Patents

Literature

93results about How to "Improve wettability and dispersibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing water-soluble solid styrene/acrylic resin and application thereof

InactiveCN101575397AAvoid it happening againAvoid cloggingInksCoatingsAcrylic resinUnsaturated monomer

The invention discloses a method for preparing water-soluble solid styrene / acrylic resin and application thereof. The method prepares the required resin by simultaneously performing free radical polymerization reaction and esterification reaction on an aromatic vinyl unsaturated monomer, an aliphatic vinyl unsaturated monomer, an unsaturated carboxylic acid monomer, fat alkanol, an initiating agent and an alpha-methyl styrene dimer in a reactor. In the method, the alpha-methyl styrene dimer is added as a chain transfer agent to reduce the branching degree and avoid the generation of gel and the blockage of the reactor; and simultaneously, the added fat alkanol performs esterification reaction with acroleic acid to inhibit the esterification reaction between an alcohol ether solvent and the acroleic acid, thus the viscosity of the reaction mixture is controlled effectively, and the finally prepared resin has narrow molecular weight distribution (Mw / Mn is less than 2.0), low molecular weight (Mw is less than 10,000), few organic volatile matters, and good wetting dispersion of pigment, and can be applied to preparing water color ink, coating or oil polish.

Owner:SUN YAT SEN UNIV

Application of biodegradable weeding mulching film in potato cultivation

ActiveCN106496968AImprove wettability and dispersibilityGood compatibilityPlant cultivationCultivating equipmentsPolymer scienceHydrophilic-lipophilic balance

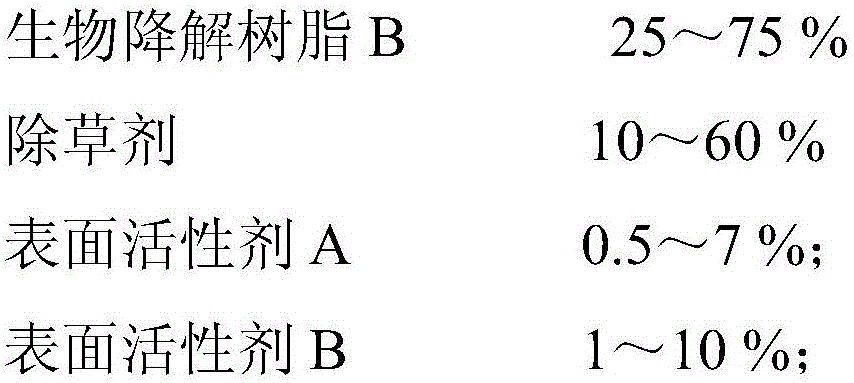

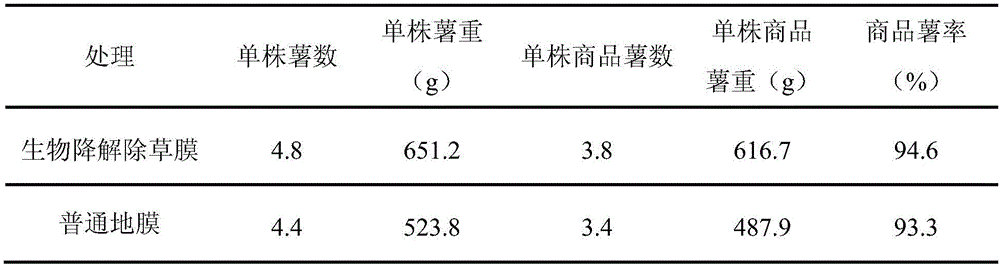

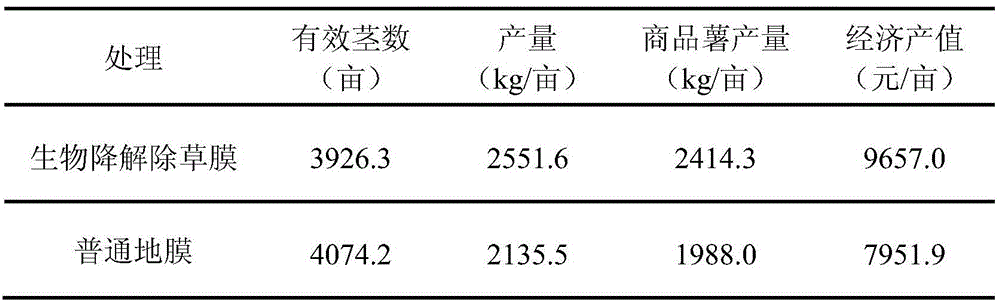

The invention belongs to the technical field of potato cultivation, and discloses an application of a biodegradable weeding mulching film in potato cultivation. The mulching film comprises the following components in percentage by mass: 70-97% of biodegradable resin A and 3-30% of biodegradable herbicide master batches, wherein the biodegradable herbicide master batches are prepared by a method comprising the following steps: mixing 10-60% of a herbicide with 0.5-7% of a surfactant A, and performing ultrasonic activation; and mixing 25-75% of biodegradable resin B and 1-10% of a surfactant B at a high speed, and performing extrusion and granulation, thereby obtaining the herbicide master batches, wherein the mass ratio of the surfactant A (the hydrophilic-lipophilic balance value is 7-10) to the surfactant B (the hydrophilic-lipophilic balance value is 3-6) is (1:1)-(1:2). As the biodegradable weeding mulching film is used in potato cultivation, the problems that weeds can grow out from furrow surfaces and environment pollution can be caused by common plastics can be effectively prevented, and the labor cost can be lowered.

Owner:广东省科学院生物与医学工程研究所

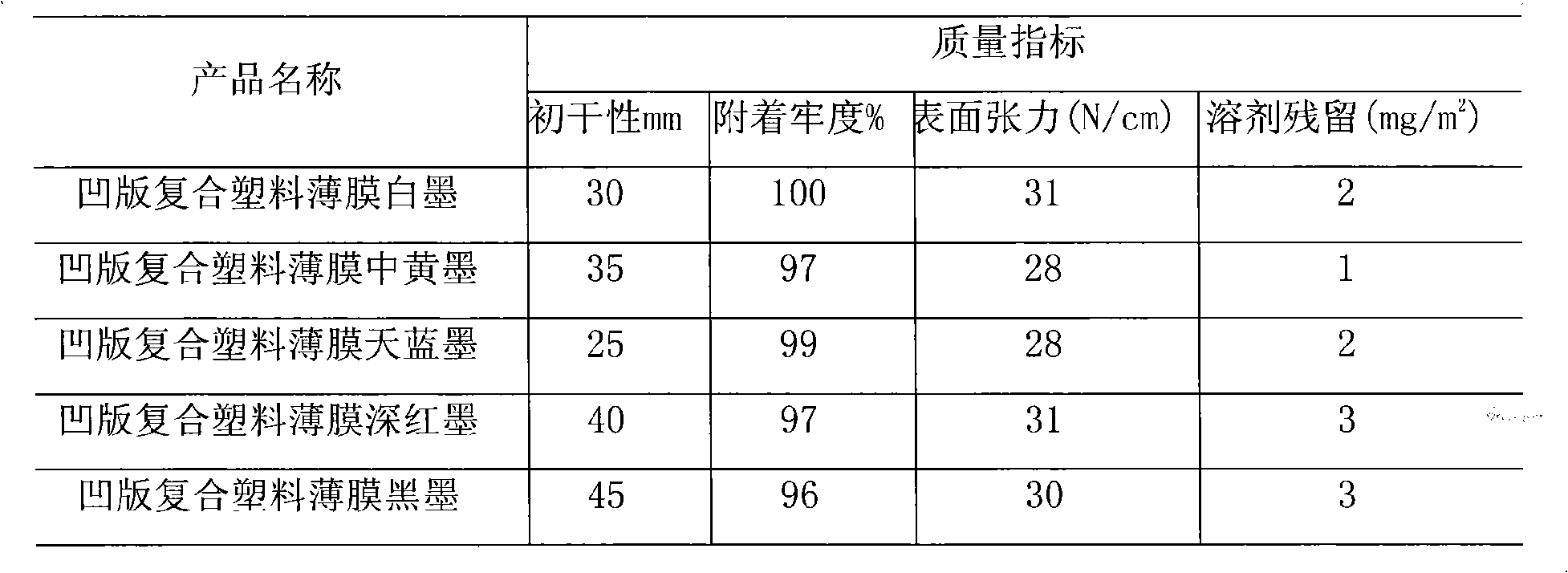

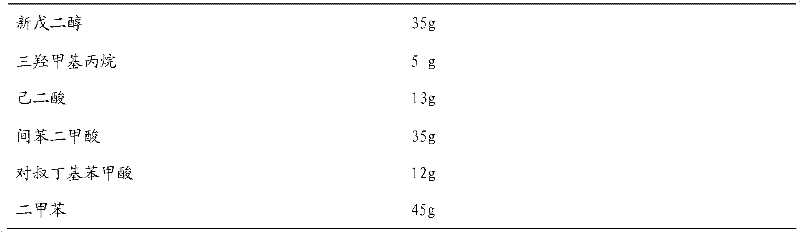

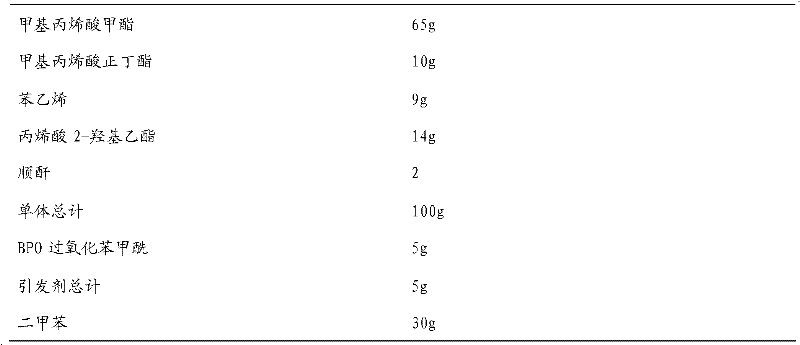

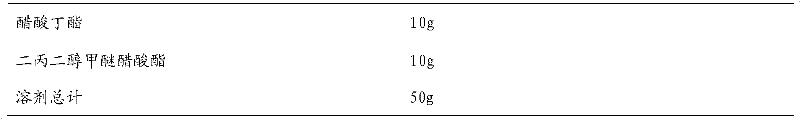

Preparing method of ethanol-soluble resin for printing ink and application thereof

The invention discloses a preparing method of ethanol-soluble resin for printing ink and the application thereof. In the method, polyester diol is prepared; aliphatic dibasic acids, aromatic acid, crystal-forming diol and non-crystal diol are added in a polyester synthesis reactor for the esterification reaction under the condition that the temperature is increased. After the esterification reaction, the low vacuum pumping is carried out, and then the high vacuum pumping is carried out. After the high vacuum pumping is stopped, the long vacuum pumping is carried out. Polycondensate obtained after the long vacuum pumping is used as polyester diol; prepolymer is prepared: the prepared polyester diol, polyether glycol and vulcabond are mixed and reacted, and obtained the reaction products are used as the prepolymer; link expansion and synthesis: organic solvent with low boiling point is added into the obtained prepolymer, stirred uniformly and gradually added into polyamine link expansion agent and ethyl alcohol to form mixed solution. The mixed solution reacts under certain temperature. After the temperature is lowered, the vacuum pumping is carried out. The organic solvent with low boiling point is removed. The ethanol-soluble resin for printing ink is obtained. The resin prepared by the method is used for printing ink and has good performance.

Owner:BEIJING COMENS NEW MATERIALS

Preparation method of polyester modified hydroxyl polyacrylate, and paint containing polyester modified hydroxyl polyacrylate

The invention relates to a polyester modified hydroxyl polyacrylate and to the field of organic polymer compounds; the modified hydroxyl polyacrylate is prepared by a method comprising the following steps of: (1) mixing hydroxyl polyester and anhydride-containing hydroxyl polyacrylate at the weight ratio of 1:(2-4), carrying out reaction at 150-180 DEG C for 1.5-6 hours until the acid value of the polyester modified hydroxyl polyacrylate is less than 15mg KOH / g, and cooling; and (2) distilling for removing a solvent, and adjusting the solid content to be 70-80%, thus obtaining the polyester modified hydroxyl polyacrylate with high solid content. The polyester modified hydroxyl polyacrylate has the advantages of polyester and polyacrylate, and has excellent pigment wetting dispersing performance. Double-component paint prepared by the polyester modified hydroxyl polyacrylate is rapid in drying speed, high in coating hardness and excellent in chemical resistance and weather resistance; the solid content is high, so that the fullness of coating is improved, and the construction cost is saved; and the paint can be used for coating and finishing automobile paint and car refinishing paint, and is also used for plastic paint, leather finishing agent, adhesive agent and ink.

Owner:YINGDE BOTE CHEM INDAL

Ferric oxide pigment composition containing phosphate auxiliary ingredients and preparation method of ferric oxide pigment composition

ActiveCN102585611ASimple preparation processImprove wettability and dispersibilityPigment pastesPhosphateViscosity

The invention discloses a ferric oxide pigment composition containing phosphate auxiliary ingredients. The composition consists of the following ingredients in weight percentage accounting for the total mass of the ferric oxide pigment composition: 45.0 to 65.0 weight percent of ferric oxide pigment, 2.0 to 10.0 weight percent of amphoteric phosphate wetting agents, 3.0 to 15.0 weight percent of anionic phosphate dispersing agents, 11.0 to 16.0 weight percent of functional auxiliary ingredients and the balance deionized water. The two kinds of phosphate auxiliary ingredients, i.e. the nionic phosphate dispersing agents and the amphoteric phosphate wetting agents are adopted for compounding, the wetting and dispersing performance of the ferric oxide pigment in water is improved, the particle diameter of pigment particles is small, the coloring capability is high, and the phenomena of pigment precipitation, obvious viscosity change and the like cannot occur after the long-time storage.

Owner:SUZHOU SUNMUN TECH CO LTD

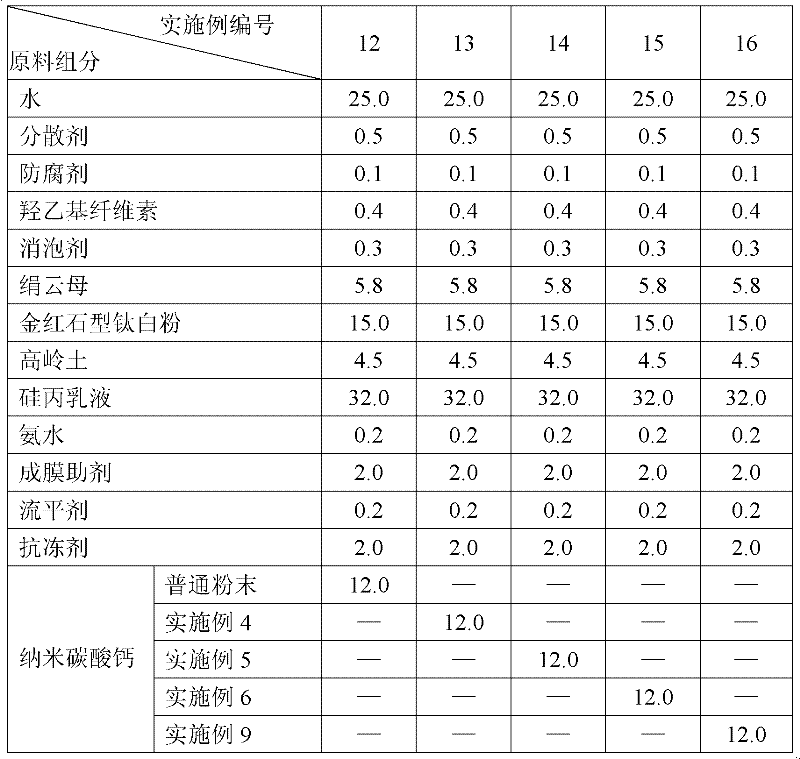

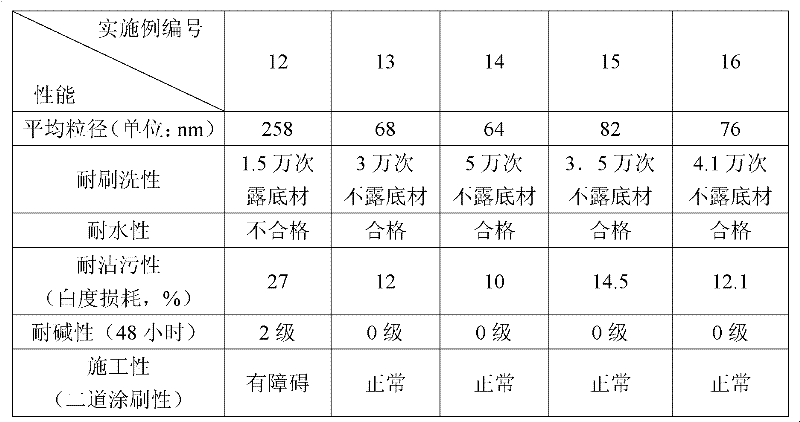

Aqueous high-content nanometer calcium carbonate dispersoid and preparation method thereof

InactiveCN102532976AImprove wettability and dispersibilityAvoid dust pollutionAntifouling/underwater paintsPaints with biocidesNanometreCalcium carbonate

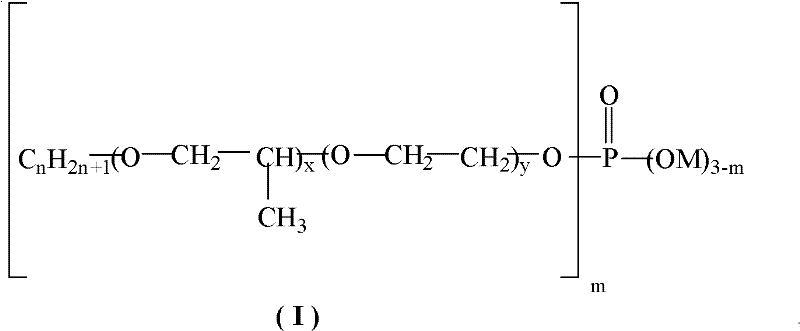

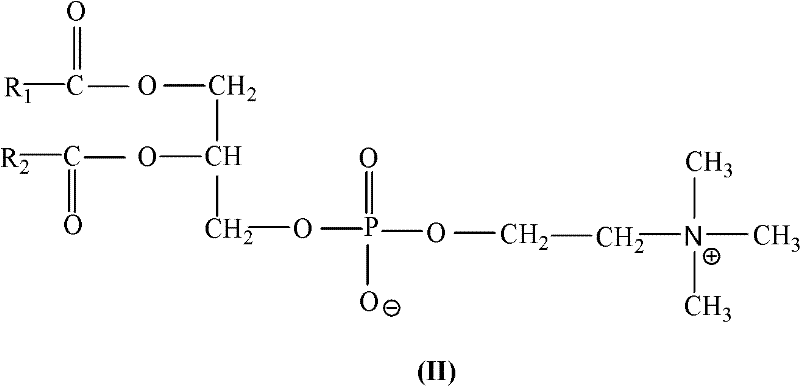

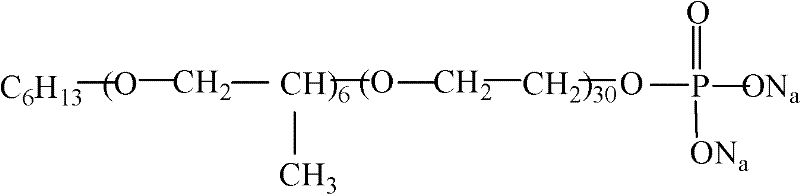

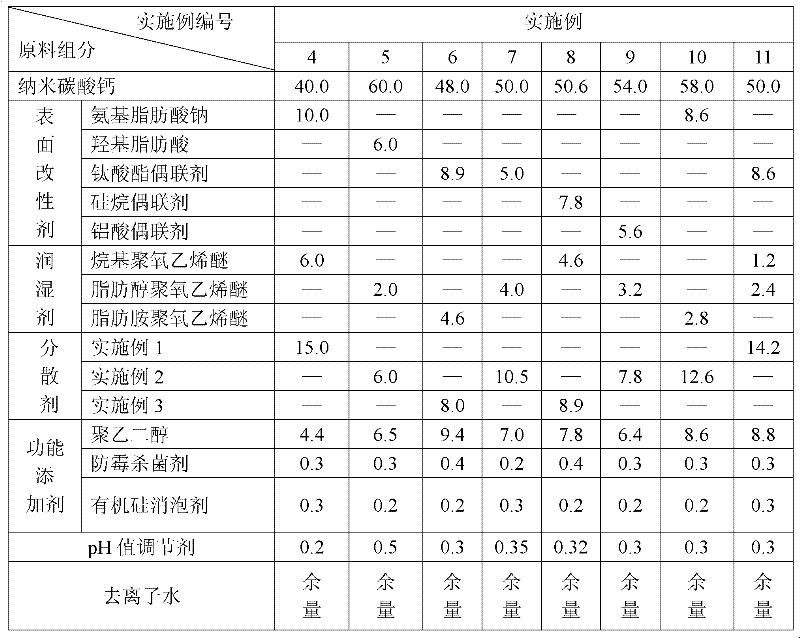

The invention discloses an aqueous high-content nanometer calcium carbonate dispersoid and a preparation method of the aqueous high-content nanometer calcium carbonate dispersoid. The aqueous high-content nanometer calcium carbonate dispersoid comprises the following ingredients through being metered by the total mass percentage: 40.0 to 60.0 weight percent of nanometer calcium carbonate, 5.0 to 10.0 weight percent of surface modifying agents, 2.0 to 6.0 weight percent of wetting agents, 6.0 to 15.0 weight percent of dispersing agents, 5.0 to 10.0 weight percent of functional additives, 0.2 to 0.5 weight percent of pH value conditioning agents and the balance de-ionized water, wherein the dispersing agents are formed by the self preparation of three polymerizable monomers through reaction. The aqueous high-content nanometer calcium carbonate dispersoid can replace nanometer calcium carbonate powder of the same quantity in the paint preparation process, in addition, the calcium carbonate dispersoid is easily dispersed, and the performance of the paint in multiple aspects of water resistance, washing resistance, stain resistance, construction performance and the like.

Owner:SUZHOU SUNMUN TECH CO LTD

Water-based flexographic printing ink for cigarette tipping paper printing and preparation method thereof

ActiveCN106928771AImprove antibacterial propertiesTroubleshoot MigrationInksFreeze thawingDispersion stability

The invention discloses a water-based flexographic printing ink for cigarette tipping paper printing and a preparation method thereof. The water-based flexographic printing ink is composed of a modified acrylic emulsion, pigment and filler, a wetting dispersant, a transfer printing agent, a defoaming agent, deionized water, and a cosolvent. The modified acrylic emulsion is a novel acrylic emulsion formed by copolymerization of an imported high quality emulsifier, acrylate and special functional monomers, and has the advantages of fantastic calcium ion stability, dilution stability, mechanical stability and freeze-thaw stability, and small pollution to the environment. The water-based flexographic printing ink for tipping paper printing provided by the invention is non-toxic and tasteless, has quick drying speed and good dispersion stability, the printing product is free of deformation and edge curling, and has bright color and excellent antibacterial properties. The printing product has few residual monomer and low odor, is green and environment-friendly, the printing ink can be used cooperatively with a flexographic press, the printing speed can reach 250-300m / min, and the machine speed is doubled than the traditional intagliotipping paper printing press, thus greatly improving the production efficiency, and saving the production cost.

Owner:JIANGSU TANGCAI PRINTING INK SCI TECH CO LTD

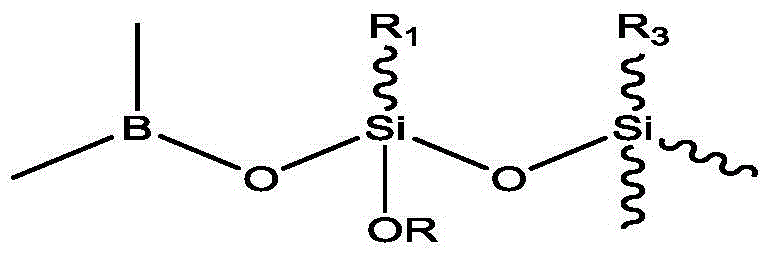

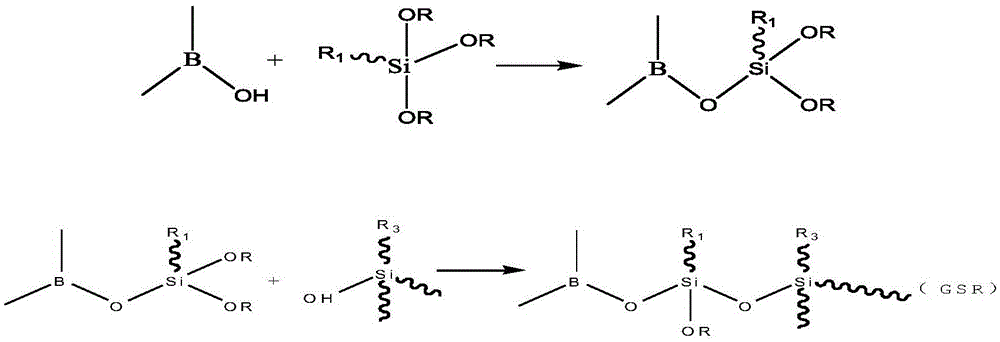

Boron silane modified silicon resin, addition type resin composition and application

The invention provides boron silane modified silicon resin and addition type resin composition containing the resin. The resin has the general structural formula shown in the specification, wherein R is an alkyl group, R1 is an epoxy group or an acrylate group or a methacrylate group, and R3 is a silicon vinyl group. A B-O bond is introduced into the molecular structure, and the heat stability of the resin is improved; at least one phenyl group is contained in the resin structure, and the resin is good in compatibility when compounded with other resin for use and can keep the transparency of final cured products; at least one silicon vinyl group is contained in the resin structure, and the resin can participate in final hydrosilylation curing and cannot affect the performance of the final cured products; active functional groups such as the alkoxy group, the epoxy group, acrylate and the like are introduced into the resin structure, during preparation of the composition, the polarity of the system can be improved greatly, and the dispersion performance of the resin to filler is improved greatly.

Owner:GUANGDONG HENGDA NEW MATERIALS TECH

Comb (block) copolymers

ActiveUS8153731B2Good wettingGood dispersionTransportation and packagingMixingEnd-groupReaction temperature

The present invention relates to comb (block) copolymers obtainable by reactingI at least one (block) copolymer comprising polymerized, optionally substituted styrene and maleic anhydride units, which copolymer has been obtained by living, free-radical polymerization, withII at least one polyalkylene oxide monoamine comprising a primary amino end group at a reaction temperature of ≧150° C.and by subsequent salification of at least 25 mol % of the free carboxyl groups of the reaction product at a reaction temperature of <100° C. and optionally after addition of H2O and to the use of these comb copolymers as wetting agents and dispersants.

Owner:BYK CHEM GMBH

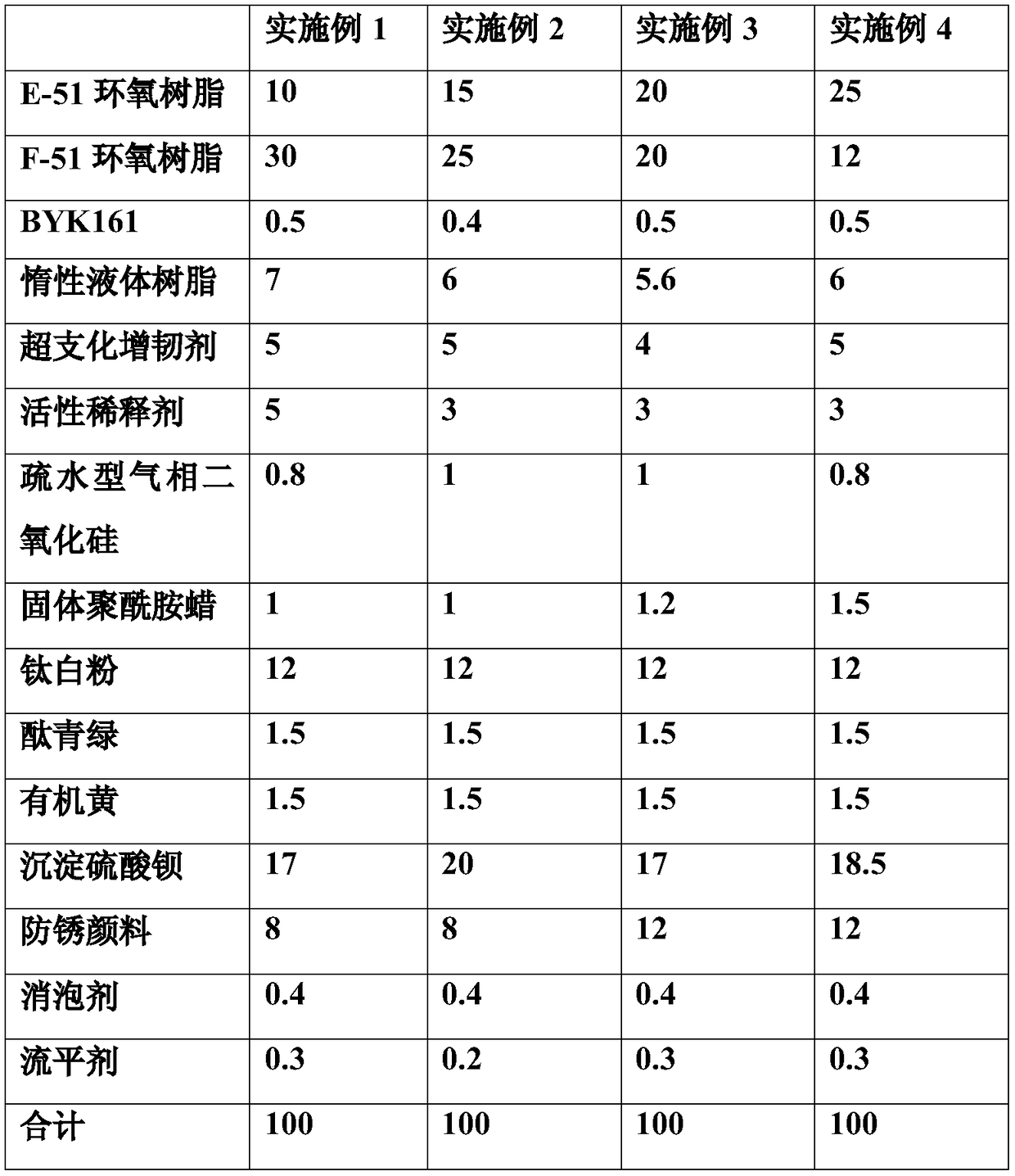

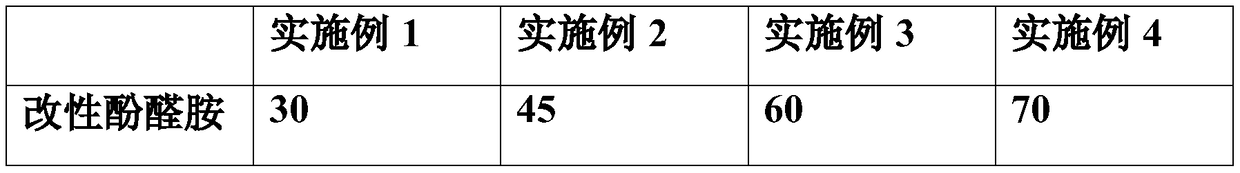

Solvent-free epoxy heavy anti-corrosion paint extruded and coated to inner wall of crude oil gathering pipeline

InactiveCN109181477AGood chemical resistanceAccelerated corrosionAnti-corrosive paintsEpoxy resin coatingsEpoxySolvent free

The invention discloses a solvent-free epoxy heavy anti-corrosion paint which is extruded and coated to the inner wall of a crude oil gathering pipeline. The paint comprises a component A and a component B, wherein the component A is prepared from the following raw materials in parts by weight: 10-25 parts of E-51 epoxy resin, 12-30 parts of F-51 epoxy resin, 10-15 parts of titanium dioxide, 1-2 parts of phthalocyanine green, 1-2 parts of organic yellow, 1.5-3 parts of a thixotropic agent, 0.3-0.5 part of a wetting dispersant, 5-8 parts of inert liquid resin, 3-5 parts of an active diluting agent, 3-5 parts of a hyperbranched toughening agent, 15-20 parts of precipitated barium sulfate, 8-15 parts of anti-rust pigment, 0.3-0.5 part of a defoaming agent, 0.2-0.4 part of a flatting agent; the component B is prepared from 30-70 parts of modified phenolic amine curing agent and 70-30 parts of modified aromatic amine curing agent; and the mass ratio of the component A to the component B is(5-7):1. The solvent-free epoxy heavy anti-corrosion paint is applicable to gathering pipeline extruding and coating processes, the pipeline inner wall coating has excellent corrosion resistance and physical performance, the coating process can be reduced, the construction time can be saved, and the work efficiency can be improved.

Owner:石家庄市油漆厂

Electrophoretic paint with high weather resistance and better spring coverage and preparation method thereof

InactiveCN106318001AGood alkali resistanceGood weather resistanceAnti-corrosive paintsPaints for electrolytic applicationsEpoxyWeather resistance

The invention relates to electrophoretic paint with high weather resistance and better spring coverage and a preparation method thereof. The electrophoretic paint is prepared by high weather resistance acrylic acid modified emulsion and weather-resistant color paste according to the ratio of 8:1, the high weather resistance acrylic acid modified emulsion is obtained by reacting 33-39 parts of epoxy grafted fluoride cation acrylic modified resin, 2-3 parts of microgel, 14-16 parts of sealing, 0.8-1 part of neutralizer and 44-52.2 parts of deionized water; the weather-resistant color paste is prepared by mixing and grinding 15-18 parts of acrylic acid grinding resin, 1-2 parts of surfactant, 42-50 parts of deionized water and 34-38 parts of pigment filler. According to the painting, the coating appearance is flat and bright, the yellowing resistance is good, and the coating has excellent mechanical property, bath stability, weather resistance, corrosion resistance and spring coverage.

Owner:HAOLISEN COATING SHANGHAI

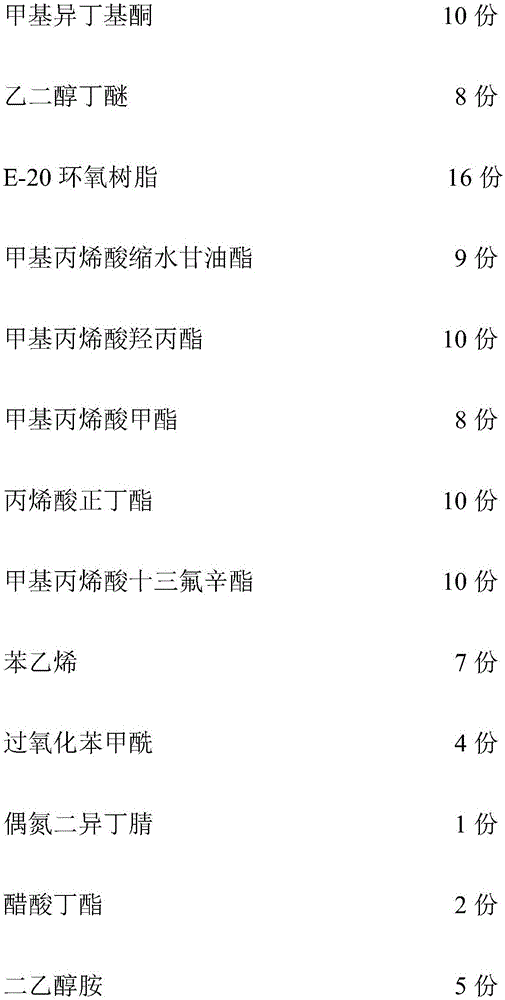

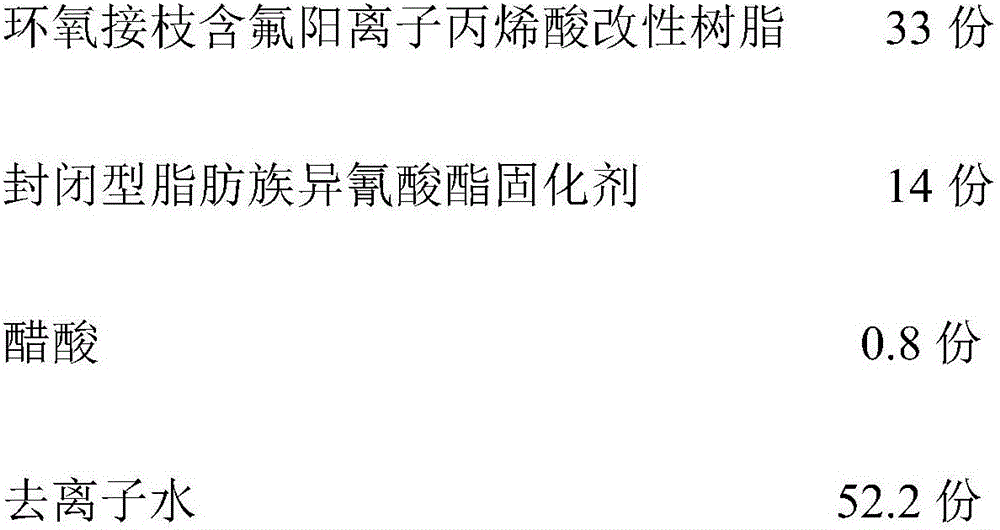

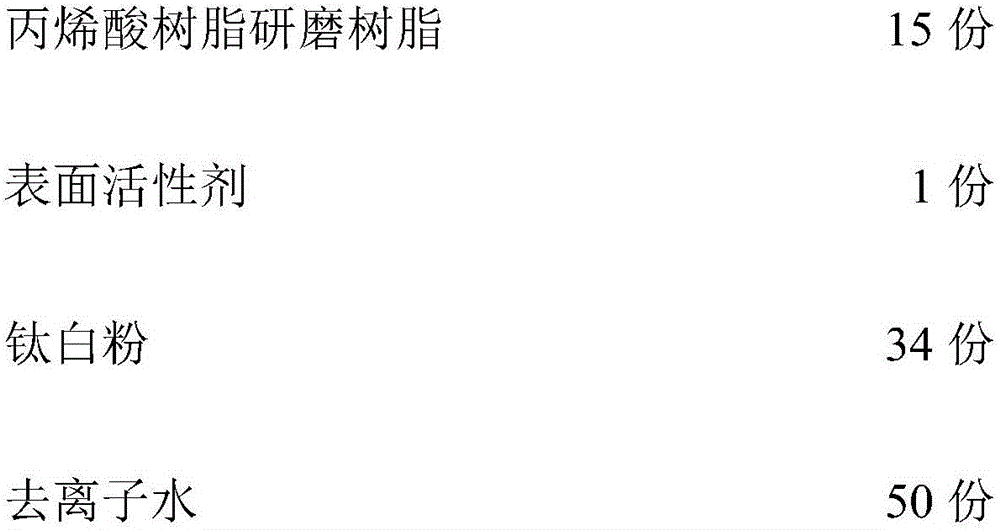

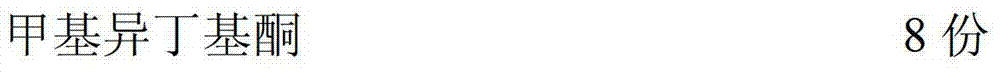

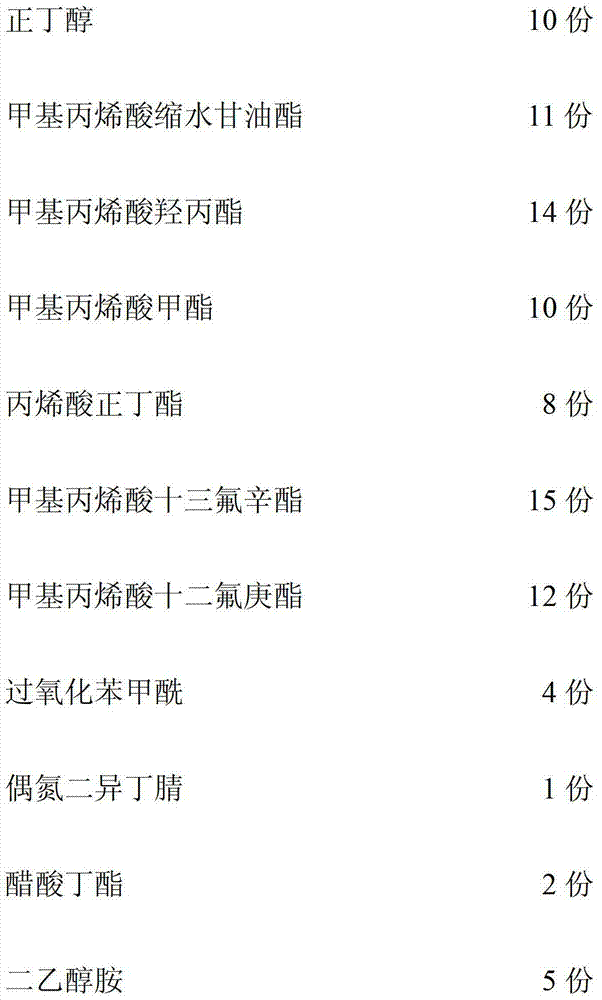

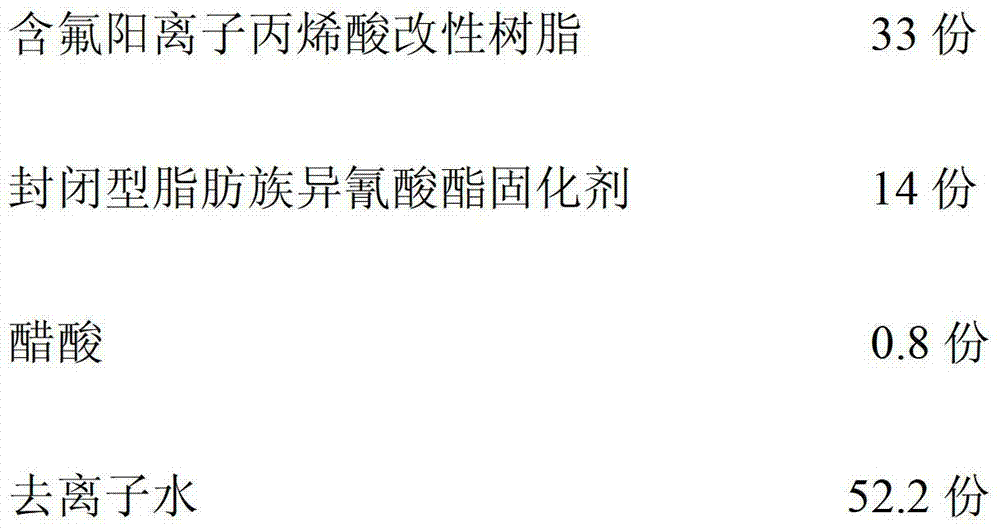

Multipurpose high weather resistant acrylic acid electrophoretic paint and preparation method thereof

ActiveCN103289498AGood alkali resistanceGood weather resistancePaints for electrolytic applicationsTO-18Weather resistance

The invention relates to a multipurpose high weather resistant acrylic acid electrophoretic paint and a preparation method thereof. The paint comprises two components, and is produced from high weather resistant acrylic acid modified emulsion and weather resistant color paste at a ratio of 8:1. The high weather resistant acrylic acid modified emulsion comprises following ingredients, by weight: 33 to 39 portions of fluorine-containing cationic acrylic acid modified resin, 14 to 16 portions of blocked aliphatic isocyanate curing agent, 0.8 to 1 portion of a neutralizer and 44 to 52.2 portions of deionized water. The weather resistant color paste comprises following ingredients, by weight: 15 to 18 portions of acrylic acid grinding resin, 1 to 2 portions of a surfactant, 42 to 50 portions of deionized water and 34 to 38 portions of a pigment filler. Fineness of the weather resistant color paste is 15um or less. The paint of the invention is suitable for colorized, white and grey systems. Appearance of coatings is flat, smooth and bright after one time of electrophoretic painting. Yellowing resistance, mechanical properties, coating liquid stability, acid resistance, alkali resistance and weather resistance of the coatings are excellent.

Owner:HAOLISEN COATING SHANGHAI +1

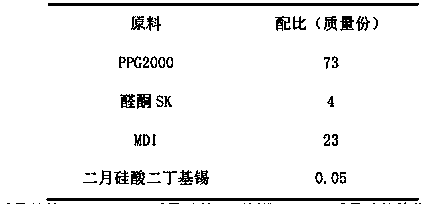

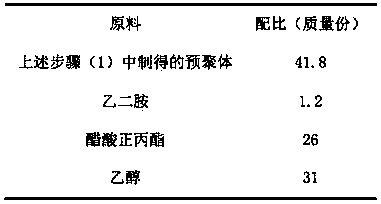

Preparation method of adhesive for table printing ink

The invention discloses a preparation method of an adhesive for table printing ink, belonging to the field of preparation of adhesives for ink. The preparation method disclosed by the invention comprises the following steps of firstly, reacting diisocyanate and high-molecular polyhydric alcohol with keto-aldehyde resin to generate a prepolymer, the terminal group of which is NCO, and then, adding the prepolymer into a solution containing an amine chain extender, thereby obtaining polyurethane resin for table printing ink. The adhesive is alcohol-ester soluble polyurethane resin free of a free isocyanate group; keto-aldehyde resin is subjected to grafting reaction in the resin, so that the table printing ink prepared from the resin has excellent luster and good adhesive force; the table printing ink prepared by utilizing the adhesive is high in glossiness; in addition, the binding strength among the table printing ink and various printing substances is high.

Owner:NANTONG GAOMENG NEW MATERIAL

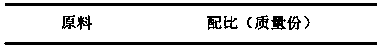

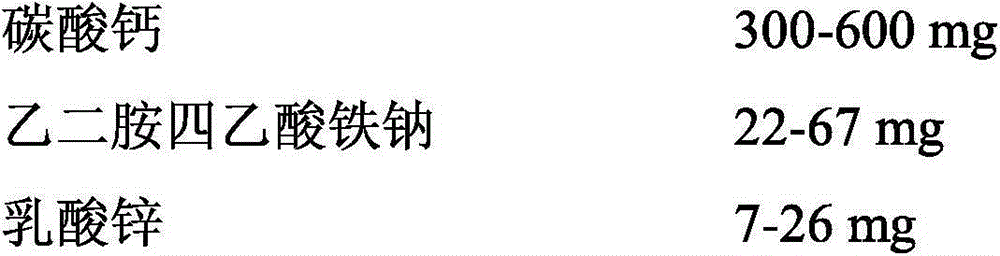

Mouth-melted type instant powder and producing method thereof

InactiveCN105105128AHigh in nutrientsImprove wettability and dispersibilityVitamin food ingredientsFood preparationChemistryEthylenediaminetetraacetic acid

The invention relates to a nutritious food, in particular to mouth-melted type instant powder and a producing method thereof. The preparation per unit is prepared from, by weight, 300-600 mg of calcium carbonate, 22-67 mg of ethylenediaminetetraacetic acid, 7-26 mg of zinc lactate, 120-450MugRE of vitamin A, 3-9 Mug of vitamin D, 0.12-0.48 mg of vitamin B1, 0.2-0.6 mg of vitamin B2, 4-12 mg of lecithin, 500-1000 mg of rock sugar, 100-200 mg of milk powder, 100-200 mg of whey powder and 1.6-3.2 mg of casein phosphopeptides. The minerals and vitamins are made into ultrafine powder, the wettability and the dispersity of the powder are improved by adding the lecithin, the mouth-melted type instant powder is not needed to be mixed with water, just melts in the mouth, facilitates absorption and has good taste in taking, the phenomenon that nutrition ingredients of the instant powder are destroyed after the instant powder is mixed with boiled water by adopting an original traditional edible method is avoided, and difficult chewing and swallowing are avoided.

Owner:WUXI LIBEILE TRADE CO LTD

Delivery systems

InactiveUS20120045486A1Outstanding wettingOutstanding dispersing propertyBiocidePowder deliveryParticulatesAdditive ingredient

The present invention provides a delivery system for active and functional ingredients. In particular, the delivery systems of the present invention find particular application in the delivery of active and functional ingredients, such as medicaments, pharmaceuticals, nutritional supplements, botanicals, cosmeceuticals etc. Further, the invention relates to a delivery system for oral or topical administration of such active and functional ingredients. The invention is a delivery system based on a particulate gel precursor that acts both as the bodying agent,as well as the dispersing and suspending agent in the formulation. By modifying the level of precursor and process conditions, a broad range of product consistencies can be achieved ranging from thin liquid suspension to firm or semi solid gel. The precursor gel is a particulate linear chain fuctan gel. Inulin is a preferred fructan.

Owner:OXFORD PHARMASCI

Water-based wetting dispersant

InactiveCN102775835AStable structureImprove wettability and dispersibilityCoatingsSolubilityWater based

The invention relates to a water-based wetting dispersant which comprises sulfonate, sulfate and polycarboxylate, wherein weight percentage of sulfonate to sulfate is 5-15%: 85-95%, weight percentage of sulfate to polycarboxylate is 10-30%: 70-90%, sulfate is one selected from the group consisting of sodium dodecyl benzene sulfonate, sodium butylnaphthalenesulfonate and sodium sulfanilate, sulfate is one selected from the group consisting of sodium dodecyl sulfate, sodium alcohol ether sulfate and sodium amine ether sulfate, and polycarboxylate is one selected from the group consisting of polyacrylic acid, polymethacrylic acid and maleic-acrylic acid. The invention is advantaged in that the anionic water-based wetting dispersant with a plurality of surfactants as main components is brought forward and has a stable structure, good dissolvability in water and good wetting dispersibility.

Owner:常州市亚邦亚宇助剂有限公司

Polymer cement waterproof coating and preparation method thereof

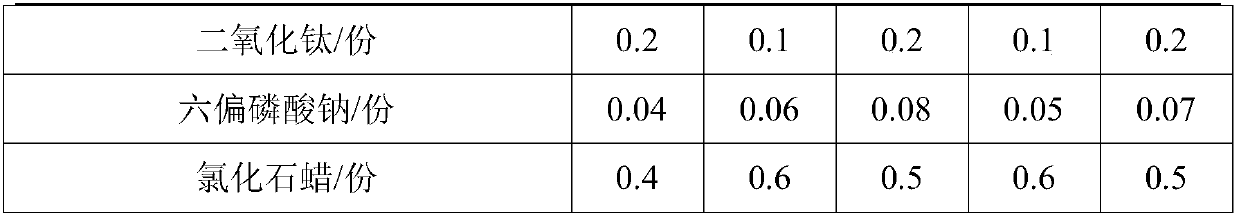

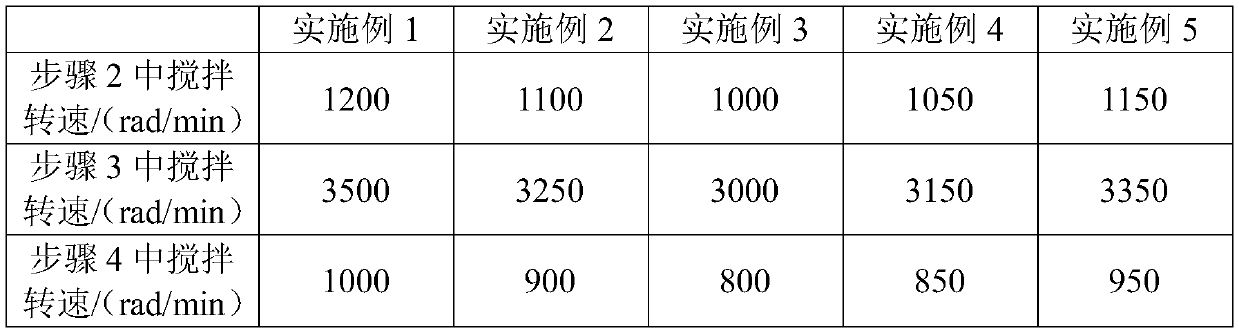

InactiveCN109626903APermanent flexibilityGood acid and alkali resistancePolymer scienceChlorinated paraffins

The invention discloses a polymer cement waterproof coating and a preparation method thereof. The polymer cement waterproof coating comprises liquid materials and powder materials, wherein the liquidmaterials comprise the following components in parts by weight: 10-15 parts of EVA emulsion, 10-15 parts of acrylate polymer emulsion, 0.05-0.1 part of a dispersant 5040, 0.8-1 part of ethylene glycolmonobutyl ether and 0.1-0.3 part of polymethyl silicone resin, 0.06-0.12 part of polyoxypropylene oxyethylene glyceryl ether, 0.2-0.4 part of an anti-aging agent, 0.2-0.4 part of a cross-linking agent, 0.1-0.2 part of a bactericide and 0.1-0.2 part of a dry film mildew inhibitor; the powder comprises the following components in parts by weight: 8-10 parts of Portland cement, 4-6 parts of heavy calcium carbonate, 4-6 parts of quartz powder, 0.5-1.5 parts of wollastonite, 0.5-0.8 part of montmorillonite, 0.1-0.2 part of nano titanium dioxide, 0.04-0.08 part of sodium hexametaphosphate and 0.4-0.6 part of chlorinated paraffin. The polymer cement-based waterproof coating has the advantages that the polymer cement-based waterproof coating has good durability.

Owner:NINGBO ZHONGYI PETROCHEM TECH

Preparation method of polyacrylate-polyurethane resin for printing ink

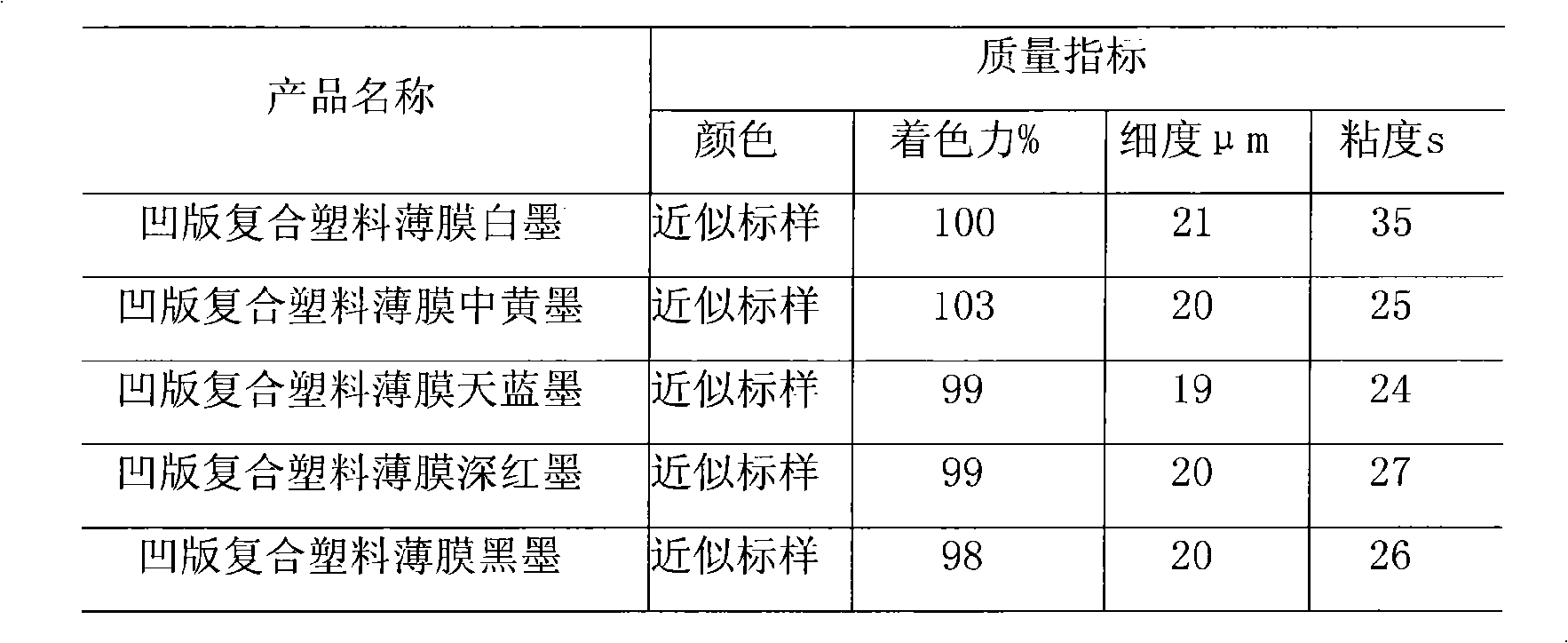

InactiveCN104151561AThe content can be adjusted in a wide rangeLarge adjustment rangeInksDispersityPrinting ink

The invention relates to a preparation method of polyacrylate-polyurethane resin for printing ink. The preparation method comprises the following steps: respectively preparing polyacrylate resin with epoxy groups, and polyurethane resin with amine groups, mixing the polyacrylate resin with epoxy groups with polyurethane resin with amine groups, so as to enable the epoxy groups and amine groups to react, to obtain the polyacrylate-polyurethane resin with a chemical bond connection structure. The prepared polyacrylate-polyurethane resin is wide in adjustment range of polyurethane content, stable in resin performances, excellent in pigment wetting and dispersity properties, and economical and environment-friendly as alcohol and ester solvents are used, the preparation method can be used for preparing single-component intaglio printing ink, and the prepared printing ink is high in tinting strength, good in mobility, stable in status, high in printing adaptability and excellent in effects.

Owner:山西省应用化学研究所

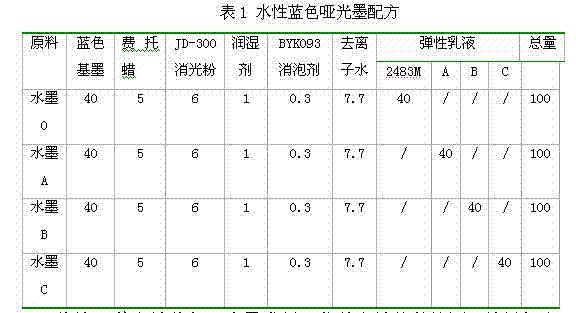

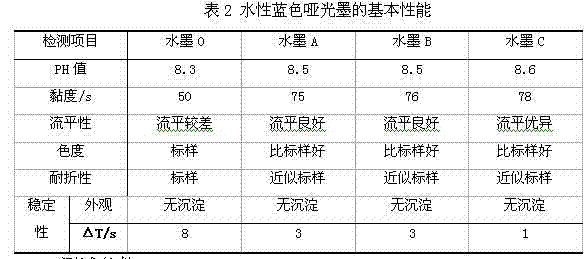

Water-based ink, elastic emulsion used for water-based ink and preparation method of elastic emulsion

InactiveCN102382509AChange rheological propertiesImprove wettability and dispersibilityInksButyl acrylateComposite material

The invention discloses an elastic emulsion for water-based ink, which is prepared by the following raw materials comprising, by weight, 5 to 8 parts of styrene, 3 to 5 parts of ethyl acrylate, 32 to 35 parts of butyl acrylate, 1 to 2 parts of itaconic acid mono-n-butyl ester, 1 to 2 parts of N-hydroxymethyl acrylamide, 5 to 10 parts of acrylic ester resin liquid, 0.05 to 0.1 part of sodium bicarbonate, 2 to 3 parts of composite emulsifying agent, 0.35 to 0.5 part of composite initiating agent and 35 to 45 parts of deionized water. The invention further discloses a preparation method of the elastic emulsion for the water-based ink and the water-based ink utilizing the elastic emulsion. The water-based ink prepared by utilizing the elastic emulsion serving as a binder has good rheological property, printing adaptability and folding resistance, and the elasticity is good after a film is formed.

Owner:GUANGDONG YINGKE GRP CO LTD

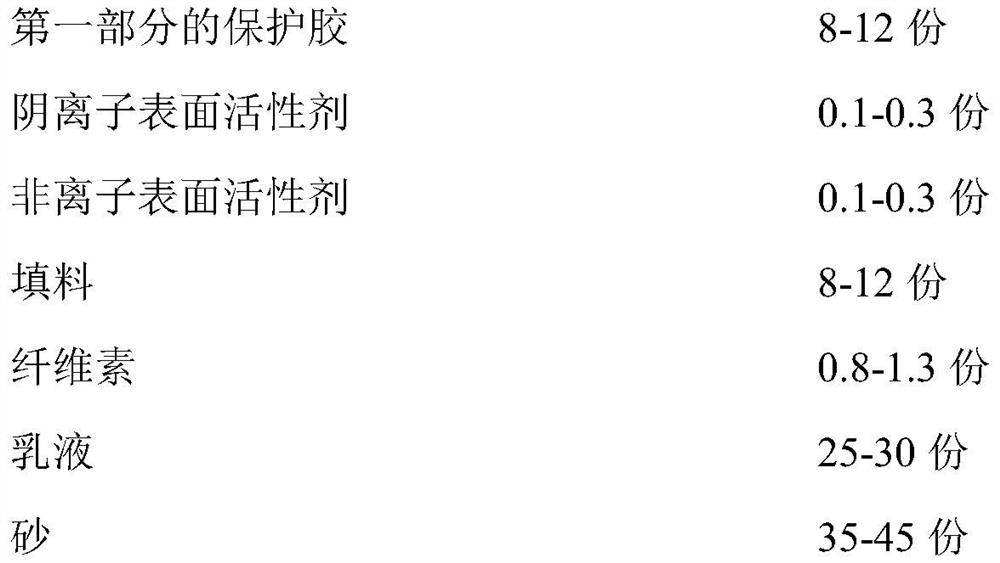

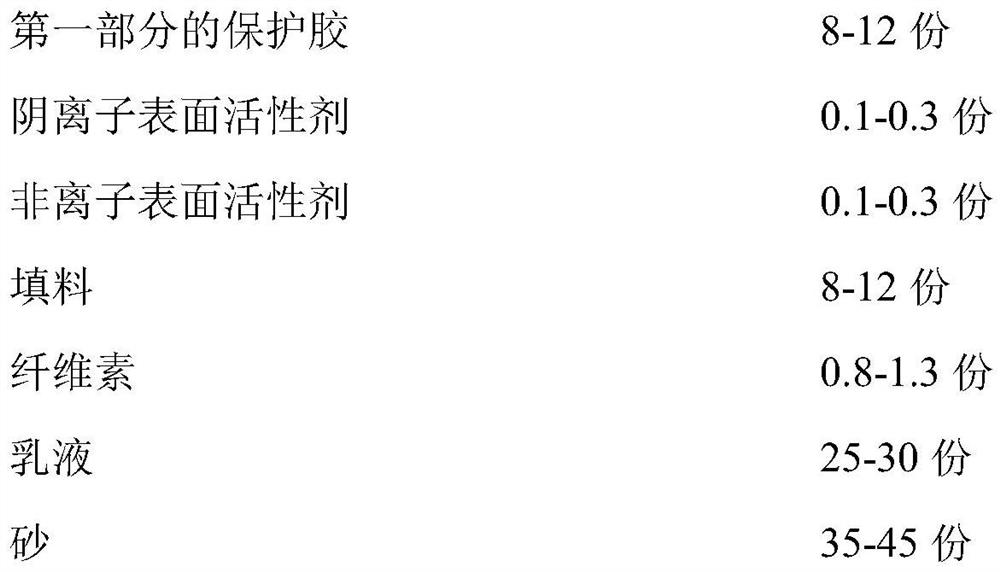

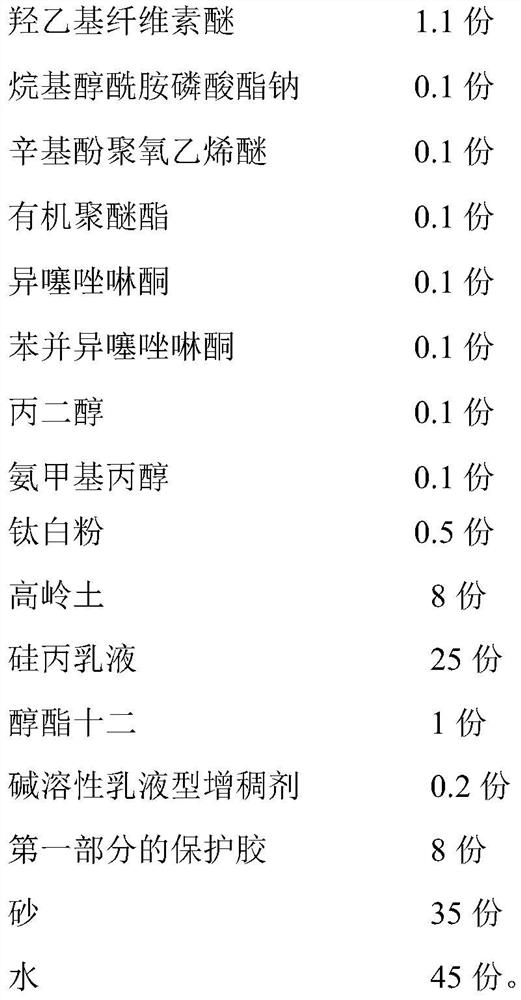

High-stability sand-in-water multicolor paint and preparation method thereof

The invention relates to a high-stability sand-in-water multicolor paint which comprises a sand-containing base paint, a continuous phase emulsion and a second part of protective glue, and the sand-containing base paint comprises a first part of protective glue, an anionic surfactant, a nonionic surfactant, a filler, cellulose, an emulsion, water and sand; the continuous phase emulsion comprises an emulsion and water; the protective glue comprises lithium magnesium silicate or modified lithium magnesium silicate and water; the first part of protective glue and the second part of protective glue are both magnesium silicate or modified magnesium silicate aqueous solutions. Due to the adoption of the mixed surfactant, three colloids, namely the sand-containing base paint, the continuous phase emulsion and the second part of protective glue, in the multicolor coating interact more uniformly and orderly, and can exist in a finished product more stably; in addition, the surfactant can improve the selection tolerance of the sand-in-water multicolor paint on main raw materials such as protective glue, emulsion, cellulose and the like, and the compatibility is enhanced.

Owner:广东嘉宝莉科技材料有限公司

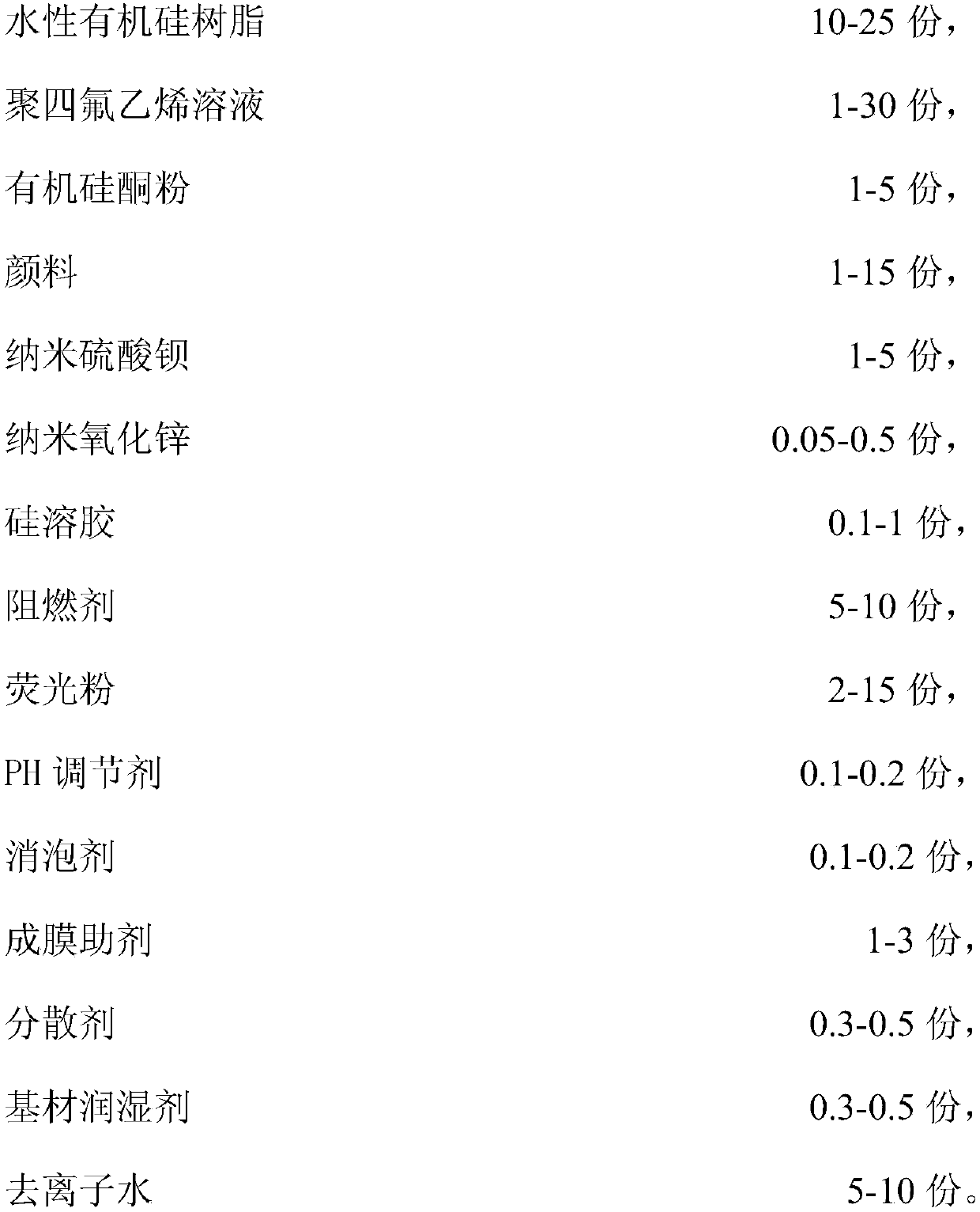

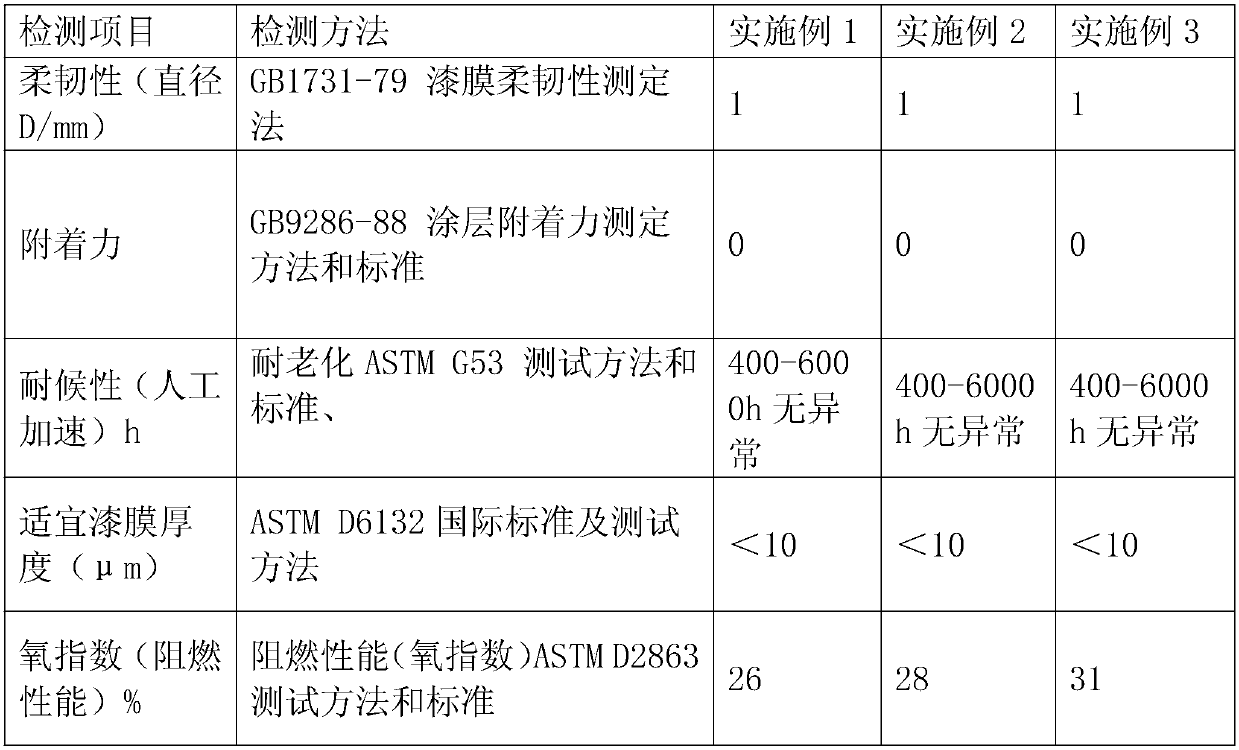

Water-based paint for multifunctional fiber textile and preparation method thereof

PendingCN107841241ALow refractive indexLarge specific surface areaFireproof paintsAntifouling/underwater paintsWater basedFiber

The invention discloses water-based paint for multifunctional fiber textile. The water-based paint is prepared from the following raw material components in parts by mass: 10 to 25 parts of water-based organic silicon resin, 1 to 30 parts of a polytetrafluoroethylene solution, 1 to 5 parts of organic silicone powder, 1 to 15 parts of a pigment, 1 to 5 parts of nano barium sulfate, 0.05 to 0.5 partof nano zinc oxide, 0.1 to 1 part of silica sol, 5 to 10 parts of a flame retardant, 2 to 15 parts of fluorescent powder and the like. Furthermore, the invention further provides a simple and feasible preparation method of the water-based paint for the multifunctional fiber textile. By adopting the formula and the method, disclosed by the invention, the prepared paint has adhesive force, flexibility, weather resistance and flame-retarding performance and has a suitable paint film thickness; meanwhile, the water-based paint also has the characteristics of no fluffiness, no fading and smooth hand feeling, and a plurality of effects of heat prevention, flame retarding, corrosion resistance, fluorescence warning, easiness for cleaning, bacterium inhibition and sterilization, environment protection and the like, so that the water-based paint has very strong market competitiveness.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

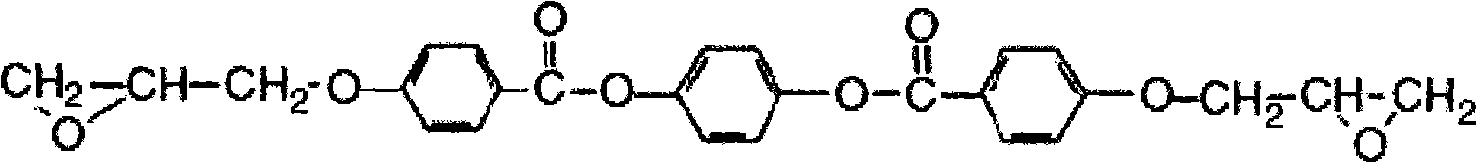

Liquid crystal epoxy modified water-based alkyd resin and preparation method thereof

InactiveCN102311543AExcellent water dispersion stabilityImprove drynessPolyester coatingsWater basedEpoxy

The invention discloses a liquid crystal epoxy modified water-based alkyd resin and a preparation method thereof and belongs to the field of macromolecule synthetic water-based alkyd resin. The invention overcomes the defects of environment pollution, damage to the human body health, resource waste, inflammability, explosion and the like of the conventional solvent borne paint. A method for preparing water-based alkyd resin by the combination of a salifying method and a hydrophilic group introducing method is adopted. Linolenic acid is firstly maleated, then liquid crystal epoxy and organic sulfonate oligomer are introduced, trimethylolpropane and neopentyl glycol are optimally combined, the salifying method and the hydrophilic group introducing method are combined, an esterification catalyst is added, and the production process is safe and simple. The resin is dispersed in water after being neutralized by amine, and the water dispersibility and pigment wetting dispersibility of the resin are improved. The liquid crystal epoxy modified water-based alkyd resin is brown transparent liquid with the viscosity higher than or equal to 25 seconds, non-volatile matter accounts for 68 + / - 2%, and the acid value is 22-32mgKOH / g.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD +1

Preparation method of environment-friendly aluminium pigment

InactiveCN103627220ALow freezing pointWill not cause the phenomenon of falling silver powderPigment treatment with macromolecular organic compoundsPigment physical treatmentAluminium powderSteel ball

The invention discloses a preparation method of an environment-friendly aluminium pigment. The preparation method comprises the following steps: a. preparing 80 parts by mass of aluminium powder, 120-130 parts by mass of D70 solvent oil and 2-2.5 parts by mass of grinding aid; b. throwing the prepared aluminium powder, D70 solvent oil and grinding aid into a ball mill internally equipped with 2000 parts by mass of steel balls, and grinding the materials for 20-23 hours, thus obtaining mixed paste; c. throwing the mixed paste obtained through grinding into a vibrating screen with 500-mesh screen pores to be filtered through screening; d. throwing the filtered paste into a filter press to be pressed until an aluminium paste filter cake with 20% volatile matter is obtained; e. throwing the aluminium paste filter cake into a kneading machine, controlling the temperature in the kneading machine to be 20-40 DEG C, adding treating agents and stirring the materials, thus obtaining uniform aluminium paste with 26-38% volatile matter. The aluminium pigment prepared by adopting the formulas has strong storage stability and is wide in application fields due to safe environmental protection characteristics.

Owner:重庆诺泰颜料有限公司

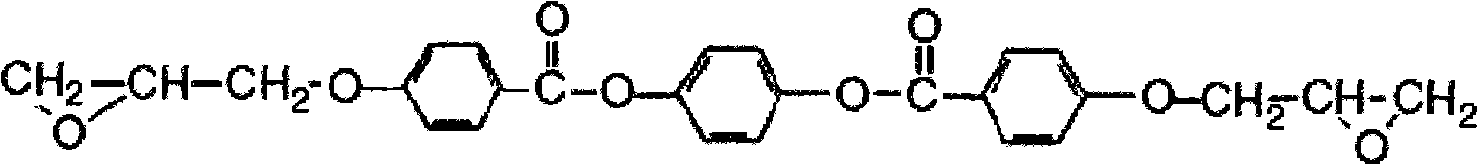

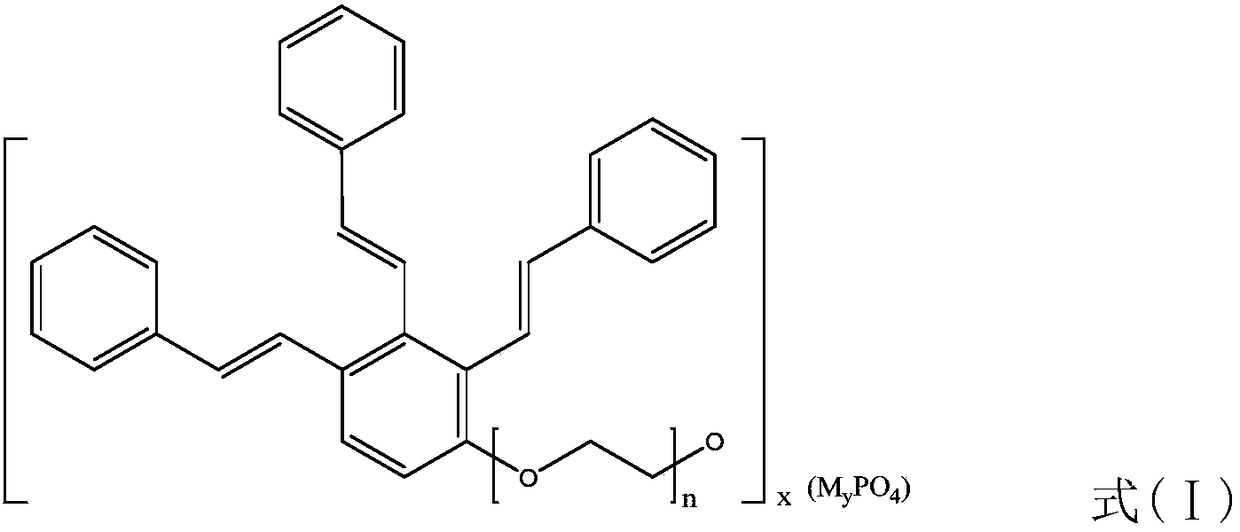

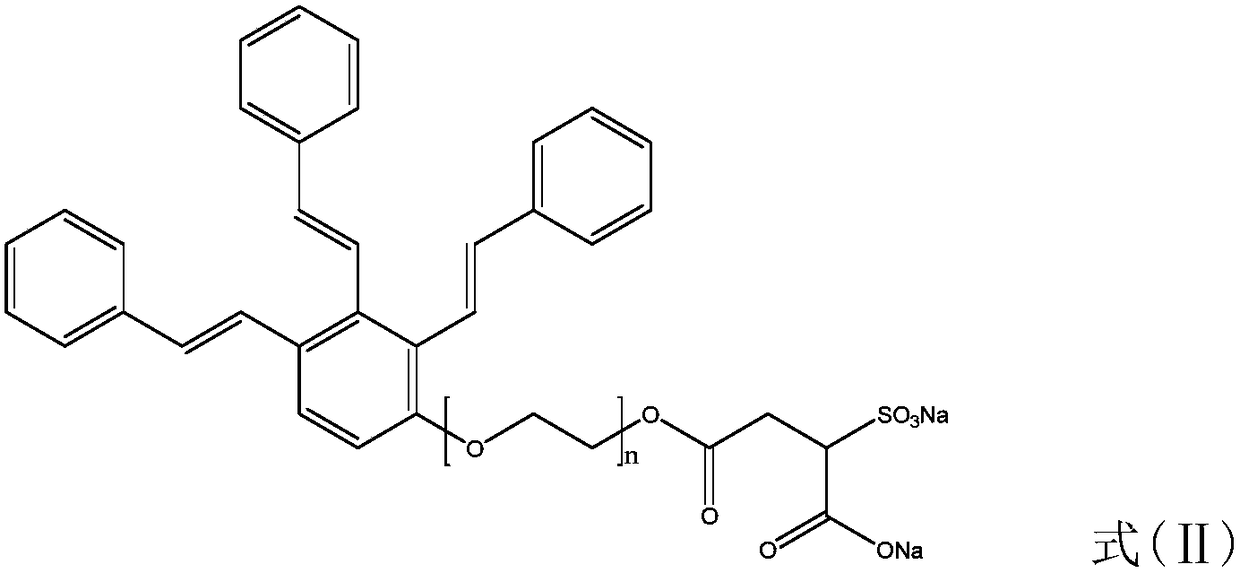

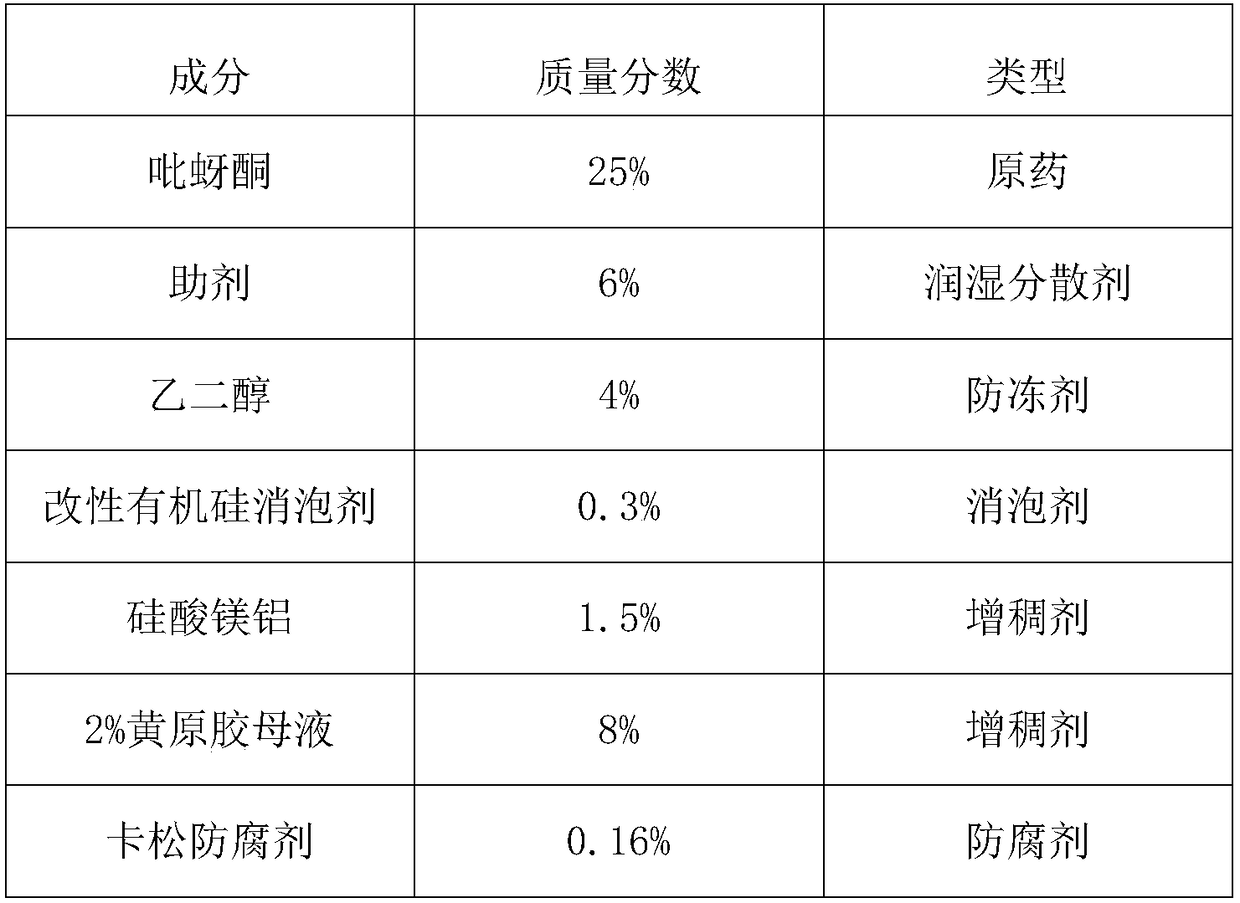

Preparation of composite synergistic wetting agent and application thereof in pymetrozine aqueous suspending agent

ActiveCN109122683APrevent flocculationPrevent creamingBiocideAnimal repellantsPhosphateSuccinic acid

The invention relates to a composite synergistic wetting agent and a preparation method thereof. The components comprise 30-50 % of tristyrylphenol ethoxylates phosphate; 20-30 % of maleic acid-acrylic acid copolymer sodium salt; 10-20 % of tristyrylphenol ethoxylates succinic acid monoester sodium sulfonate; and 10-20 % of propylene glycol block polyether. The composite synergistic wetting agenthas excellent wetting and dispersing performance, and the combination of the auxiliary agent components of the invention is adopted to provide surface energy for original drug particles, the particlesare wrapped to form steric hindrance, electrostatic repulsion and to destroy the hydrogen bond combination of the compound and water. The invention further provides the application of the composite synergistic wetting agent in pymetrozine and a composite aqueous suspending agent combined with pymetrozine and other original drugs (clothianidin), which has good universality for the original drug ofthe pymetrozine produced by different processes, and the obtained preparation agent has good stability.

Owner:GUANGZHOU FANGZHONG CHEM CO LTD

High-dispersion nano organic clay composition and preparation method thereof

InactiveCN108503891AImprove wettability and dispersibilityDisperse fastChemical industrySURFACTANT BLEND

The invention relates to a high-dispersion nano organic clay composition and a preparation method thereof and belongs to the field of the chemical industry. A main surfactant, an auxiliary surfactantand a surface modifier which are different in type are adopted for conducting layer insertion on the surface, modification and decoration on clay, the wetting dispersion performance of the organic clay is improved, and the quick dispersion requirement is met. The high-dispersion nano organic clay product is mainly applied to the fields of paint, ink systems and nano composite materials, and the thixotropic performance mechanical performance, blocking performance and flame retardant performance of the system are improved.

Owner:ZHEJIANG FENGHONG NEW MATERIAL

Method for printing double smooth surfaces at one time and matting agent for printing ink

ActiveCN102690553AShorten the timeShorten the production cycleInksOther printing apparatusParaffin waxSmooth surface

The invention discloses a method for printing double smooth surfaces at one time and a matting agent for printing ink. The matting agent is prepared from the following raw materials in part by weight: 90 to 95 parts of polyethylene paraffin scattered in a fluffy state, 2 to 4 parts of hydrogenated castor oil and 0.4 to 1 part of polyacrylamide. The preparation method comprises the following step of uniformly mixing the three substances in a high speed mixer. The method for printing double smooth surfaces at one time comprises the following steps: uniformly mixing gravure ink and the matting agent in a ratio of 1:(2-4); printing matted patterns on parts of a base material requiring a matting effect through gravure equipment by using the mixed matting gravure ink; and printing bright patterns on parts of the base material requiring a bright effect by using gravure ink without the matting agent, or reversing the sequence to achieve the same effect.

Owner:JIANGSU JIN JIA NEW PACKAGING MATERIALS CO LTD

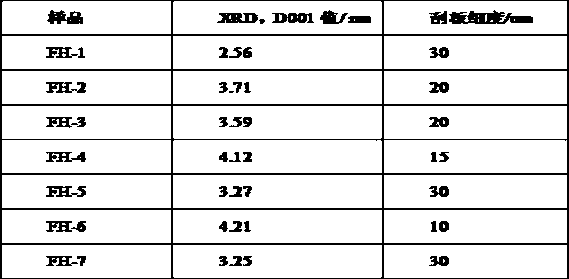

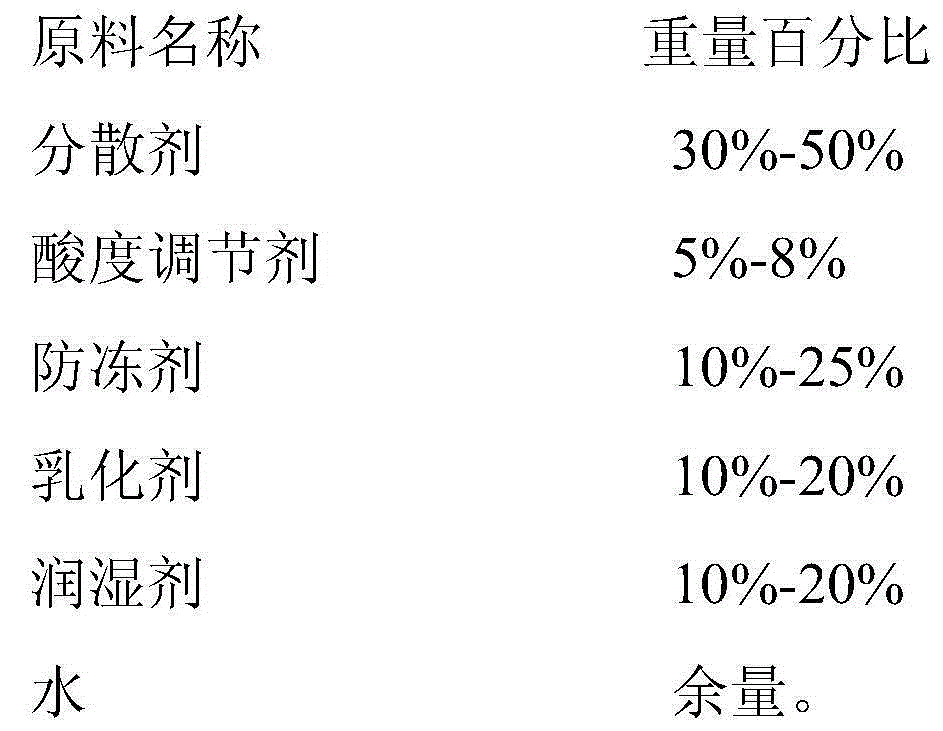

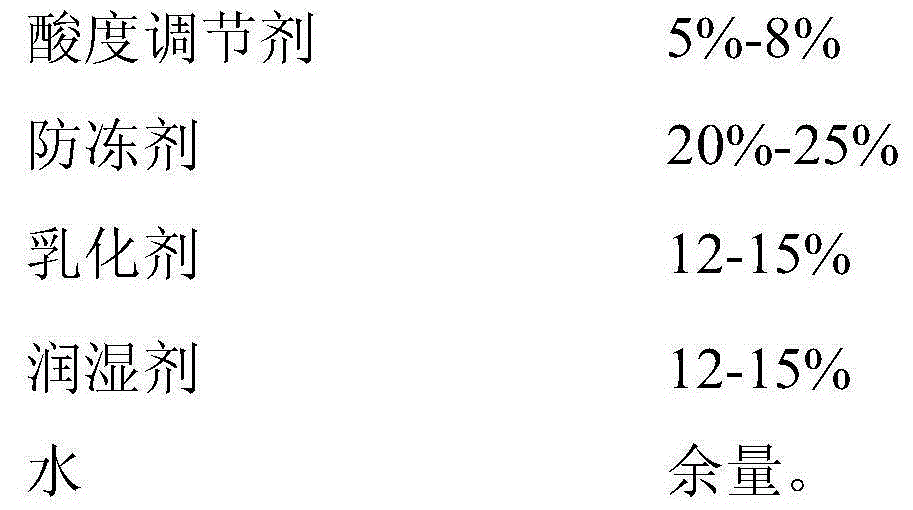

Pesticide adjuvant composition and preparation method thereof

InactiveCN104982432AImprove low temperature resistanceImprove general performanceBiocideAnimal repellantsDispersityPESTICIDE ADJUVANTS

The invention discloses a pesticide adjuvant composition and a preparation method thereof, and belongs to the technical field of pesticide preparations. The pesticide adjuvant composition comprises the following components in percentage by weight: 30 to 50 percent of dispersing agent, 5 to 8 percent of acidity regulator, 10 to 25 percent of antifreezing agent, 10 to 20 percent of emulsifying agent, 10 to 20 percent of wetting agent and the balance of water. The pesticide adjuvant composition has the advantages of simplified formula technology, flexibility in use, time conservation, high generality, high wetting dispersity, high low-temperature resistance, good compatibility with the pesticide preparation and the like.

Owner:GUANGZHOU FANGZHONG CHEM CO LTD

Synthetic resin for water-soluble printing ink and preparation method thereof

The invention belongs to the field of synthetic resin and provides synthetic resin for water-soluble printing ink. The synthetic resin is prepared from 15-21 parts of turpentine oil, 15-45 parts of butyl acrylate, 7-15 parts of methyl methacrylate or styrene, 20-35 parts of vinyl acetate and 6-12 parts of active functional group monomer. A preparation method comprises the following steps of: reacting the turpentine oil under the effect of a mixed catalyst of benzyl chloride and aluminum chloride to obtain a terpene prepolymer; making the terpene prepolymer into an emulsion; adding butyl acrylate, methyl methacrylate, vinyl acetate and part of the active functional group monomer into the terpene prepolymer emulsion; adding part of an initiator and the remaining monomer mixture at 60-80 DEG C, and reacting for 10-20 minutes; adding the remaining initiator and heating to 90-95 DEG C for reaction; and cooling to obtain the synthetic resin for water-soluble printing ink.

Owner:贺红专 +1

Photoresist pigment color paste and preparation method thereof

ActiveCN113064323AGood dispersionPrevent self-aggregationPhotosensitive materials for photomechanical apparatusPigment pastesBenzyl mercaptanEthylic acid

The invention discloses photoresist pigment paste and a preparation method thereof, and relates to the technical field of liquid crystal display materials. The preparation method comprises the following steps: mixing a graphene oxide aqueous solution with N, N-dimethylformamide, carrying out spray drying on the obtained mixture and hot inert gas, carrying out thermal reduction to obtain modified graphene, mixing molten paraffin with an initiator, adding styrene, carrying out a reaction to obtain pretreated paraffin, mixing the pretreated paraffin and a toluene solution containing maleic anhydride, vinyl benzyl mercaptan and an initiator for a reaction, preparing modified paraffin, stirring and mixing the modified paraffin, modified graphene and pigment under the low-temperature condition, and performing stirring and mixing under the high-temperature condition to obtain pretreated pigment; finally, mixing propylene glycol methyl ether acetate with n-butyl acetate, adding acrylic resin, the pretreated pigment and a wetting dispersant, and performing stirring and mixing to obtain the photoresist pigment paste. The photoresist pigment color paste prepared by the invention has excellent stability and good pigment dispersity.

Owner:纳琳威纳米科技南通有限公司

Preparation method of high-strength blocky aluminium oxide aerogel

ActiveCN110357133ALow densityLow thermal conductivityAluminium oxide/hydroxide preparationAluminium oxides/hydroxidesSupercritical dryingHigh intensity

The invention relates to a preparation method of high-strength blocky aluminium oxide aerogel, and belongs to the field of heat insulation materials. The preparation method comprises the steps of preparing aluminium oxide sol by taking aluminium sec-butoxide as an aluminium source, uniformly mixing hollow glass microspheres with the aluminium oxide sol, gelling and aging, supercritically drying and the like to prepare the high-strength blocky aluminium oxide aerogel. By adopting the limited technology, the obtained high-strength blocky aluminium oxide aerogel has excellent characteristics of good formability and mechanical property, high porosity, small aperture, high temperature resistance, low thermal conductivity, good thermal stability and the like.

Owner:浙江鹏辰造纸研究所有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com