Method for producing solid oxide fuel cell anode substrate and die

A solid oxide and fuel cell technology, applied to fuel cell parts, fuel cells, battery electrodes, etc., can solve problems such as uneven distribution of slurry, separate addition of initiator, single-step ball grinding slurry, etc., to avoid Changes in rheological properties and distribution uniformity, simplified operation, and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

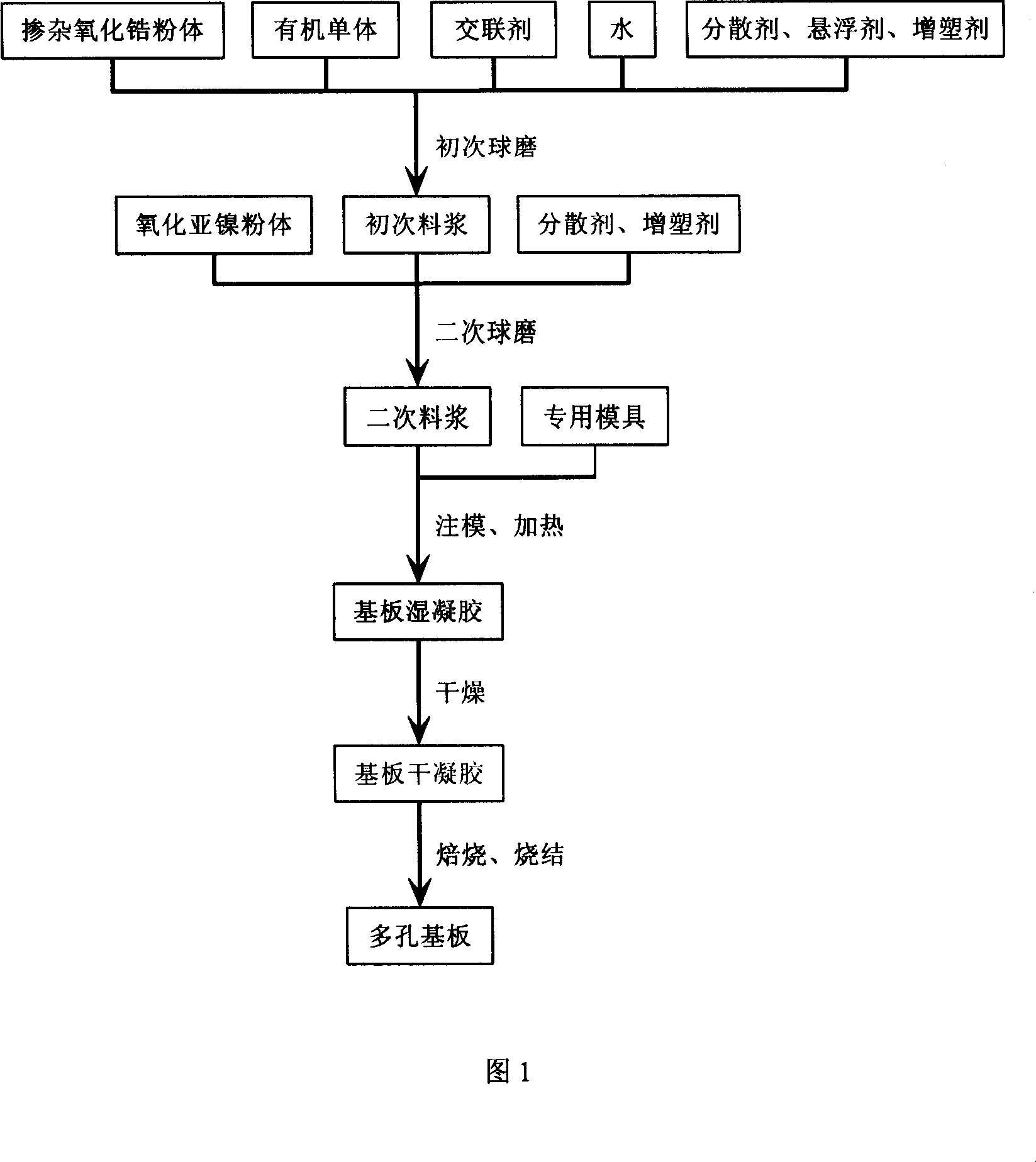

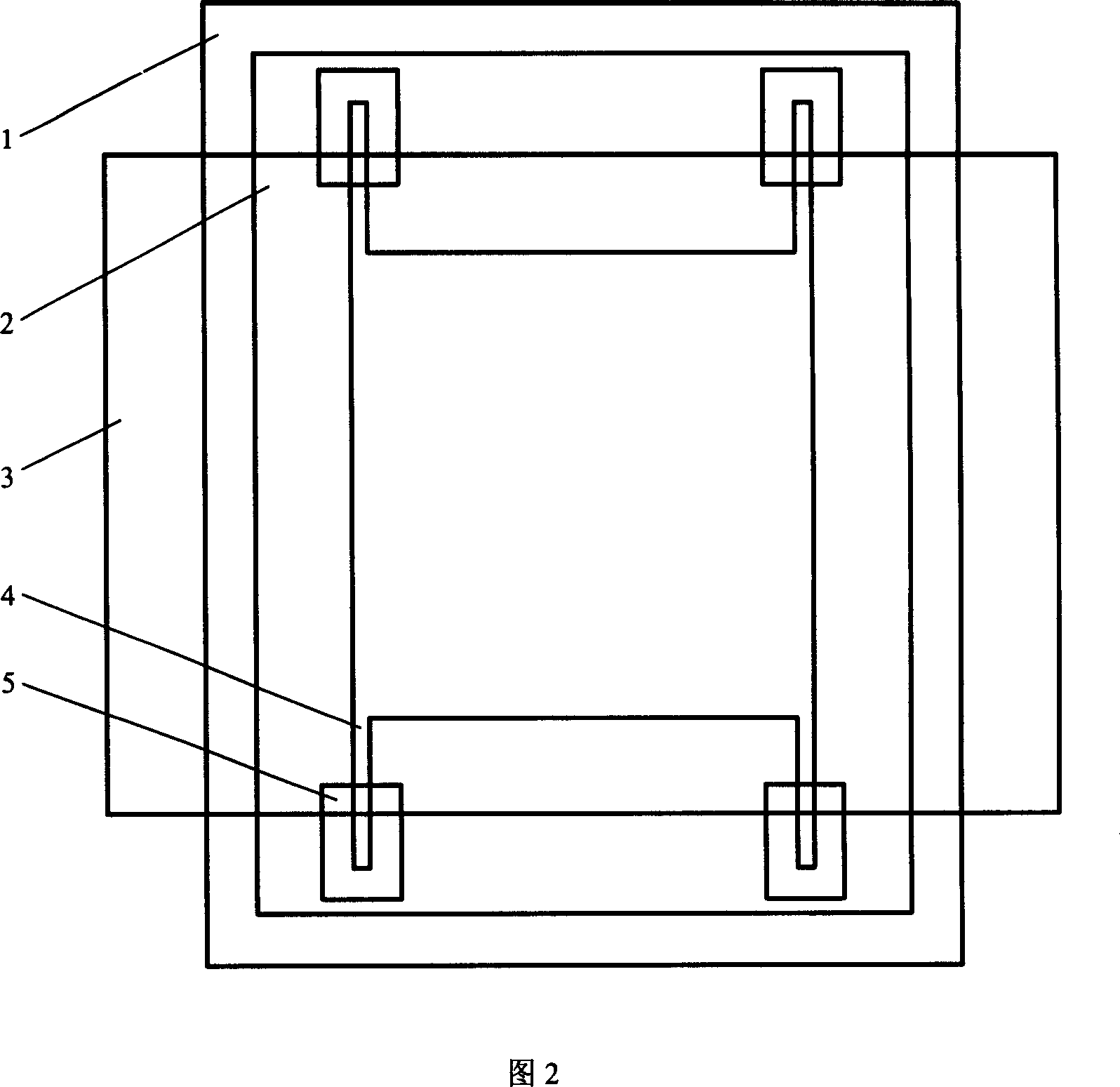

[0018] Embodiment 1: put into the nylon ball mill jar 170g of agate grinding balls, the average particle diameter is 8YSZ (8mol.%Y) of 5.0 μ m 2 o3 Doped ZrO 2 ) 60.00g, methacrylamide (MAM) 13.50g, N, N-methylenebisacrylamide (MBAM) 0.67g, distilled water 36.00g, polyammonium acrylate (PAA) 1.20g; ball milling tank at 750rpm for 15h Adding the average particle diameter in the above-mentioned ball mill jar is 88.80g of nickelous oxide, PAA2.20g of 5.0 μm; With 650rpm ball milling 1h; Get ready each part of special-purpose mold shown in Fig. 2) Place the glass backing plate (1) horizontally, pour the above-mentioned slurry into the area limited by the special-shaped dividing ring (2), cover the glass cover plate (3) from top to bottom, and place the exhaust channel (4 ) to expose the part (exhaust port) of the cover plate (3), seal it with a transparent tape sealing strip (5), then heat the mold filled with slurry to 70°C and keep it for 3 hours, the slurry in the mold is comp...

Embodiment 2

[0019] Embodiment 2: put into the nylon ball mill jar 90g of agate balls, 8YSZ 27.00g, acrylamide (AM) 6.10g, MBAM 0.34g, distilled water 16.50g, polyethylene glycol (PEG) with an average particle diameter of 5.0 μm 0.27g, ammonium polyacrylate (PAA) 0.27g; Ball milling jar with 500rpm ball milling 1h, then with 800rpm ball milling 13h; In above-mentioned ball milling jar, add nickelous oxide 40.50g, PEG 0.40g, PAA0 .40g; with 420rpm ball milling for 0.5h, then with 800rpm ball milling for 1h; prepare the parts of the special mold shown in Figure 2, place the glass backing plate (1) with the plastic special-shaped dividing ring (2) horizontally, and place it on the special Pour the slurry into the area defined by the shape dividing ring (2), cover the glass cover plate (3) from top to bottom, and expose the exhaust channel (4) to the part of the cover plate (3) (exhaust port) , sealed with scotch tape sealing strip (5), then heated the mold filled with slurry to 60°C and kept ...

Embodiment 3

[0020] Embodiment 3: put into the nylon ball mill jar 76g of agate balls, 8YSZ 27.00g, AM 6.30g, MBAM0.23g, gum arabic 0.42g, deionized water 50.60g of 8.0 μ m in average particle diameter; 1100rpm ball milling 12h; In above-mentioned ball milling jar, add the nickel suboxide 40.50g that average particle size is 3.0 μ m; With 650rpm ball milling 2h; Prepare each part of special-purpose mold shown in Fig. ) of the glass backing plate (1) placed horizontally, pour the above-mentioned slurry into the area limited by the special-shaped dividing ring (2), cover the glass cover plate (3) from top to bottom, and then the The mold is heated to 50°C in a nitrogen atmosphere and kept for 2 hours, the slurry in the mold is completely gelled; the cover (3) is uncovered, and the wet gel of the substrate with a smooth surface is taken out; Between the plates, dry naturally to form a substrate xerogel with a smooth surface and a smooth surface; place the xerogel between two smooth and smooth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com