Spray desuperheater

A water spray desuperheating and desuperheater technology, which is applied in the control of superheat temperature, steam superheating, steam generation, etc., can solve the problems of large volume, complex manufacturing process and low heat exchange efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

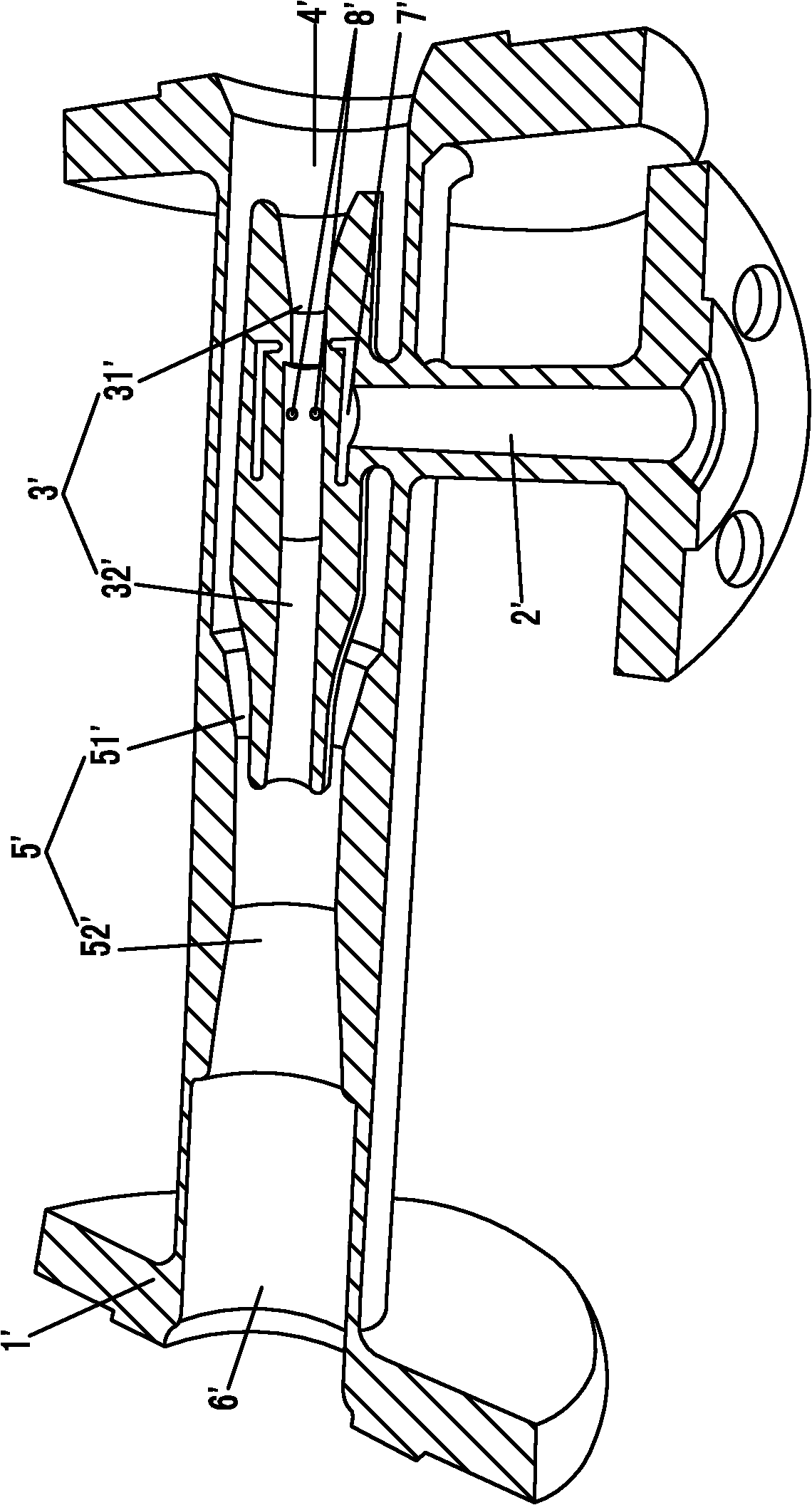

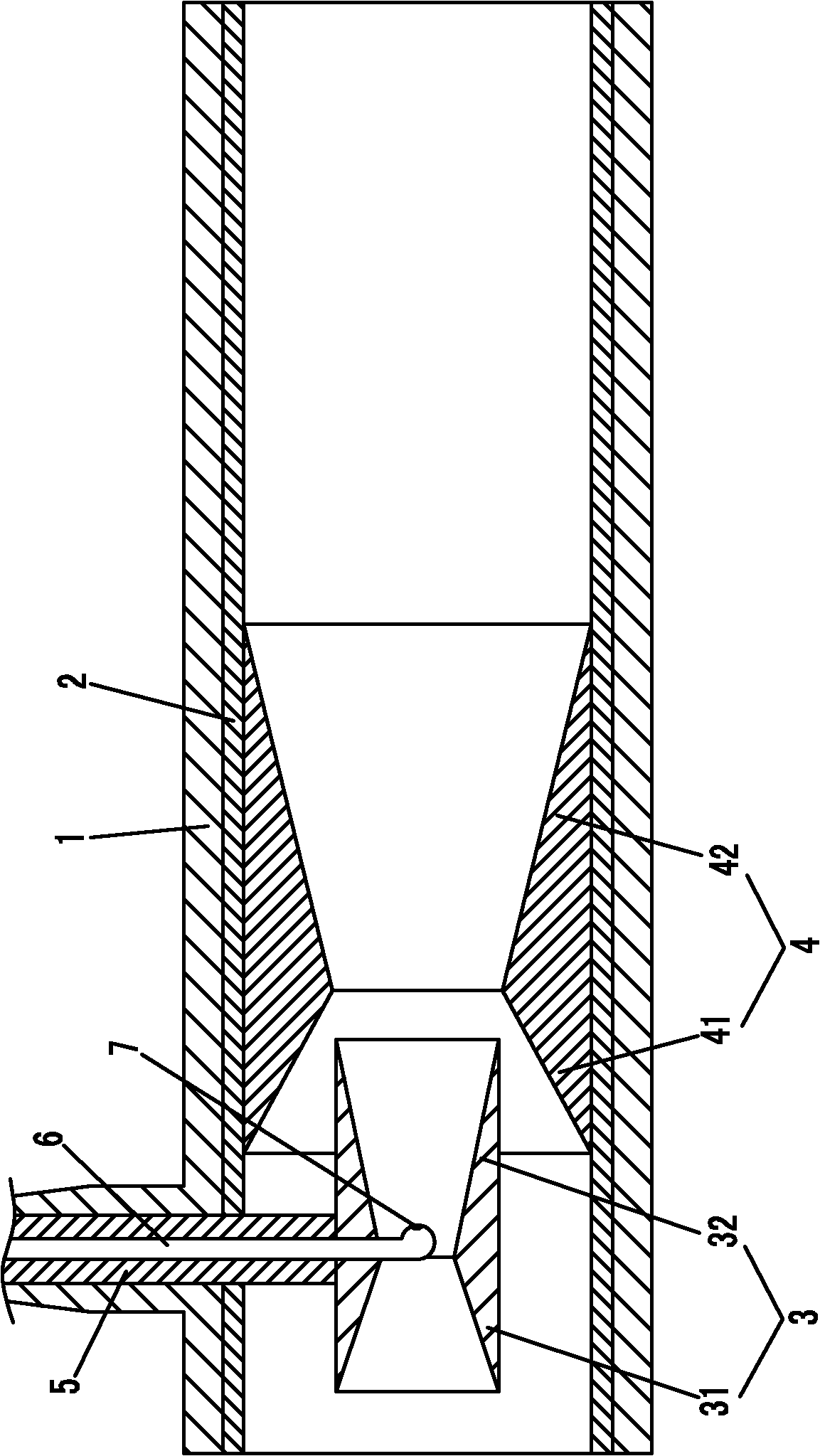

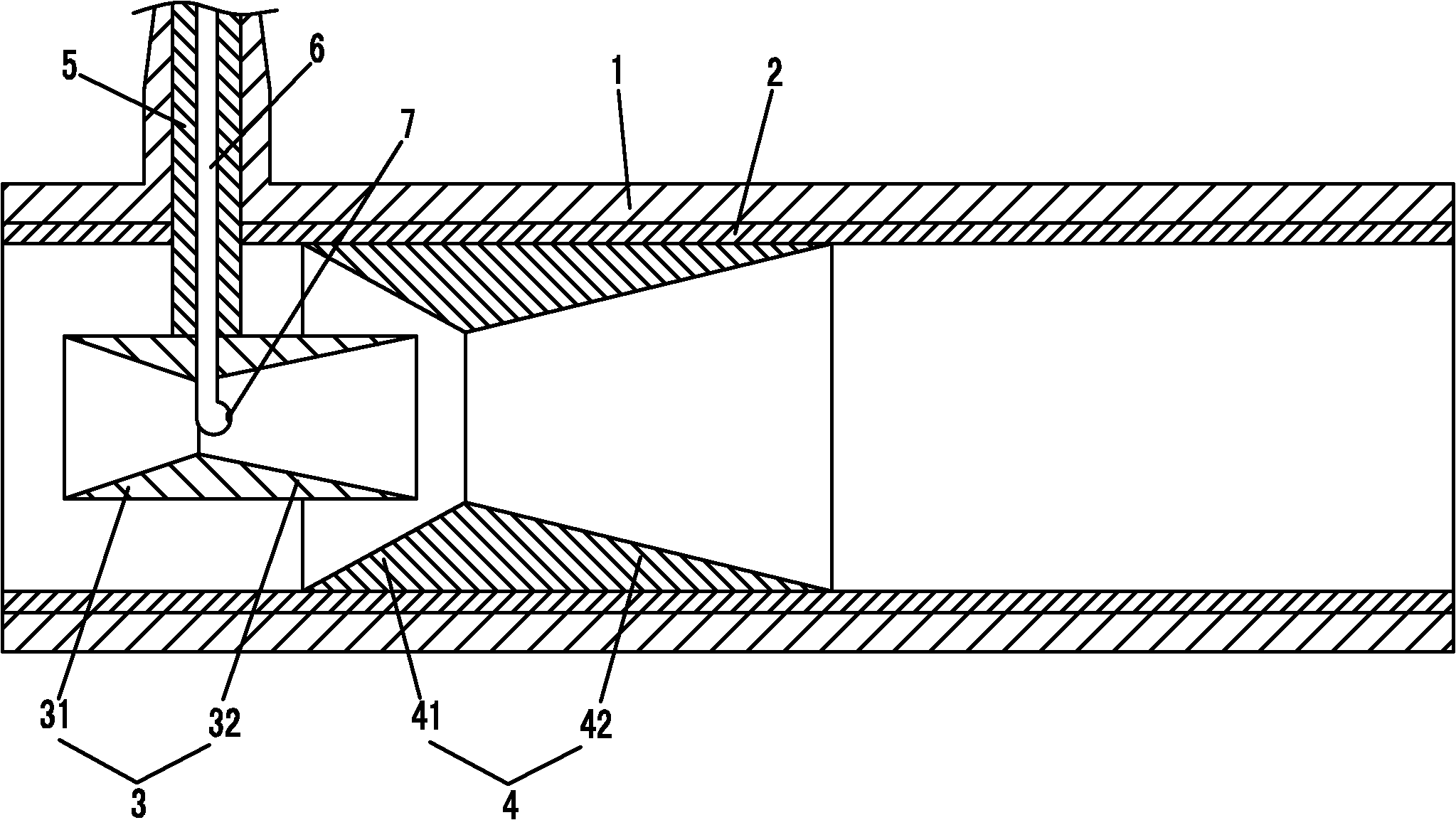

[0012] see figure 2 As shown, the spray desuperheater of the present invention includes a tubular desuperheater header 1, an inner sleeve 2, a first-stage Venturi tube 3, a second-stage Venturi tube 4, a cooling water pipe 5 and an L-shaped centrifugal Nozzle 6;

[0013] The inner sleeve 2 is sleeved in the inner cavity of the desuperheater header 1, the first-stage Venturi tube 3 and the second-stage Venturi tube 4 are sleeved in the inner cavity of the inner sleeve 2, and the first-stage Venturi tube 3 It is composed of the necking section 31 on the left and the flared section 32 on the right. The second-stage Venturi tube 4 is composed of the necking section 41 on the left and the flared section 42 on the right. The first-stage Venturi tube 3 The right end of the flaring section 32 on the right extends from the left end of the second-stage Venturi tube 4 into the throat cavity of the second-stage Venturi tube 4;

[0014] The cooling water pipe 5 vertically passes through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com