Adjustable high-efficient waste acid combined burner

A combined burner and adjustable technology, which is applied in the direction of combustion method, combustion type, incinerator, etc., can solve the problems of furnace corrosion, large occupied area, and limited adjustment range, so as to improve cracking efficiency, prolong service life, and reasonable layout Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

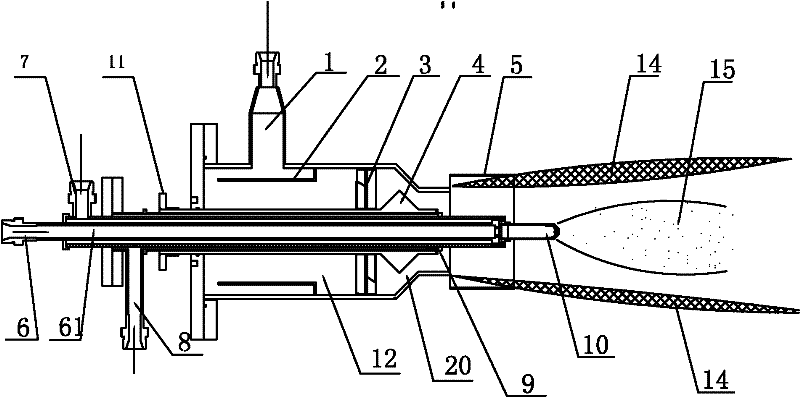

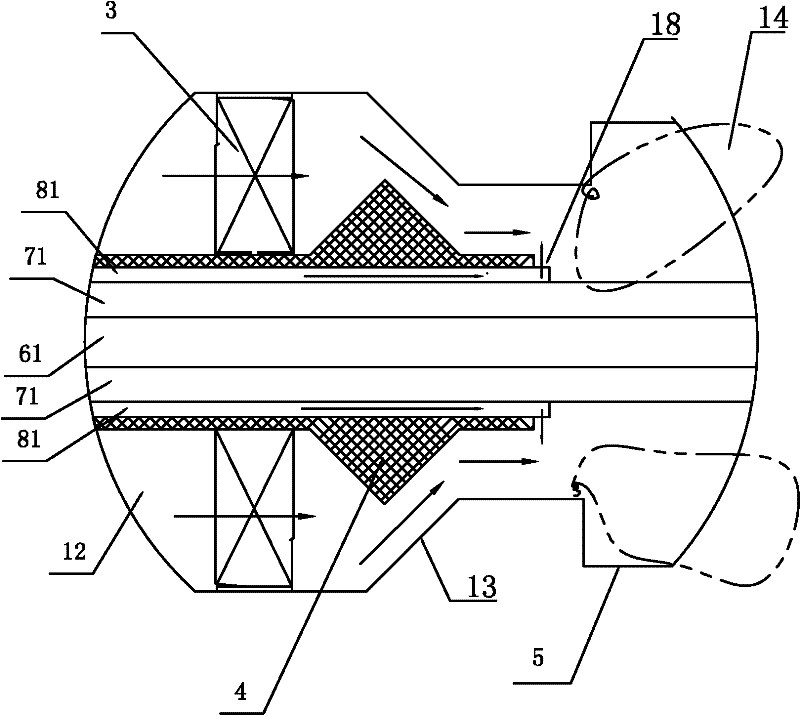

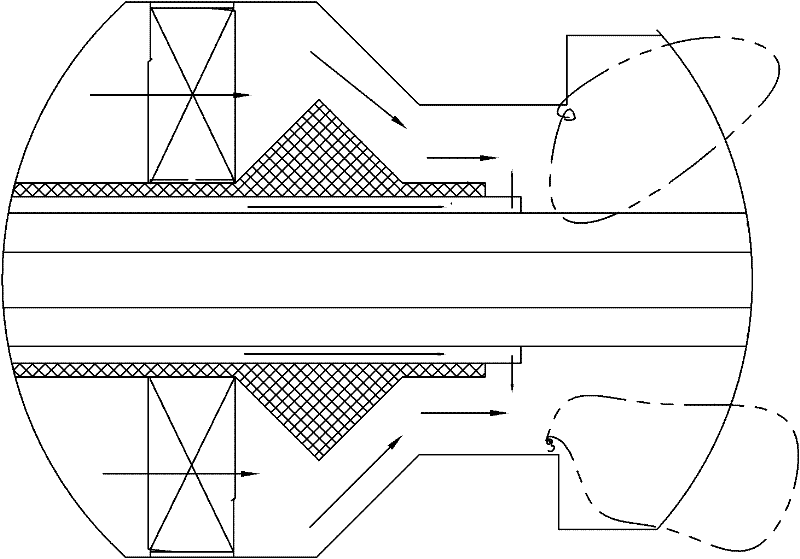

[0032] An adjustable high-efficiency waste acid combination burner, including a waste acid spray gun and a burner surrounding the waste acid spray gun; the waste acid spray gun and burner are arranged coaxially.

[0033] The waste acid spray gun includes a waste acid inlet 6, a waste acid pipeline 61, an atomizing gas inlet 7, an atomizing gas pipeline 71, a mixer 17, a mixing chamber 16 and a nozzle 10; the atomizing gas pipeline is arranged around the waste acid pipeline One end of the atomizing gas pipeline is connected to the atomizing gas inlet 7, and the other end is opened to the mixer, one end of the waste acid pipeline is connected to the waste acid inlet 6, and the other end is opened to the mixer, and the mixer 17 is arranged at the rear end of the mixing chamber 16 and open in the mixing chamber; the nozzle 10 is set at the front end of the mixing chamber 16; the mixer is an internal mixing T-shaped structure, and the waste acid can be better atomized at a small gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com