Preparation method of adhesive for table printing ink

An adhesive and ink technology, applied in ink, application, household appliances, etc., can solve the problems of high odor, poor water resistance, intolerance to grease and freezing of surface printing ink, and achieve good environmental protection, low odor, improved Wetting and dispersing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0013] The embodiment of the present invention provides a method for preparing an adhesive for surface printing ink, which is an alcohol-soluble polyurethane resin adhesive, and the method comprises the following steps:

[0014] Preparation of NCO-terminated prepolymers:

[0015] Mix 42-73 parts by mass of polyether diol, 4-19 parts by mass of aldehyde and ketone resin, 0.05-0.1 part by mass of catalyst, and 23-39 parts by mass of diisocyanate, then react at 70-120°C The reaction product obtained after 2 to 4 hours is the NCO-terminated prepolymer, and the structure of the NCO-terminated prepolymer is: OCN-B-(-NH-CO-O-R 1 -O-CO-NH-) m -B-NCO; where, R 1 Is a methyl group, methylene group, ether group, cyclohexyl group or aromatic hydrocarbon group, B is a methyl group, methylene group, aromatic hydrocarbon group or alicyclic hydrocarbon group;

[0016] Chain extension synthesis:

[0017] Mix 1.2 to 6 parts by mass of amine chain extenders, 26 to 38 parts by mass of ester s...

Embodiment 1

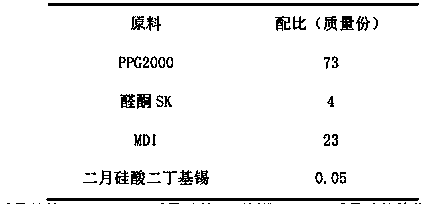

[0031] (1) Preparation of NCO-terminated prepolymer:

[0032]

[0033] Mix 73 parts by mass of PPG2000, 4 parts by mass of aldehyde and ketone resin, 0.05 parts by mass of catalyst, and 23 parts by mass of MDI, and react at 70°C for 4 hours to obtain a prepolymer with an NCO of 1.97%;

[0034] (2) Chain extension synthesis:

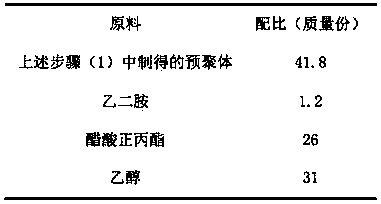

[0035]

[0036] Prepare another flask, add 1.2 parts by mass of ethylenediamine, 26 parts by mass of n-propyl acetate, and 31 parts by mass of ethanol, stir evenly to form a mixed solution, and place 41.8 parts by mass of the prepolymer prepared in step (1) in Put it into the above mixed solution for chain extension reaction within 5 minutes. The reaction temperature is controlled at 30°C. After 2.5 hours of reaction, the polyurethane resin is obtained, which is the adhesive for surface printing ink.

Embodiment 2

[0038] (1) Preparation of NCO-terminated prepolymer:

[0039]

[0040]

[0041] Mix 63 parts by mass of PEG2000, 13 parts by mass of aldehyde and ketone CA, 0.1 part by mass of catalyst, and 24 parts by mass of TDI, and react at 90°C for 3 hours to obtain a prepolymer with an NCO of 2.88%;

[0042] (2) Chain extension synthesis:

[0043]

[0044] Prepare another flask, add 3.2 parts by mass of 1,6-hexamethylenediamine, 38 parts by mass of butyl acetate, and 19 parts by mass of isopropanol, stir evenly to form a mixed solution, and prepare 40 parts by mass of The obtained prepolymer is put into the above mixed solution for chain extension reaction within 30 minutes, the reaction temperature is controlled at 40° C., and the polyurethane resin is obtained after 2 hours of reaction, which is the adhesive for surface printing ink.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com