Water-based ink, elastic emulsion used for water-based ink and preparation method of elastic emulsion

A technology of water-based ink and elastic emulsion, which is applied in the direction of ink, application, household appliances, etc., and can solve the problems of difficult application of water-based ink, low viscosity of elastic emulsion, poor rheology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

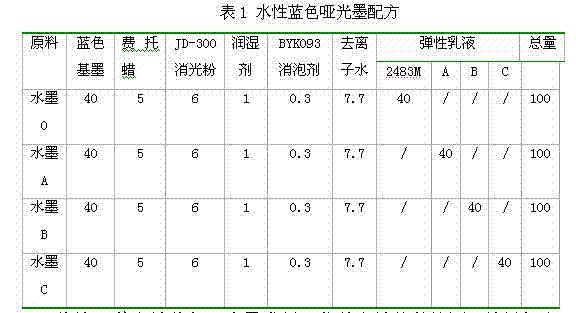

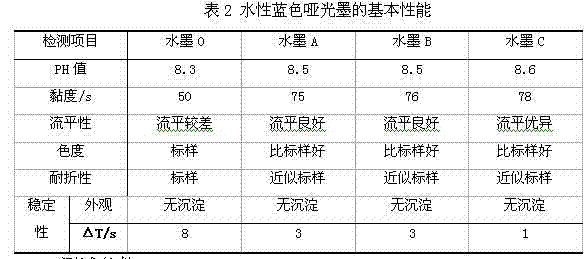

Embodiment 1

[0044] In a three-necked flask with a stirrer, add 70 parts of alkali-soluble acrylic emulsion with a solid content of 42%, an acid value of 150, a molecular weight of 50,000 to 100,000, and Tg=78°C, and then add 16.8 parts of deionized water and 8 1 part of isopropanol, and then add 5.2 parts of monoethanolamine while stirring to obtain a transparent acrylic resin solution with a solid content of 29.4%. The measured viscosity is 150-200 seconds (domestic Tu 4# cup, the test temperature is 40 ℃) , PH value is 9.6.

[0045]

Embodiment 2

[0047] 1. In a round bottom flask with stirring (stirring on, 300-500 rpm), add 130 grams of deionized water, 5 grams of polymerizable emulsifier Emulsogen APS 100 (100%, Clariant Note: 100% is The effective content of this emulsifier, German Clariant products, can be polymerized anionic emulsifier allyl polyoxyethylene ether ammonium sulfate), 12 grams of Emulsogen EPA073 (28%, Clariant, that is, anionic emulsifier alkyl polyoxyethylene ether sulfate Sodium), 9 grams of Emulsogen LCN 407 (70%, Clariant, that is, non-ionic emulsifier alkyl polyoxyethylene ether containing 40 EO), stirred for 5 minutes, and then added 50 grams of styrene, 30 gram of ethyl acrylate, 350 gram of butyl acrylate, 20 gram of N-methylolacrylamide (48%), 10 gram of monobutyl itaconate to prepare the pre-emulsion;

[0048] 2. Dissolve 3.5 grams of ammonium persulfate with 100 grams of deionized water to obtain an aqueous solution of ammonium persulfate;

[0049] 3. Add 200 grams of deionized water, 1 ...

Embodiment 3

[0054] In the pre-emulsion of Embodiment 1, the consumption of monobutyl itaconate is changed into 20 grams, and the consumption of butyl acrylate is changed into 340 grams. Elastic Lotion B.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com