Novel furnace-process carbon black production device and use method

A technology of furnace carbon black and production equipment, which is applied in the field of furnace carbon black, can solve the problems of long production line, large flow rate and flow rate, and affect the efficiency of granulation, so as to achieve shortened length, uniform viscosity, and improved granulation Effect

Active Publication Date: 2022-06-21

FENGCHENG HEIBAO CARBON BLACK

View PDF13 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] However, although the existing production method can produce furnace carbon black, there are still many defects: 1, the production line of the existing furnace carbon black is long, and the operation of the equipment needs more labor to realize, and in When atomizing, the production line directly uses the combination of air pump and pump head to atomize. Although this type of atomization has high efficiency, the effect is not good due to the rapid injection of crude oil or secondary fuel, and the current atomization effect is It is not directly related to the power of the atomizing pump. Even if the suction force of the pump is increased, there will still be excess large particles of crude oil dripping, thereby reducing the efficiency of particle formation

2. At present, the crude oil in the production line is mainly pumped out through pumps. The output of crude oil is relatively large, and it is difficult to control the actual needs of crude oil. Moreover, the existing technology mainly directly mixes crude oil, secondary fuel and air, and the mixed not effectively

3. The existing turbulent flow system is mainly set inside the cavity, and the turbulent flow is realized by changing the diameters of the end and the tail. However, due to the influence of the flow velocity near the side wall in the turbulent flow system, it can be close to the inner wall. Poor flow rate of crude oil or secondary fuel, which affects the efficiency of agglomeration

4. The current cooling system only cools the end of the turbulent system, but the cooling effect is not good due to the large flow rate and flow in the turbulent system, so there is an urgent need for a new type of furnace carbon black. Production device and method of use

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

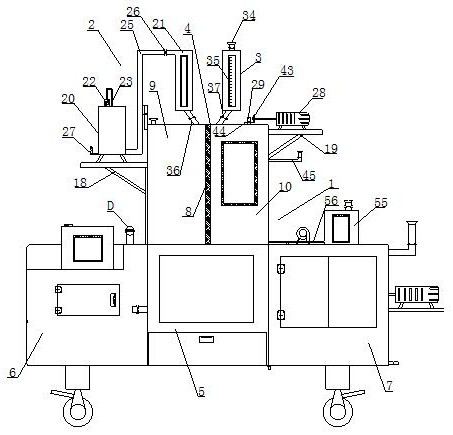

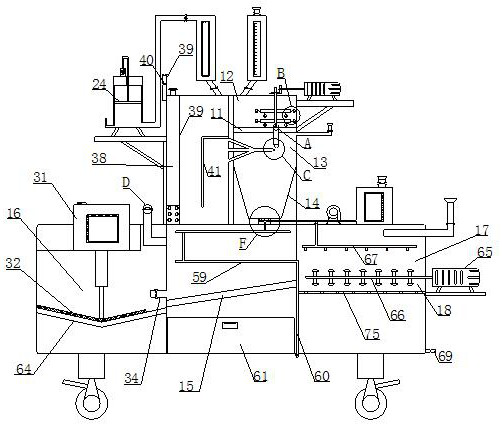

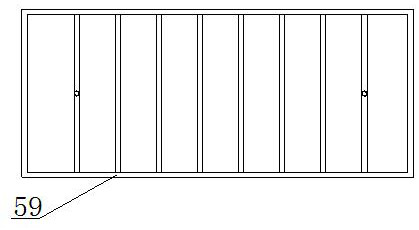

The invention discloses a novel furnace method carbon black production device and a using method, the novel furnace method carbon black production device comprises a T-shaped processing box body, the T-shaped processing box body is provided with a blower device and a refueling box body, and the interior of the T-shaped processing box body is provided with a processing cavity I, a processing cavity II, a processing cavity III and a processing cavity IV; a first vertical airtight partition plate is arranged in the first machining cavity and divides the first machining cavity into a first cavity section and a second cavity section, the first cavity section and the second cavity section are equal in size, a first transverse partition plate is arranged in the second cavity section, the second cavity section is divided into a third cavity section and a fourth cavity section through the first transverse partition plate, and the third cavity section and the fourth cavity section are arranged in the second cavity section. The size of the fourth cavity section is larger than that of the third cavity section, a first stirring device is arranged in the third cavity section, and a turbulence device is arranged in the fourth cavity section. The granulating machine has the beneficial effects that the structure is compact, the working intensity of workers is relieved, and the granulating efficiency is improved.

Description

technical field [0001] The invention relates to the technical field of furnace carbon black, in particular to a production device and a use method of a novel furnace carbon black. Background technique [0002] Furnace carbon black is to use gaseous hydrocarbons, liquid hydrocarbons or their mixtures as raw materials, supply an appropriate amount of air, and form a closed turbulent system in the reaction furnace, burn a part of the raw material hydrocarbons and air to generate high temperature, and crack the other part to produce carbon. black. Carbon black is a black powdery substance formed by incomplete gas phase combustion or pyrolysis of hydrocarbons under strictly controlled process conditions. Its main component is elemental carbon and contains a small amount of oxygen, hydrogen, sulfur, etc. Carbon black particles are approximately spherical, with a particle size of 10-500 μm. Carbon black products are used in rubber processing and added to rubber as reinforcing age...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F26B9/06F26B21/00F26B25/00F26B25/04F26B25/12F26B25/18C09C1/50C09C1/56C09C1/58

CPCF26B9/06F26B21/001F26B25/002F26B25/04F26B25/18F26B25/12C09C1/50C09C1/56C09C1/58Y02P20/10

Inventor 王雪宁张洪君张金辉

Owner FENGCHENG HEIBAO CARBON BLACK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com