System for treating desulfurization wastewater by coupling low-temperature flue gas with dry slag waste heat and construction method of system

A technology for desulfurization wastewater and low-temperature flue gas, which is used in gaseous effluent wastewater treatment, special treatment targets, water/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

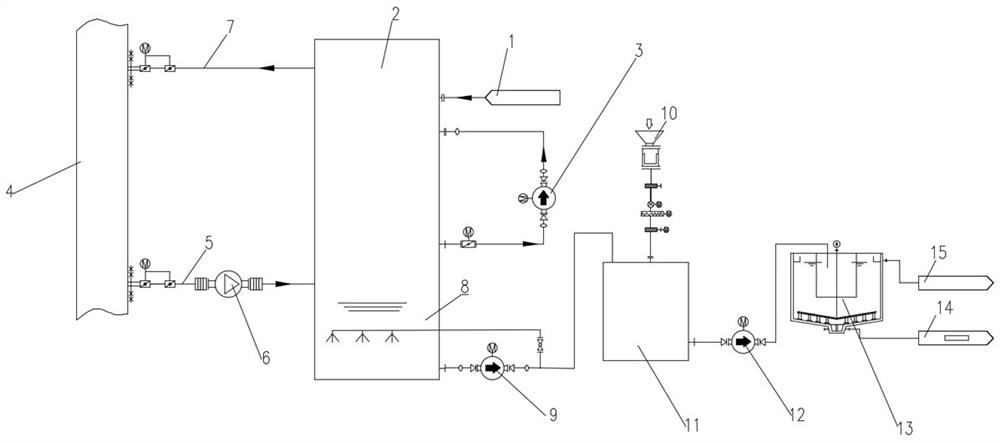

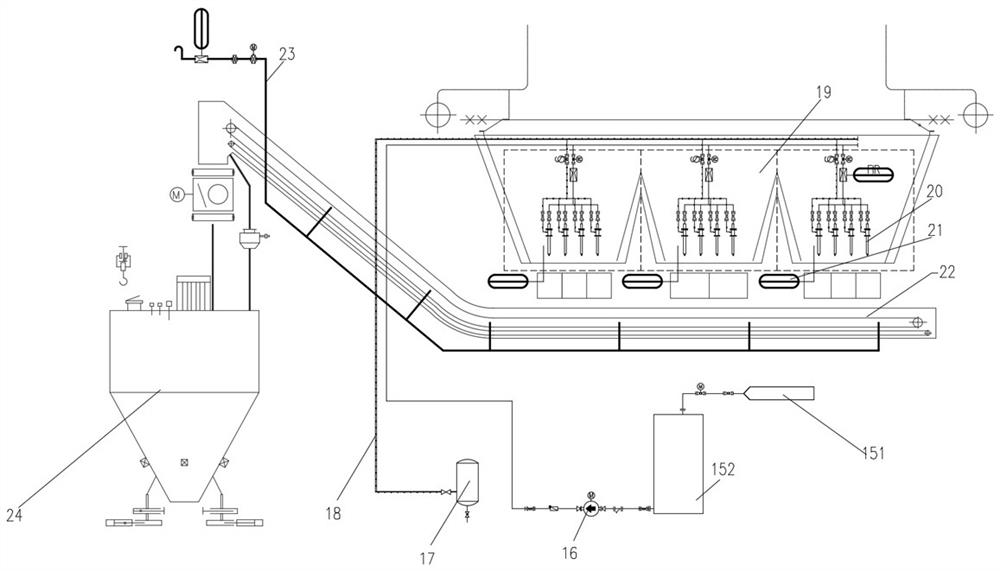

[0036] Taking the desulfurization wastewater treatment device of a 1000MW coal-fired unit as an example, the design output of desulfurization wastewater is 15 tons / hour, of which the solid content of the wastewater is 0.5%, the pH value is 5~6, and the density is 1030kg / m 3 , Chloride ion concentration 20000mg / L. Applying this system, the untreated desulfurization wastewater directly enters the concentration and neutralization system and the drying system connected to the concentration and neutralization system.

[0037] In this embodiment, the concentration and neutralization system includes a concentration tower 2, a desulfurization waste water supplier 1 connected to the top of the concentration tower 2, a flue 4 connected to one side of the concentration tower 2, and a flue 4 connected between the concentration tower 2 The flue gas inlet pipe 5 and the flue gas outlet pipe 7 are connected to the thick slurry first discharge pump 9 on the bottom side of the thickening tower...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com