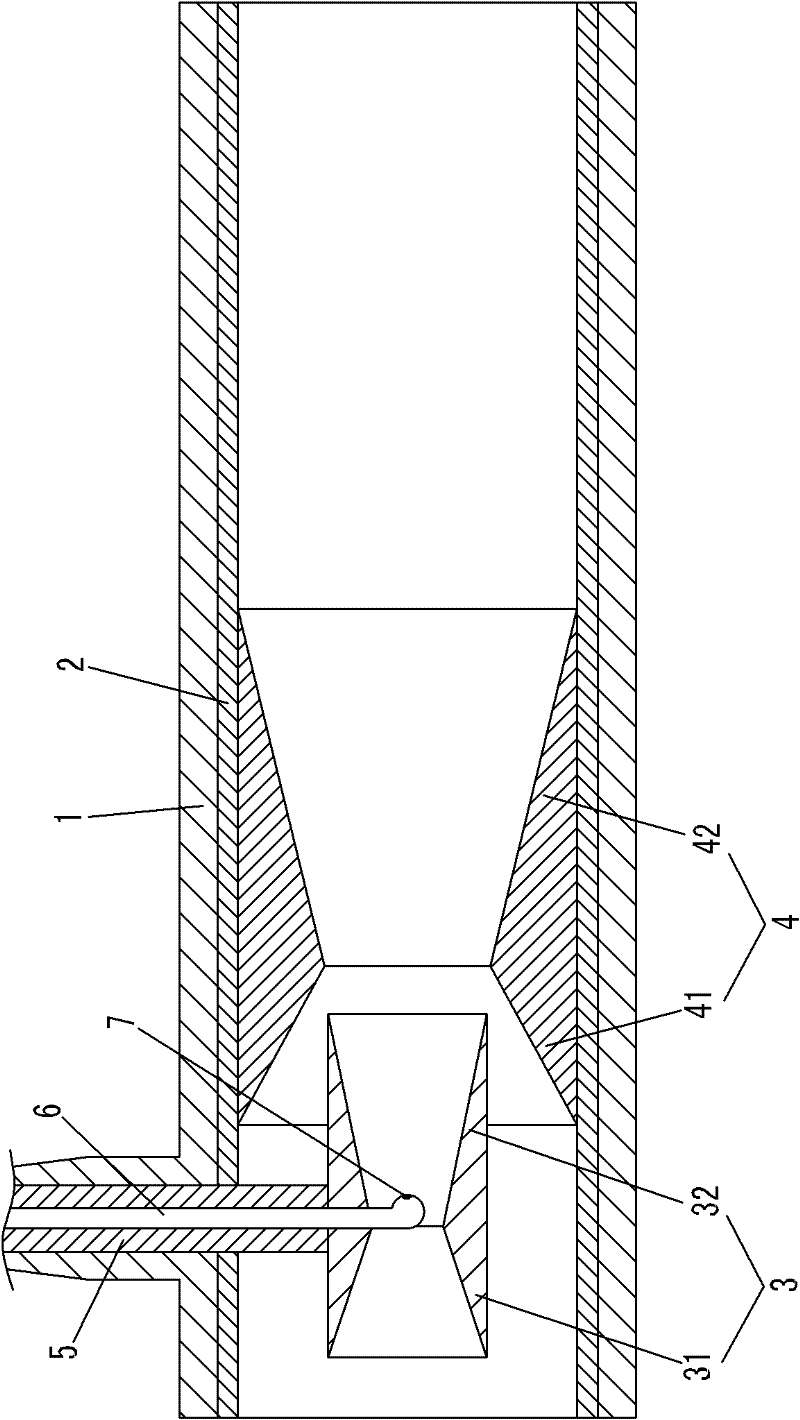

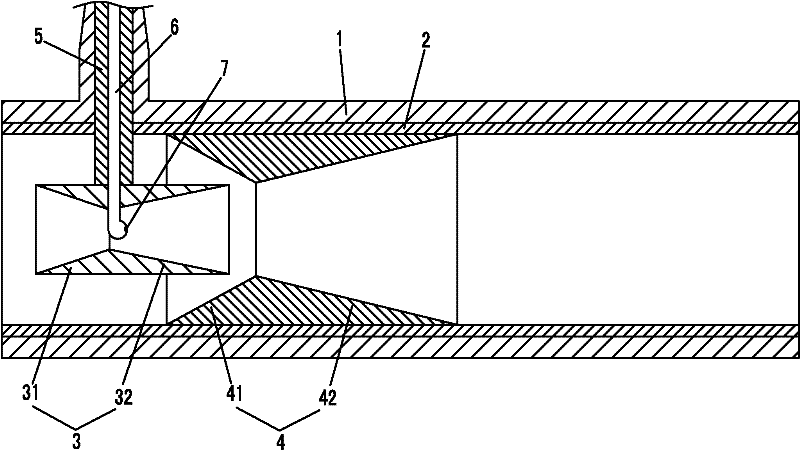

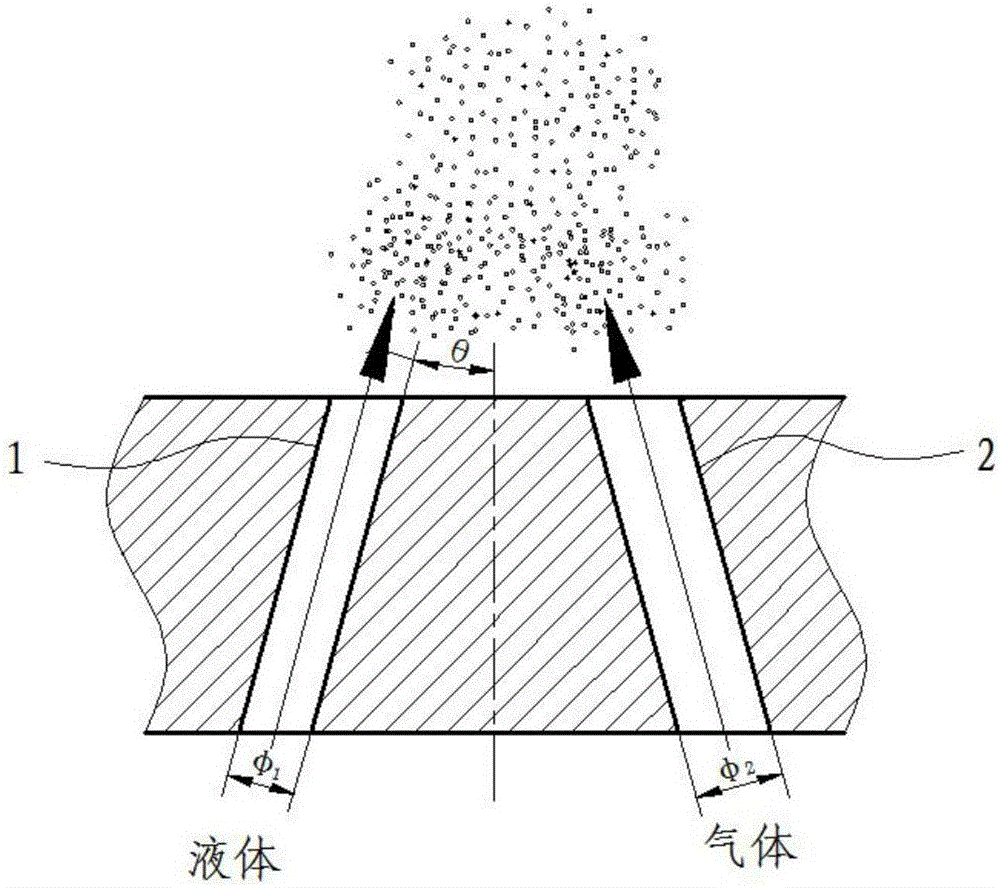

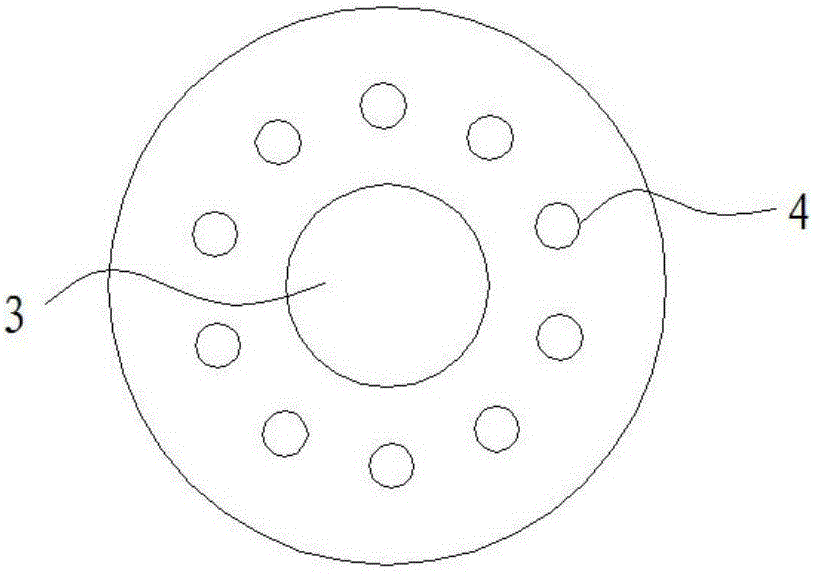

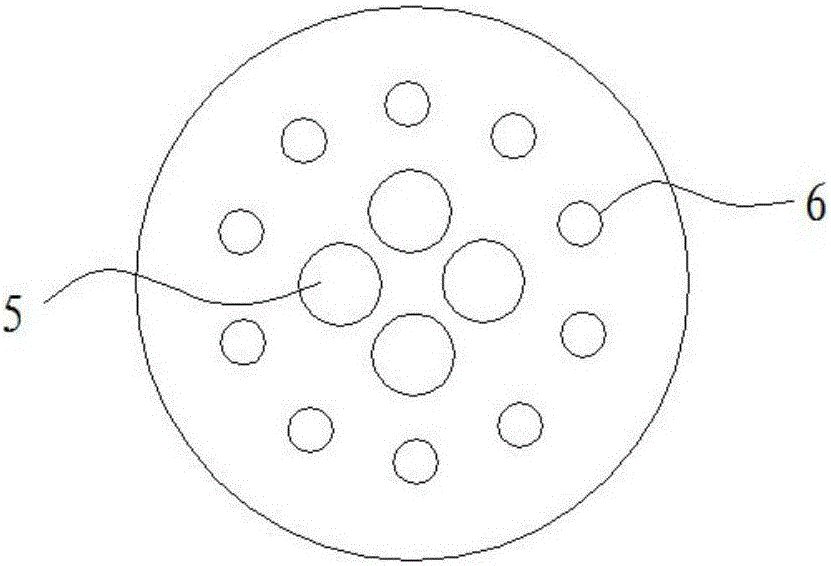

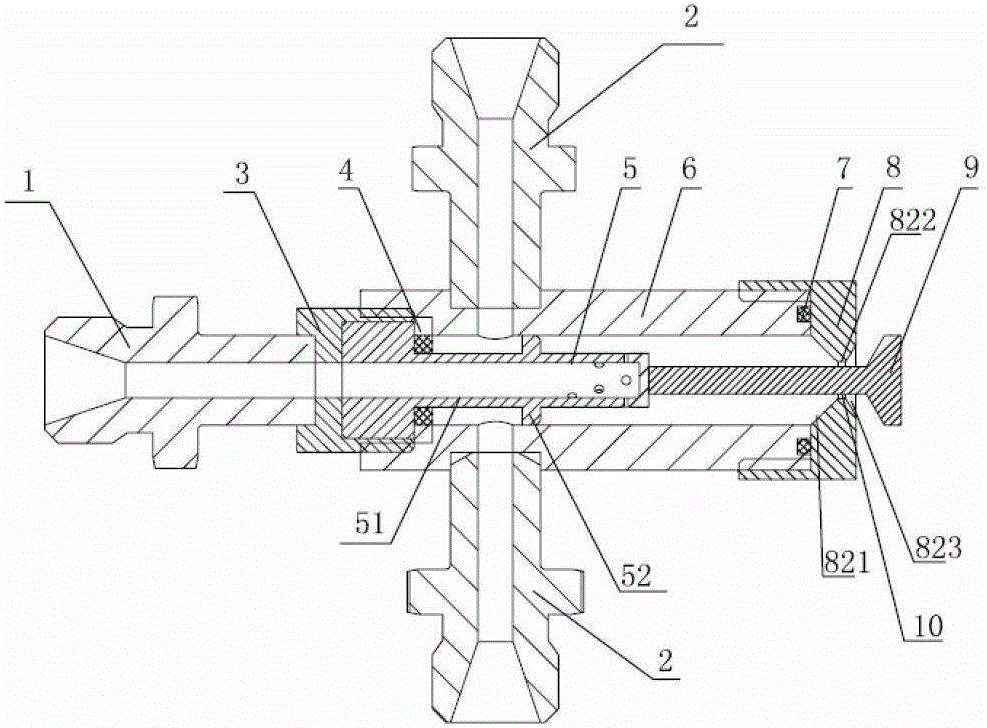

Atomizing nozzle and atomizing spray head using atomizing nozzle

InactiveCN105944862AEfficient atomizationSpray nozzlesLiquid spraying apparatusLiquid mediumPipe fitting

The invention discloses an atomizing nozzle and an atomizing spray head using the atomizing nozzle, relates to the atomizing nozzle for atomizing a liquid medium and the atomizing spray head using the atomizing nozzle, and aims to provide the atomizing nozzle capable of efficiently atomizing the medium at high speed and the atomizing spray head using the atomizing nozzle. The atomizing nozzle comprises a nozzle body (1); the nozzle body (1) is provided with an airflow channel (2) and a liquid channel (3); and the airflow channel and the liquid channel form an included angle. The atomizing spray head using the atomizing nozzle further comprises a spray head connecting piece (5) and a shell (6); the atomizing nozzle is connected to the shell through the spray head connecting piece; an airflow through hole (9) and a liquid through hole (10) are formed in the spray head connecting piece; one end of the airflow through hole is communicated with the airflow channel, and the other end is connected with an air supply pipe fitting (7); and one end of the liquid through hole is communicated with the liquid channel, and the other end is connected with a liquid supply pipe fitting (8).

Owner:BEIJING INST OF SPACE LAUNCH TECH +1

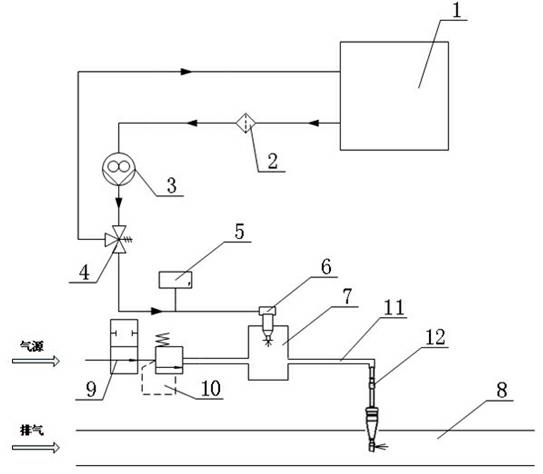

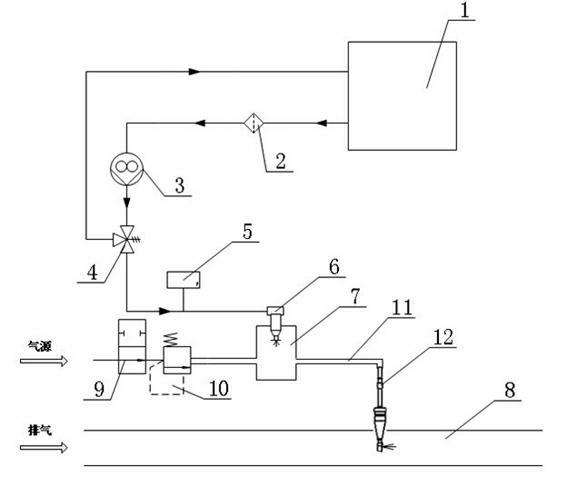

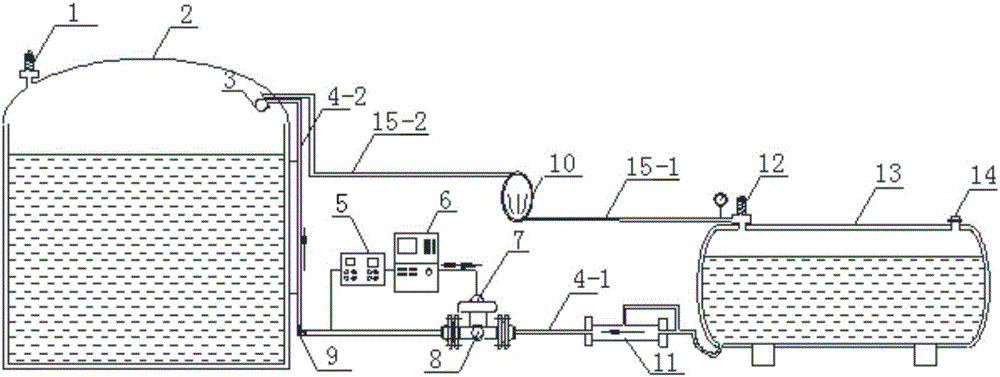

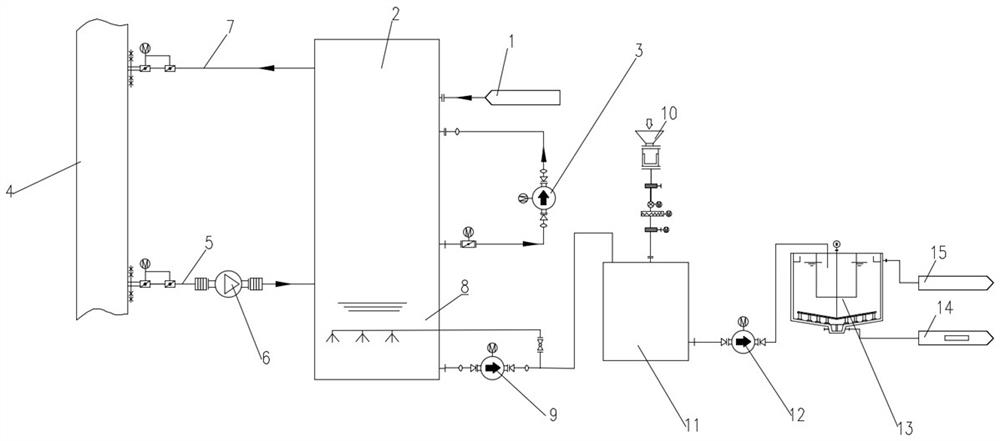

A diesel engine scr urea injection device

ActiveCN102297005ANo leaksImprove reliabilityExhaust apparatusSilencing apparatusSpray nozzleEngineering

The invention discloses a selective catalytic reduction (SCR) urea jet device of a diesel engine, and belongs to the technical field of engine exhaust purification treatment. The SCR urea jet device comprises a mixing cavity; the mixing cavity is provided with a gas source inlet, a urea inlet and a liquid outlet pipe; the gas source inlet is sequentially connected with an air pressure maintainingvalve and an air electromagnetic valve through pipelines; a nozzle is fixedly arranged on the urea inlet; the nozzle is sequentially connected with a safety pressure limiting valve, a gear pump, a urea filter and a urea tank through pipelines; the tail end of the liquid outlet pipe is connected with a mechanical atomizer; and the atomizer is arranged on an exhaust pipe of the external diesel engine. The SCR urea jet device of the diesel engine has simple structure and is reasonable in design. Quantitative jet of aqueous solution of urea is realized through the electromagnetic nozzle; and meanwhile, the urea corrosion and high temperature resistant mechanical atomizer is directly arranged on the high temperature exhaust pipe by adopting an air assisting mode, so that the reliability of thesystem is promoted.

Owner:ZHEJIANG BONDLYE ENVIRONMENTAL TECH CO LTD

Method for preparing compact-type porous ceramic-based titanium electrothermal film

ActiveCN105693287ANo pollutionSimple preparation processHeating element materialsCeramicwarePolyvinyl butyralPolyvinyl alcohol

The invention belongs to a preparation method of a titanium film, belongs to the field of electrothermal films and particularly relates to a method for preparing a compact-type porous ceramic-based titanium electrothermal film. The method comprises the following steps of: mixing and ball-grinding titanium or titanium hydride powder, a polyving akohol aqueous solution or a polyvinyl butyral ethanol solution in a certain ratio so as to obtain uniform and stable titanium slurry; then spraying the titanium slurry on a porous ceramic base, drying at a low temperature, and performing high-temperature sintering in the presence of inert gas or under high-vacuum protection, thereby obtaining the compact-type porous ceramic-based titanium electrothermal film. The preparation method is low in preparation process cost, high in production efficiency, high in operability and free from environmental pollution, and conforms to the sustainable development policy; the prepared compact-type porous ceramic-based titanium electrothermal film has the advantages of high electrothermal conversion efficiency, safety, no toxicity, better atomization effect, small driving voltage and the like, and can be applied to electrothermal devices of compact-type medical atomization devices and the like.

Owner:XIANGTAN UNIV

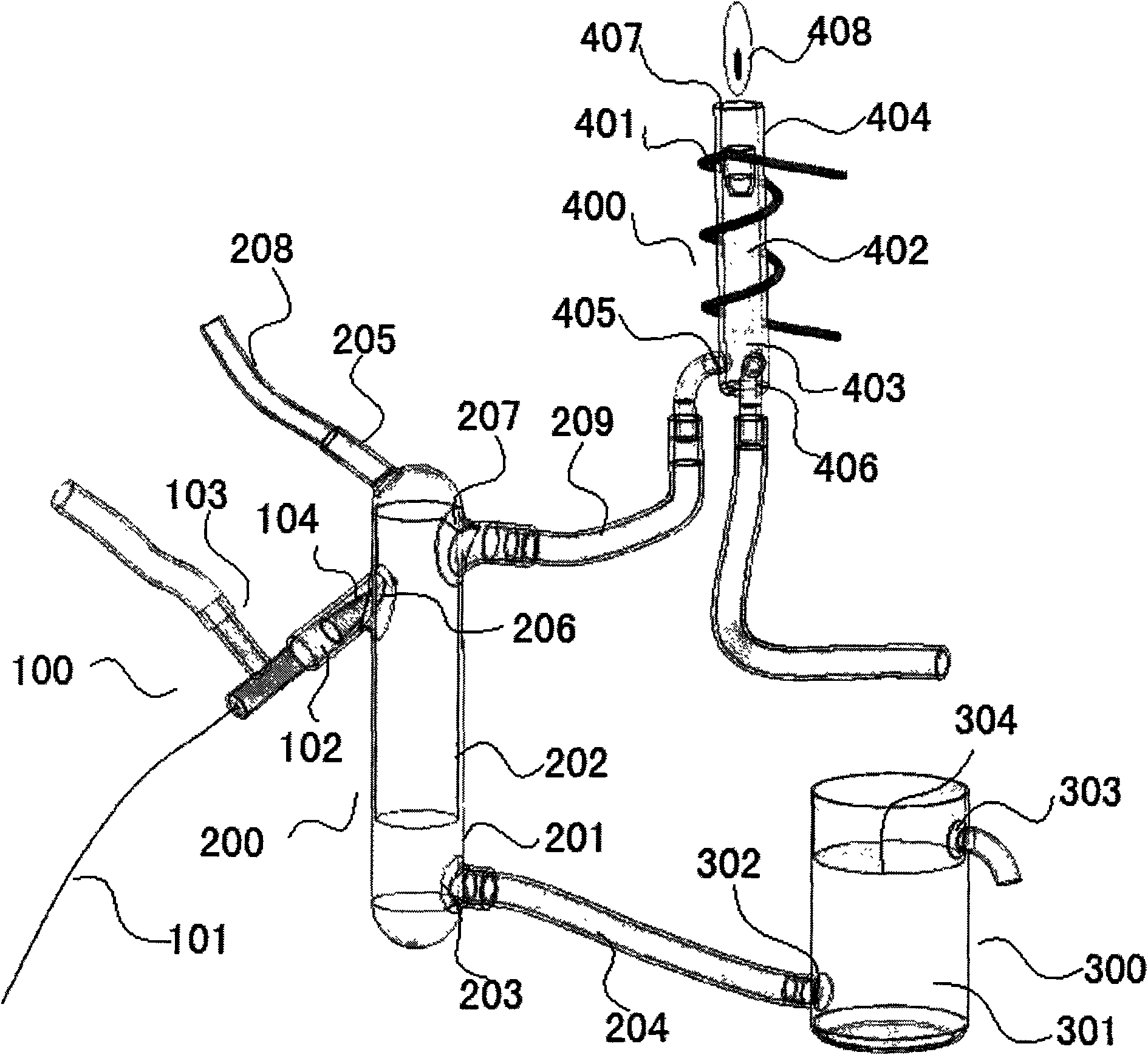

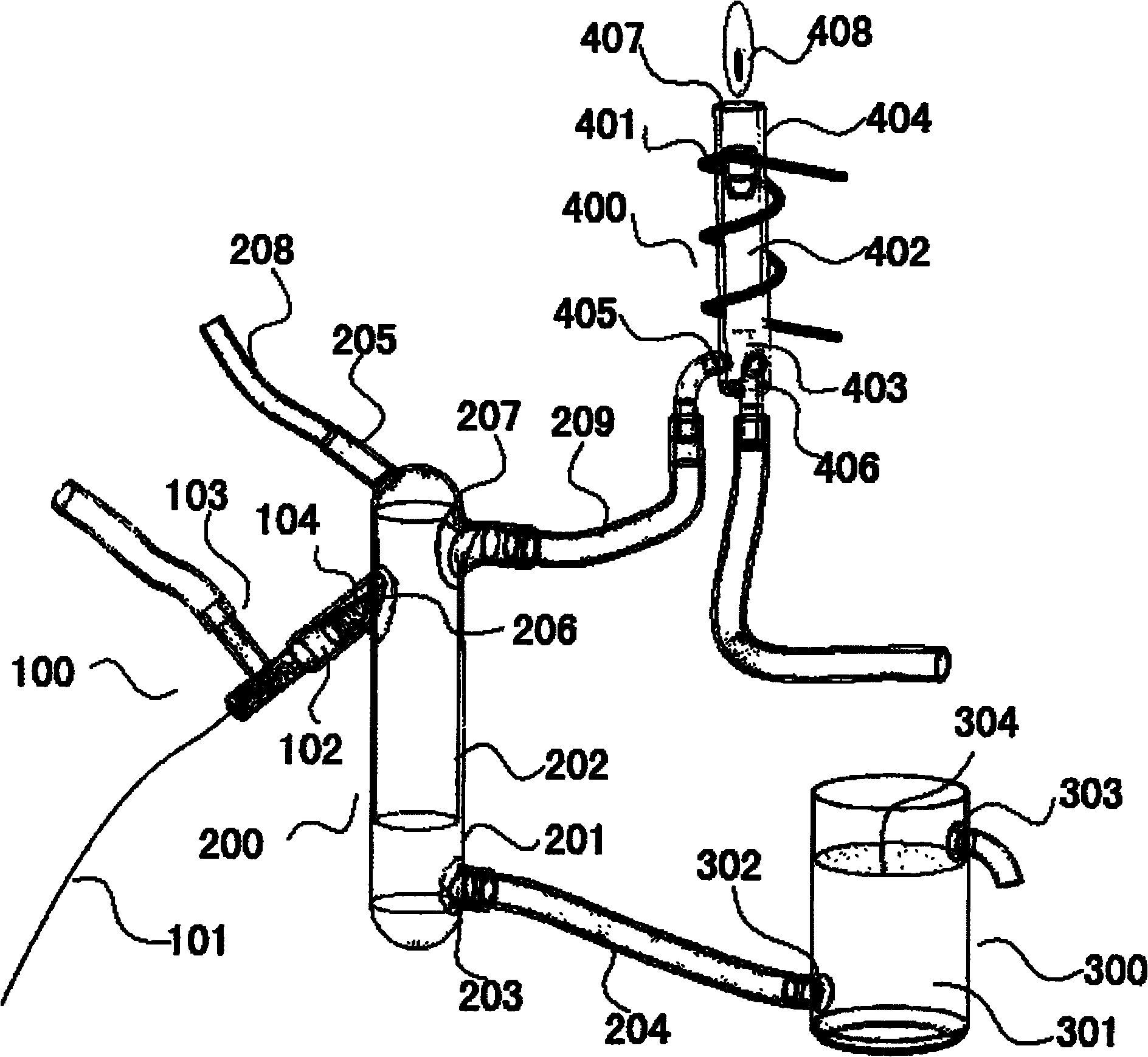

Sensitive and stable atomic fluorescence generating system capable of atomizing continuously

InactiveCN102012369AEasy to collectAvoid interferenceFluorescence/phosphorescenceElectricityHydrogen

The invention discloses a sensitive and stable atomic fluorescence generating system capable of atomizing continuously. The system comprises an electrically heated quartz tube, an argon source, a solution atomizer, a gas-liquid separating and gas mixing device, a water seal, and a hydrogen generator, wherein the solution atomizer is connected with the argon source and the gas-liquid separating and gas mixing device which is respectively communicated with the hydrogen generator, the electrically heated quartz tube and the water seal. The sensitive and stable atomic fluorescence generating system capable of atomizing continuously has the advantages of stable flame, high atomic fluorescence sensitivity and high sample atomizing efficiency, and has the characteristic of continuous sample introduction, so that an analytical instrument can reduce the measurement error through prolonging the measurement time so as to obtain ideal measurement precision and detection limit.

Owner:SHANGHAI SPECTRUM INSTR

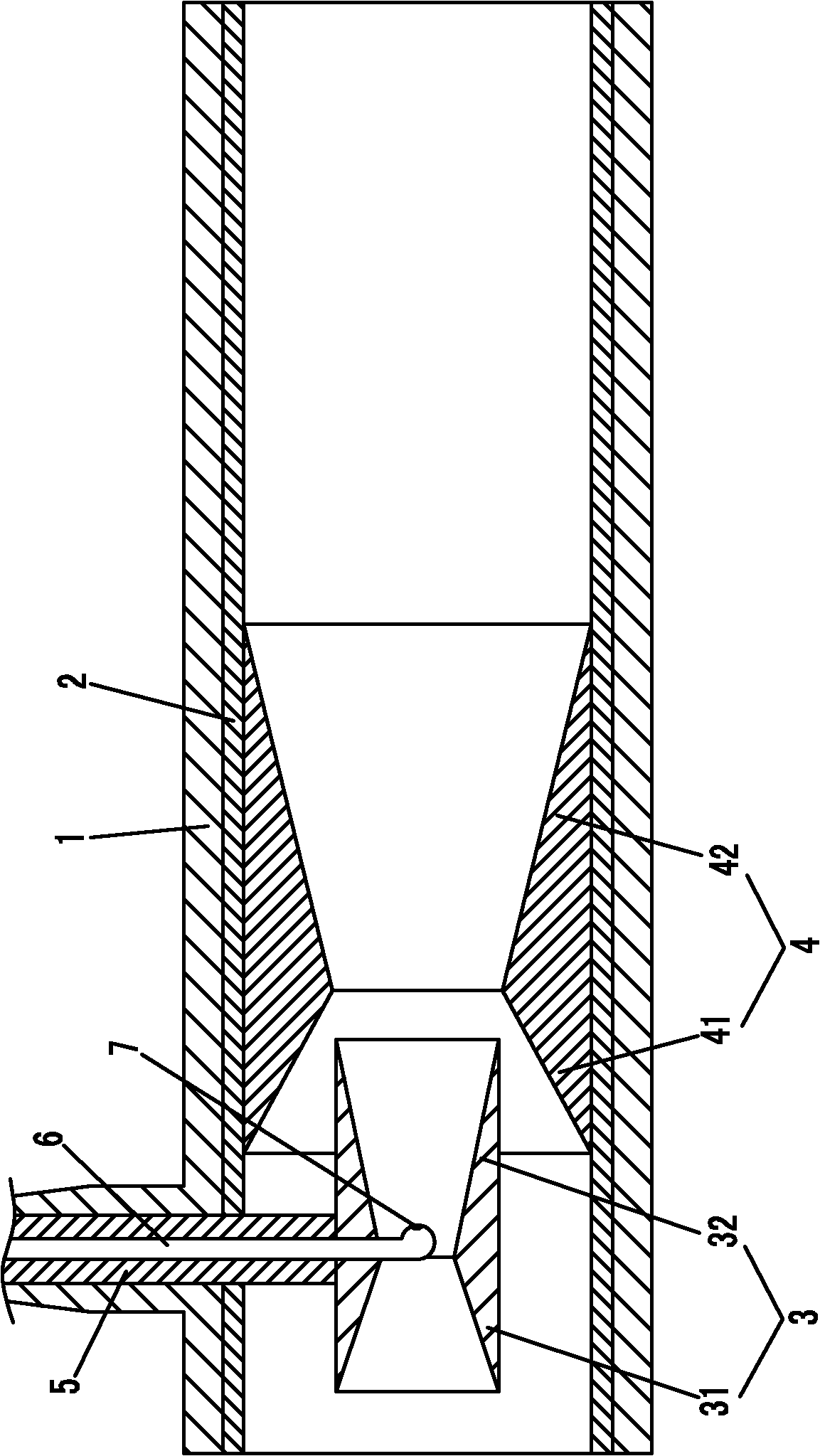

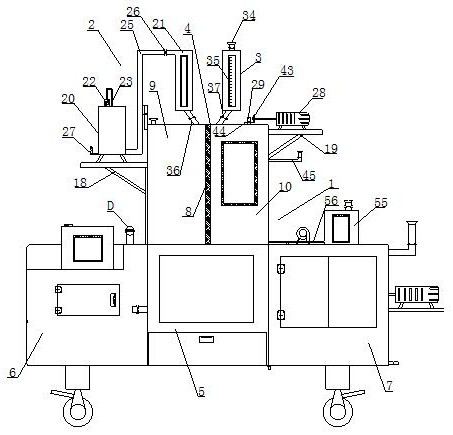

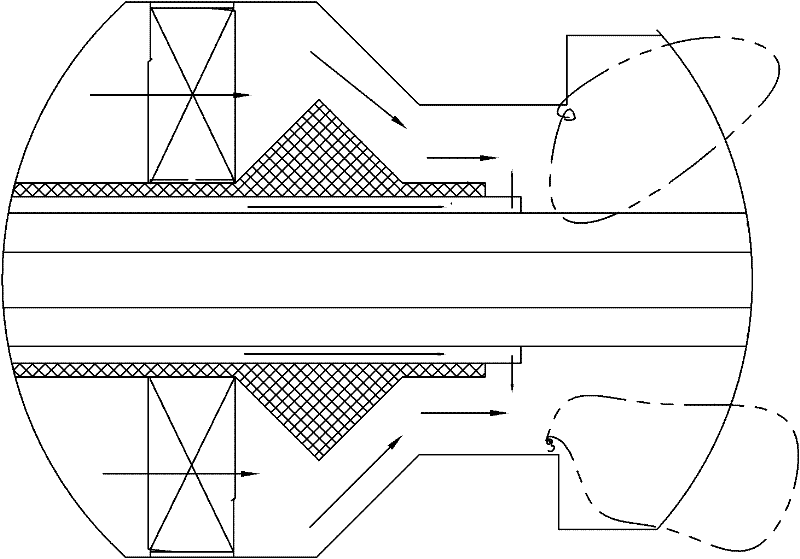

Ultrasonic efficient atomization device of water currents under narrow-slit airflow oscillation stirring

The invention discloses an ultrasonic efficient atomization device of water currents under narrow-slit airflow oscillation stirring. The device comprises a liquid-air leading shell and an atomization device generation shell; a liquid-air leading valve element is arranged in the liquid-air leading shell; an airflow gradual shrinking narrow-slit channel is formed in the outer side of the valve element; a center through hole of the liquid-air leading valve element is a jet water gradual shrinking channel, and a jet water outlet at the tail part is aligned with a water current ultrasonic oscillation cavity; an airflow self-exciting oscillation cavity is formed in the tail end of the atomization device generation shell; a horn-shaped airflow baffle plate is arranged in the center of the airflow self-exciting oscillation cavity; a water mist gradual shrinking channel is formed in the airflow baffle plate; and the water mist gradual shrinking channel, a water mist guide channel and a water mist jet outlet are smoothly transited and connected. An air flow enters the airflow self-exciting oscillation cavity after being accelerated by the airflow gradual shrinking narrow-slit channel; and the airflow baffle plate and the airflow self-exciting oscillation cavity are matched to form an airflow self-exciting oscillation field so as to successfully realize efficient liquid atomization. The device has the advantages of high atomization efficiency and simple structure, and is also suitable for efficient atomization of other liquid.

Owner:TAIYUAN UNIV OF TECH

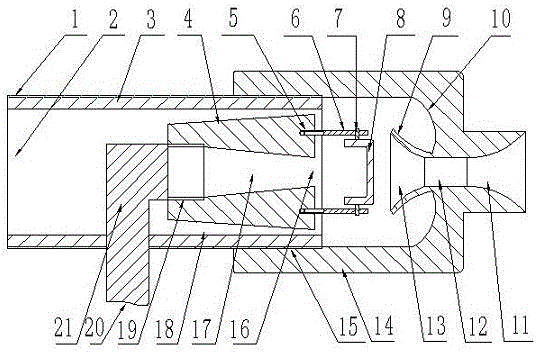

Spray desuperheater

InactiveCN101979918AImprove heat transfer efficiencyImprove spraying effectSuperheating controlBoiler plantEngineering

The invention discloses a spray desuperheater, which belongs to the field of boiler plants. The spray desuperheater comprises a tubular desuperheater header and the like. An inner sleeve is sleeved to a cavity of the desuperheater header. A primary venturi tube and a secondary venturi tube are arranged in the cavity of the inner sleeve, wherein the flared section of the primary venturi tube enters the cavity at the throat of the secondary venturi tube from the left end of the secondary venturi tube. A cooling water pipe vertically runs through the desuperheater header and the inner sleeve; the lower end of the cooling water pipe is connected with an upper end at the throat of the primary venturi tube; and the cavity of the cooling water pipe is communicated with that of the primary venturi tube. The lower end of a centrifugal nozzle runs through the cooling water pipe and then is extended into the cavity of the primary venturi tube; and the spray directions of spray orifices at the lower end of the centrifugal nozzle are dead against the secondary venturi tube. Due to the combination of the centrifugal nozzle and the primary and secondary venturi tubes, the spray desuperheater solves the problem of small atomization range and poor heat exchange effect of desuperheating water, is simple to machine, and can highly-efficiently atomize the desuperheating water in large scale to further effectively improve the heat exchange performance of the desuperheater.

Owner:FEICHENG BAIZHUANG COAL MINE +2

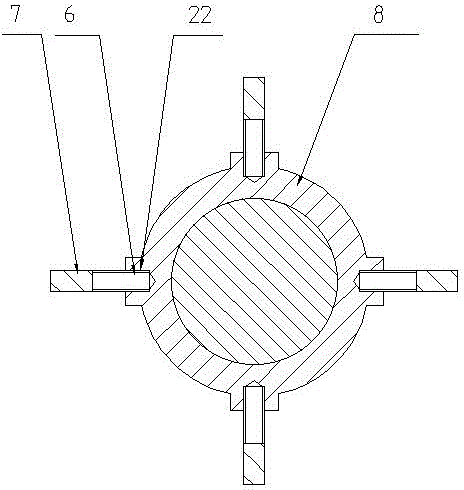

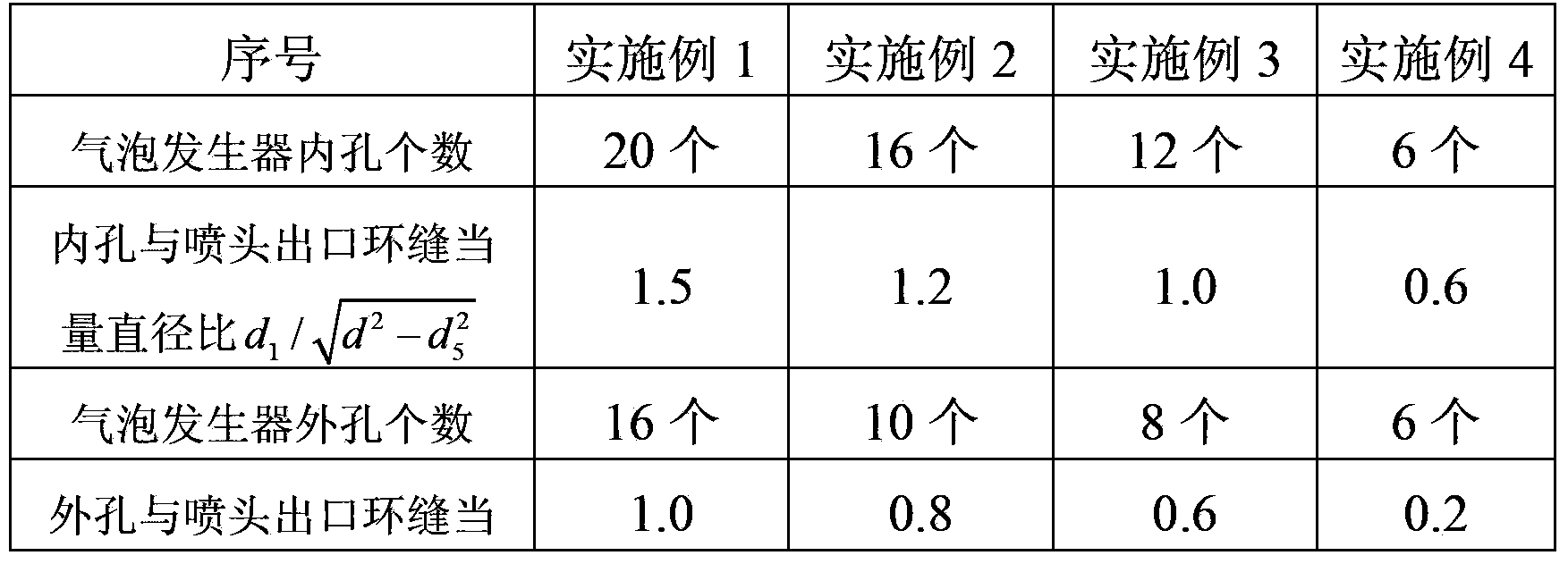

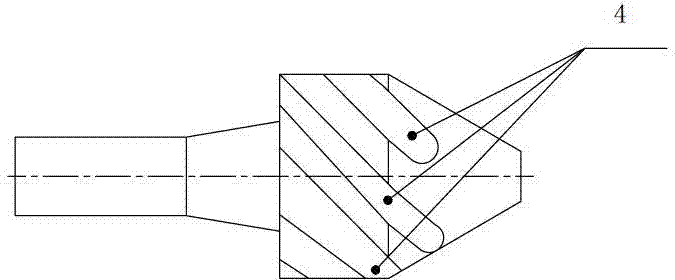

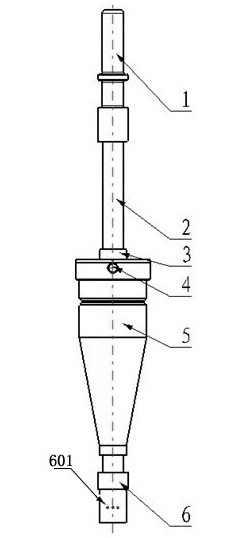

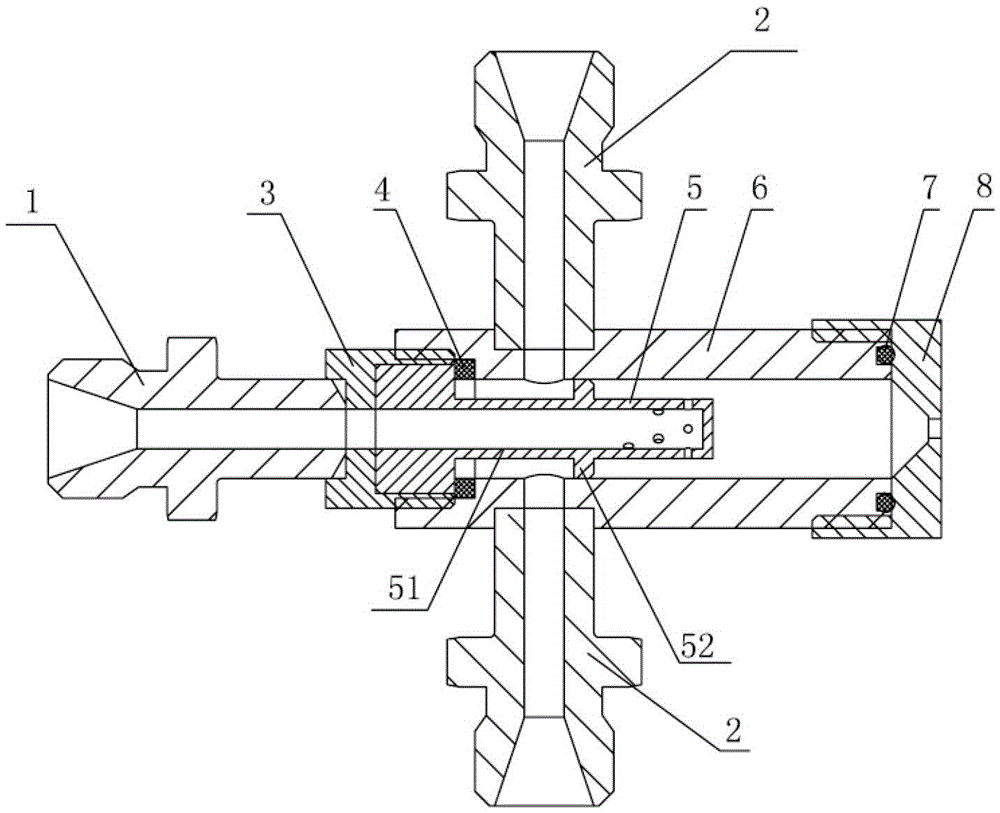

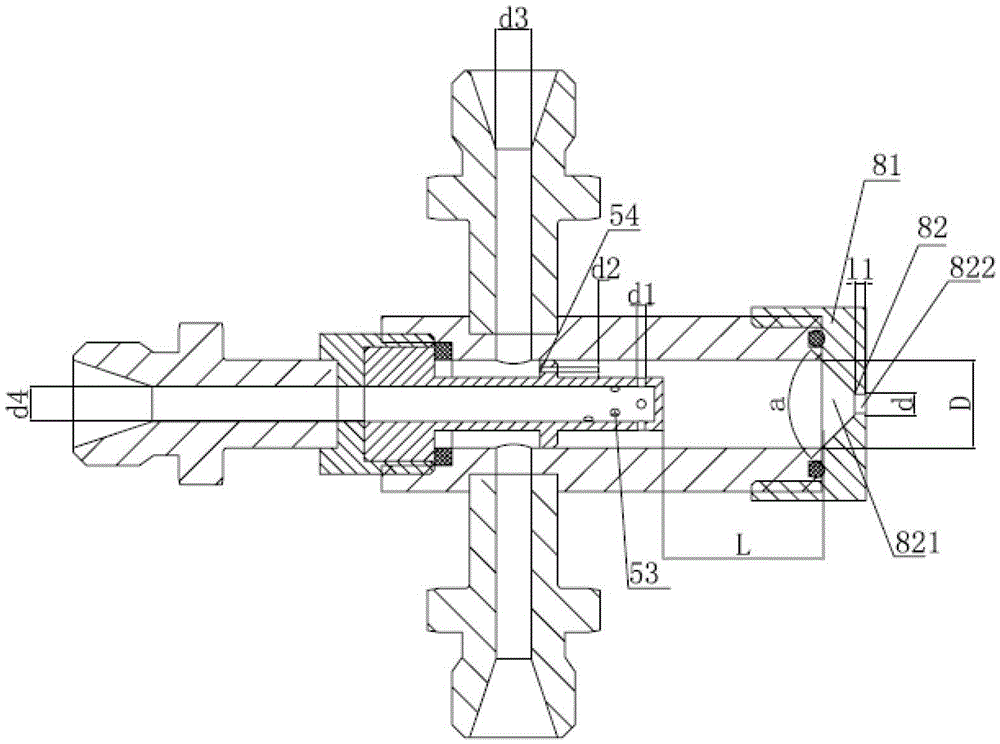

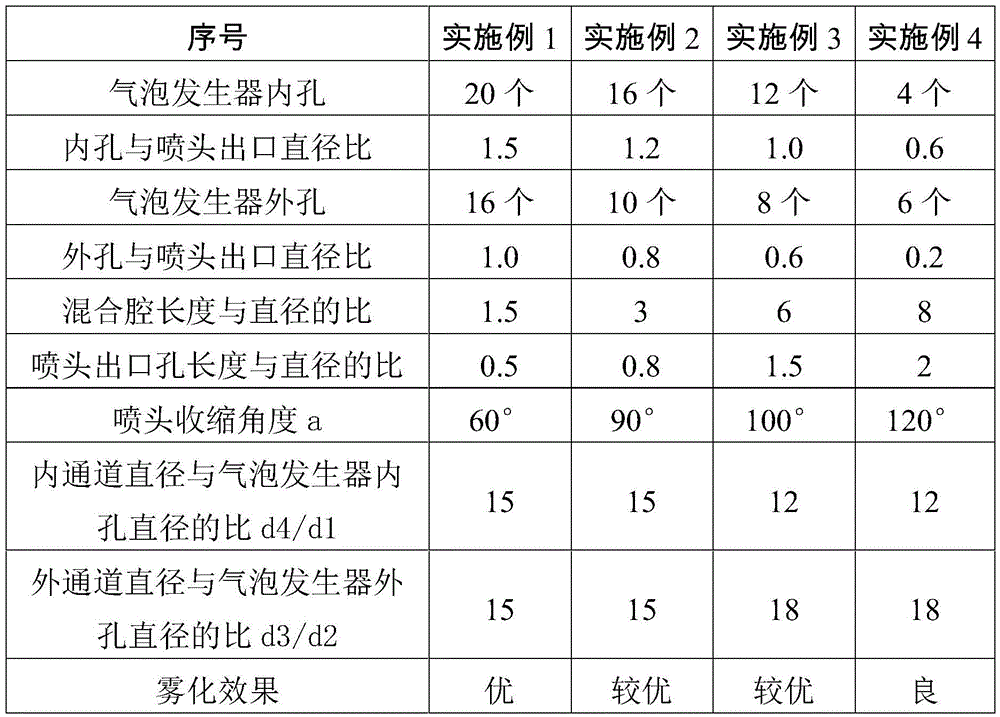

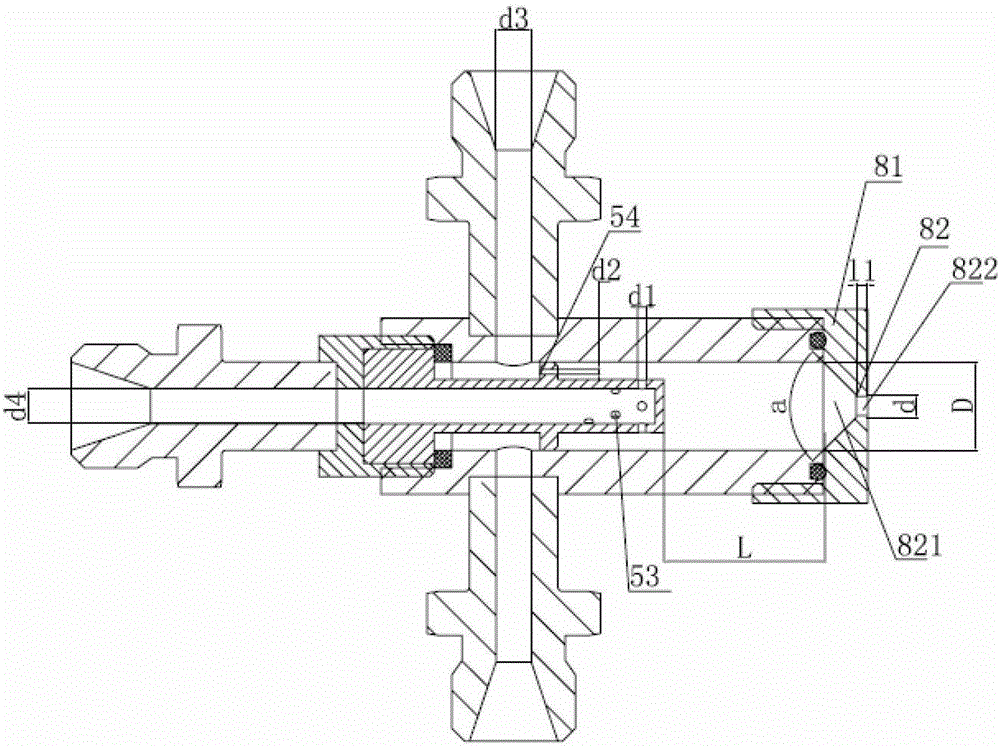

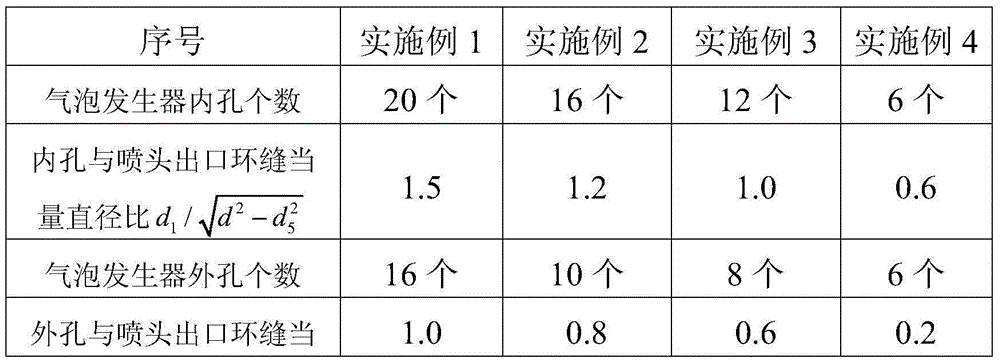

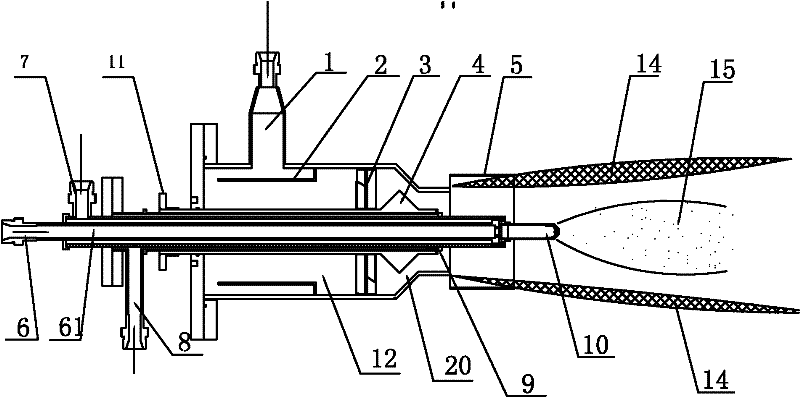

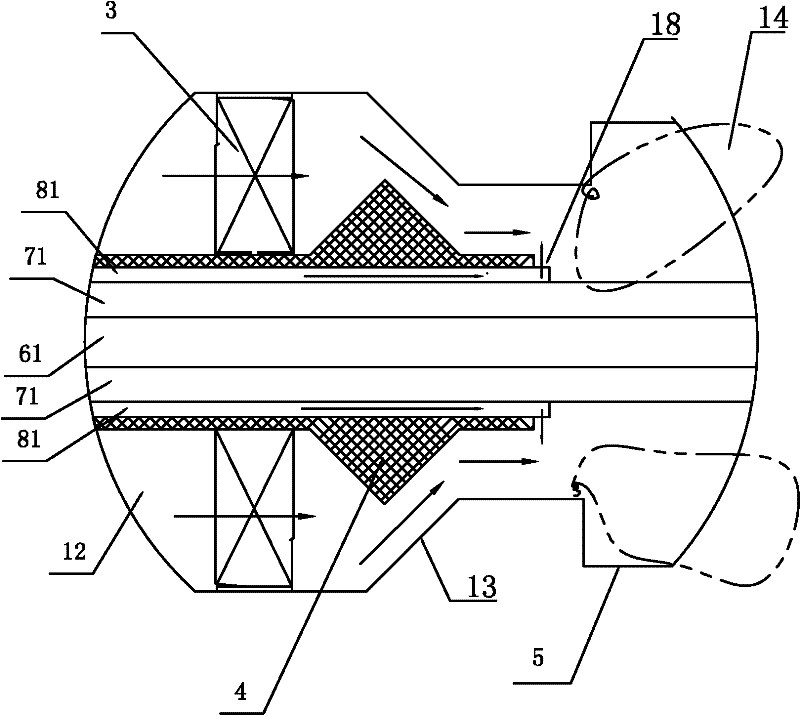

Hollow conical bubble atomizing nozzle applicable to high-viscosity non-Newtonian fluid

ActiveCN103372510ASmall atomization effectEfficient atomizationSpray nozzlesLiquid spraying apparatusAverage diameterEngineering

The invention relates to a hollow conical bubble atomizing nozzle applicable to high-viscosity non-Newtonian fluid. The hollow conical bubble atomizing nozzle comprises an inner connector, an outer connector, a sleeve, a bubble generator, a mixer, a sprayer and a needle-shaped cone; the inner connector is fixed to one end of the mixer by the aid of the sleeve, the sprayer is fixed to the other end of the mixer, the outer connector is fixed onto the mixer, and the bubble generator is arranged in the mixer; the bubble generator comprises a flow guide barrel and a flow guide plate, the flow guide barrel is communicated with the inner connector, an outer flow channel is communicated with the outer connector, a plurality of outer flow guide holes are formed in the flow guide plate, and a plurality of inner flow guide holes are formed in a mixing chamber; the sprayer comprises a sprayer body and a spray nozzle; an outlet circular seam is formed between the needle-shaped cone and a straight section of the sprayer. The hollow conical bubble atomizing nozzle has the advantages that technical problems of poor atomizing effect, high atomizing gas consumption rate and large average fluid drop diameter of an existing nozzle for high-viscosity non-Newtonian fluid are solved, the hollow conical bubble atomizing nozzle is excellent in atomizing quality within a wide flow regulation range, and the average diameter of fluid drops is greatly reduced under the condition of a low gas consumption rate.

Owner:NO 11 INST OF NO 6 ACADEMY OF CHINA AEROSPACE SCI & TECH

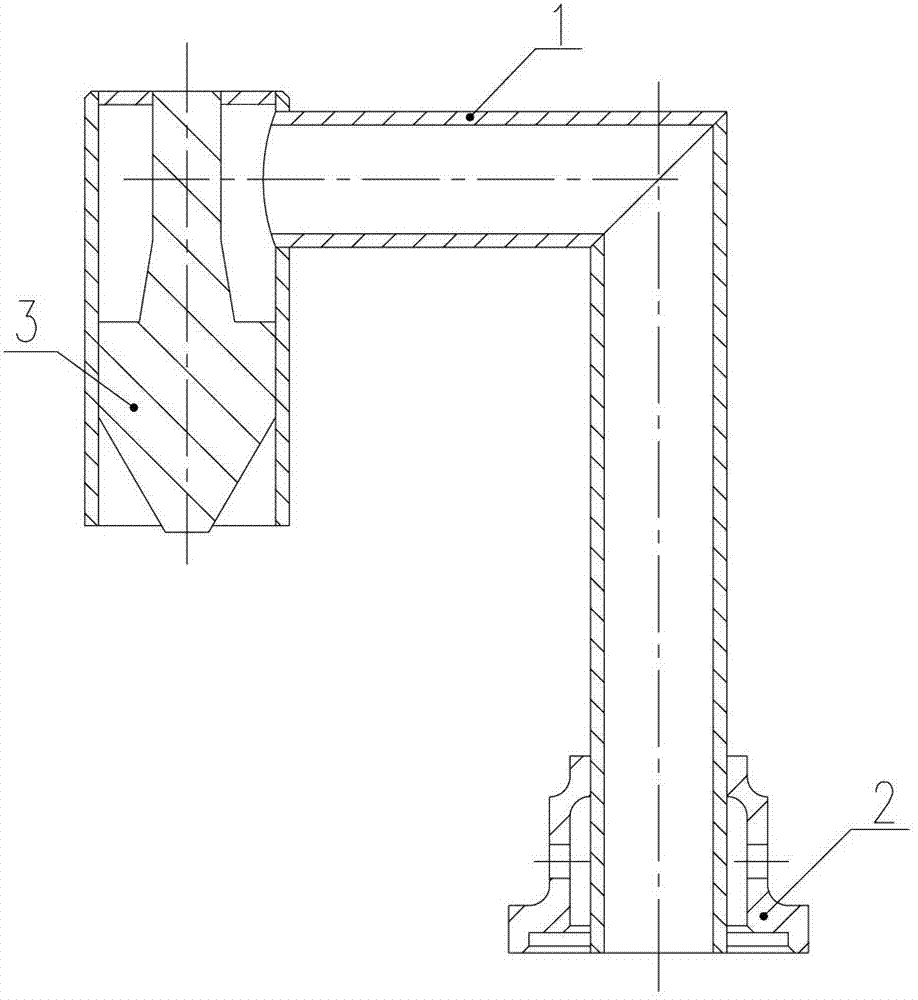

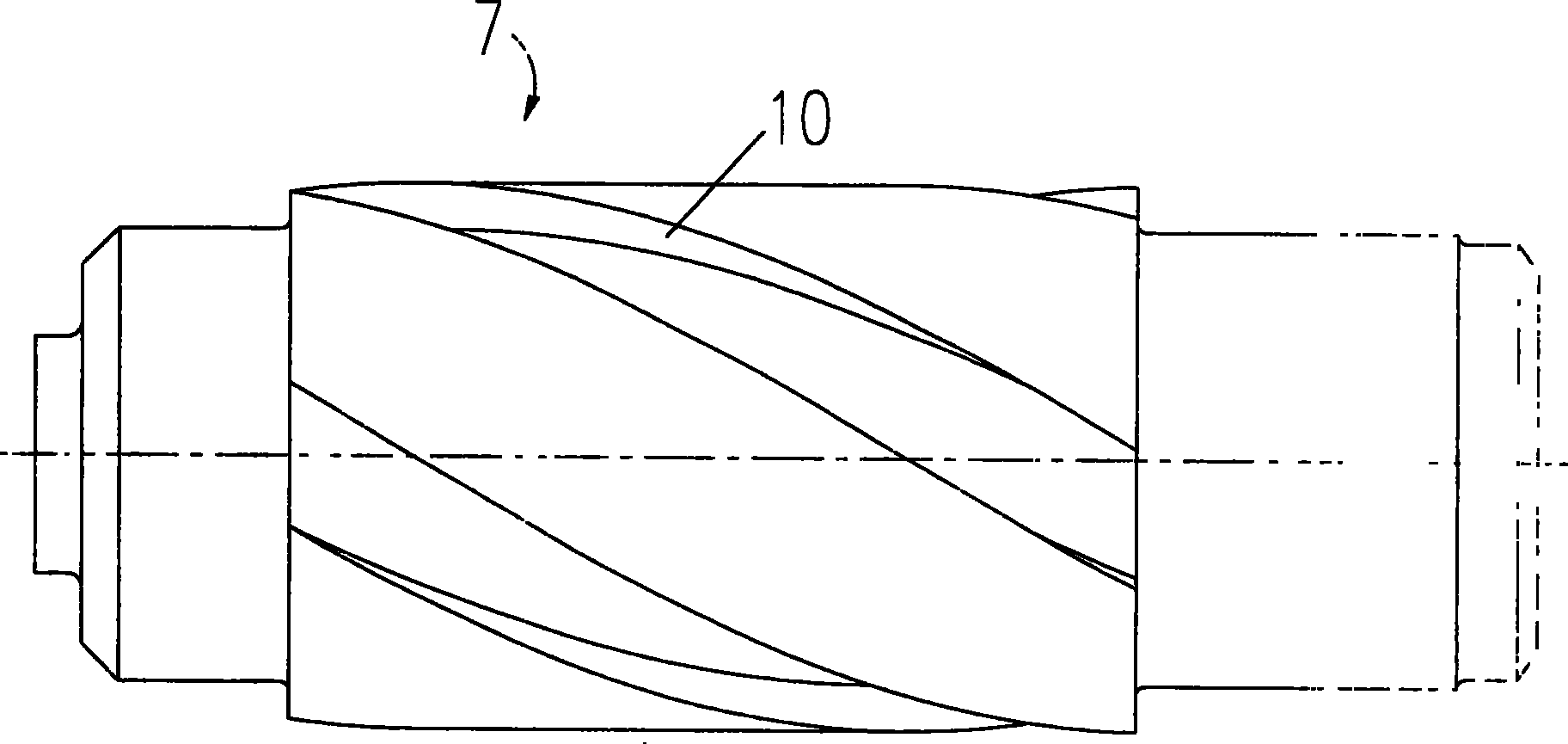

Fuel oil atomizing device

InactiveCN102889615AReduce axial jet velocityIncrease the average areaContinuous combustion chamberCombustion typesCombustionFuel oil

The invention relates to a fuel oil atomizing device which comprises an evaporation pipe, an air cup and an oil rotating device, wherein the evaporation pipe is formed by three sections of reversed-L-shaped pipes which form angles of 90 degrees; the oil rotating device is arranged at the inner part of a fuel oil outlet of the evaporation pipe; 4-6 spiral grooves are arranged on the outer surface of the oil rotating device; the air cup is mounted at the outer part of the evaporation pipe at the fuel oil inlet; a cup opening of the air cup is leveled with the fuel oil inlet of the evaporation pipe; and an air outlet is arranged on the side wall of the air cup. The fuel oil atomizing device disclosed by the invention realizes the aim of sufficiently atomizing under the condition of a very short oil mist range so that the evaporation rate is improved and good conditions are provided for stable and efficient combustion.

Owner:HARBIN DONGAN ENGINE GRP

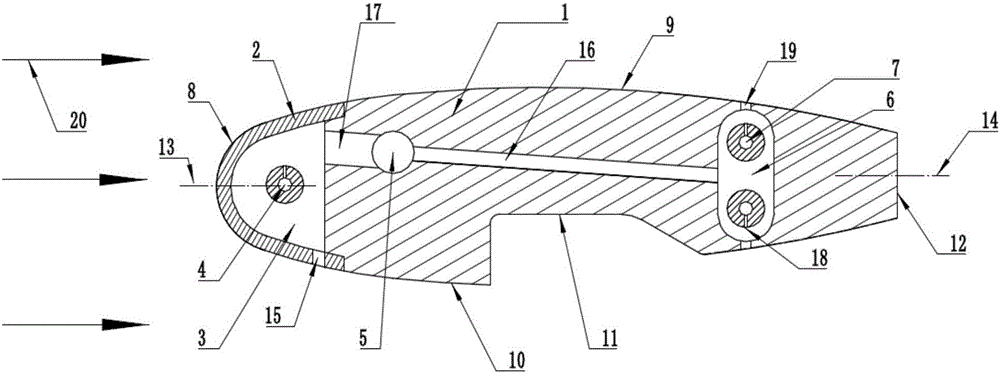

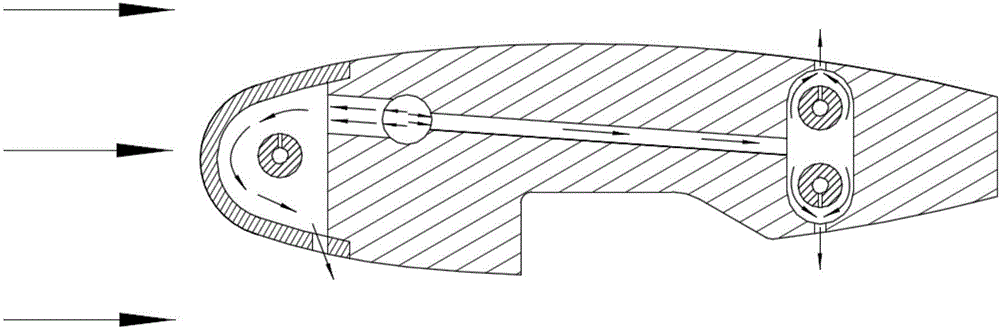

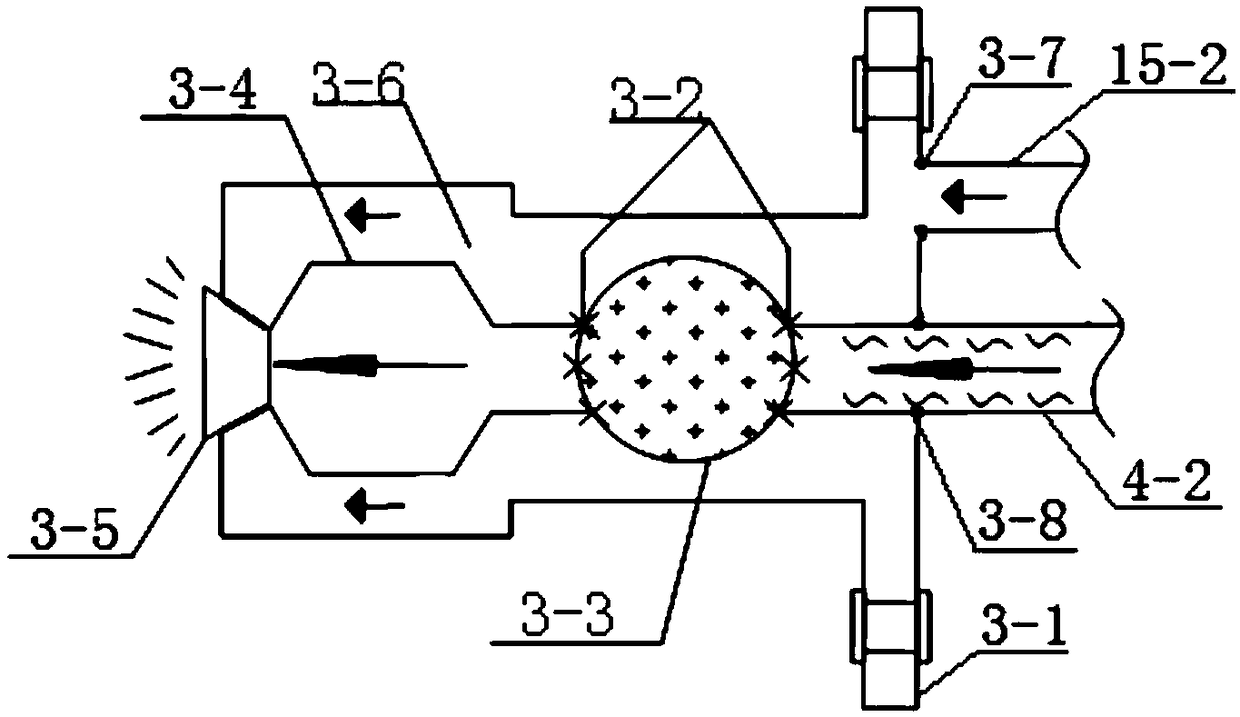

Flame stabilizing device for TBCC subsonic combustion ramjet engine combustion chamber

ActiveCN106642202AImprove atomization effectReliable ignitionContinuous combustion chamberRamjetCombustion chamber

The invention provides a flame stabilizing device for a TBCC subsonic combustion ramjet engine combustion chamber. The flame stabilizing device for the TBCC subsonic combustion ramjet engine combustion chamber comprises a supporting plate, a cover hood and an on-duty fuel injector bar. The supporting plate and the cover hood are connected together to form a cavity, the on-duty fuel injector bar is arranged in the cavity, the supporting plate has an upper surface and a lower surface, the lower surface has a concave cavity while the upper surface has a convex cavity, the supporting plate has a front cavity and a back cavity, the front cavity is located between the cavity and the back cavity, the front cavity is used for introducing cooling gas, a primary oil way fuel injector bar is arranged in the back cavity, a cooling gas round channel communicating the front cavity with the back cavity is formed between the front cavity and the back cavity, and a cooling gas round channel communicating the front cavity with the cavity is formed between the front cavity and the cavity. By reasonably arranging the fuel supply positions of the on-duty fuel injector bar and the primary oil way and improving the atomizing effect by way of various modes such as pressure atomization, pneumatic atomization and colliding atomization, the ignition property of the TBCC subsonic combustion ramjet engine combustion chamber is improved, the combustion property in a wide range is considered, and the integral property of the TBCC subsonic combustion ramjet engine combustion chamber is improved.

Owner:中航空天发动机研究院有限公司

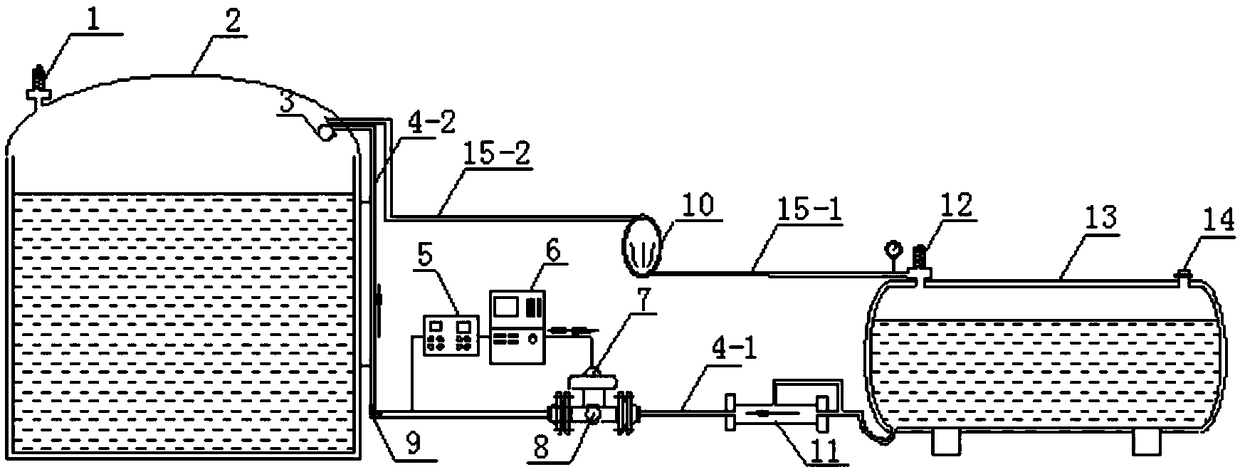

Automatic liquid nitrogen fire-extinguishing and explosion-suppressing system for oil tank region

ActiveCN106552386AAdequate heat and mass transferEfficient atomizationFire rescueGlass ballFire detector

The invention discloses an automatic liquid nitrogen fire-extinguishing and explosion-suppressing system for an oil tank region. The automatic liquid nitrogen fire-extinguishing and explosion-suppressing system comprises a liquid nitrogen storage station, a low-temperature liquid nitrogen booster pump and a monitoring-jetting integrated box, wherein the monitoring-jetting integrated box comprises a housing, a glass ball expansive type constant-temperature fire detector with a glass ball fracture free surface, an expanding cavity and a horn-shaped outlet; the glass ball expansive type constant-temperature fire detector, the expanding cavity and the horn-shaped outlet define a low-temperature nitrogen gas cavity; the top of the liquid nitrogen storage station is connected with a self-lifting buffer tank through a gas exhaust interface; the self-lifting buffer tank communicates with the low-temperature nitrogen gas cavity through a housing upper interface; the low-temperature liquid nitrogen booster pump is connected with an inlet of a low-temperature ball valve; an outlet of the low-temperature ball valve is connected with the glass ball fracture free surface through a rear section of a gas storage tube; a connecting line is arranged on the rear section of the gas storage tube; a pressure feedback device, a fire-fighting linkage controller and an alarm are sequentially connected on the connecting line; and the alarm is connected with a control end of the low-temperature ball valve. The system can solve the fire efficient response problem, the liquid nitrogen effective conveying problem, the liquid nitrogen efficient atomizing problem and the liquid nitrogen diffusing problem, so that the purpose of automatically and efficiently suppressing explosion and extinguishing fire in an oil tank is achieved.

Owner:CHINA UNIV OF MINING & TECH

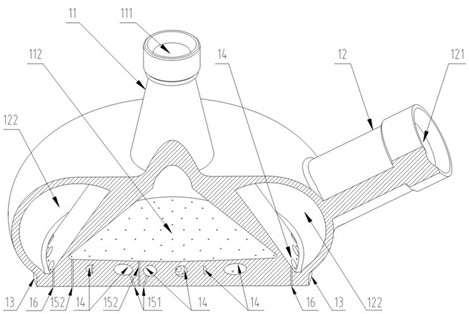

Fuel gas generator

The invention provides a fuel gas generator. The fuel gas generator is composed of an injector, an eccentric turbulent flow ring, a spherical-cone-shaped combustion chamber and a three-way bent pipe. The injector is in a round cake shape, the whole injector is printed through a 3D printer, the upper half part of the eccentric turbulent flow ring is a cylindrical ring, the top face of the cylindrical ring is fixedly welded with the edge of the bottom face of a lower boss of the injector, the bottom edge of the side face of the cylindrical ring is fixedly welded with the hole wall of a side hole of the spherical-cone-shaped combustion chamber, and the lower half part of the eccentric turbulent flow ring is a conical ring with an eccentric opening. The spherical-cone-shaped combustion chamber comprises a spherical cavity and a cone cavity, a side hole is formed in the side face of the spherical cavity, an outlet is formed in the top of the cone cavity and fixedly welded with a middle inlet of the three-way bent pipe, the three-way bent pipe is integrally in a side T shape, a left port is formed in the left side of the three-way bent pipe, a flange structure connection mode is adopted, a right port is formed in the right side of the three-way bent pipe, a middle inlet is formed in the middle part of the three-way bent pipe, and a boss positioning form is adopted. The structure of the fuel gas generator is optimized, propellants can be efficiently atomized, mixed and combusted, and the combustion efficiency is improved.

Owner:星河动力(北京)空间科技有限公司 +1

Gas phase auxiliary atomizing nozzle with built-in magnetization structure and atomizing method

PendingCN112974012AShorten the magnetization lengthPneumatic low pressureWater/sewage treatment by magnetic/electric fieldsLiquid spraying apparatusAtomizer nozzleGas phase

The invention discloses a gas phase auxiliary atomizing nozzle with a built-in magnetization structure and an atomizing method. The gas phase auxiliary atomizing nozzle comprises a cylindrical shell. A liquid inlet is formed in the first end of the shell, and a cyclone outlet is formed in the second end of the shell. An air inlet is formed in the middle of the side wall of the shell, the liquid inlet is provided with a tapered inner flow channel, the tapered inner flow channel communicates with the liquid inlet and a bubble-shaped flow outlet, an aeration hole is formed in the side wall of a diffusion section of the tapered inner flow channel, a magnetization cavity is formed in the outer side of the diffusion section, and a magnetization ring is arranged in the magnetization cavity. An air cavity is formed at the outer side of the magnetization cavity and the outer side of the aeration hole section, the air cavity communicates with the air inlet and the cyclone outlet, and the aeration hole communicates with the air cavity and the tapered inner flow channel. The bubble-shaped flow outlet communicates with the cyclone outlet. Rotational flow channels are uniformly arranged in the air cavity in the circumferential direction. The volume of a pre-magnetizer placed at the liquid inlet of the nozzle is reduced, the magnetization distance is shorter, the application scene is more flexible, the physical and chemical effect is better, and the gas phase auxiliary atomization condition and cost are reduced.

Owner:XI AN JIAOTONG UNIV

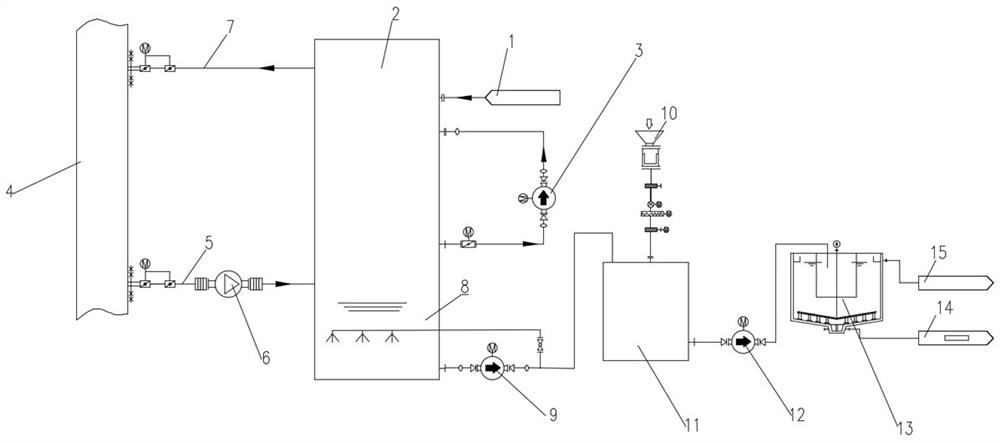

System for treating desulfurization wastewater by coupling low-temperature flue gas with dry slag waste heat and construction method of system

ActiveCN113277585AAchieve drying and curingAchieve concentration reductionGeneral water supply conservationSpecific water treatment objectivesPower stationWater vapor

The invention discloses a system for treating desulfurization wastewater by coupling low-temperature flue gas with dry slag waste heat and a construction method of the system. The system comprises a concentration and neutralization system for receiving desulfurization wastewater and a drying system connected to the concentration and neutralization system. Two kinds of power station waste heat are adopted, low-temperature flue gas at the temperature of 90-150 DEG C is firstly utilized to achieve concentration and reduction, then dry residue waste heat is utilized to achieve waste water drying and curing, drying and curing of the wastewater are achieved through a two-step method, and energy conservation and consumption reduction are achieved through matching and coupling of the two heat sources; through combined arrangement of a flue, a flue gas inlet pipe and a flue gas outlet pipe, after desulfurization wastewater is dried, crystal water enters flue gas for recycling in a water vapor form; the dried salt-containing powder is mixed with the dry slag, so that comprehensive utilization is realized; and waste heat of a slag well and an air temperature device are combined and utilized, and drying is optimized by cooperating with a dry slag conveyor, so that energy conservation and consumption reduction of the boiler are realized.

Owner:BEIJING GUODIAN LONGYUAN ENVIRONMENTAL ENG +1

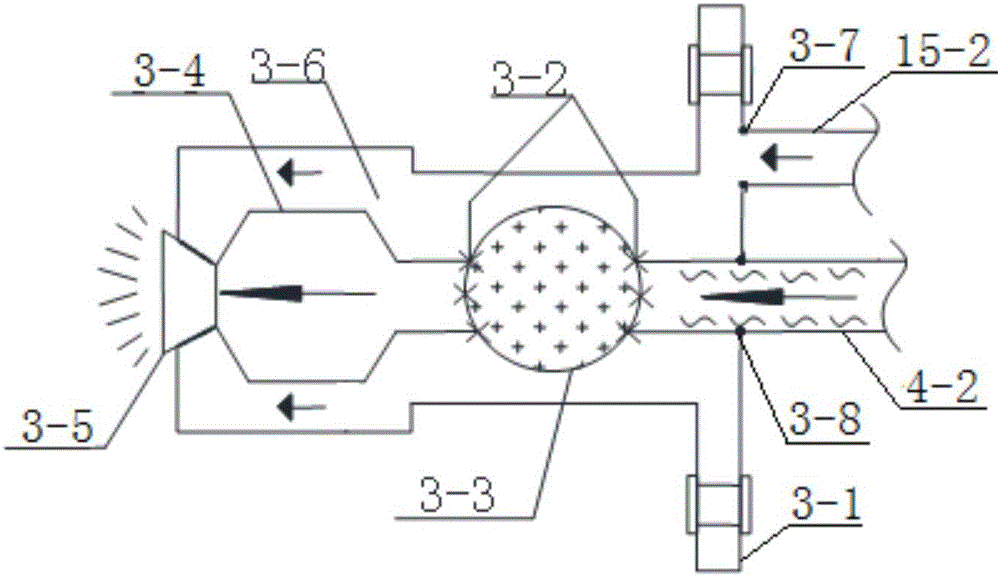

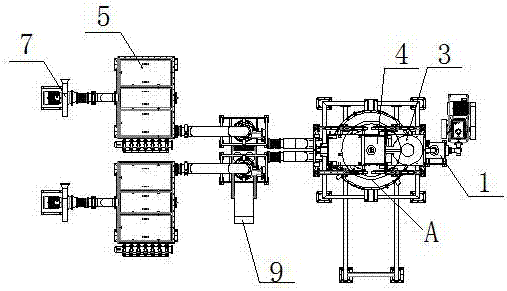

A Diesel Engine SCR Atomizer Used in Air-Assisted Mode

InactiveCN102278179ASimple structureChange structureExhaust apparatusSilencing apparatusNebulizerThermal insulation

The utility model relates to an SCR atomizer for a diesel engine in an air-assisted mode, which belongs to the technical field of diesel engine atomization devices. It includes a hollow pipeline, the top of the pipeline is connected with a pipe joint for connecting with an external device, the tail end of the pipeline is connected with a nozzle with a spray hole, and the pipe body of the pipeline is sleeved with a heat insulation shell for heat insulation. The above-mentioned SCR atomizer for diesel engine in the air-assisted mode has a simple structure and a reasonable design. It changes the structure of the electromagnetic nozzle in the atomizer in the prior art, and realizes the efficient atomization of the urea aqueous solution through the combination of a simple mechanical structure. Improve NOx conversion efficiency. Compared with the existing electromagnetic nozzle, the cost of the invention is reduced by more than 50%, the conversion efficiency of NOx is increased by more than 10%, high temperature resistance and high reliability.

Owner:ZHEJIANG BONDLYE ENVIRONMENTAL TECH CO LTD

Novel furnace-process carbon black production device and use method

ActiveCN114646192AShorten the lengthWell mixedPigmenting treatmentChemical industryEngineeringMachining

The invention discloses a novel furnace method carbon black production device and a using method, the novel furnace method carbon black production device comprises a T-shaped processing box body, the T-shaped processing box body is provided with a blower device and a refueling box body, and the interior of the T-shaped processing box body is provided with a processing cavity I, a processing cavity II, a processing cavity III and a processing cavity IV; a first vertical airtight partition plate is arranged in the first machining cavity and divides the first machining cavity into a first cavity section and a second cavity section, the first cavity section and the second cavity section are equal in size, a first transverse partition plate is arranged in the second cavity section, the second cavity section is divided into a third cavity section and a fourth cavity section through the first transverse partition plate, and the third cavity section and the fourth cavity section are arranged in the second cavity section. The size of the fourth cavity section is larger than that of the third cavity section, a first stirring device is arranged in the third cavity section, and a turbulence device is arranged in the fourth cavity section. The granulating machine has the beneficial effects that the structure is compact, the working intensity of workers is relieved, and the granulating efficiency is improved.

Owner:FENGCHENG HEIBAO CARBON BLACK

Nozzle for minisize gas-turbine combustor

ActiveCN101206029BReduce manufacturing costThe atomization effect remains unchangedBurnersContinuous combustion chamberCombustion chamberCombustor

Owner:江苏中国科学院能源动力研究中心 +1

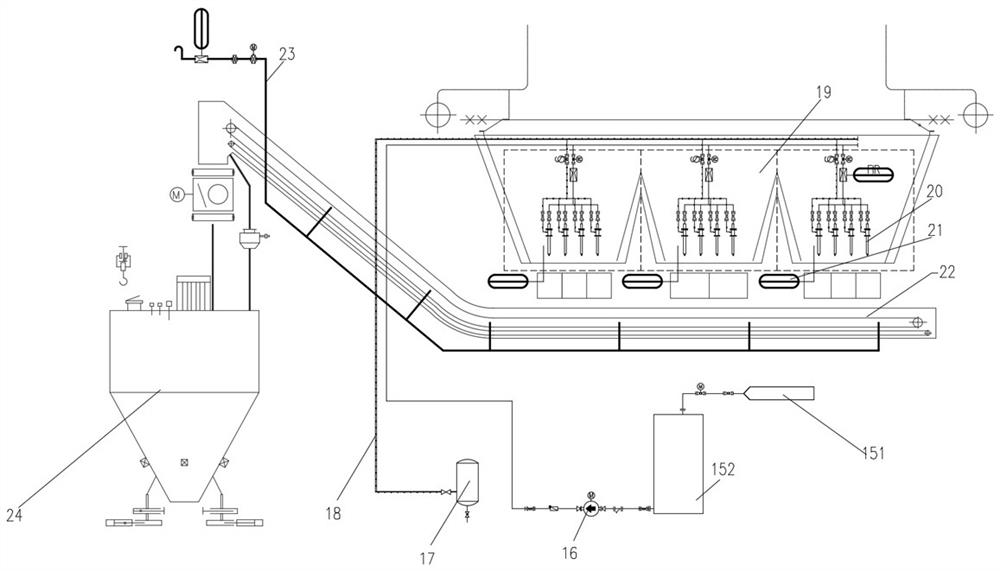

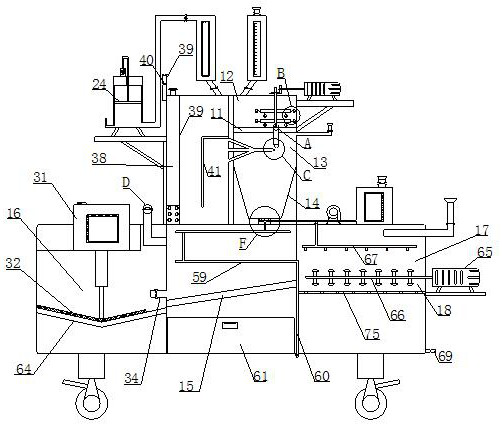

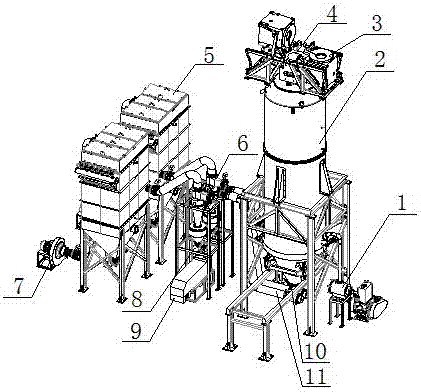

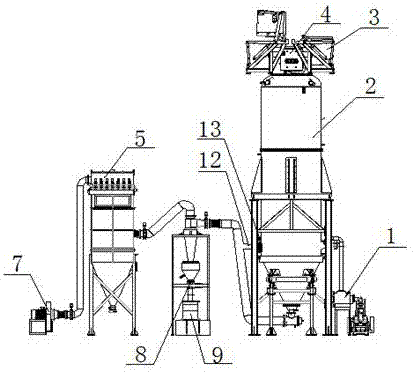

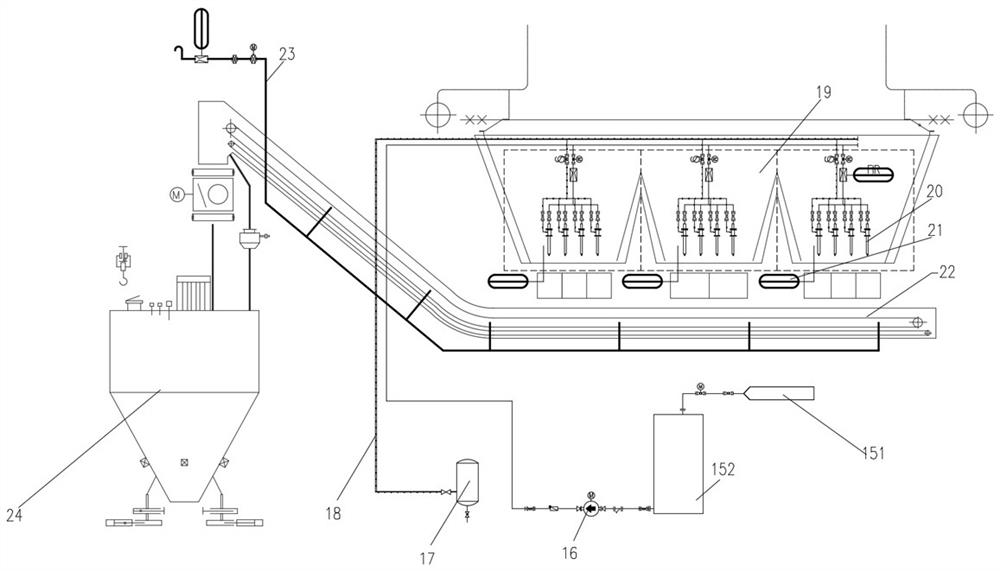

Large-yield efficient gas atomization powder manufacturing apparatus

The invention provides a large-yield efficient gas atomization powder manufacturing apparatus which comprises a smelting system, an atomization system, a powder feeding system, a dust removal system, a screening system and a vacuum-pumping system. The smelting system comprises two or more smelting furnace; the atomization system comprises a transition material bag and an atomization tower; and the powder feeding system, the dust removal system and the screening system are sequentially connected. The powder feeding system comprises a herringbone connector, an air pipe and an air pipe branch pipe. The design of multiple smelting furnaces, dual pipes, dual dust removal equipment and the like are adopted, when one of the dual facilities breaks down, equipment use is not influenced, the halt production maintaining risk is greatly decreased, and atomization powder manufacturing of 2-5 t / furnace can be achieved; and according to the vacuum-pumping system, an atomization chamber is pumped to be vacuum before atomization, filling of protective atmosphere is then carried out, the oxygen content in the atomization environment is reduced to a large extent, and the oxygen content in the powder is reduced.

Owner:湖南旭博冶金科技有限公司

Medical administration atomizing cup

PendingCN108704202AEfficient atomizationFast intersectMedical devicesMedical atomisersEngineeringAirflow

The invention relates to a medical administration atomizing cup. The medical administration atomizing cup comprises an atomizing cup body and is characterized in that the atomizing cup body comprisesan upper cup body and a lower cup body and is characterized in that the lateral wall of the upper cup body is provided with a mist outlet, the top of the upper cup body is provided with an air inlet,an adjusting valve cover is arranged on the air inlet, the inner side of the air inlet extends downwardly to form an air inlet tube, the lateral wall on one side, away from the mist outlet, of the airinlet tube is provided with an air inlet, and the bottom of the air inlet tube is provided with a mist blocking plate; the center of the bottom of the lower cup body is provided with an air inlet nozzle, the air inlet nozzle faces the mist blocking plate, and a space between the lower cup body bottom on the outer side of the air inlet nozzle and the lateral part of the lower cup body forms a medicine storage groove; the top of the air inlet nozzle is provided with an air inlet hole, a flow forming cover wraps the air inlet nozzle and is detachably connected with the air inlet nozzle, the topof the flow forming cover is provided with a jet hole directly facing the air inlet hole, the inner wall of the flow forming cover is provided with a liquid suction groove, and the liquid suction groove and the outer wall of the air inlet nozzle jointly form a liquid suction channel. By the structure, the medical administration atomizing cup has the advantages that liquid medicine is finely atomized by the high-speed movement of air flow, and noise during atomizing is lowered.

Owner:威海盛洁医疗科技有限公司

Low temperature flue gas coupling dry slag waste heat treatment desulfurization wastewater system and its construction method

ActiveCN113277585BAchieve drying and curingAchieve concentration reductionGeneral water supply conservationSpecific water treatment objectivesPower stationWater vapor

The invention discloses a low-temperature flue gas coupling dry slag waste heat treatment desulfurization wastewater system and a construction method thereof. The system includes a concentration neutralization system for receiving desulfurization wastewater and a drying system connected to the concentration neutralization system; the invention uses two kinds of power station waste heat, First use the low-temperature flue gas at 90-150°C to achieve concentration and weight reduction, and then use the waste heat of dry slag to dry and solidify the wastewater. The two-step method realizes the drying and solidification of wastewater. Through the matching and coupling of the two heat sources, energy saving and consumption reduction are realized; through The flue, the flue gas inlet pipe and the flue gas outlet pipe are jointly installed. After the desulfurization wastewater is dried, the crystal water enters the flue gas in the form of water vapor for reuse; and the dried salt powder is mixed into the dry residue to realize comprehensive utilization; Combining the waste heat of the slag well, the air temperature device and the optimization of drying with the dry slag conveyor, the energy saving and consumption reduction of the boiler are realized.

Owner:BEIJING GUODIAN LONGYUAN ENVIRONMENTAL ENG +1

A liquid nitrogen automatic fire extinguishing and explosion suppression system in an oil tank area

The invention discloses an automatic liquid nitrogen fire-extinguishing and explosion-suppressing system for an oil tank region. The automatic liquid nitrogen fire-extinguishing and explosion-suppressing system comprises a liquid nitrogen storage station, a low-temperature liquid nitrogen booster pump and a monitoring-jetting integrated box, wherein the monitoring-jetting integrated box comprises a housing, a glass ball expansive type constant-temperature fire detector with a glass ball fracture free surface, an expanding cavity and a horn-shaped outlet; the glass ball expansive type constant-temperature fire detector, the expanding cavity and the horn-shaped outlet define a low-temperature nitrogen gas cavity; the top of the liquid nitrogen storage station is connected with a self-lifting buffer tank through a gas exhaust interface; the self-lifting buffer tank communicates with the low-temperature nitrogen gas cavity through a housing upper interface; the low-temperature liquid nitrogen booster pump is connected with an inlet of a low-temperature ball valve; an outlet of the low-temperature ball valve is connected with the glass ball fracture free surface through a rear section of a gas storage tube; a connecting line is arranged on the rear section of the gas storage tube; a pressure feedback device, a fire-fighting linkage controller and an alarm are sequentially connected on the connecting line; and the alarm is connected with a control end of the low-temperature ball valve. The system can solve the fire efficient response problem, the liquid nitrogen effective conveying problem, the liquid nitrogen efficient atomizing problem and the liquid nitrogen diffusing problem, so that the purpose of automatically and efficiently suppressing explosion and extinguishing fire in an oil tank is achieved.

Owner:CHINA UNIV OF MINING & TECH

Spray desuperheater

InactiveCN101979918BImprove heat transfer efficiencyImprove spraying effectSuperheating controlBoiler plantEngineering

Owner:FEICHENG BAIZHUANG COAL MINE +2

A Solid Cone Bubble Atomizing Nozzle Suitable for High Viscosity Non-Newtonian Fluids

ActiveCN103372509BEfficient atomizationLow gas consumptionLiquid spraying apparatusEngineeringNon-Newtonian fluid

The invention relates to a solid cone-shaped bubble atomizing nozzle suitable for high-viscosity non-Newtonian fluids, which includes an inner interface, an outer interface, a sleeve, a bubble generator, a mixer and a spray head, and the inner interface is fixed on the side of the mixer through the sleeve. One end, the nozzle is fixed on the other end of the mixer, the external interface is fixed on the mixer, and the bubble generator is set in the mixer; the bubble generator includes a guide tube and a guide plate fixed on the guide tube, and the guide plate The inner cavity of the mixer is divided into the outer flow channel and the mixing chamber. One end of the guide tube is connected to the inner interface through the sleeve, and the outer flow channel is connected to the outer interface. There are multiple outer guide holes evenly distributed on the circumference of the guide plate, which are located in the mixing chamber. One end of the indoor guide tube is provided with a plurality of inner guide holes. The invention solves the technical problems of poor nozzle atomization effect, high atomization gas consumption rate and large average droplet size of the existing high-viscosity non-Newtonian fluid. quality.

Owner:NO 11 INST OF NO 6 ACADEMY OF CHINA AEROSPACE SCI & TECH

Ammonia selective catalytic reduction method for diesel injected by assistance of compressed natural gas

InactiveCN101749087BEmission reductionEfficient atomizationMethane captureInternal combustion piston enginesCompressed natural gasAtmospheric air

The invention belongs to the technical field of diesel tail gas aftertreatment, and in particular relates to an ammonia selective catalytic reduction method for a diesel injected by assistance of compressed natural gas. The method comprises the following steps: pumping urea out of a urea aqueous solution tank; filtering the urea, and delivering the urea to a urea gauger; introducing the compressed natural gas in a compressed natural gas tank into the urea gauger through a primary valve, mixing the compressed natural gas and urea solution, ensuring that the volume ratio of the compressed natural gas to the urea solution is 1:100-20 : 100, and primarily atomizing the urea solution; before the urea solution which is primarily atomized enters an exhaust pipe through a urea nozzle, mixing the compressed natural gas and urea solution which is primarily atomized, ensuing that the volumetric mixture ratio of the compressed natural gas to urea solution which is primarily atomized is 1:100-20:100 so as to improve the mixing uniformity and the atomization degree; decomposing the urea into NH3 and water at a high temperature in an exhaust pipe mixing zone, fully mixing the NH3 and the water and exhaust gas, introducing the mixture into an SCR selective catalytic reduction device; and in the SCR selective catalytic reduction device, reacting NH3 with NOx to generate ammonia gas and H2O, and then discharging the two into the atmosphere. The method realizes efficient atomization of the urea, also reduces the emission of the NOx by reduction through natural gas CH4, and improves the purifying effect on the diesel tail gas NOx.

Owner:TONGJI UNIV

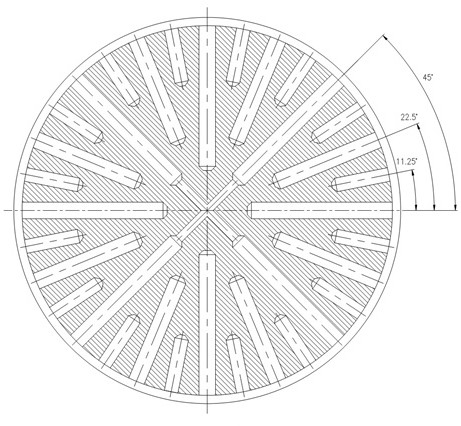

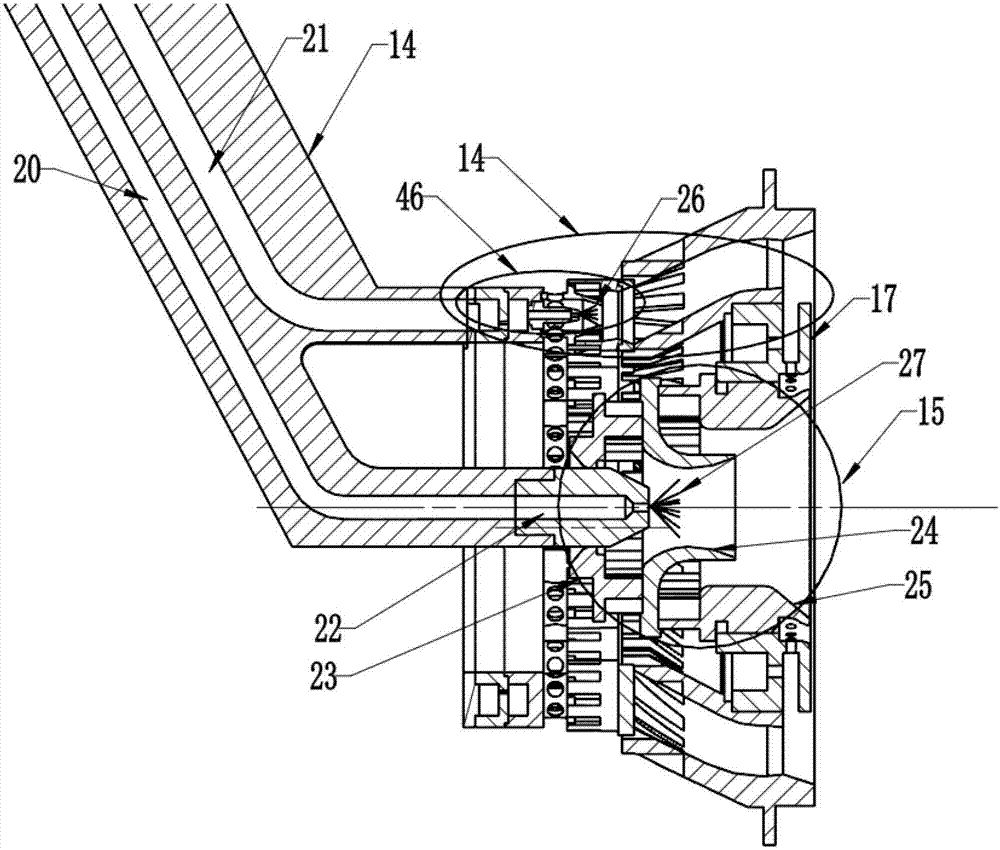

Premixing pre-evaporation low-pollution combustion chamber with multi-point axial double-stage air auxiliary atomizing nozzle main combustion stage

ActiveCN103185355BIncrease profitGuaranteed radial uniformityContinuous combustion chamberAviationCombustion chamber

The invention relates to a premixing pre-evaporation low-pollution combustion chamber with a multi-point axial double-stage air auxiliary atomizing nozzle main combustion stage, which adopts a single ring cavity structure. The combustion chamber adopts a staged combustion manner; the head of the combustion chamber is divided into a pre-combustion stage and the main combustion stage; the pre-combustion stage adopts a diffusion combustion manner, so that when combustion stability is ensured, pollutant discharge under the small working condition is reduced; and the main combustion stage adopts a premixing pre-evaporation combustion manner, so that combustion pollutants can be effectively reduced. According to the invention, the central staged structure is adopted and the pre-combustion stage has a simple structure; the main combustion stage adopts the scheme of combining a multi-point axial double-stage air auxiliary atomizing nozzle and a premixing pre-evaporation section and is positioned and installed by a main combustion stage spray nozzle installation ring; the main combustion stage has a simple structure; fuel is atomized, evaporated and mixed under the action of two strands of rotational flow and interacts with rotational flow air in the premixing pre-evaporation section to form a uniform fuel-gas mixture; and the premixing pre-evaporation low-pollution combustion chamber is beneficial to the pollutant discharge level of the integral landing and take-off cycle of an aircraft engine combustion chamber.

Owner:BEIHANG UNIV

Liquid medium atomizing method

InactiveCN105903589AAtomization high speedEfficient atomizationLiquid spraying apparatusMomentumLiquid medium

A liquid medium atomizing method relates to a method for atomizing a liquid medium. The invention aims to provide the liquid medium atomizing method which can realize high-speed and high-efficiency atomization of the liquid medium. The liquid medium atomizing method comprises the following steps: arranging a liquid passage for circulating the liquid medium; arranging a gas flow passage for circulating a gas medium; enabling the gas medium to flow at a high speed; and converging and mixing the liquid medium and the gas medium so as to atomize the liquid medium by virtue of the high-speed / momentum characteristic of the gas medium.

Owner:BEIJING INST OF SPACE LAUNCH TECH +1

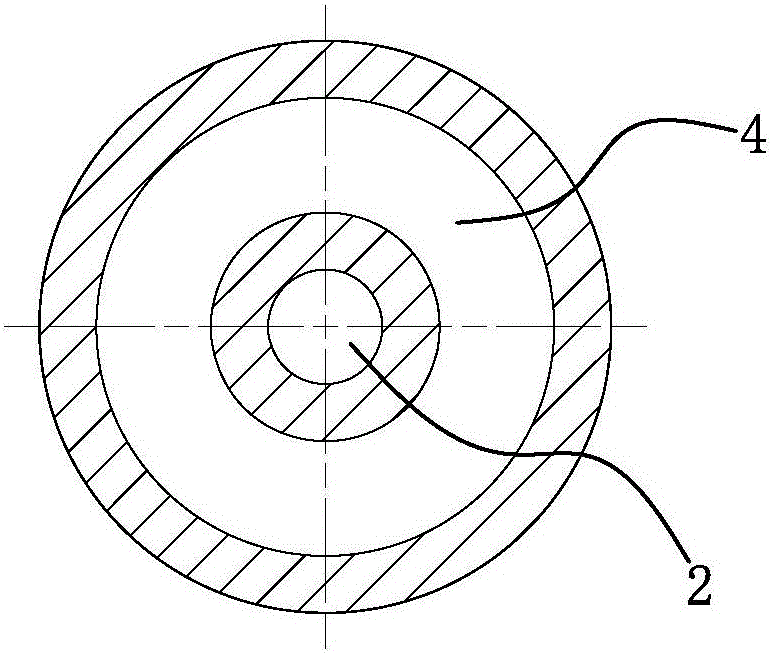

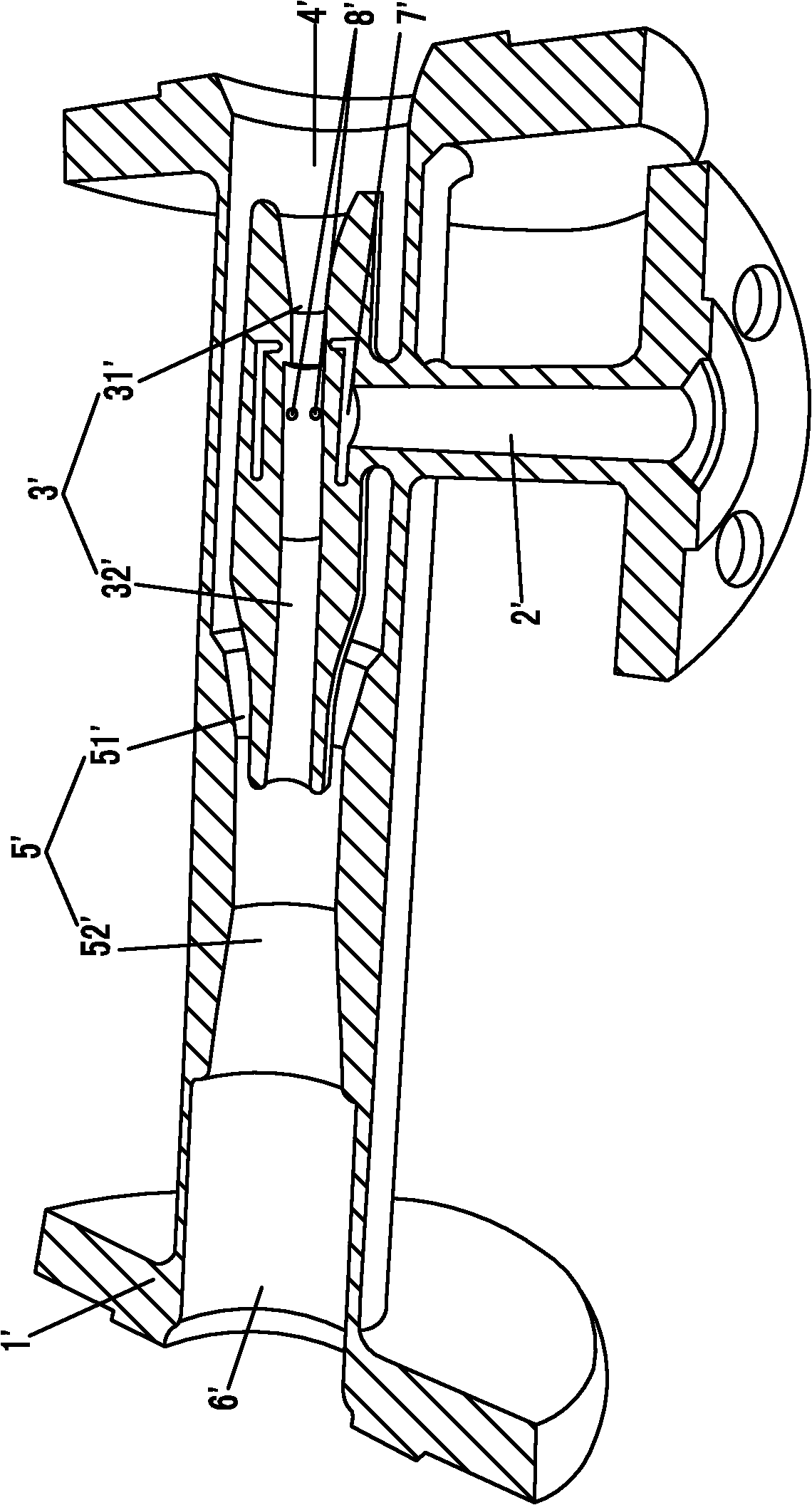

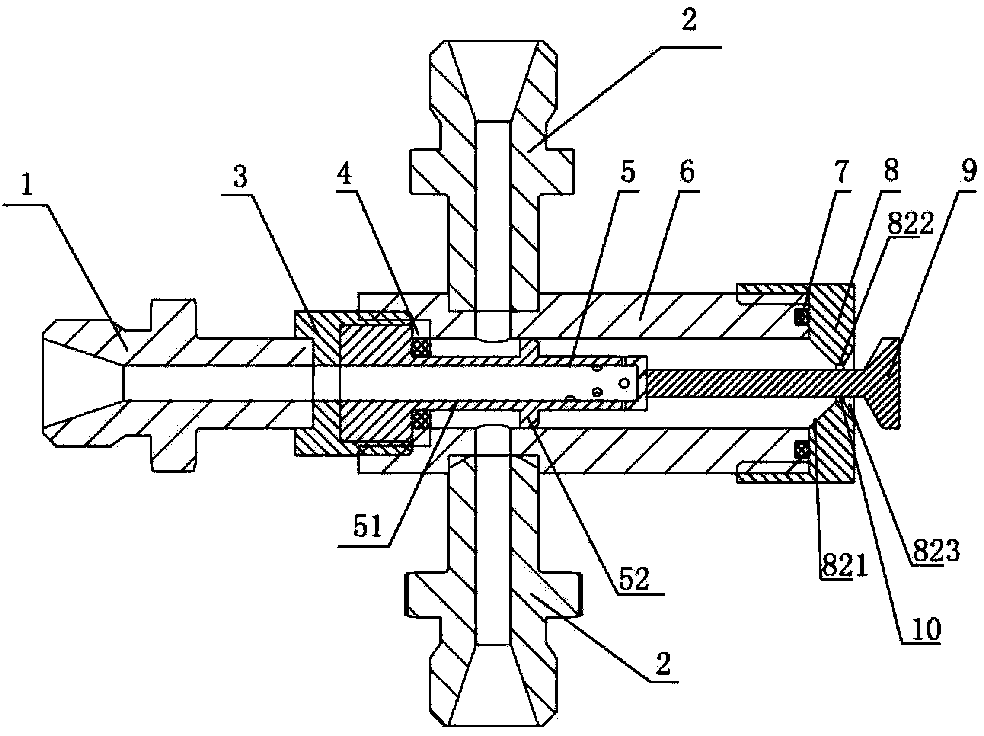

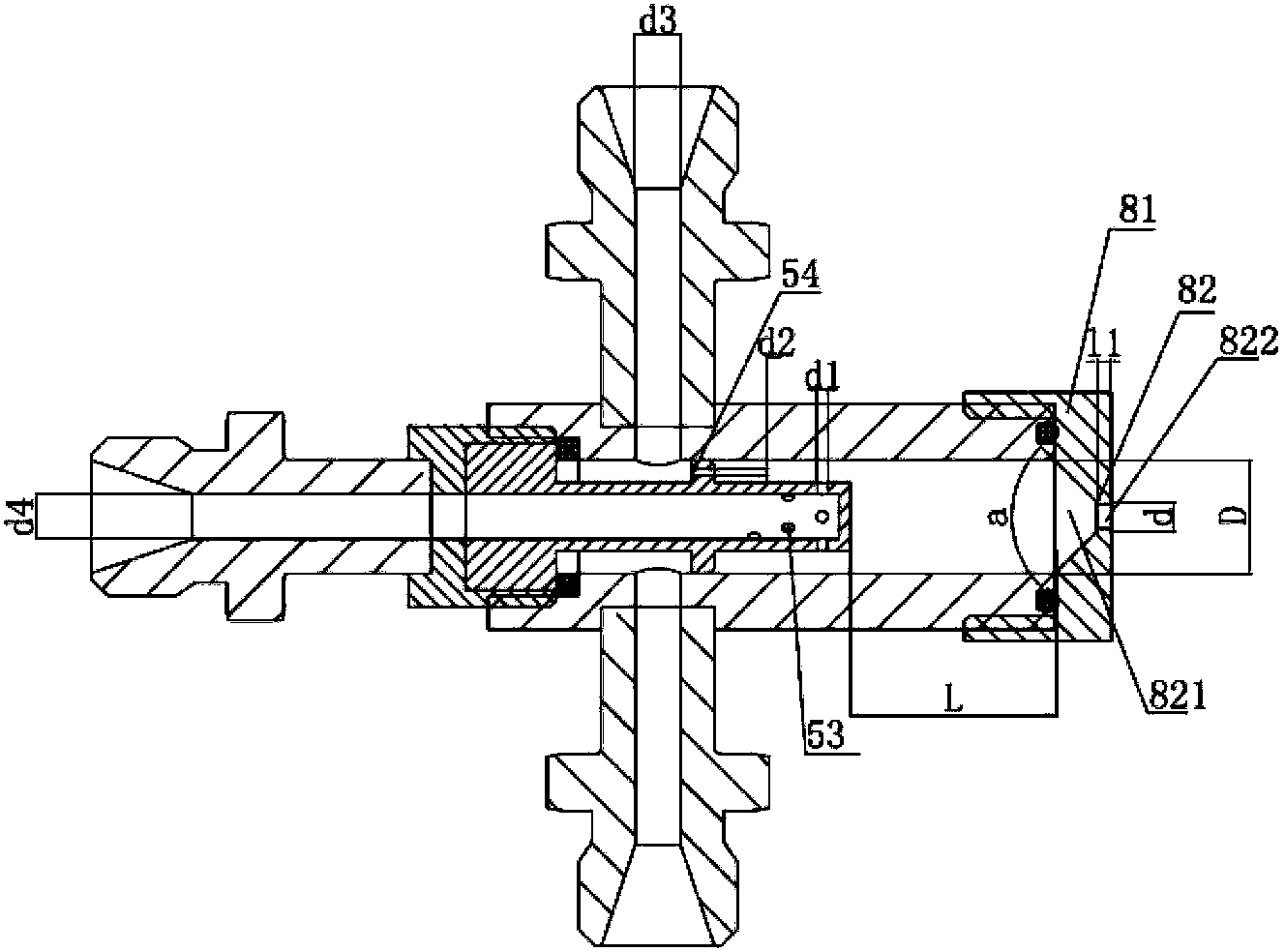

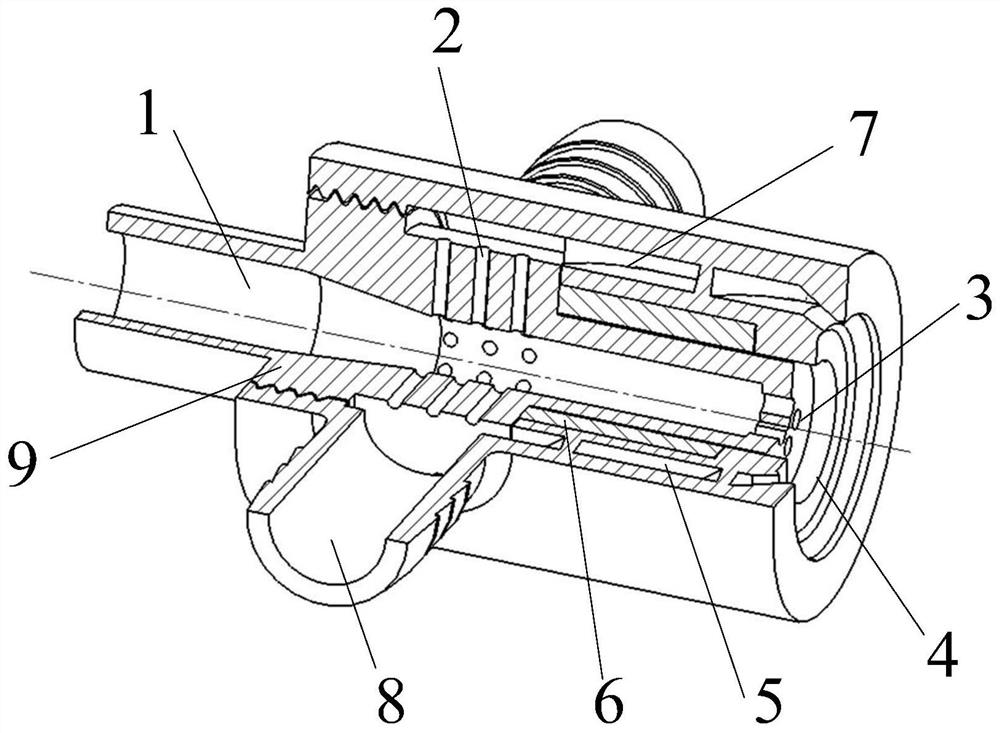

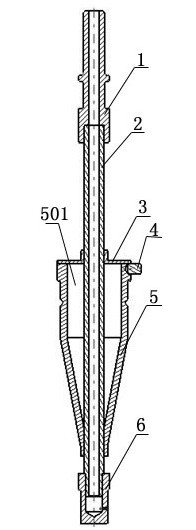

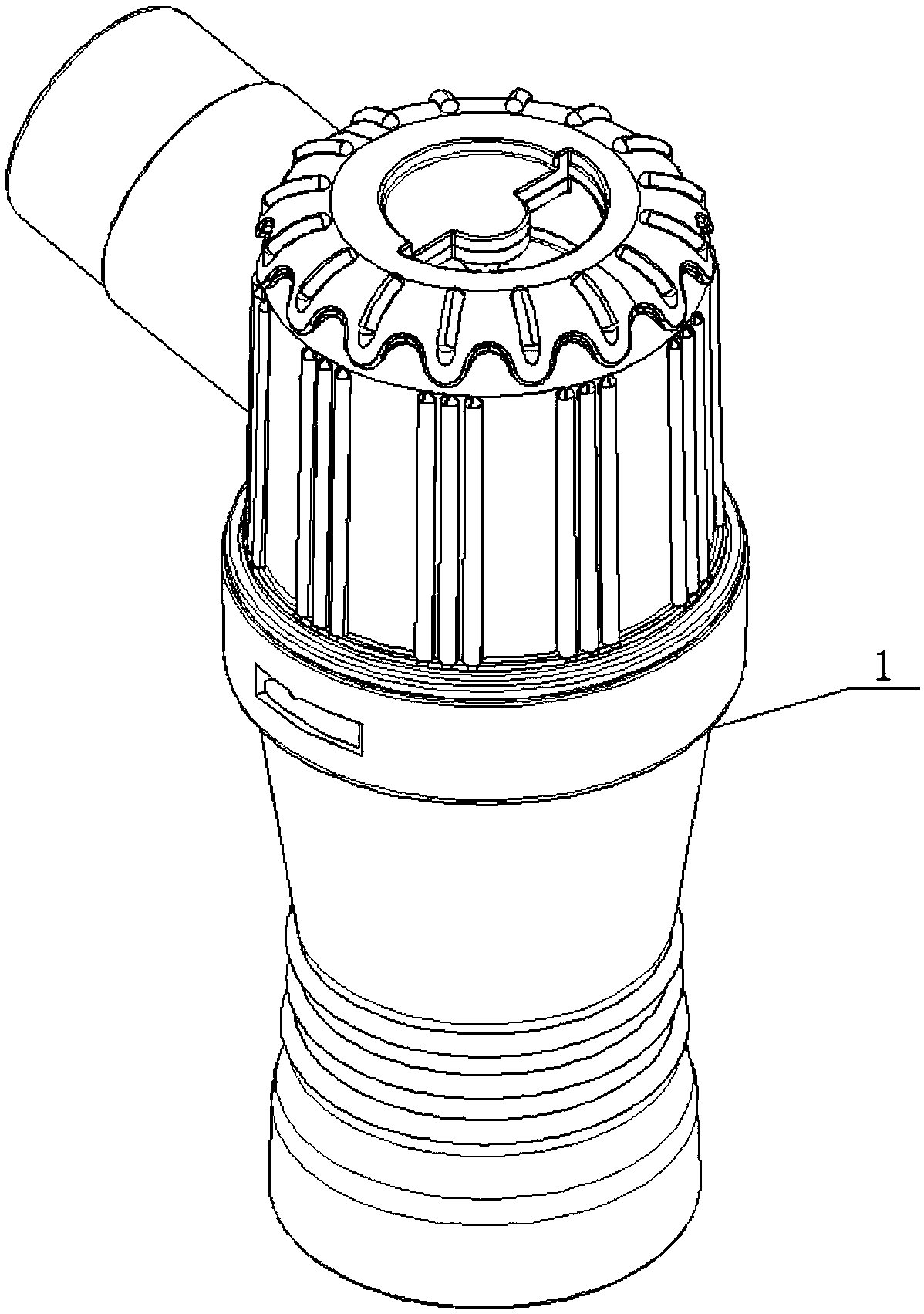

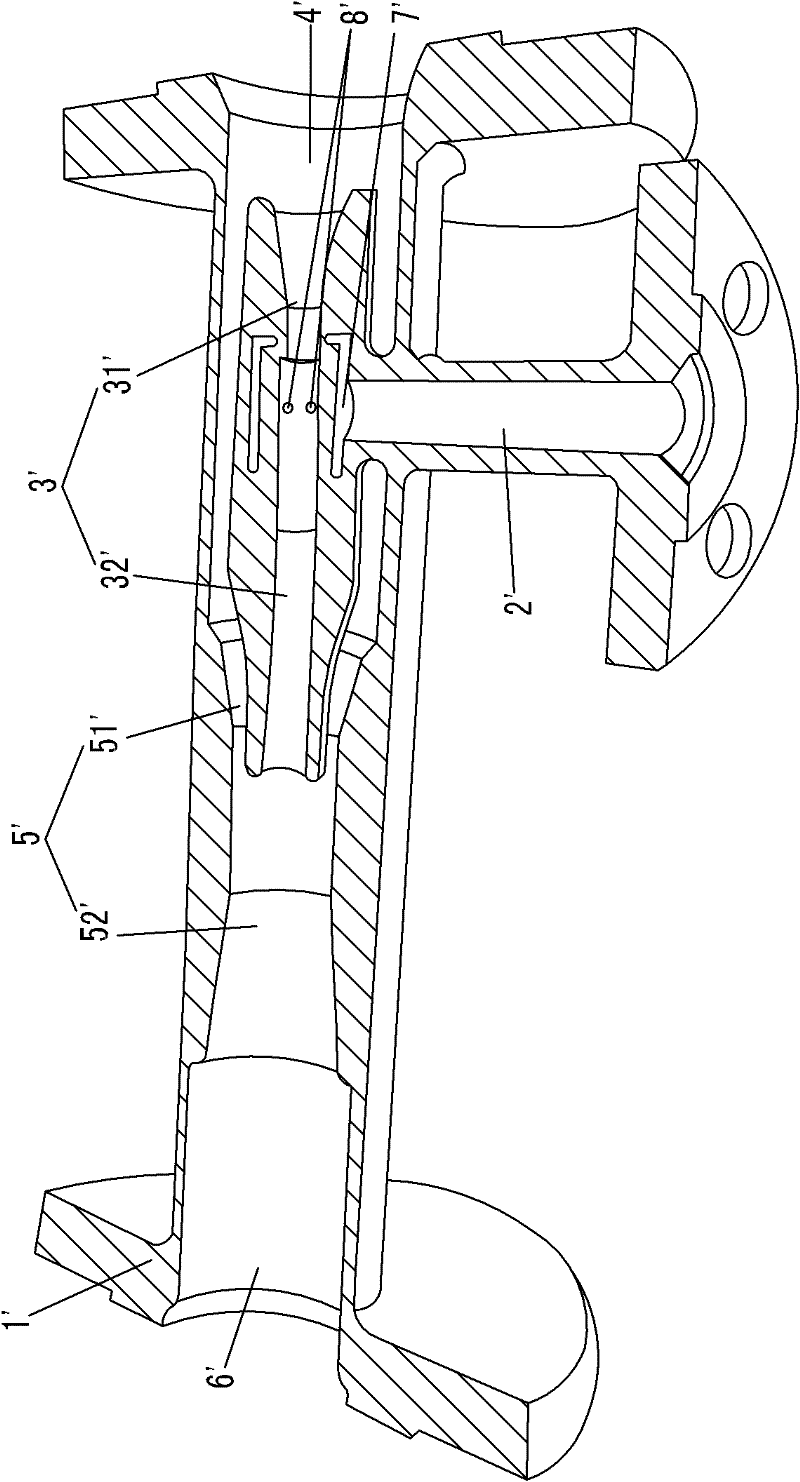

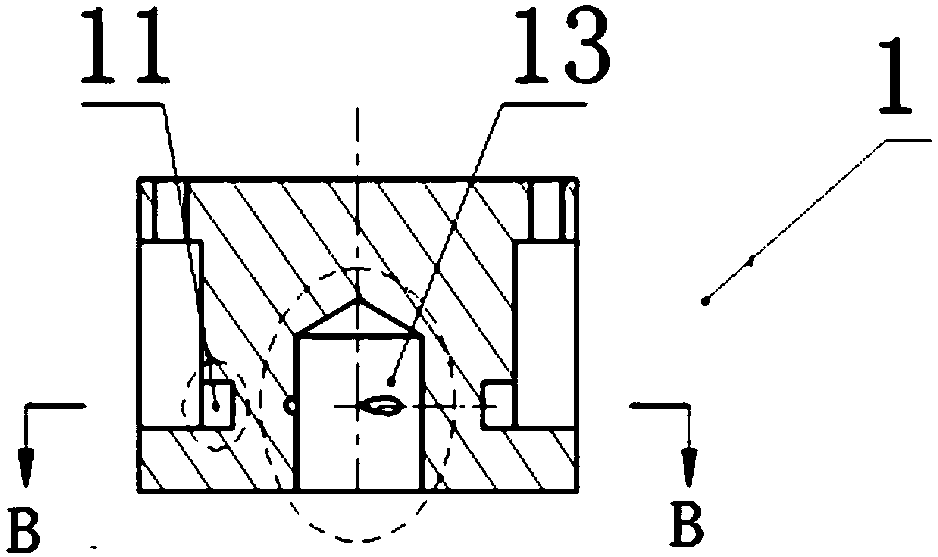

Anti-backfire nozzle for rocket engine

ActiveCN106762225BStop the spreadAnti-tempering functionRocket engine plantsCombustionThermal insulation

The invention provides an anti-backfire nozzle for a rocket engine. The anti-backfire nozzle comprises a rotary core body (1), an anti-backfire ring (2) and a shell (3); the anti-backfire ring (2) is arranged between the rotary core body (1) and the shell (3); the inner wall face and the outer wall face of the anti-backfire ring (2) cling to the outer wall face of the rotary core body (1) and the inner wall face of the shell (3) respectively; a liquid propellant storing and distributing cavity (11), a tangential hole (12) and a swirl chamber (13) are formed in the rotary core body (1); the shell (3) is provided with a nozzle exit (31) and a thermal insulation material (32); and a propellant flows along a flowing passage defined by the anti-backfire ring (2), the liquid propellant storing and distributing cavity (11), the tangential hole (12), the swirl chamber (13) and the nozzle exit (31), is uniformly distributed and shunted by the liquid propellant storing and distributing cavity (11), forms uniform conical mist spray at the outlet of the nozzle exit and is atomized. The anti-backfire nozzle has the advantages of simple structure, mature process and the like, has both the functions of backfire resistance and efficient combustion and is suitable for other engines and combustion devices with high requirements on performance and easiness in generating backfire.

Owner:SHANGHAI INST OF SPACE PROPULSION

A Hollow Cone Bubble Atomizing Nozzle for High Viscosity Non-Newtonian Fluids

ActiveCN103372510BSmall atomization effectEfficient atomizationSpray nozzlesLiquid spraying apparatusSpray nozzleEngineering

The invention relates to a hollow conical bubble atomizing nozzle applicable to high-viscosity non-Newtonian fluid. The hollow conical bubble atomizing nozzle comprises an inner connector, an outer connector, a sleeve, a bubble generator, a mixer, a sprayer and a needle-shaped cone; the inner connector is fixed to one end of the mixer by the aid of the sleeve, the sprayer is fixed to the other end of the mixer, the outer connector is fixed onto the mixer, and the bubble generator is arranged in the mixer; the bubble generator comprises a flow guide barrel and a flow guide plate, the flow guide barrel is communicated with the inner connector, an outer flow channel is communicated with the outer connector, a plurality of outer flow guide holes are formed in the flow guide plate, and a plurality of inner flow guide holes are formed in a mixing chamber; the sprayer comprises a sprayer body and a spray nozzle; an outlet circular seam is formed between the needle-shaped cone and a straight section of the sprayer. The hollow conical bubble atomizing nozzle has the advantages that technical problems of poor atomizing effect, high atomizing gas consumption rate and large average fluid drop diameter of an existing nozzle for high-viscosity non-Newtonian fluid are solved, the hollow conical bubble atomizing nozzle is excellent in atomizing quality within a wide flow regulation range, and the average diameter of fluid drops is greatly reduced under the condition of a low gas consumption rate.

Owner:NO 11 INST OF NO 6 ACADEMY OF CHINA AEROSPACE SCI & TECH

Adjustable high-efficient waste acid combined burner

The invention relates to an adjustable high-efficient waste acid combined burner which comprises a waste acid spray gun and a burner around the waste acid spray gun, wherein the waste acid spray gun comprises a waste acid inlet, a waste acid pipeline, an atomized gas inlet, an atomized gas pipeline, a mixer, a mixing cavity and a spray head; the atomized gas pipeline is arranged outside the wasteacid pipeline in a surrounding mode; one end of the atomized gas pipeline is connected with the atomized gas inlet, the other end of the atomized gas pipeline is open at the mixer, one end of the waste acid pipeline is connected with the waste acid inlet, the other end of the waste acid piple is open at the mixer, and the mixer is arranged at the back end part of the mixing cavity and open at themixing cavity; the spray head is arranged at the front end part of the mixing cavity; and the burner comprises a combustion-supporting air cavity, a fuel gas pipeline, an adjustable needle cone, an adjustable needle cone disk and a pre-combustion chamber. By utilizing the adjustable high-efficient waste acid combined burner, the technical problems in the background art is solved, and work reliably when the flow rate of waste acid changes between 30% and 100%, and has the characteristics of high combustion efficiency, controllable cracking temperature, good waste acid atomization, fast decomposition, compact layout and the like.

Owner:XIAN AEROSPACE SOURCE POWER ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com