Polymer cement waterproof coating and preparation method thereof

A waterproof coating and polymer technology, which is applied in the field of architectural coatings, can solve the problems of insufficient durability of waterproof coatings, and achieve the effects of UV aging resistance, firm adhesion, and not easy to peel off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] A preparation method of polymer cement waterproof coating includes the following steps:

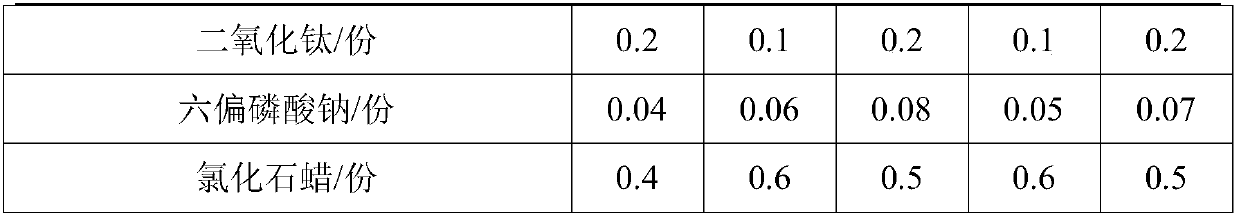

[0059] Step 1: Weigh EVA emulsion, acrylate polymer emulsion, dispersant 5040, ethylene glycol monobutyl ether, polymethyl silicone resin, polyoxypropylene oxide ethylene glycerol ether, antioxidant, crosslinking agent, Bactericide, dry film antifungal agent, Portland cement, heavy calcium carbonate, quartz powder, wollastonite, montmorillonite, titanium dioxide, sodium hexametaphosphate, chlorinated paraffin;

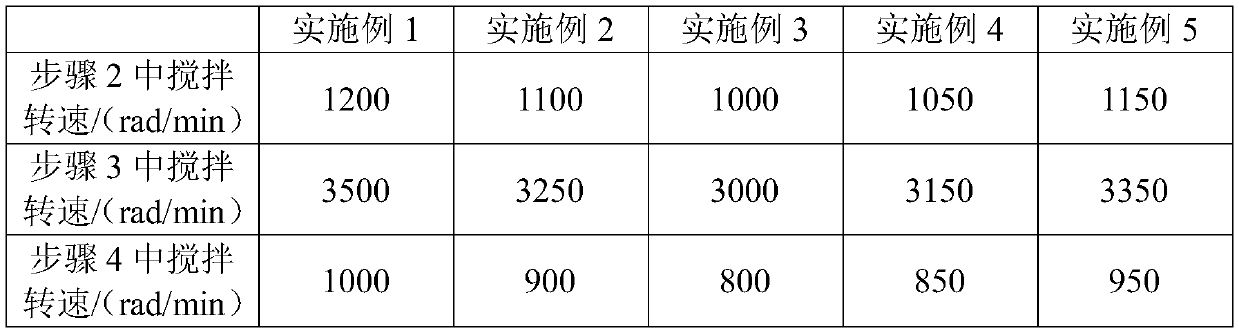

[0060] Step 2: Stir and disperse EVA emulsion and acrylic polymer emulsion at 1000-1200rad / min, and then add dispersant 5040, ethylene glycol monobutyl ether, polymethyl silicone resin, polyoxypropylene oxide ethylene glycerol ether, anti-aging Agent, cross-linking agent, bactericide and dry film anti-mold agent, mixed uniformly to obtain liquid material;

[0061] Step 3: Stir and disperse Portland cement, heavy calcium carbonate, quartz powder, wollastonite, montmorillonite, tit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com