High-flame-retardance conductive foam gum and preparation process thereof

A conductive foam, high flame-retardant technology, applied in lamination, layered products, metal layered products, etc. Cotton-backed adhesive application surface is narrow and other problems, to achieve the effect of light weight, high specific strength and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

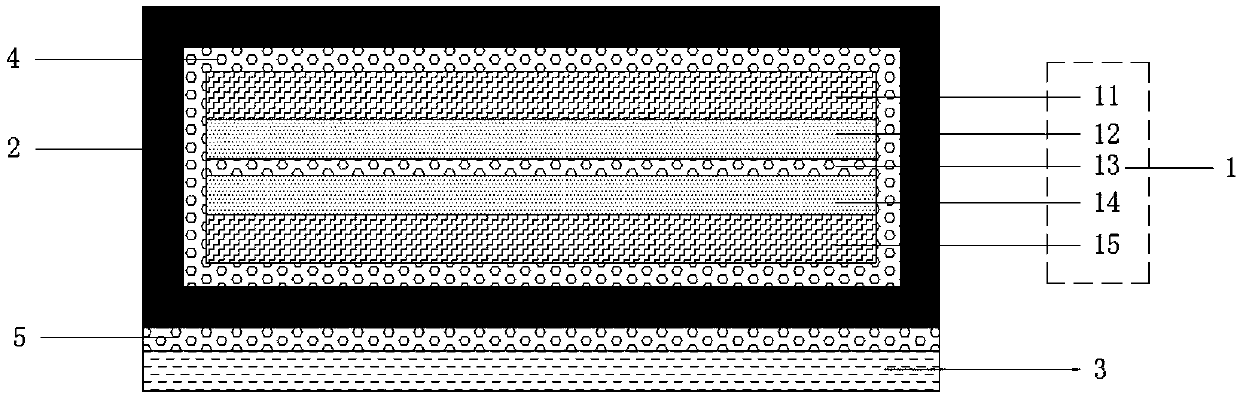

[0083] like figure 1 A highly flame-retardant conductive foam back adhesive shown includes: a foam layer unit 1, an aluminum foil cloth 2 and an embossed release paper 3; the outer side of the foam layer unit 1 is surrounded by an aluminum foil cloth 2; The side of the aluminum foil cloth 2 away from the foam layer unit 1 is provided with an embossed release paper 3; the foam layer unit 1 includes: a first porous material flame-retardant layer 11, a PET conductive buffer foam layer base material 12, the first conductive glue bonding layer 13, the EVA conductive buffer foam layer base material 14, the second porous material flame-retardant layer 15; one side of the first conductive glue bonding layer 13 is provided with a PET conductive buffer foam Cotton layer substrate 12; the other side of the first conductive glue bonding layer 13 is provided with an EVA conductive buffer foam layer substrate 14; the PET conductive buffer foam layer substrate 12 is far away from the first c...

Embodiment 2

[0126] like figure 1 A highly flame-retardant conductive foam back adhesive shown includes: a foam layer unit 1, an aluminum foil cloth 2 and an embossed release paper 3; the outer side of the foam layer unit 1 is surrounded by an aluminum foil cloth 2; The side of the aluminum foil cloth 2 away from the foam layer unit 1 is provided with an embossed release paper 3; the foam layer unit 1 includes: a first porous material flame-retardant layer 11, a PET conductive buffer foam layer base material 12. First conductive glue bonding layer 13, EVA conductive buffer foam layer substrate 14, second porous material flame-retardant layer 15; one side of the first conductive glue bonding layer 13 is provided with PET conductive buffer foam layer substrate 12; the other side of the first conductive glue bonding layer 13 is provided with an EVA conductive buffer foam layer substrate 14; the PET conductive buffer foam layer substrate 12 is far away from the first conductive glue bonding la...

Embodiment 3

[0169] like figure 1 A highly flame-retardant conductive foam back adhesive shown includes: a foam layer unit 1, an aluminum foil cloth 2 and an embossed release paper 3; the outer side of the foam layer unit 1 is surrounded by an aluminum foil cloth 2; The side of the aluminum foil cloth 2 away from the foam layer unit 1 is provided with an embossed release paper 3; the foam layer unit 1 includes: a first porous material flame-retardant layer 11, a PET conductive buffer foam layer base material 12. First conductive glue bonding layer 13, EVA conductive buffer foam layer substrate 14, second porous material flame-retardant layer 15; one side of the first conductive glue bonding layer 13 is provided with PET conductive buffer foam layer substrate 12; the other side of the first conductive glue bonding layer 13 is provided with an EVA conductive buffer foam layer substrate 14; the PET conductive buffer foam layer substrate 12 is far away from the first conductive glue bonding la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com