High-dispersion nano organic clay composition and preparation method thereof

A nano-organic and organic clay technology, applied in the chemical industry, can solve the problems of low stability, poor dispersion performance, difficulty in dispersing and forming peeling nanosheets, etc., to achieve improved wetting performance, good dispersion, and improved wetting and dispersion performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

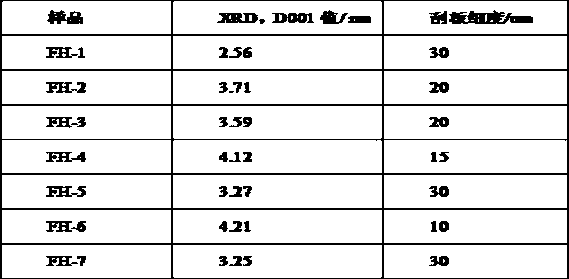

Embodiment 1

[0047] Add 1kg of bentonite mineral powder, add 15L of water, stir and disperse to make slurry, then add 50g of sodium carbonate, stir and disperse for 2h. Centrifugal purification to obtain purified montmorillonite slurry. At this time, the solid content of the slurry is 35g / L, and the cation exchange capacity (CEC) is 95mmol / 100g 土 . Take 10L of slurry and raise the temperature to 80°C, adjust the pH to 3-4 with dilute sulfuric acid, stir at constant temperature for 1h, add octadecyltrimethylammonium chloride: 105g (1.0 times CEC), stir at constant temperature for 1h; add lactic acid fatty acid glyceride: 30g, constant temperature stirring reaction for 1h; add titanate: 4g, constant temperature stirring reaction for 1.5h, plate and frame filter press dehydration, drying, pulverization, micronization treatment, control the particle size of the finished dry powder D50≤5um, and obtain quick-dispersion nano-organic clay. Designation FH-1.

Embodiment 2

[0049] Take purified montmorillonite slurry (implementation example 1): 10L, heat the slurry to 60°C, adjust the slurry to pH 5-6 with oxalic acid solution, stir at constant temperature for 1 hour, add dihydrogenated tallow dimethyl ammonium chloride: 192g (1.0 times CEC ), stirred at constant temperature for 1 hour; added glyceryl monostearate: 20g, stirred at constant temperature for 1 hour; added hexanediol: 35g, stirred at constant temperature for 1 hour, dehydrated by plate and frame filter press, dried, pulverized, and micronized to control the finished product The particle size of the dry powder is D50≤5um, and the quick-dispersion nano-organic clay is obtained. Designation FH-2.

Embodiment 3

[0051] Take purified montmorillonite slurry (implementation example 1): 10L, heat the slurry to 60°C, adjust the slurry to pH 5-6 with oxalic acid solution, stir at constant temperature for 1 hour, add dihydrogenated tallow dimethyl ammonium chloride: 200g (1.02 times CEC ), stirred at constant temperature for 1 hour; added triacetin: 15 g, stirred for 1 hour at constant temperature; added fatty alcohol ethoxylate: 5 g, stirred for 1 hour at constant temperature, dehydrated by plate and frame filter press, dried, pulverized, micronized, controlled The particle size of the finished dry powder is D50≤5um, and the quick-dispersion nano-organic clay is obtained. Designation FH-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com