Atomizing nozzle and atomizing spray head using atomizing nozzle

A technology of atomizing nozzles and nozzles, applied in the direction of spraying devices, spraying devices, liquid spraying devices, etc., can solve the problems of high-speed and high-efficiency atomization of the medium, and achieve the effect of high-efficiency atomization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

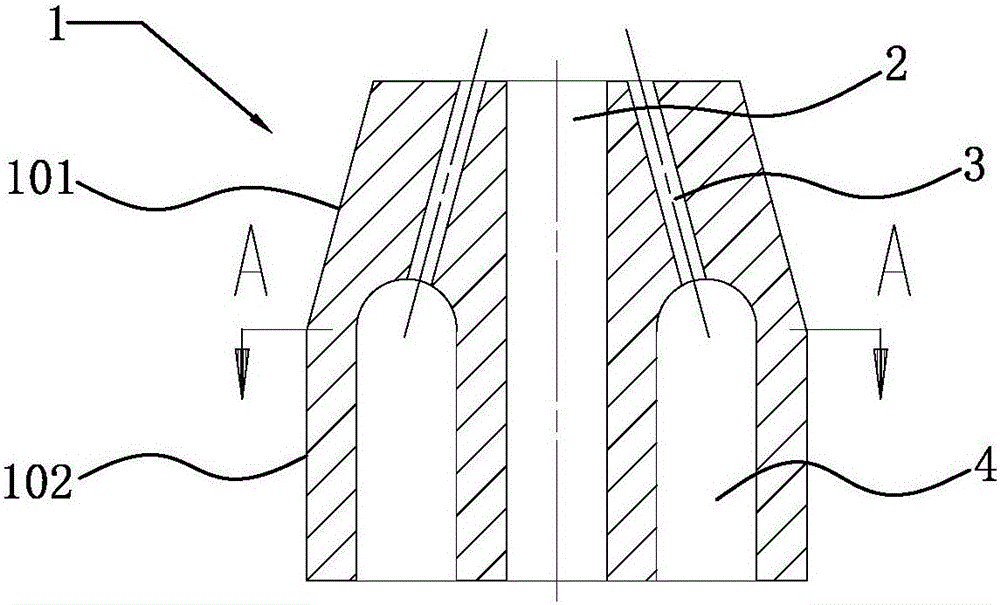

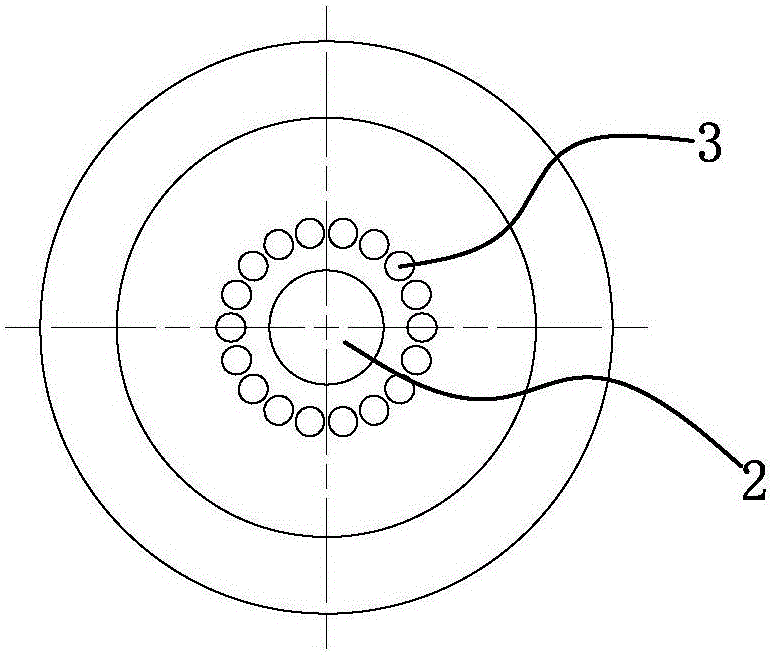

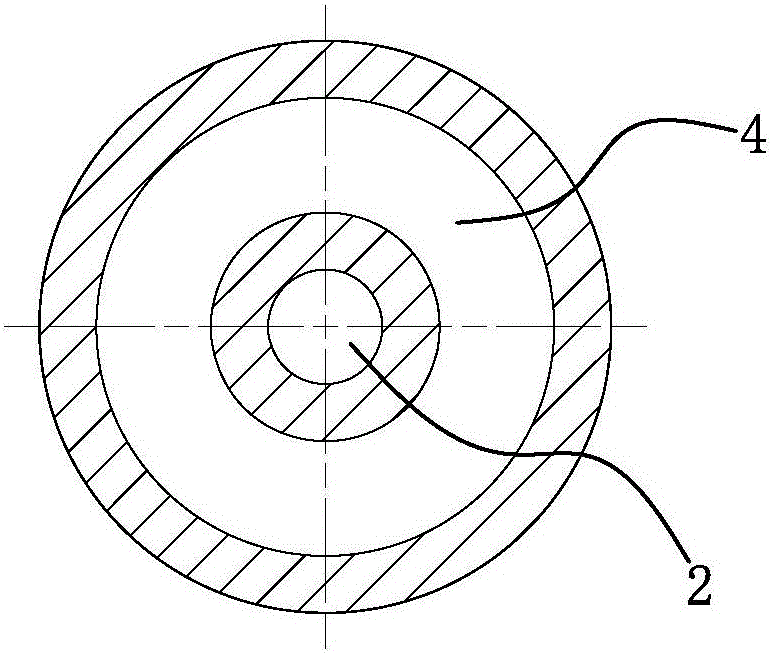

[0025] Such as figure 1 shown, combined with figure 2 , 3 As shown, the atomizing nozzle in the present invention includes a nozzle body 1, and the nozzle body 1 is provided with an air flow channel 2 and a liquid channel 3, and the air flow channel 2 and the liquid channel 3 are arranged at an angle, from the air flow channel 2 The ejected air flow can intersect the liquid ejected from the liquid channel 3. The number of the air flow channel 2 is one, which is arranged in the middle of the nozzle body 1 , and there are multiple liquid channels 3 , and the plurality of liquid channels 3 are evenly distributed around the air flow channel 2 . A liquid storage ring 4 is also provided on the nozzle body 1 , and the liquid storage ring 4 communicates with the liquid channel 3 .

[0026] The nozzle body 1 includes an integrally formed first body part 101 and a second body part 102, the first body part 101 is in the shape of a truncated cone, the second body part 102 is in the sh...

Embodiment 2

[0034] The difference between the present embodiment and the first embodiment is that the number of the liquid channel 3 is one. Such as Figure 7 As shown, the liquid channel 3 is arranged beside the air flow channel 2 .

Embodiment 3

[0036] The difference between this embodiment and the first embodiment is that the number of liquid channels 3 is two. Such as Figure 8 As shown, the two liquid channels 3 are symmetrically arranged on both sides of the gas flow channel 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com